Patents

Literature

54results about How to "Clean effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

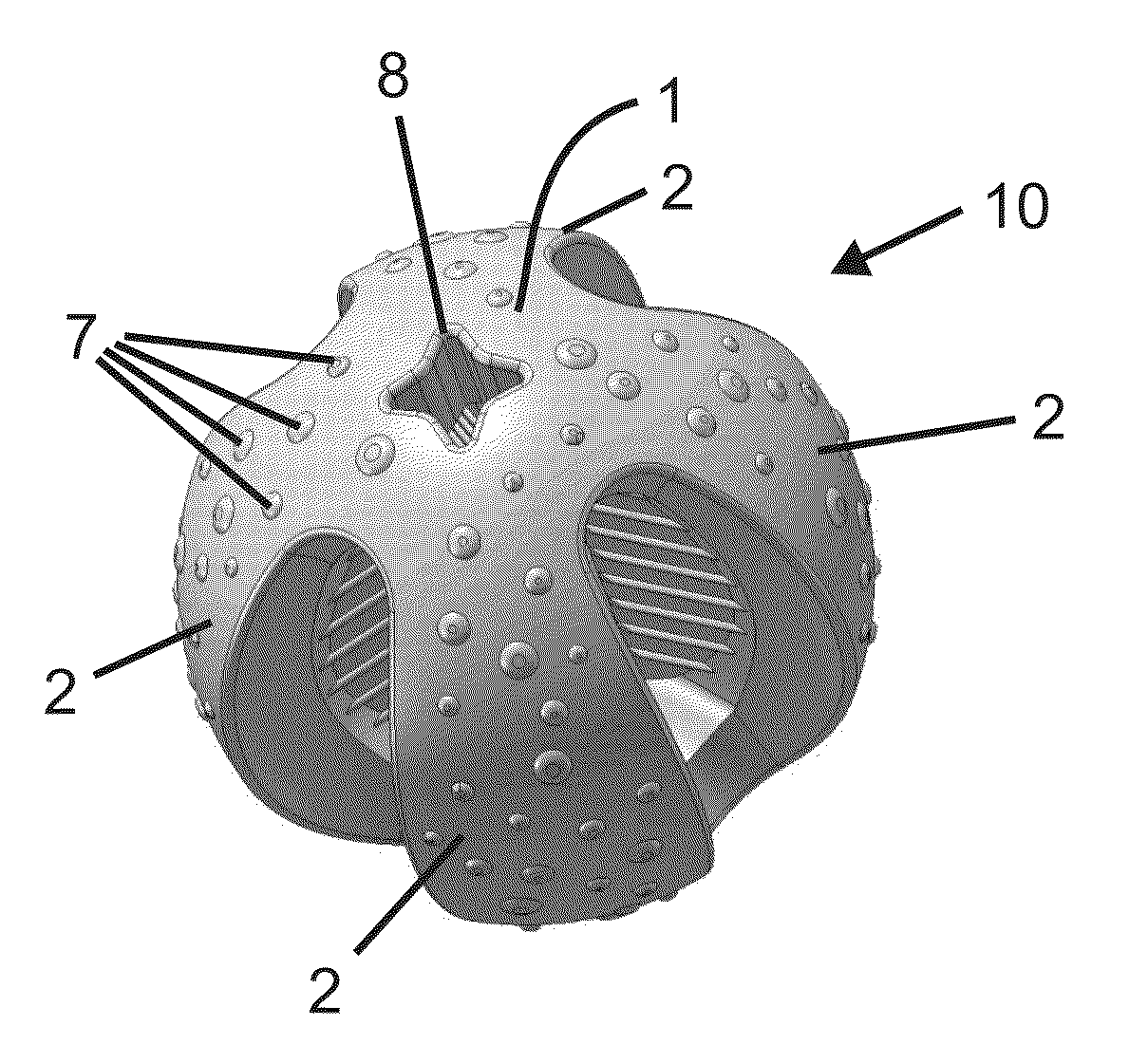

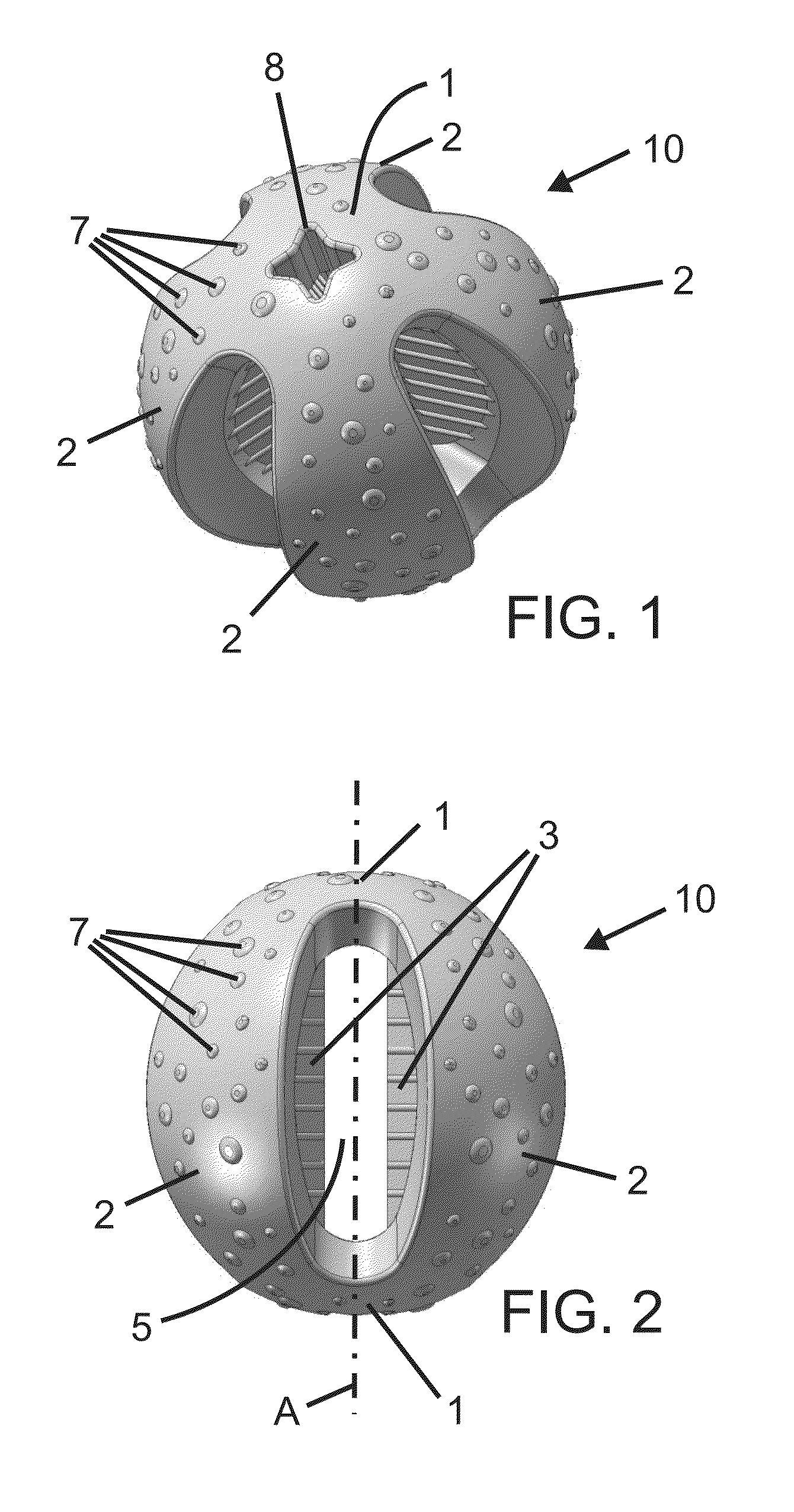

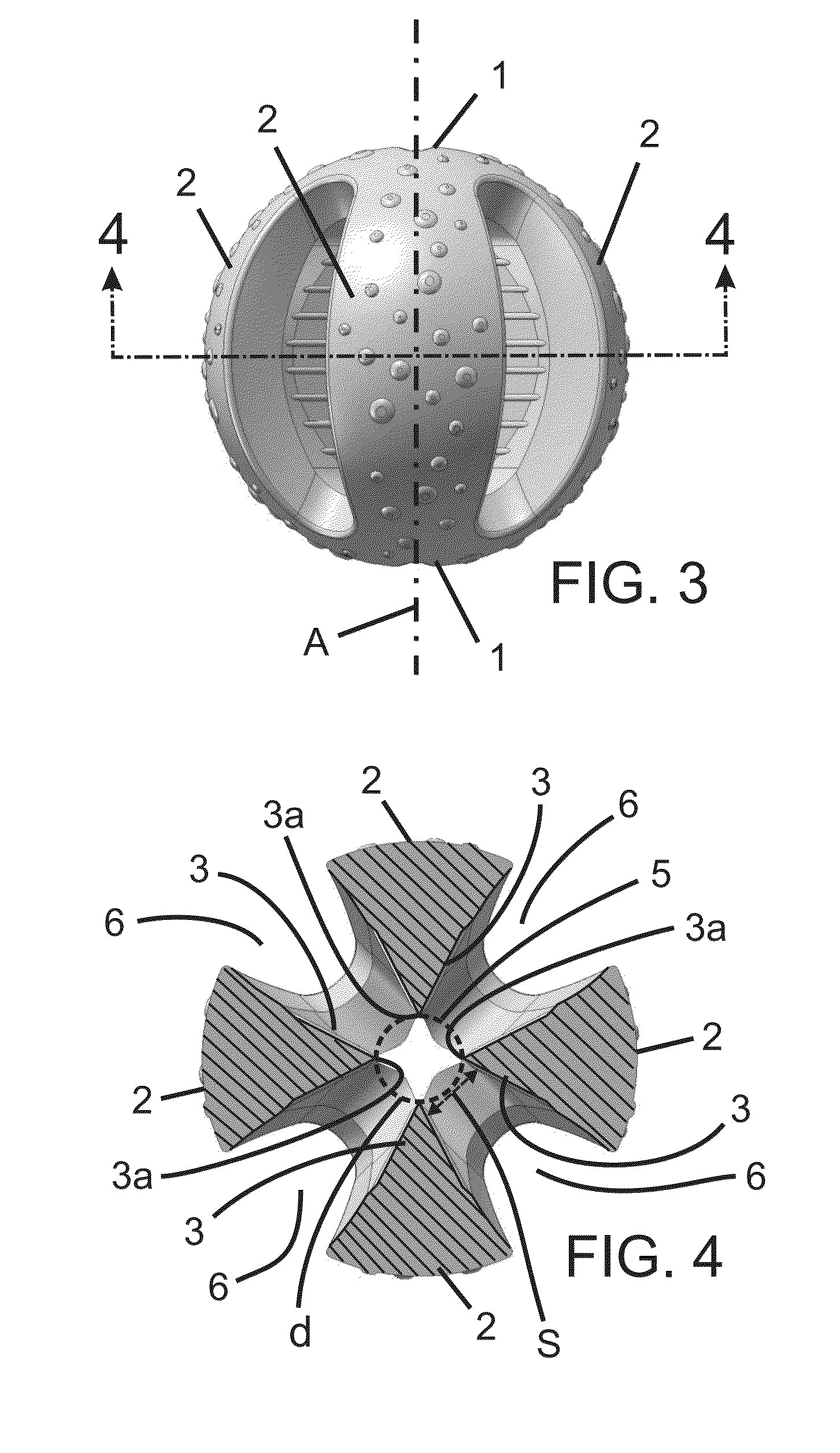

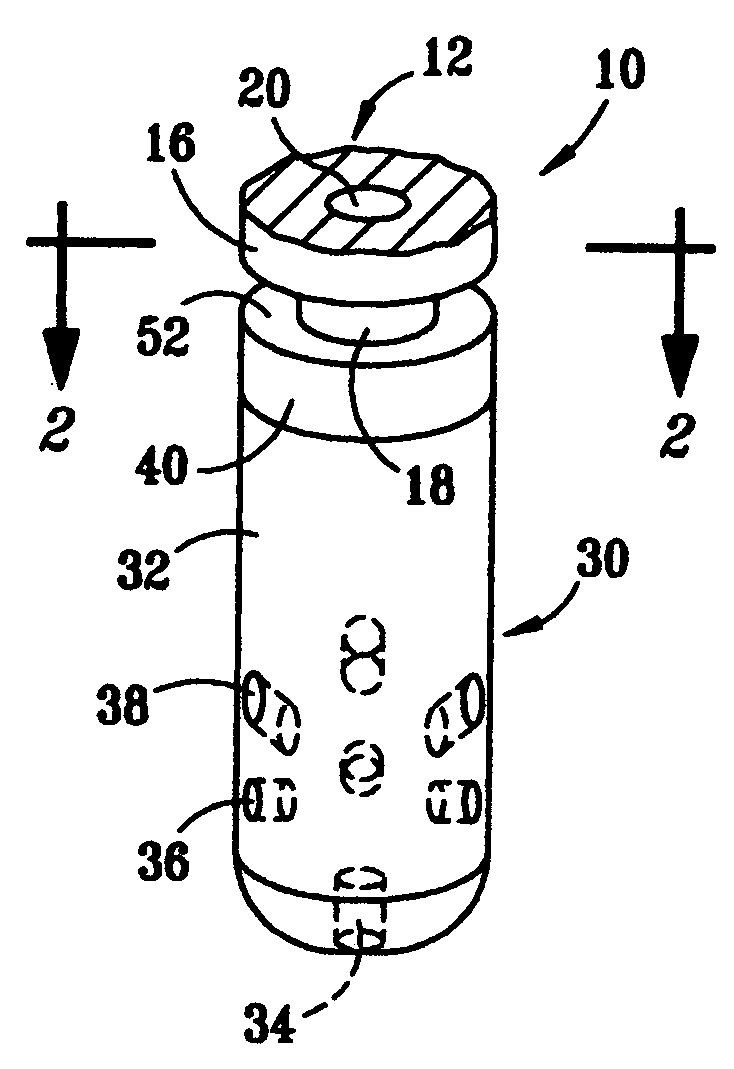

Multi-function pet toy

InactiveUS20130074780A1Fine textureClean effectOther apparatusTaming and training devicesEngineeringMultiple function

A pet toy can be used as a fetch toy, chew toy and / or a treat dispenser, and / or also optionally as a dental aid. The toy includes a body having a central toy axis which extends between opposed poles of the body, the body further including at least three circumferentially spaced-apart ribs which extend between the poles to define an outer envelope of the pet toy. The material comprising the body is advantageously an elastomer, including natural or synthetic rubber, or a suitable plastic having elastomeric properties.

