Solar pipe hacking machine

A technology of tube palletizer and solar energy, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient handling, and achieve the effect of reducing labor force, labor intensity and labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

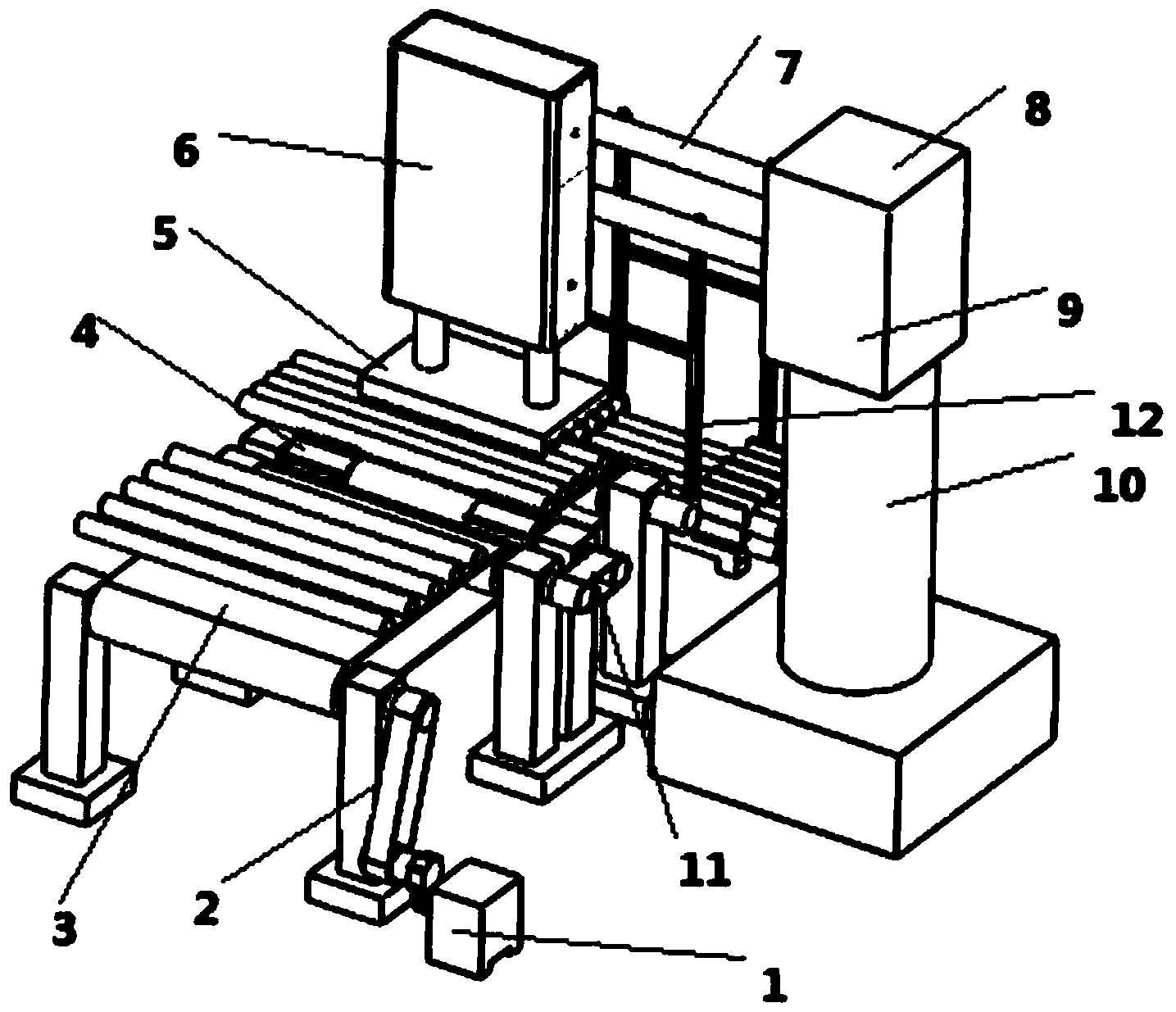

[0008] A solar tube palletizer is composed of a main motor 1, a pulley 2, a conveyor belt 3, a conveyor chain 4, a suction cup 5, a cylinder 6, a connecting rod 7, a rotating block 8, an auxiliary rotating motor 9, a motor bracket 10, and a connecting belt 11. Put the main motor 1 on the ground and connect the conveyor belt 3 through the pulley 2, and then connect the conveyor chain 4 through the connecting belt 11 and drive it to move, send the solar tube to the suction cup, and the cylinder 6 drives the suction cup 5 to suck up the solar tube , driven by the auxiliary rotating motor 9 to rotate the block 8 to rotate, the solar tube is put into the placement frame 12 under the drive of the connecting rod 7.

[0009] When the device was working, the controller controlled the main motor 1 and the auxiliary rotating motor 9 to move the conveyor belt 3 and the conveyor chain 4, the suction cup 5 descended, and the rotating block 8 rotated 3 to suck up the solar tube and put it int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com