Automatic EPE pasting production system

A production system and automatic pasting technology, which is applied to layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of time-consuming and labor-intensive packaging, and achieve the effects of improving production efficiency, saving labor, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

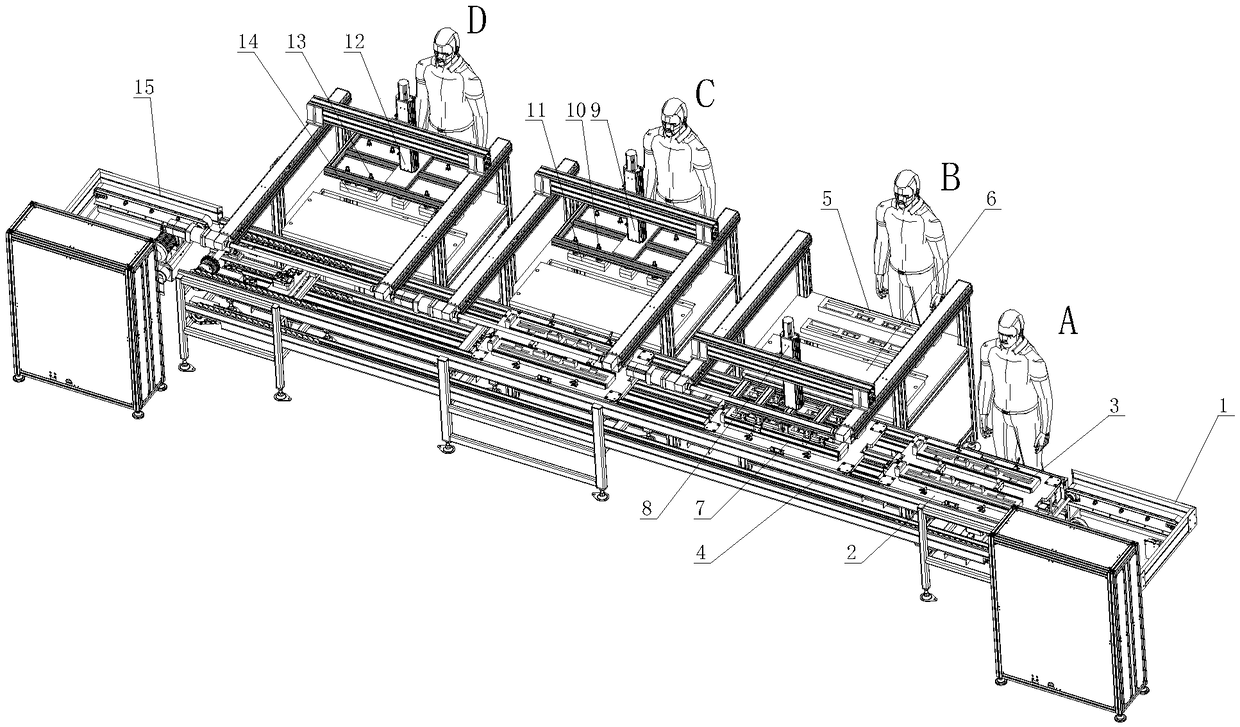

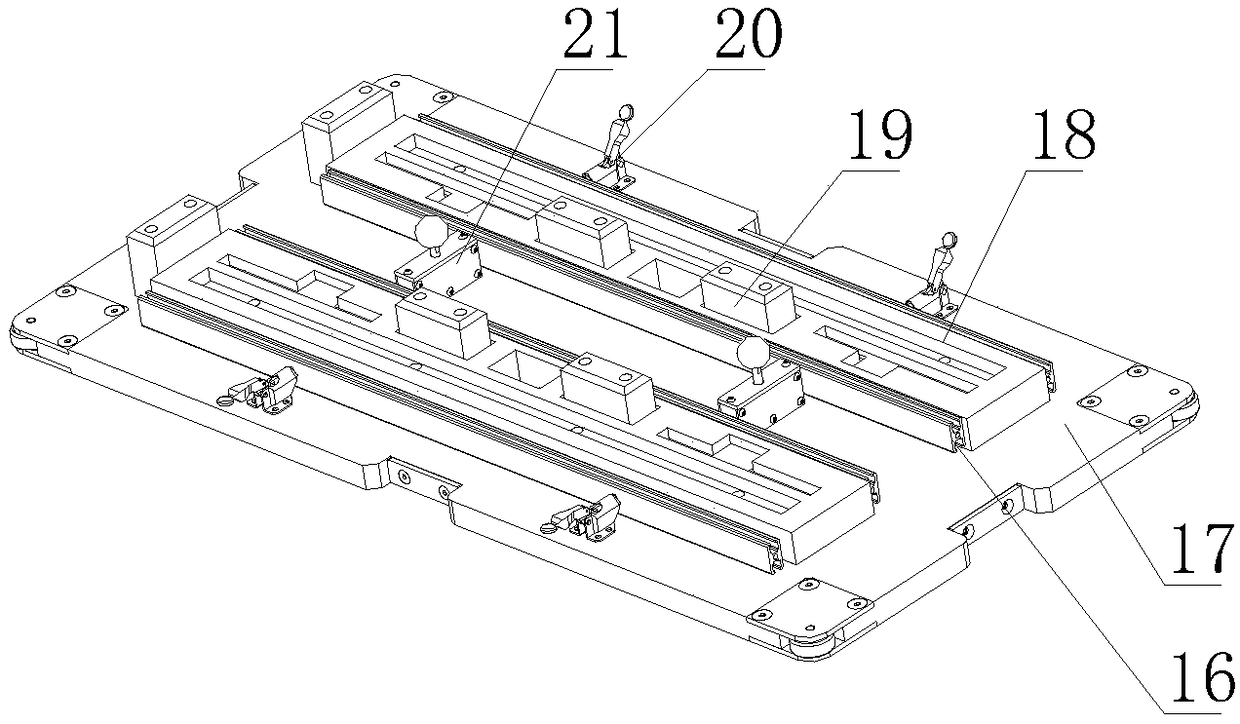

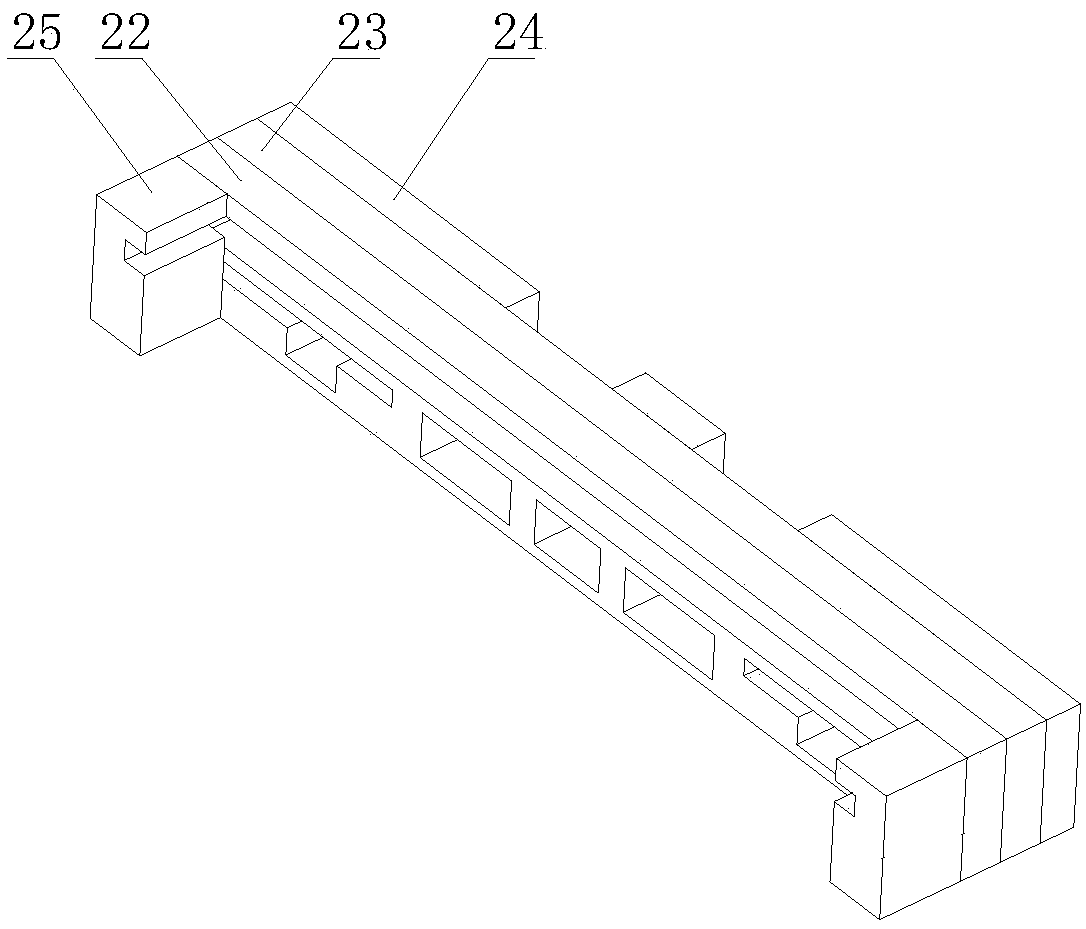

[0030] Such as figure 1 As shown, an EPE automatic pasting production system includes a double-speed chain conveyor, a tooling board, a grabbing station and a workpiece group. The two ends of the double-speed chain conveyor are respectively provided with a lift a and a lift b, through the lift a or Elevator b places the tooling board on the double-speed chain conveyor; the same side of the double-speed chain conveyor is provided with a grabbing station at a certain distance, and the position corresponding to the grabbing station is provided with a positioning plate, a smokeless ironing board, a three-axis robot and The workpiece group, the workpiece group is placed on the tooling plate or positioning plate, the bottom of the three-axis robot is equipped with a gripper, and the workpiece group is grabbed by the gripper, the top of the three-axis robot is installed on the supporting slide rail, and the three-axis robot is controlled by the supporting slide rail. The axis robot m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com