Owner:WECHSLER LAWRENCE I

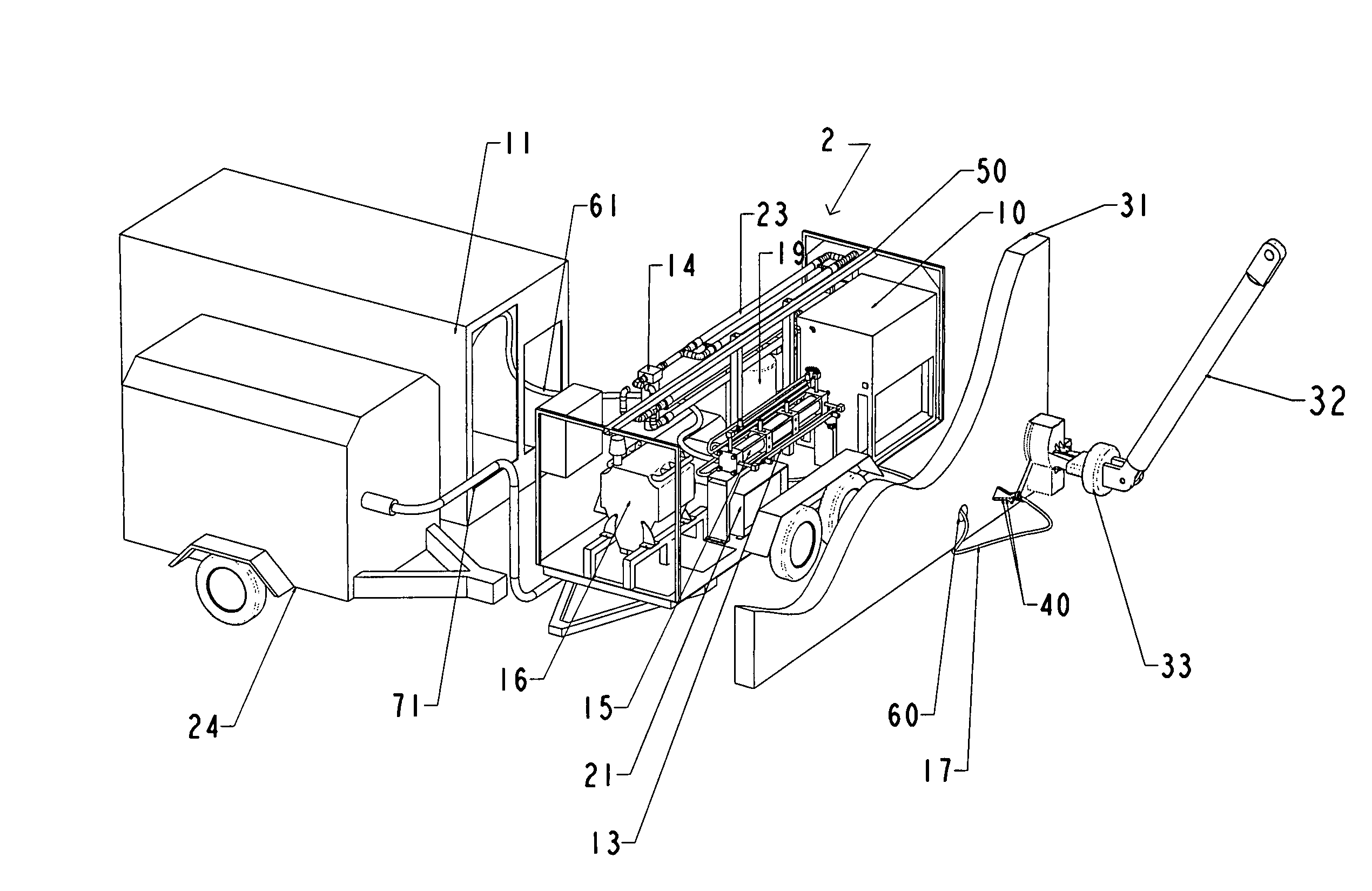

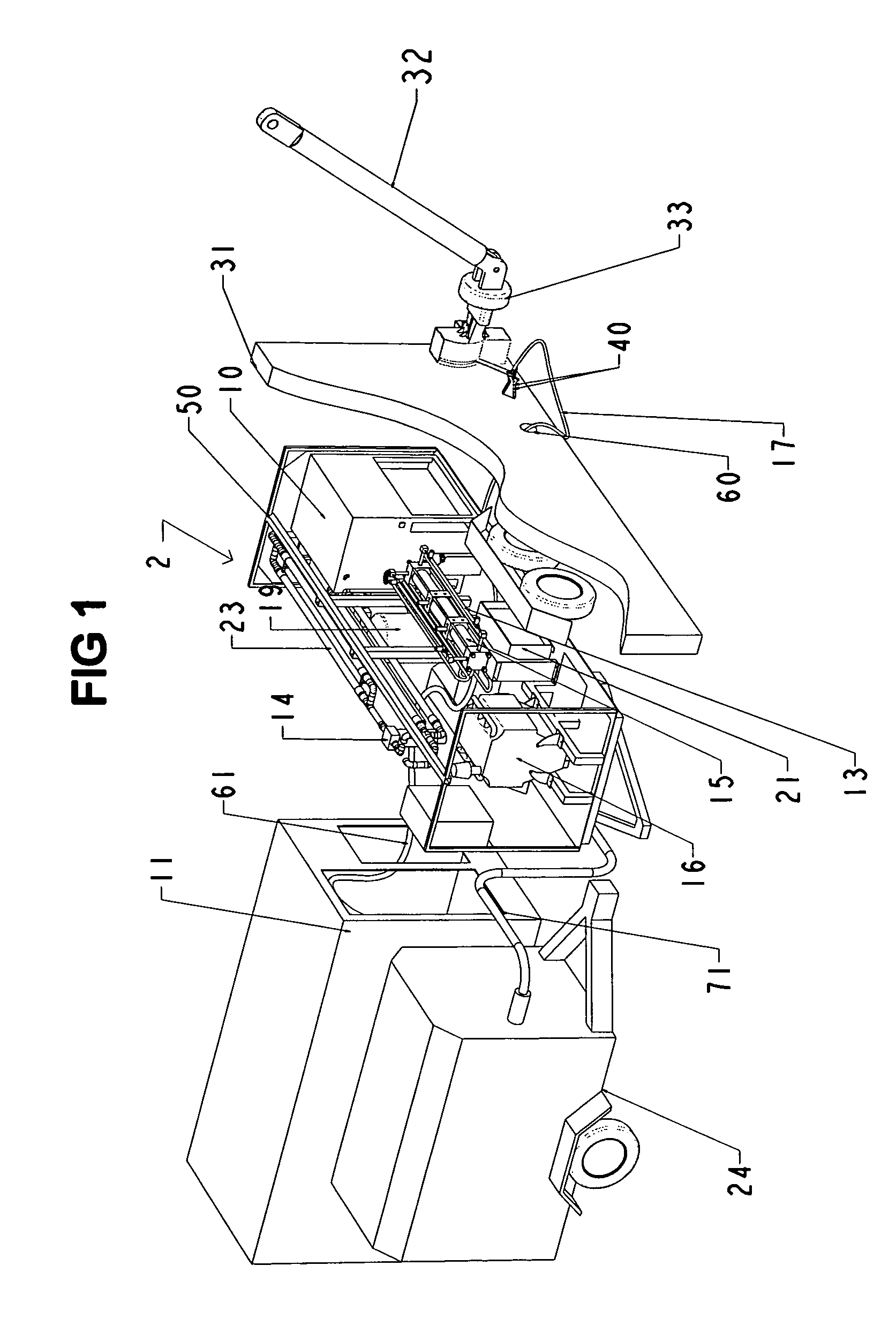

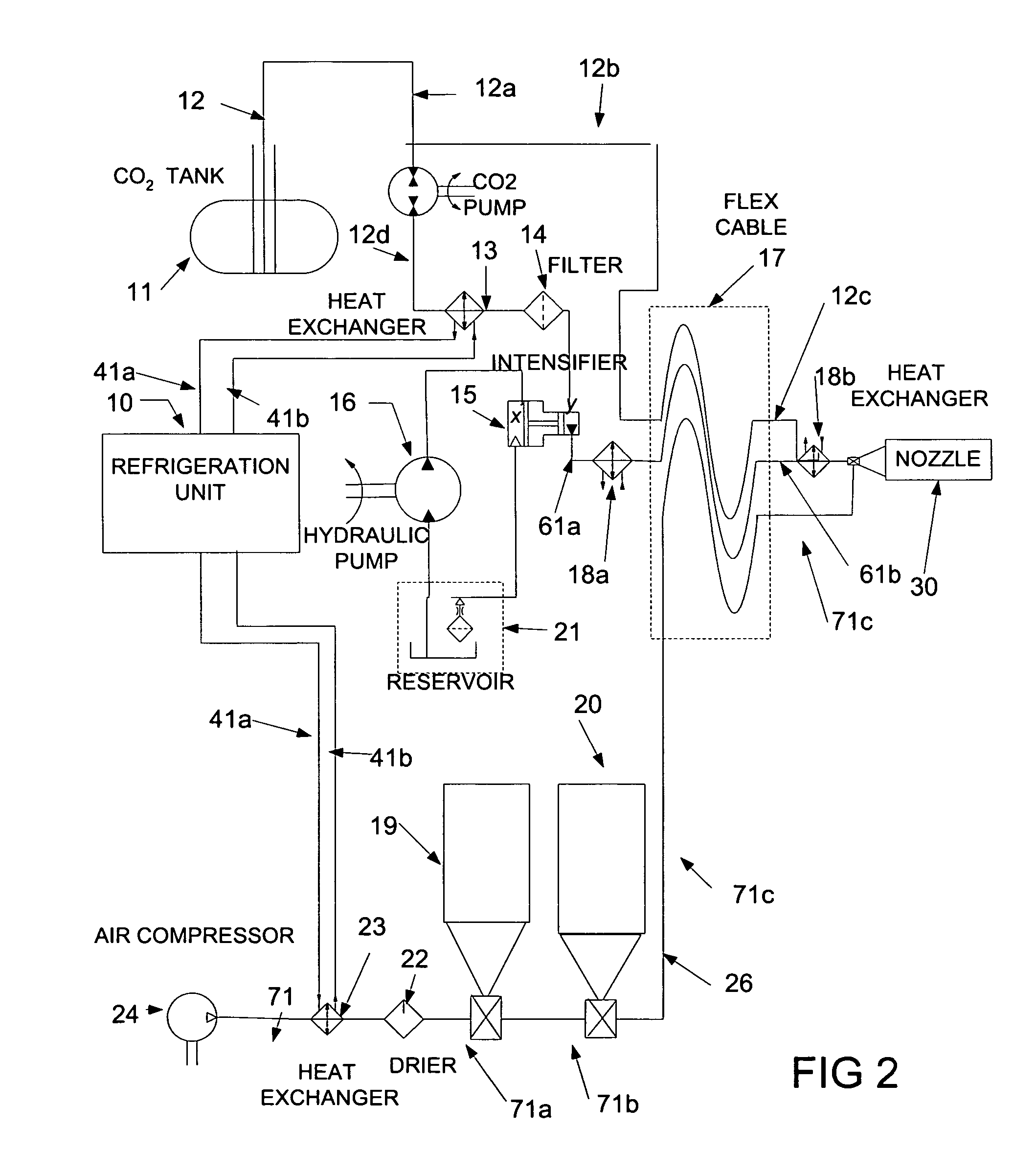

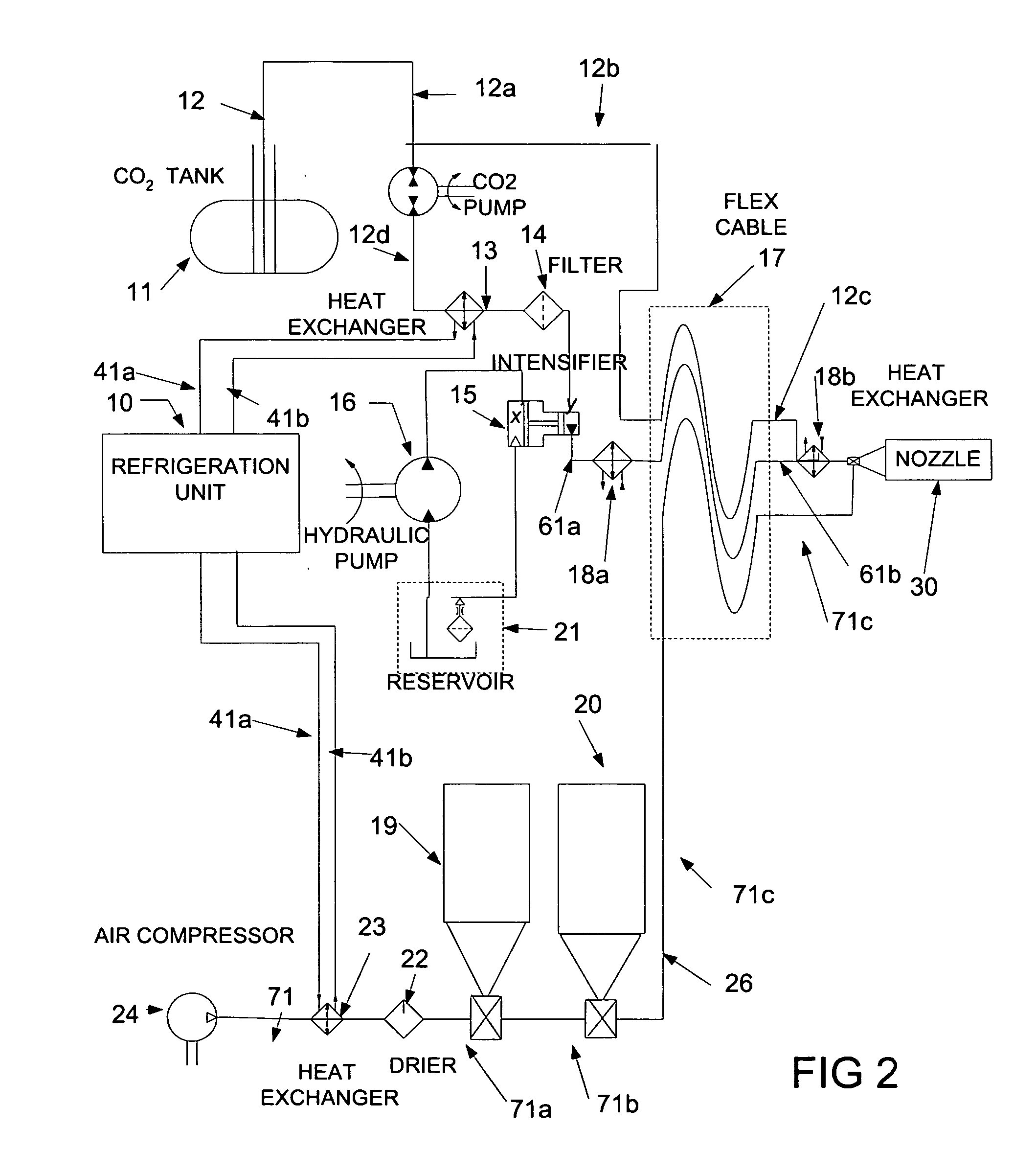

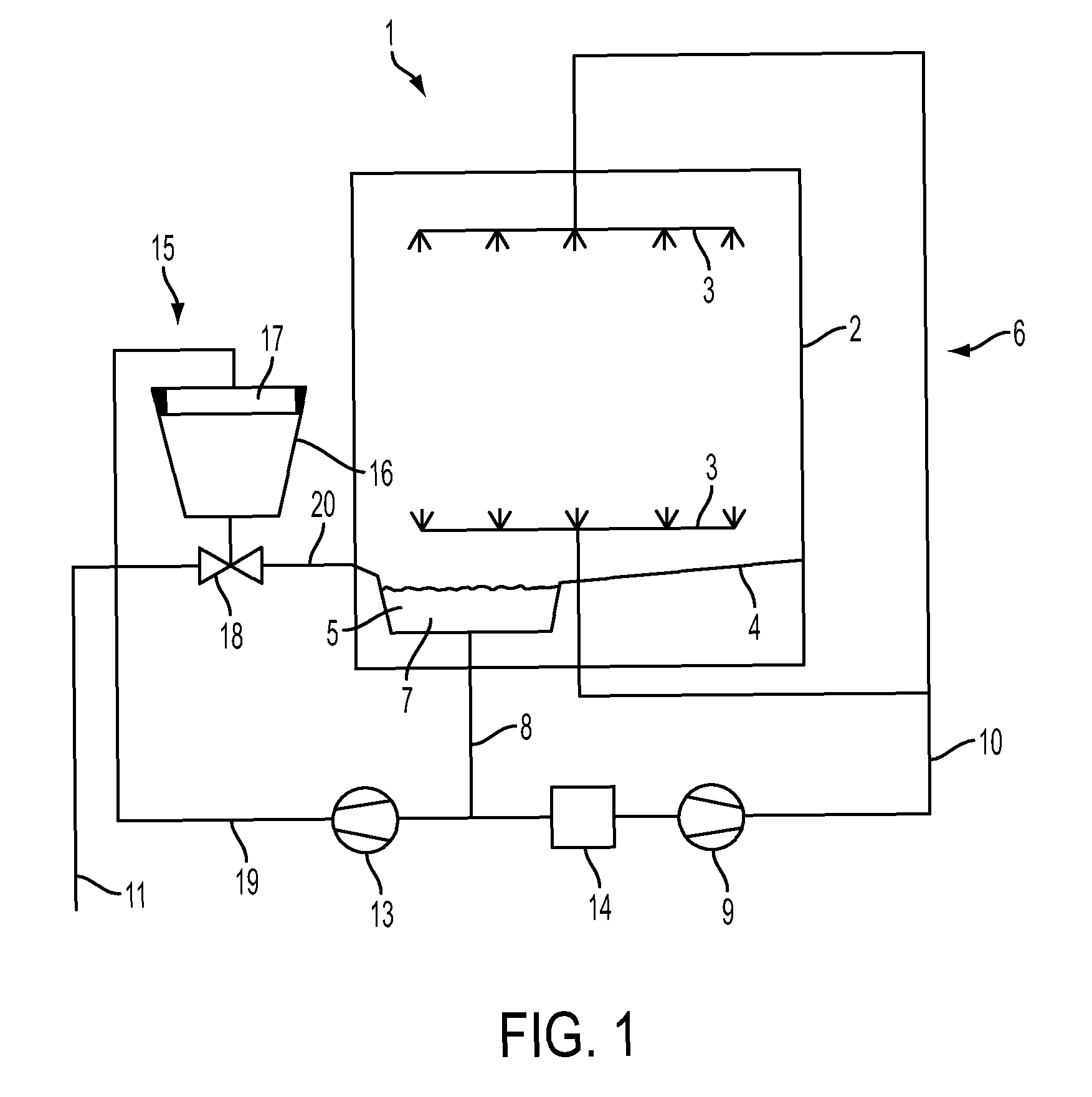

High pressure cleaning and decontamination system

InactiveUS7140954B2Suitable protectionClean effectAbrasive feedersAbrasive machine appurtenancesTriple pointRoom temperature

Abrasive cleaning and decontamination methods and systems are disclosed. The methods and systems use a high pressure liquefied gas, such as carbon dioxide, which produces insignificant quantities of secondary waste. These principles of the invention exploit the properties of the relatively high triple point of CO2 in order to first pressurize it to 35,000 to 60,000 PSI from a pressurized liquid. In the pressurized state, such a fluid can be at or above room temperature, allowing for transport over long distances in a flexible high pressure hose. At a point of use, a heat exchanger may subsequently chill the liquid, so that after expansion through a small high pressure orifice, a significant fraction of the liquid is converted to solid phase crystals exiting at high velocity to effectively clean and decontaminate. For more aggressive cleaning, abrasive particles and / or small diameter solid CO2 pellets can be entrained into the high pressure CO2 slipstream.

