Nickel anode plate cleaning machine

A technology of nickel anode and cleaning machine, which is applied in the direction of photography process, instrument, photography auxiliary process, etc., can solve the problems of reducing the production efficiency of electrolytic nickel, high labor intensity, and the influence of subsequent processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described through the following examples, which are only used to explain the present invention and will not constitute any limitation to the present invention.

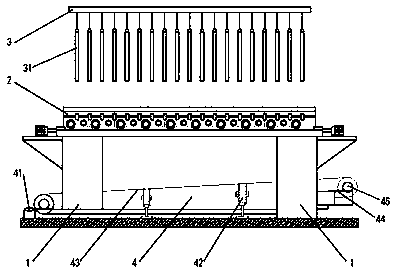

[0027] A nickel anode plate cleaning machine, such as figure 1 , figure 2 As shown, it includes a basic platform 1, a cleaning mechanism 2, a crane mechanism 3, and an anode slime recovery mechanism 4. The basic platform 1 is fixedly connected to the cleaning mechanism 2, and the anode slime recovery mechanism 4 is directly below the cleaning mechanism 2. The cleaned anode slime is transported to the recovery barrel, and the crane mechanism 3 lifts the nickel anode plate 31 from the workshop electrolysis platform to the top of the cleaning mechanism 2 .

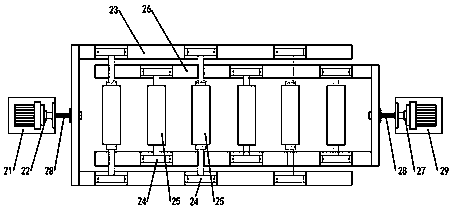

[0028] As mentioned, the cleaning mechanism 2 includes an outer frame motor 21, a reversing switch 1 (22), an outer frame 23, a motor 24, a wire wheel 25, an inner fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com