Owner:KURION INC

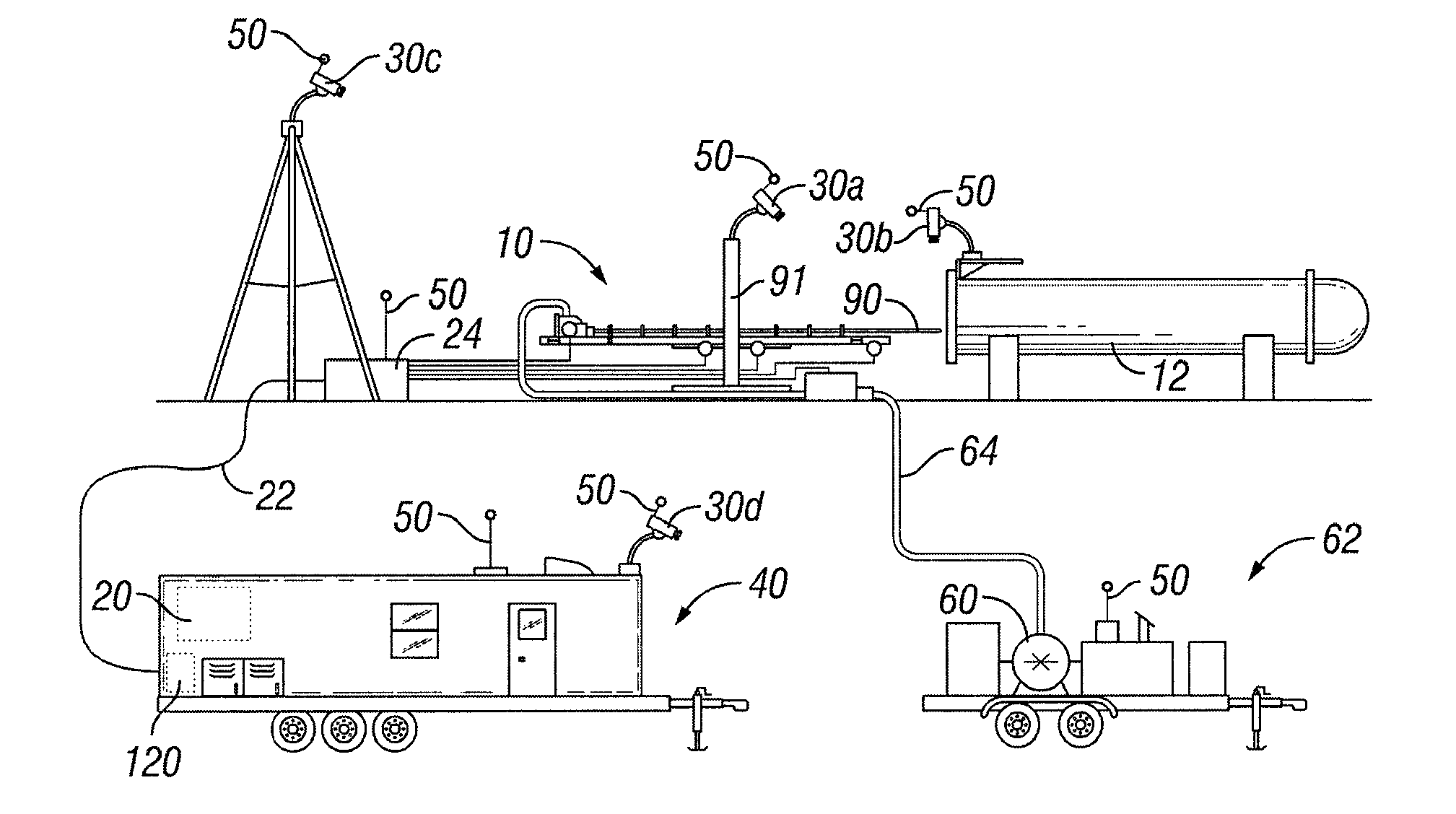

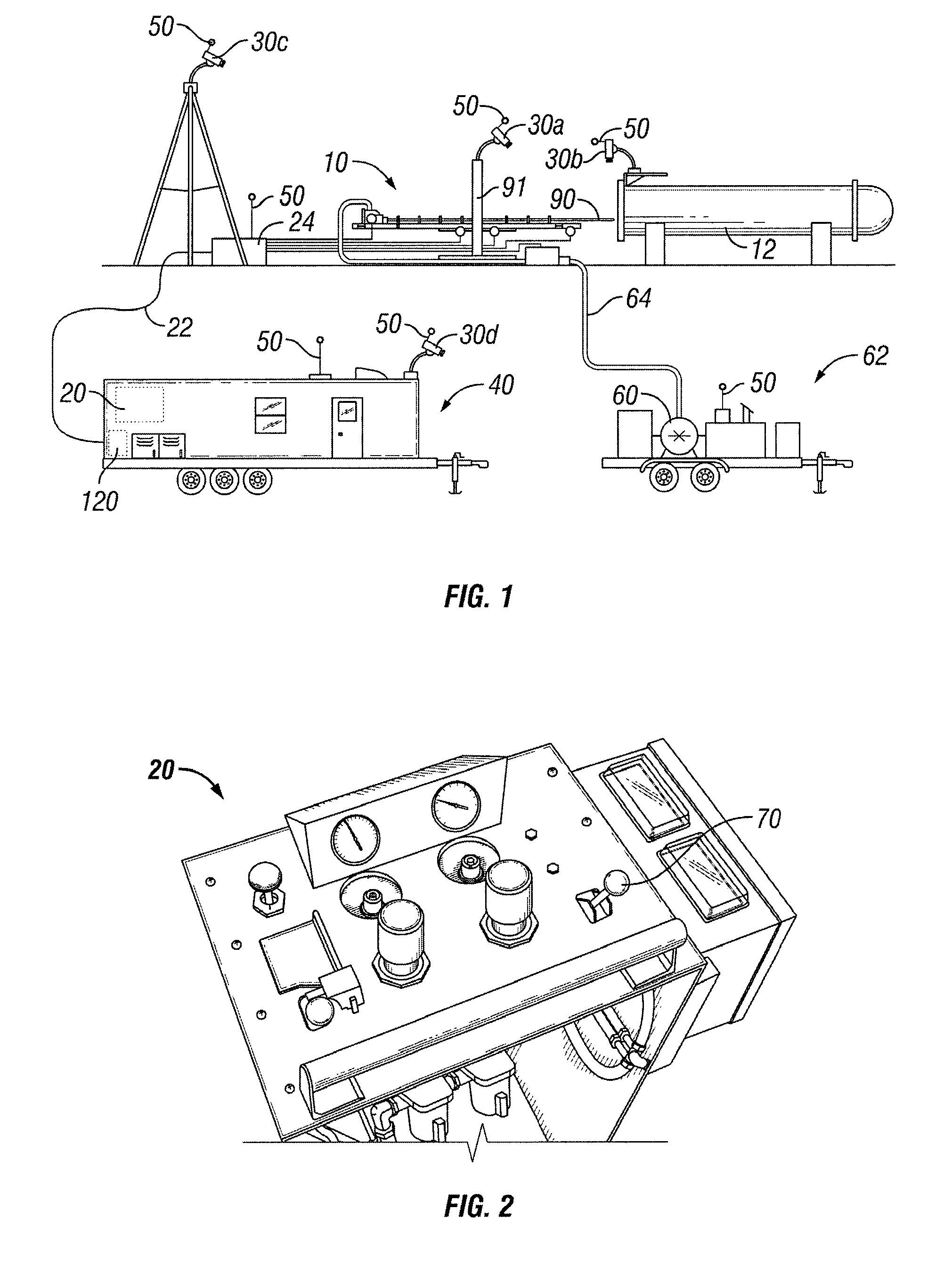

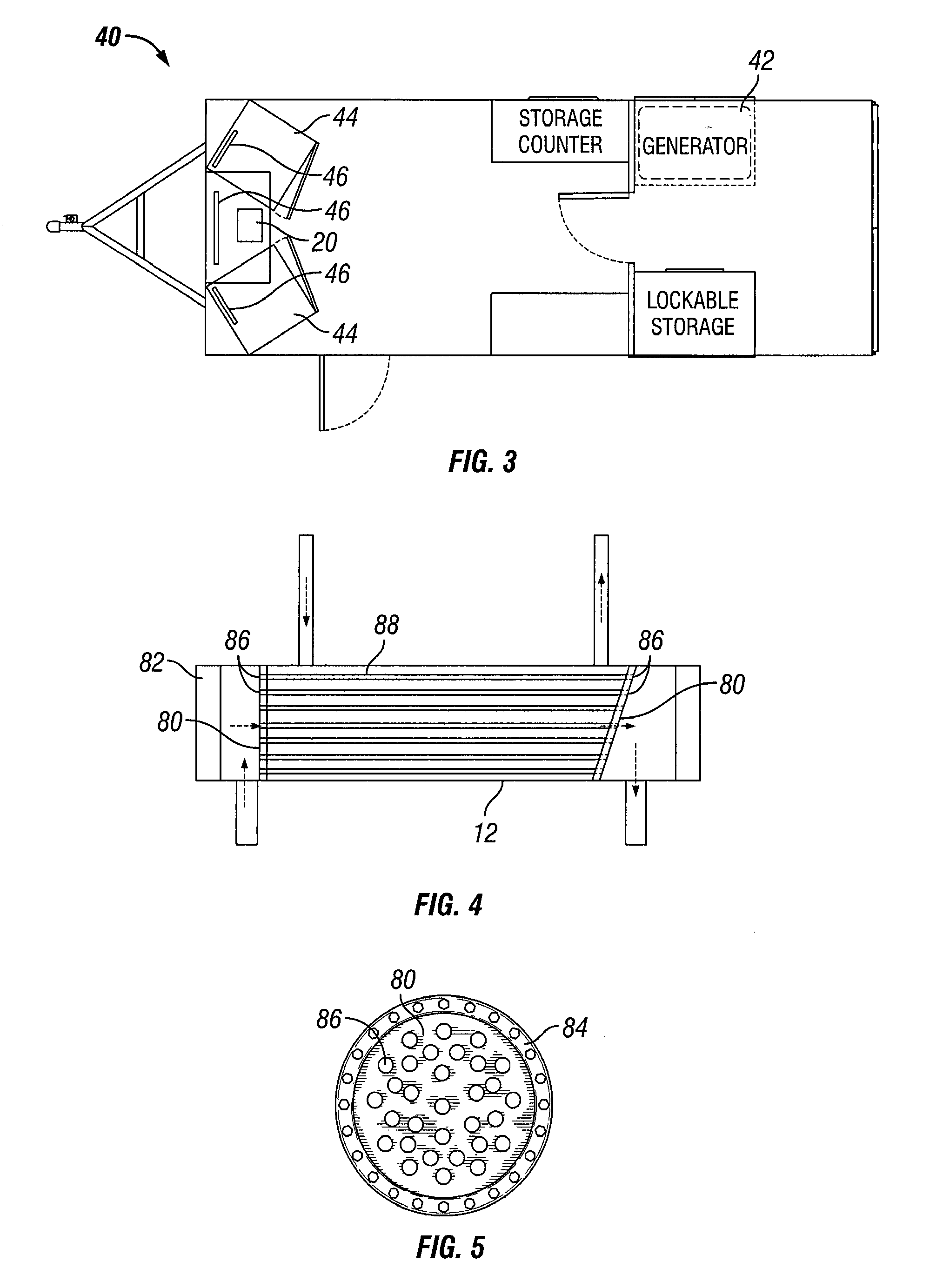

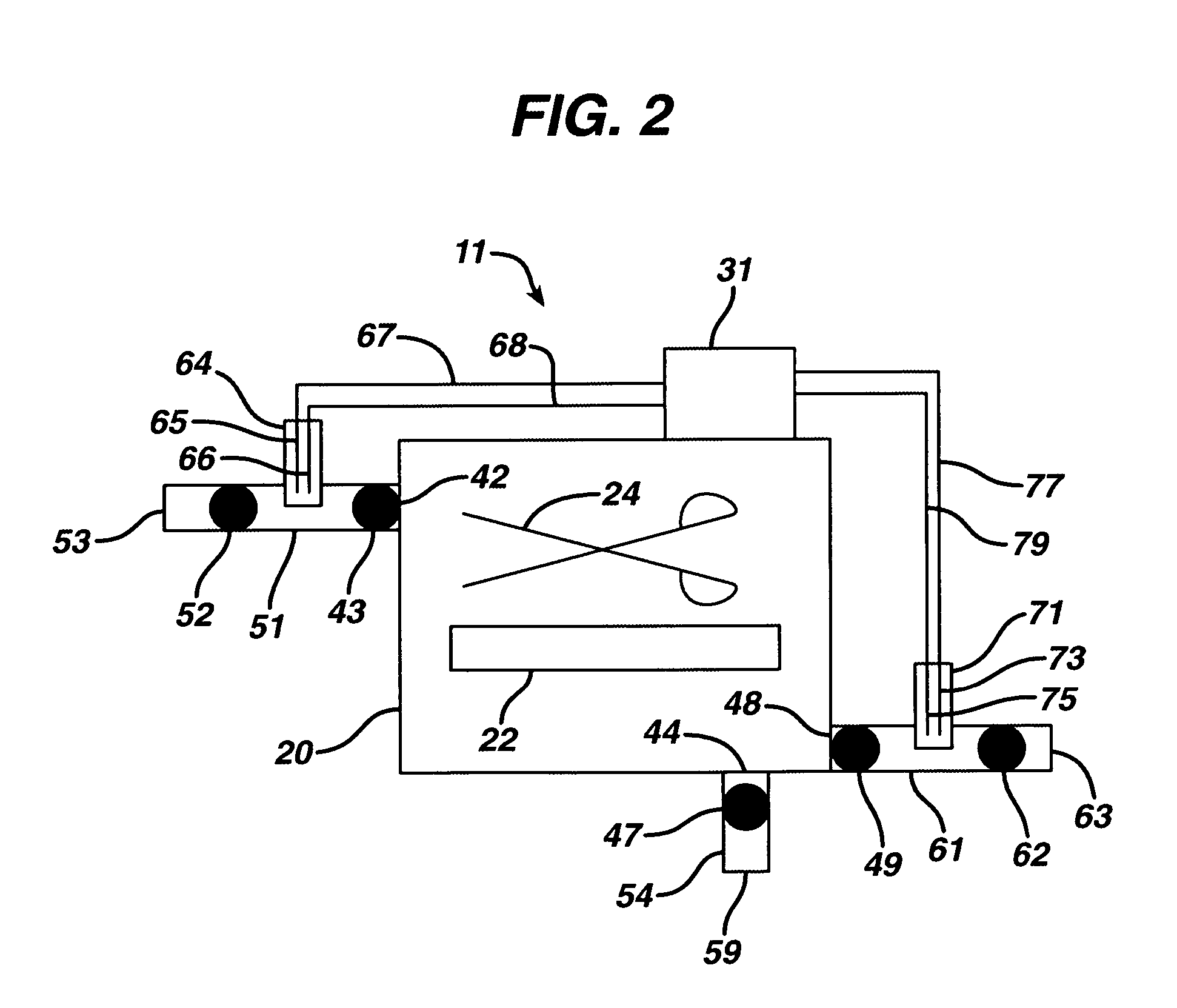

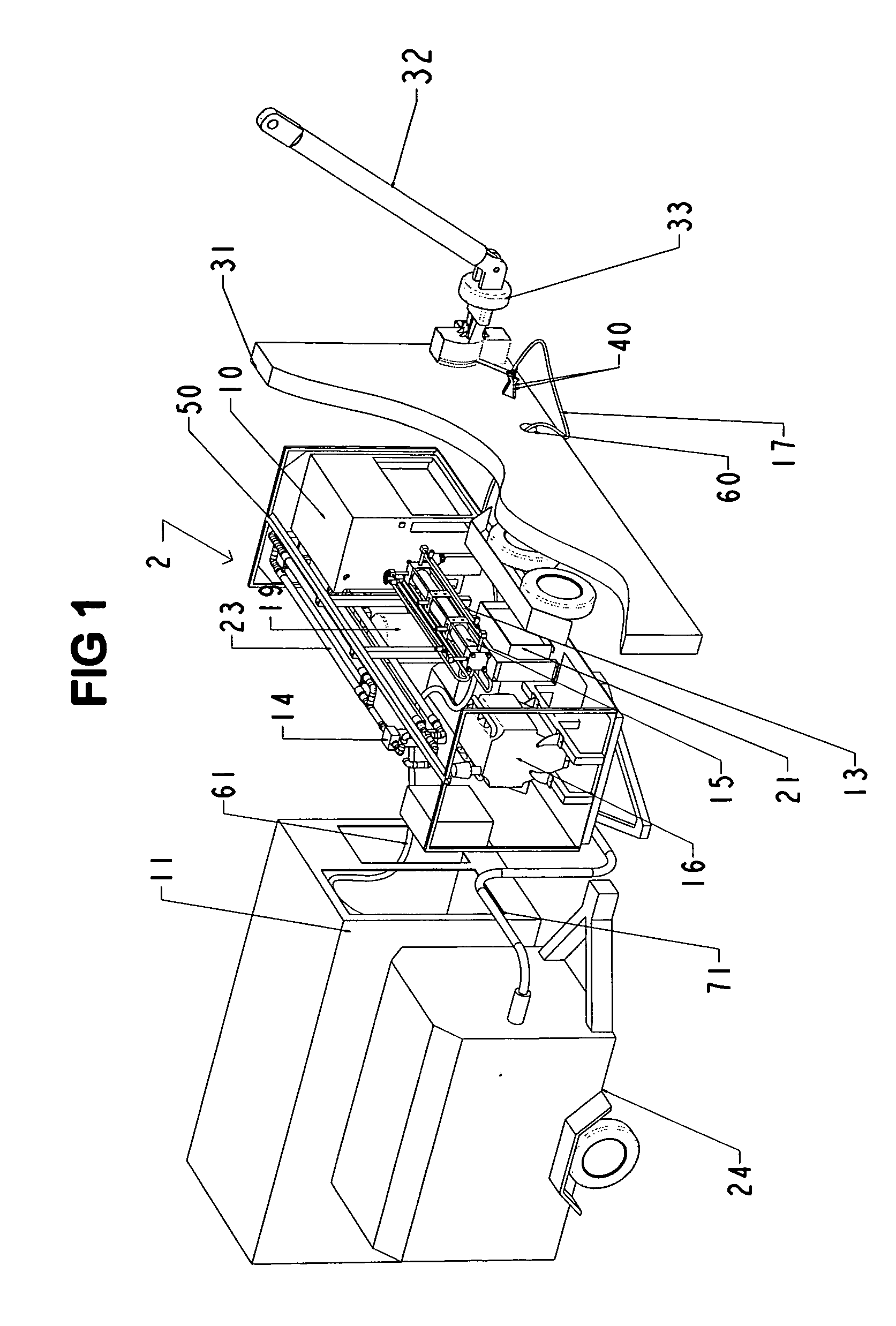

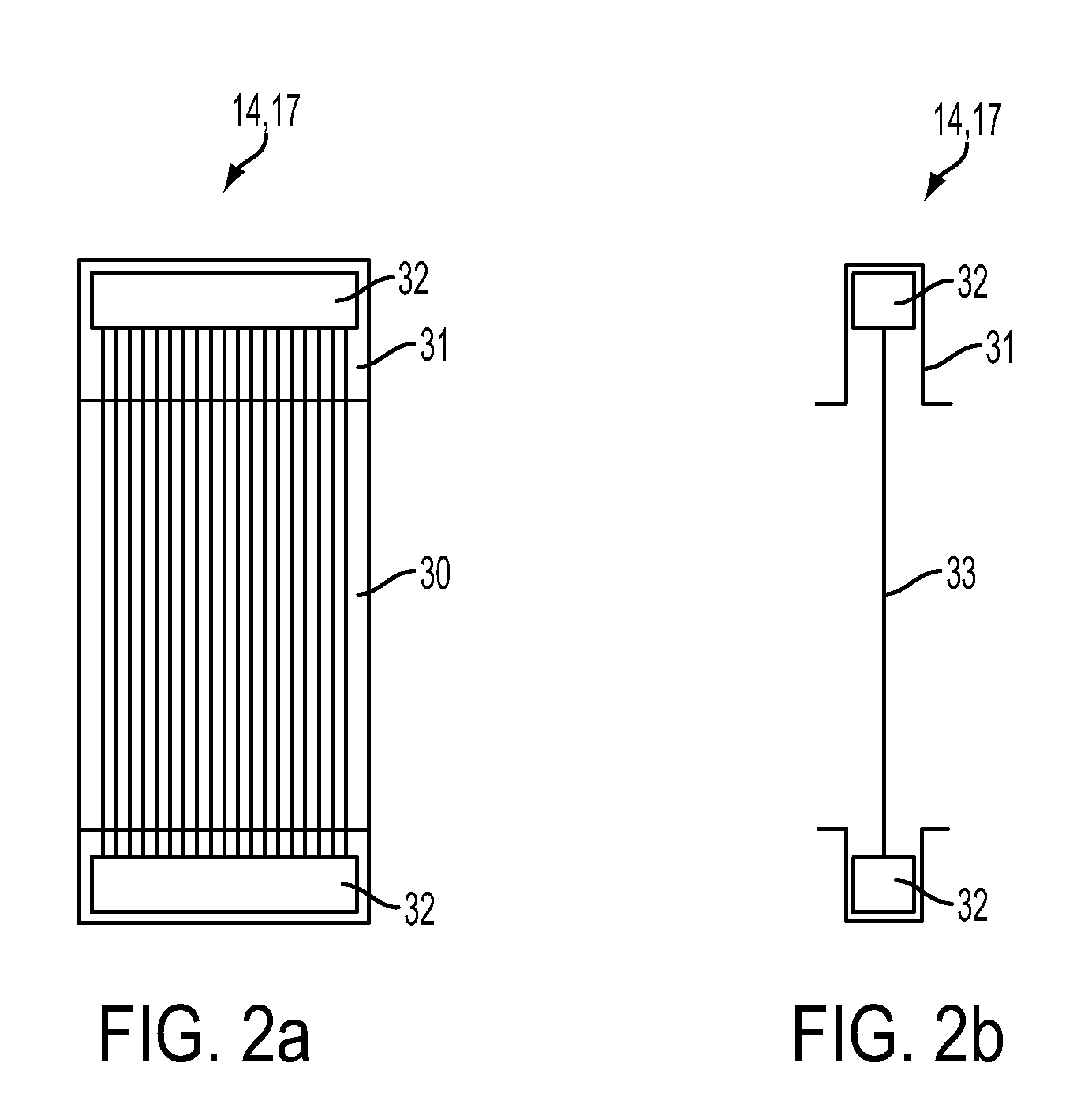

Automated heat exchanger tube cleaning assembly and system

ActiveUS20090255557A1Clean effectHollow article cleaningVehicle position/course/altitude controlSurvey resultThree dimensional measurement

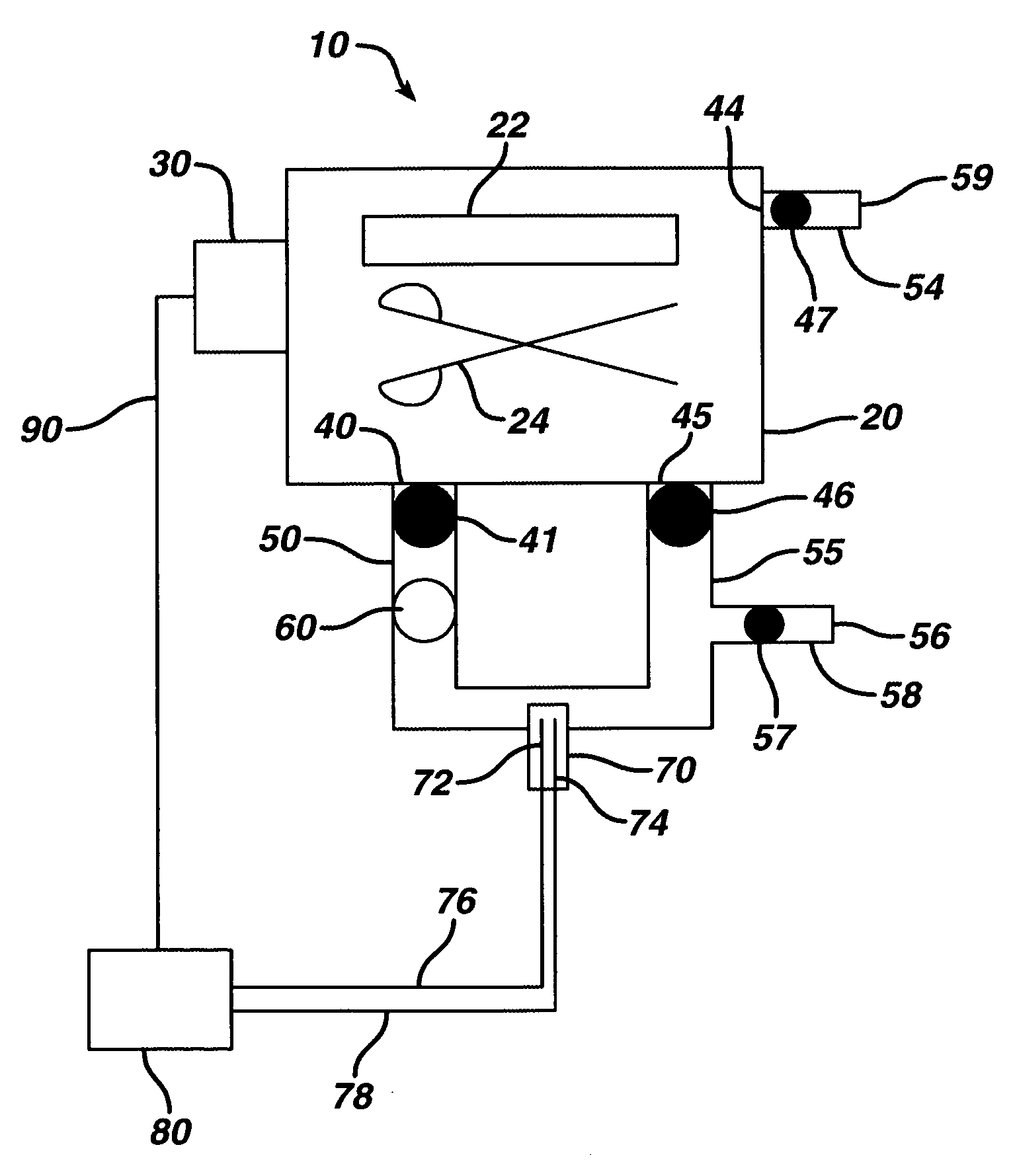

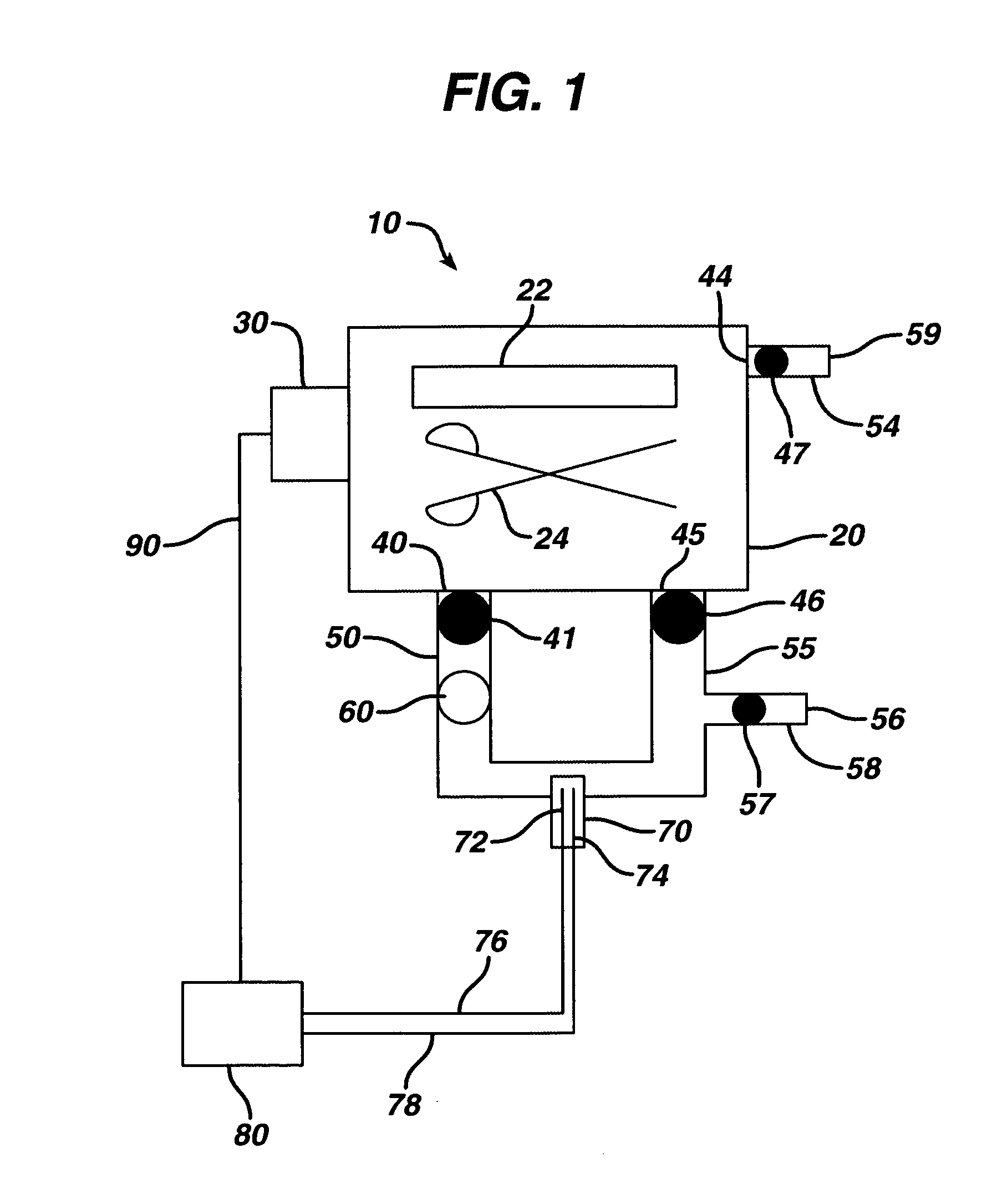

An automated heat exchanger tube cleaning assembly and system are provided. The present system can automatically (without ongoing human intervention) survey the tube sheet of a heat exchanger in three-dimensions, convert and record the survey results as a digital file in three-dimensions, and then, according to sequential parameters input via custom software, automatically coordinate via computer one or more cleaning devices to effect the cleaning of each desired tube of the heat exchanger.

Owner:HYDROCHEM

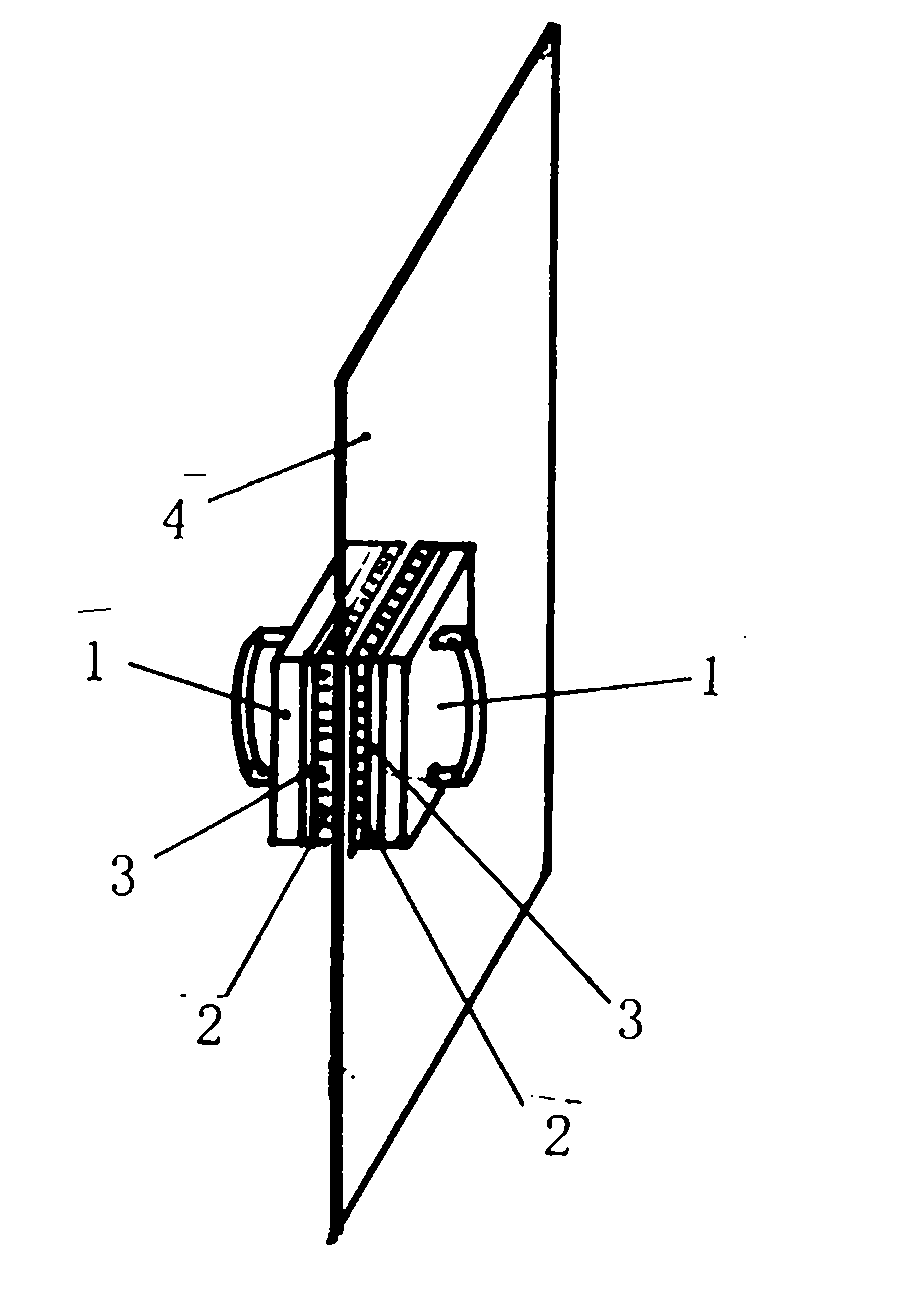

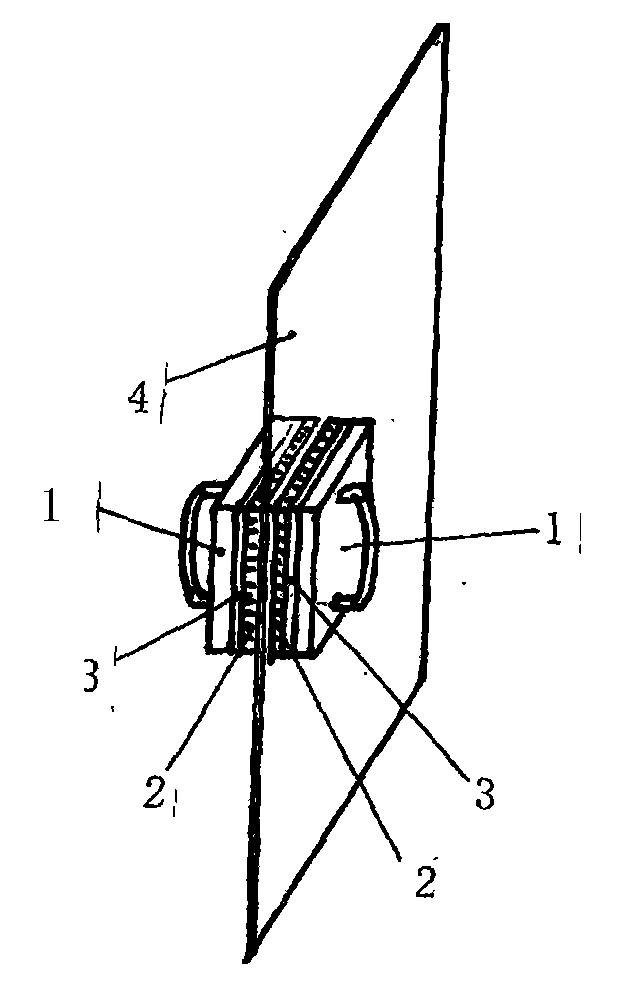

Glass double-sided magnetic cleaning wiper

The invention provides a glass double-sided magnetic cleaning wiper. Two cleaning wipers which can be oppositely and respectively arranged on both surfaces of glass and are adsorbed on the glass in a sliding structure through the magnetism, and magnetic blocks which can be mutually adsorbed are arranged between plate bodies and wiper bodies of the two cleaning wipers. When a glass window is wiped, the two cleaning wipers are respectively arranged on the both surfaces of the glass and are oppositely adsorbed together through the magnetism, and a user can hold a single cleaning wiper on the inner surface of the window body to drive the opposite cleaning wiper to wipe the both surfaces of the glass in a mode of sliding back and forth, therefore, the invention has simple operation, can avoid dangers by wiping the window outsides and has the effects of cleanly and rapid cleaning.

Owner:张雷寒

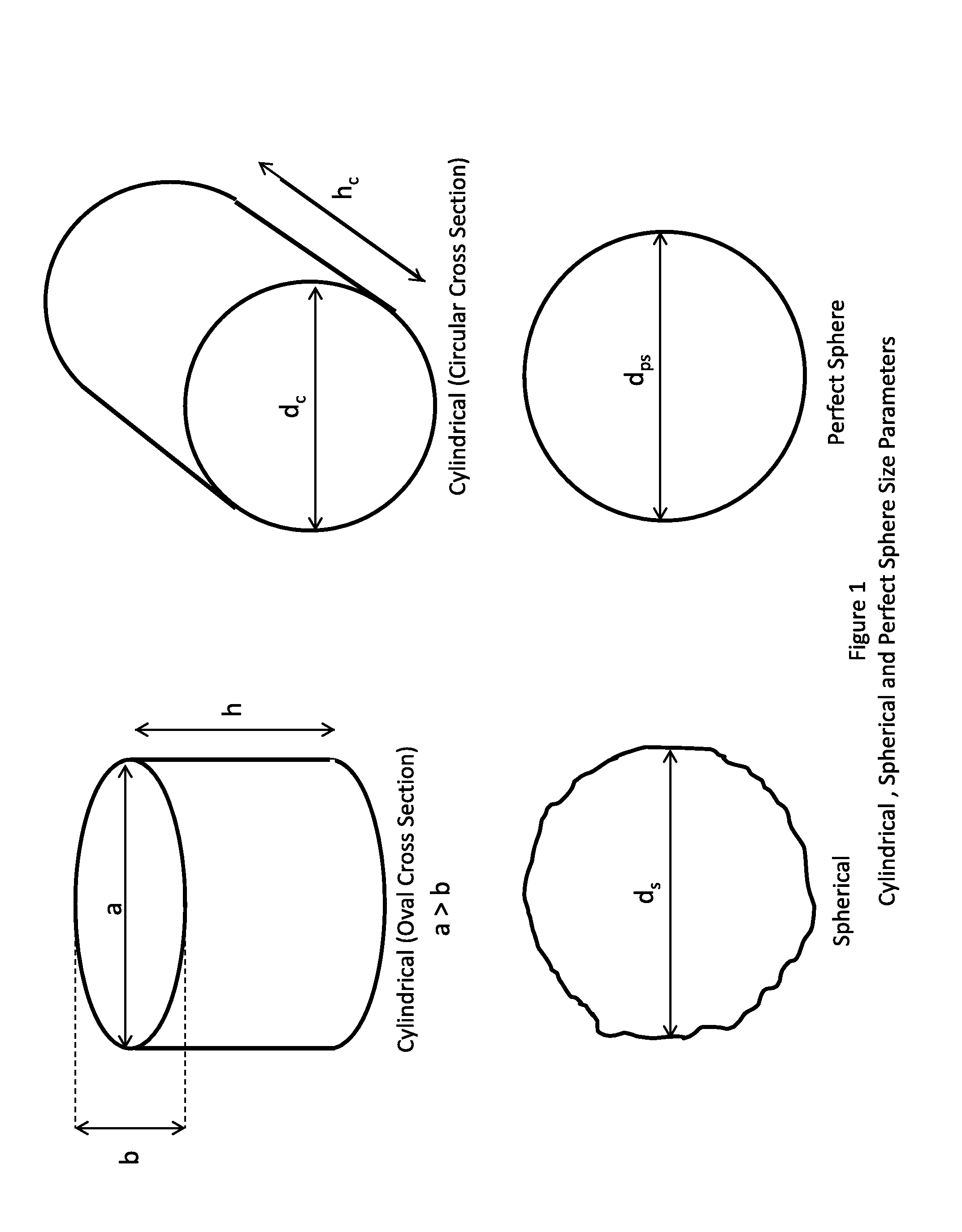

Cleaning method

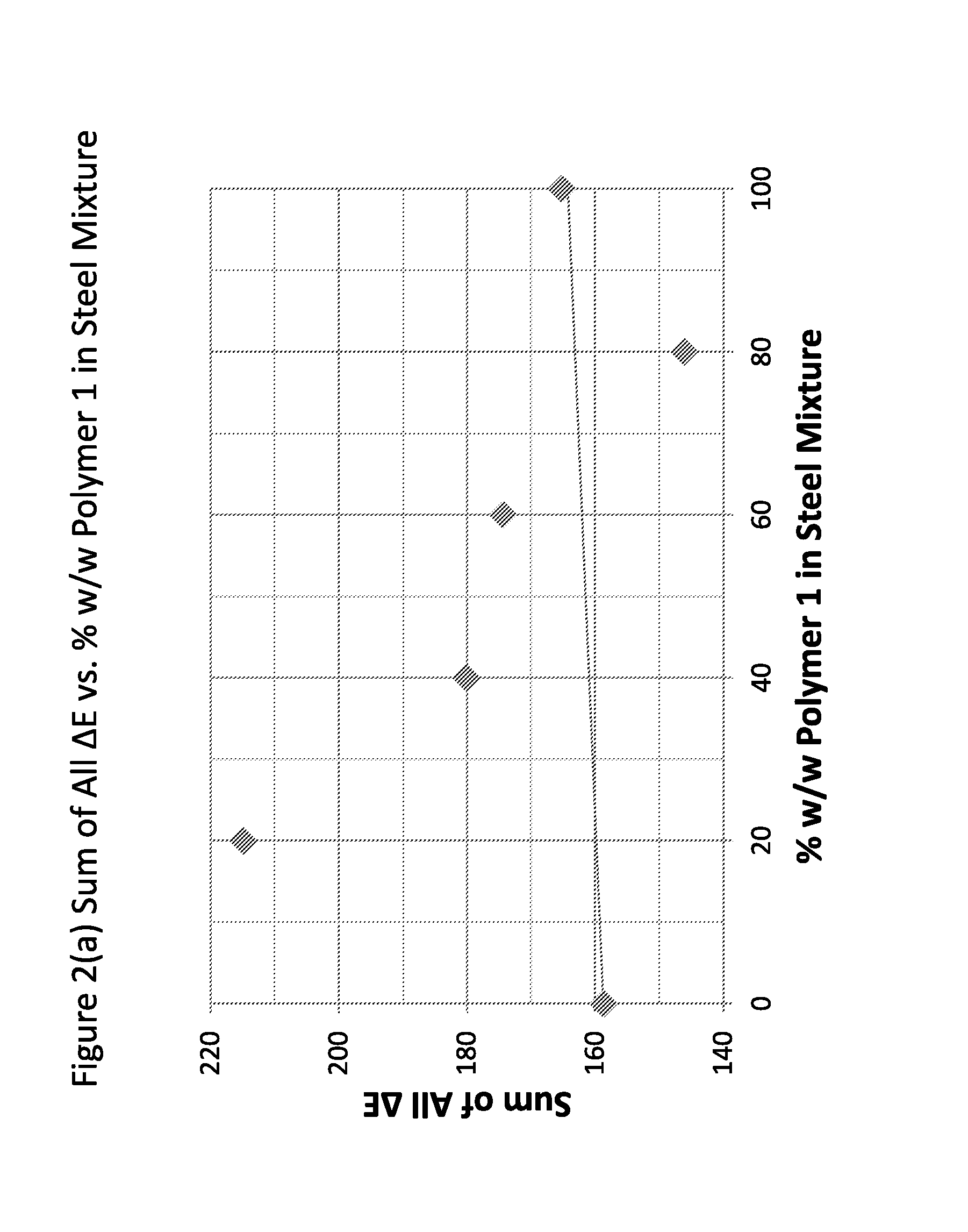

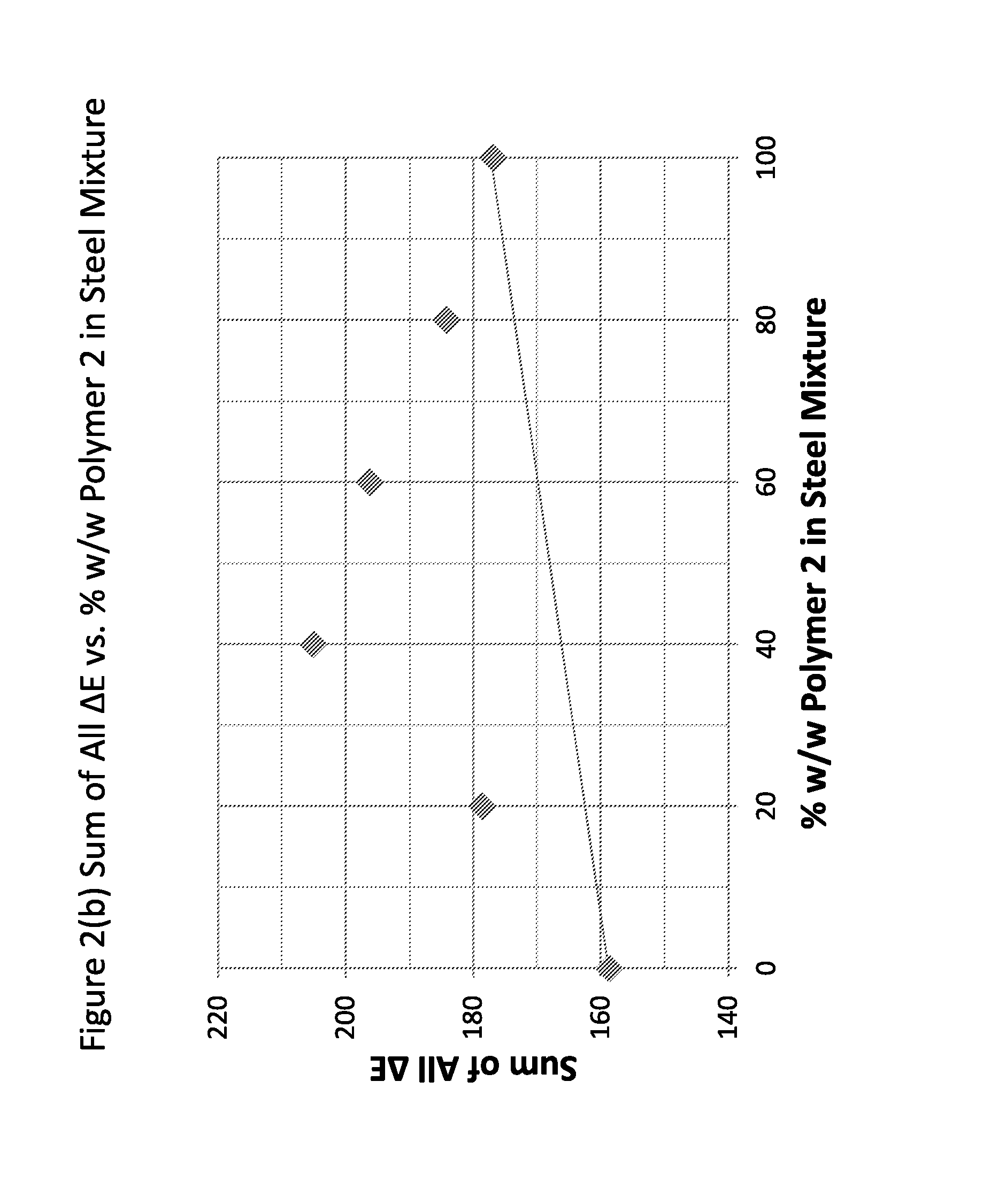

ActiveUS20130283542A1Small surface areaIncrease in sizeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParticulatesWash water

The invention provides a method for the cleaning of a soiled substrate, the method comprising treating the substrate with a non-polymeric solid particulate cleaning material and wash water, the treatment being carried out in an apparatus comprising a drum comprising perforated side walls and having a capacity of between 5 and 50 litres for each kg of fabric in the washload, wherein the solid particulate cleaning material comprises a multiplicity of non-polymeric particles at a particle to fabric addition level of 0.1:1-10:1 by mass, each of the particles being substantially cylindrical or spherical in shape, and wherein the drum comprising perforated side walls is rotated at a speed which generates G forces in the range of from 0.05 to 900 G. The non-polymeric particles may comprise particles of glass, silica, stone, wood, or any of a variety of metals or ceramic materials. Preferably the solid particulate cleaning material additionally comprises a multiplicity of polymeric particles each of which is substantially cylindrical or spherical in shape. Preferably, at least one detergent is employed in the cleaning process. The invention provides optimum cleaning performance as a result of improved mechanical interaction between substrate and cleaning media and is preferably used for the cleaning of textile fabrics. The method allows for significant reductions in the consumption of detergents, water and energy when compared with the conventional wet cleaning of textile fabrics, and also facilitates reduced washing-related textile fabric damage. The invention also envisages a cleaning composition comprising a solid particulate cleaning composition and at least one additional cleaning agent.

Owner:XEROS LTD

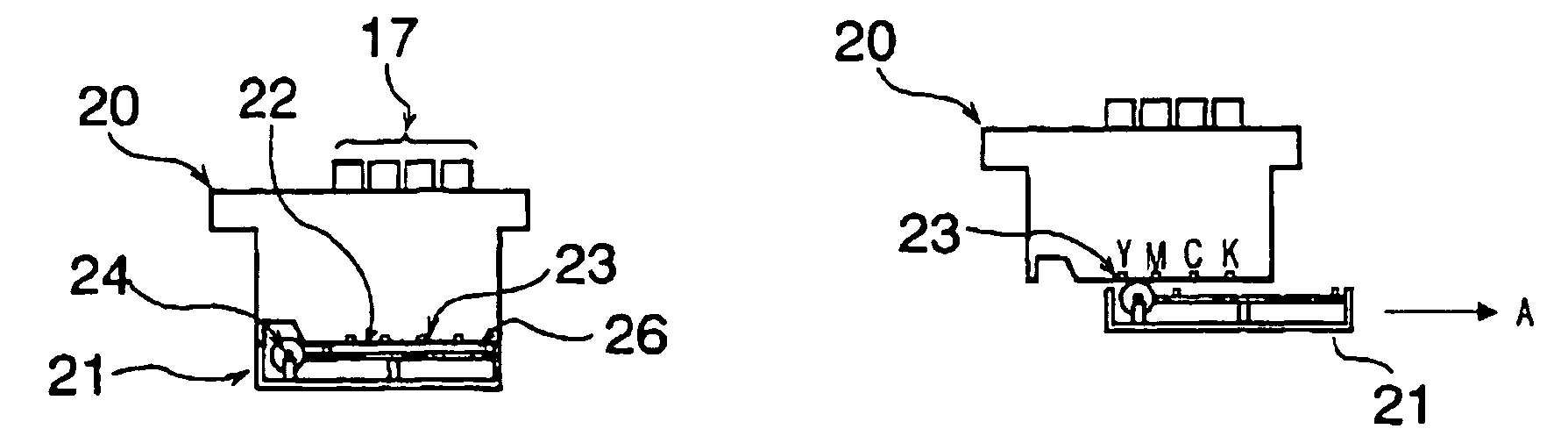

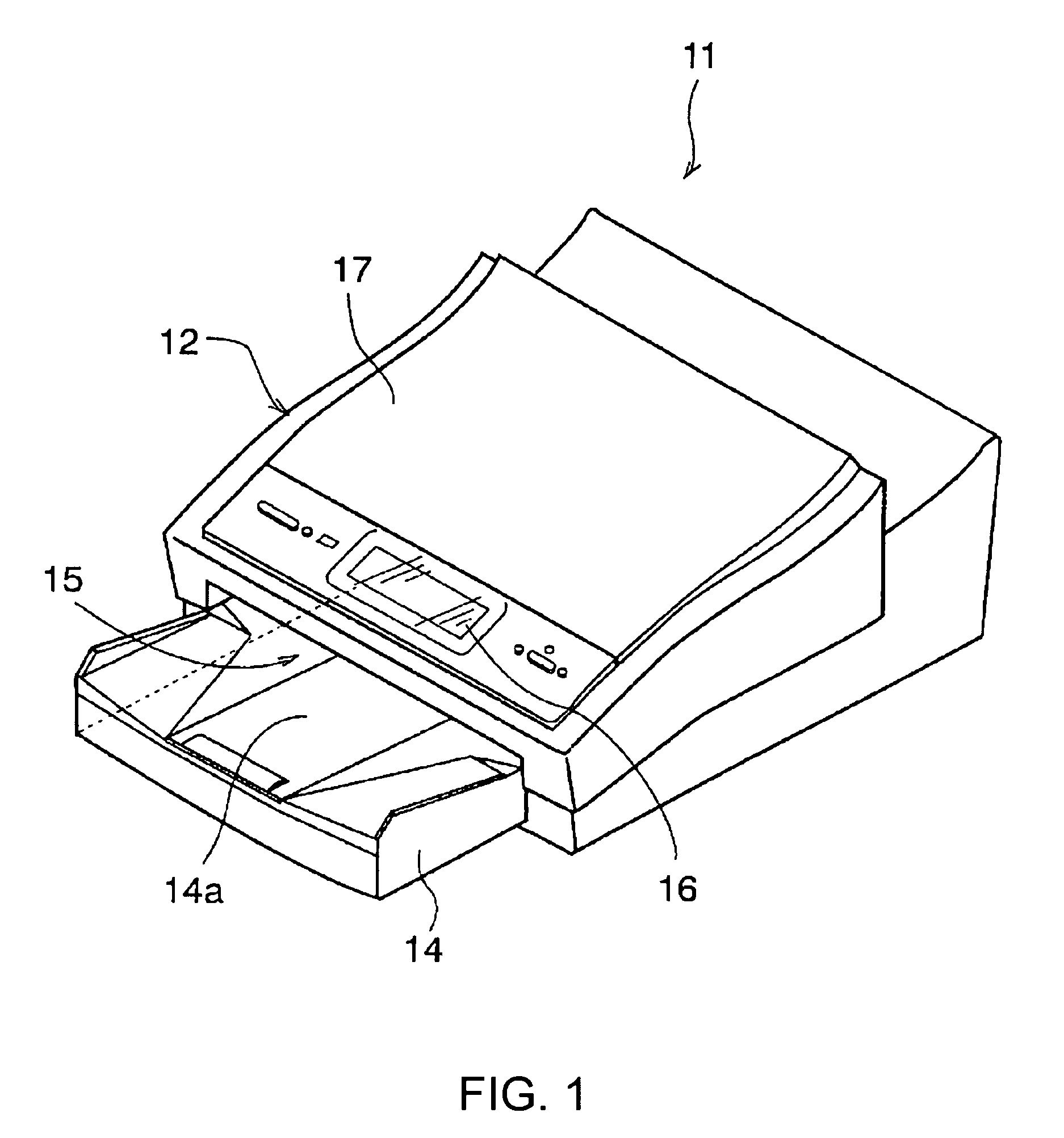

Liquid Discharging Apparatus and Control Method Therefor

InactiveUS20080049058A1Reduce printing timeTimely maintenanceOther printing apparatusLiquid dropWaste management

In a liquid discharging apparatus for discharging droplets from a liquid discharge nozzle to a discharge object to be discharged and in a method for controlling the liquid discharging apparatus, cleaning effects for the ink discharge nozzle and the adjacent areas can be enhanced, and the time required for a series of performance maintaining operations can be reduced. The apparatus includes a platen plate for supporting recording paper as the discharge object, defining a positional relationship between the discharge object and the liquid discharge head, and receiving the droplets discharged from the liquid discharge head. Ink droplets are preliminarily discharged from the ink discharge nozzle to the platen plate.

Owner:SONY CORP

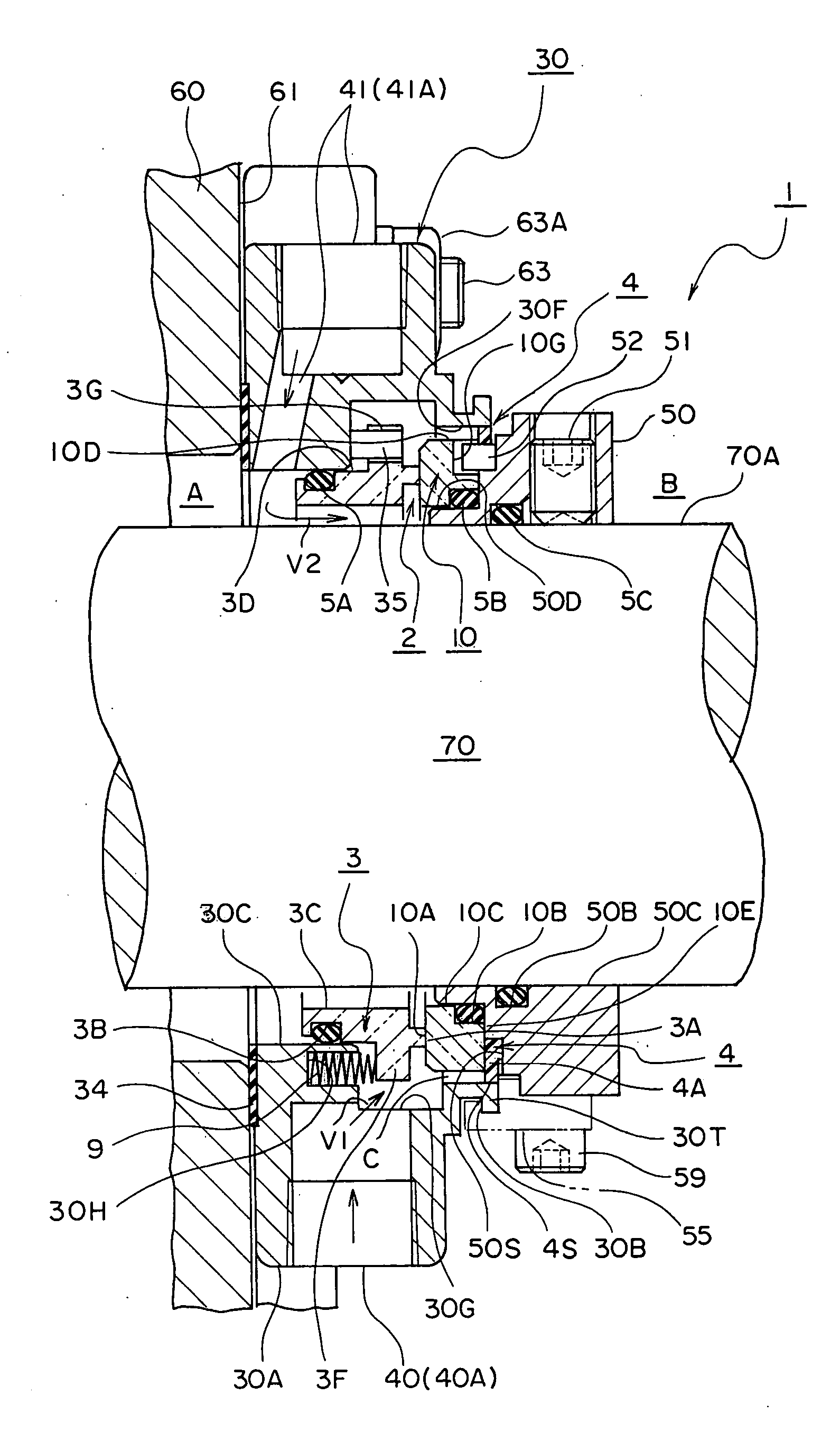

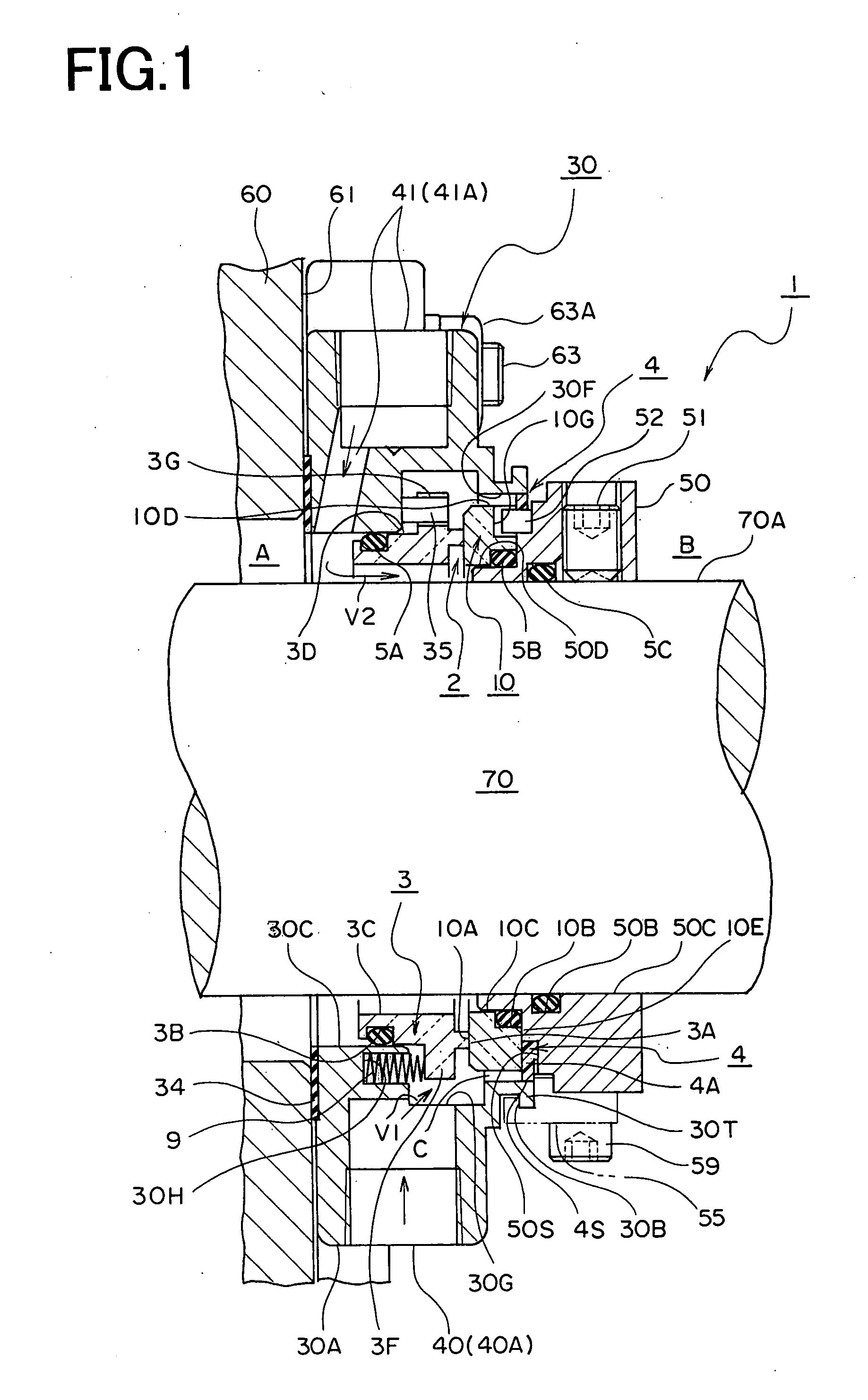

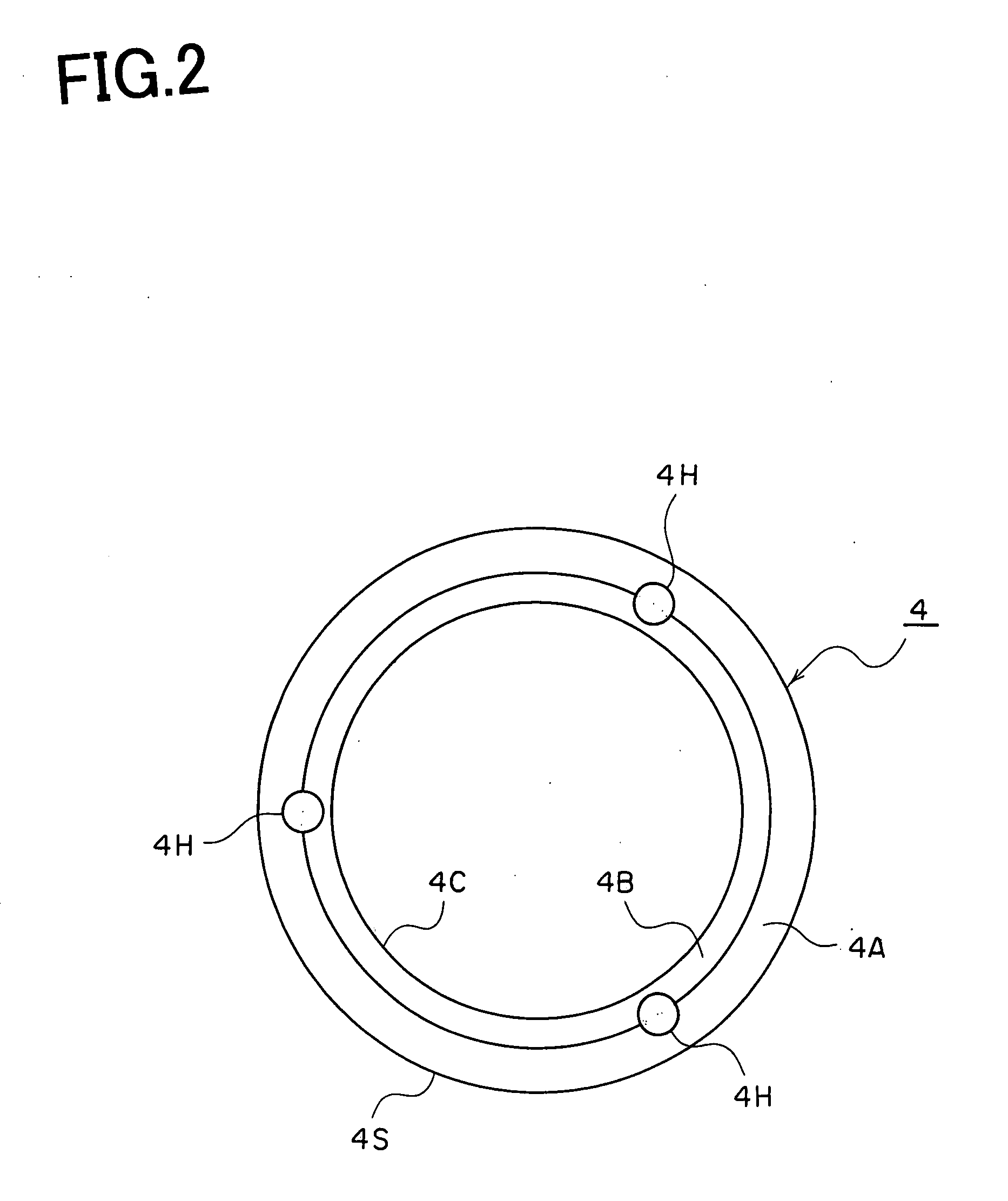

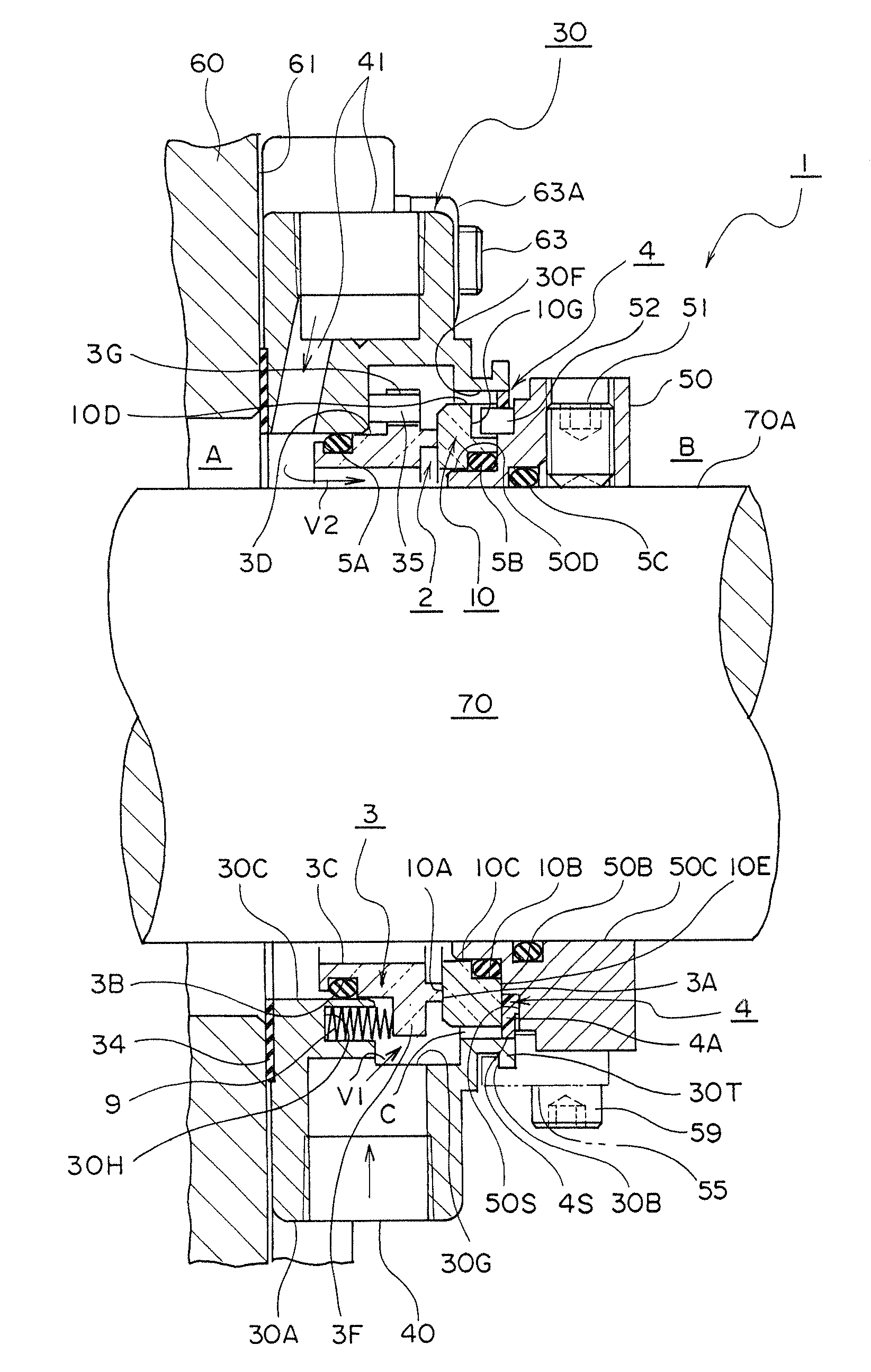

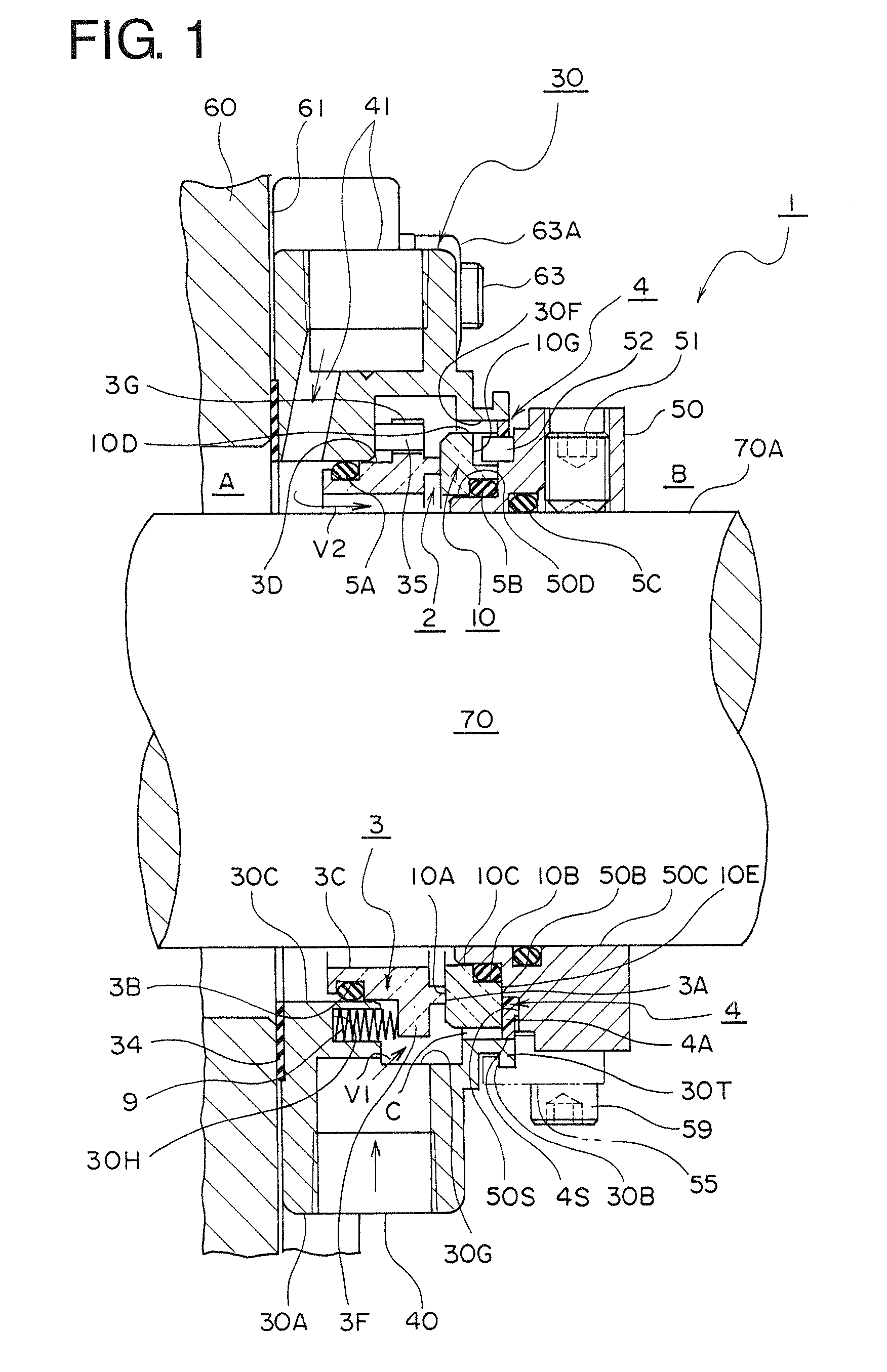

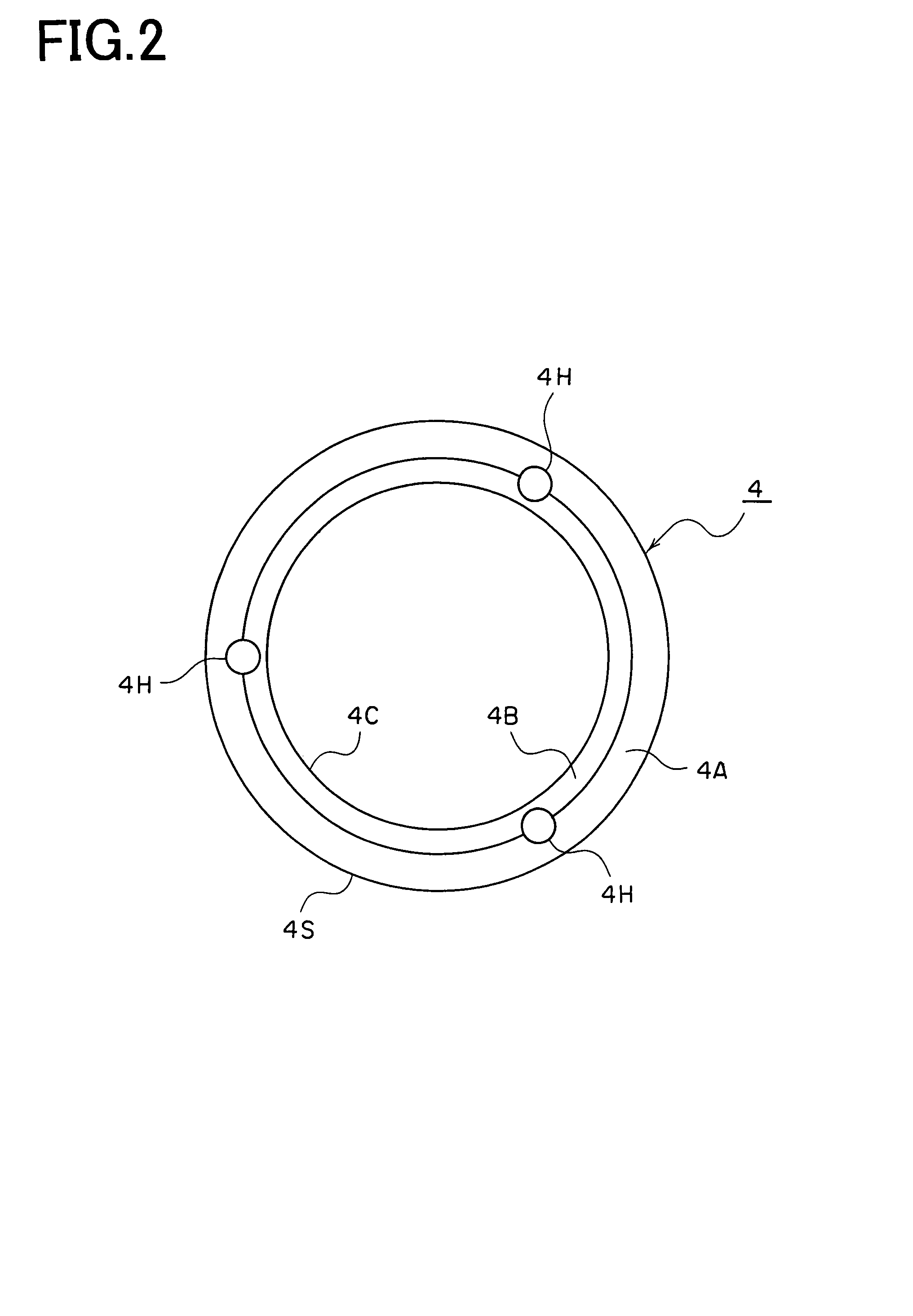

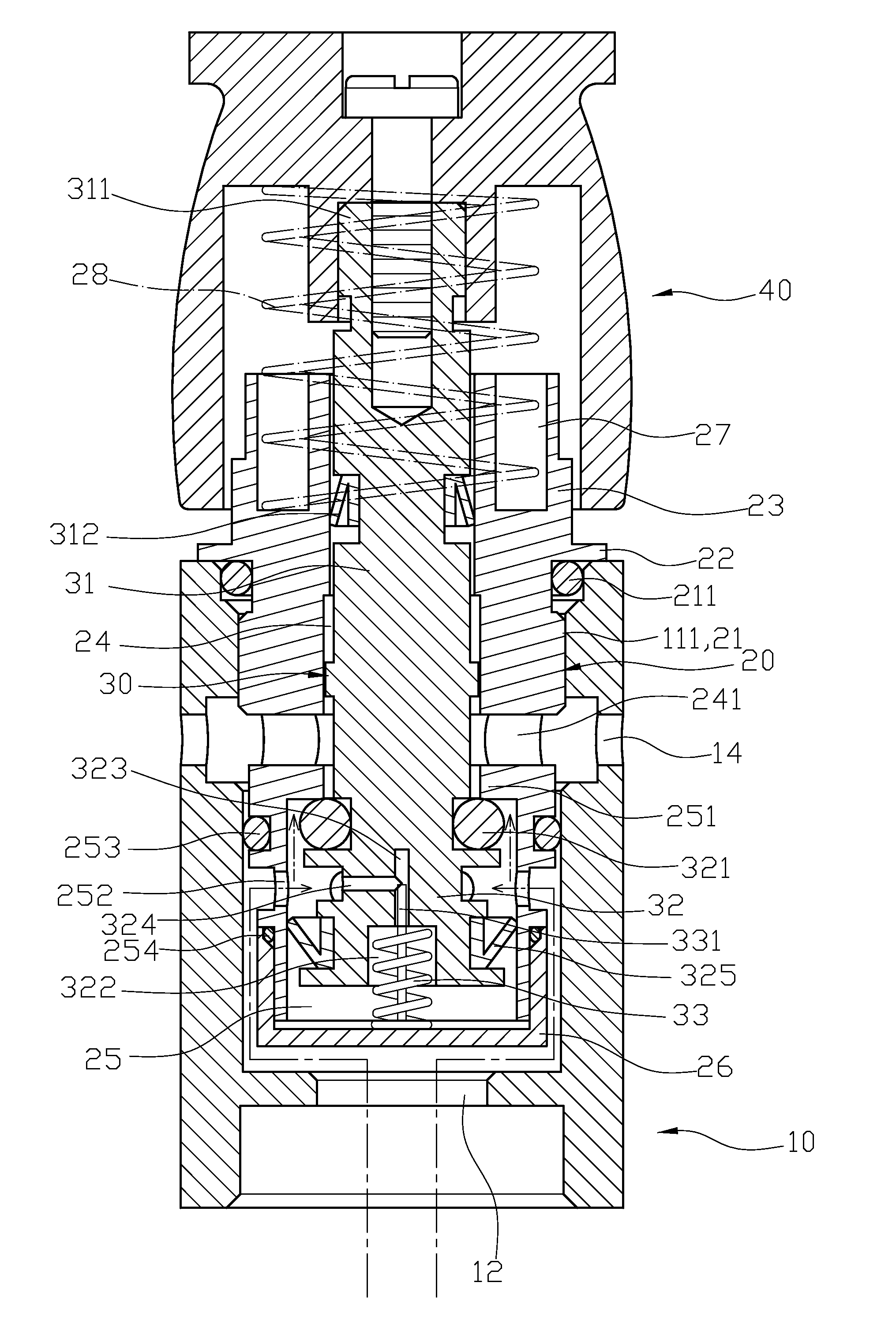

Mechanical Seal Device

A mechanical seal in which cooling and cleaning of each seal ring and, in addition, lubrication of a slide seal surface are improved, which can be reduced in size, and whose assembly and disassembly are facilitated. The mechanical seal device has a seal cover (30) attached to an outer surface (61) of a device body, having a fitting surface (30C) through which a shaft is insertable, and forming a space section (30G) that is more on the outside (B) of a machine than the fitting surface (30C); a quenching path (40) penetrating through the space section (30G) and supplying quenching fluid into the space section (30G); an annular restriction section (30F) constructed in the seal cover (30) and provided more on the outside of the machine than the space section (30G); a first seal ring (3) having a movement surface (3D) that is sealingly movably fitted to the fitting surface (30C) of the seal cover (30) and having a seal surface (3A) inward of the space section (30G); a second seal ring (10) having a relative slide seal surface (10A) that can be in tight contact with the seal surface (3A) of the first seal ring (3) and having on its outer peripheral surface a seal surface (10D) that faces the restriction surface (30F); a seal collar (50) for holding the second seal ring (10) in a sealed state and sealingly fixed to the shaft; and a packing (4) in tight contact with the seal surface (10D) of the second seal ring (10) and with the restriction surface (30F) of the seal cover (30) to prevent the quenching fluid from leaking out of the machine.

Owner:EAGLE INDS

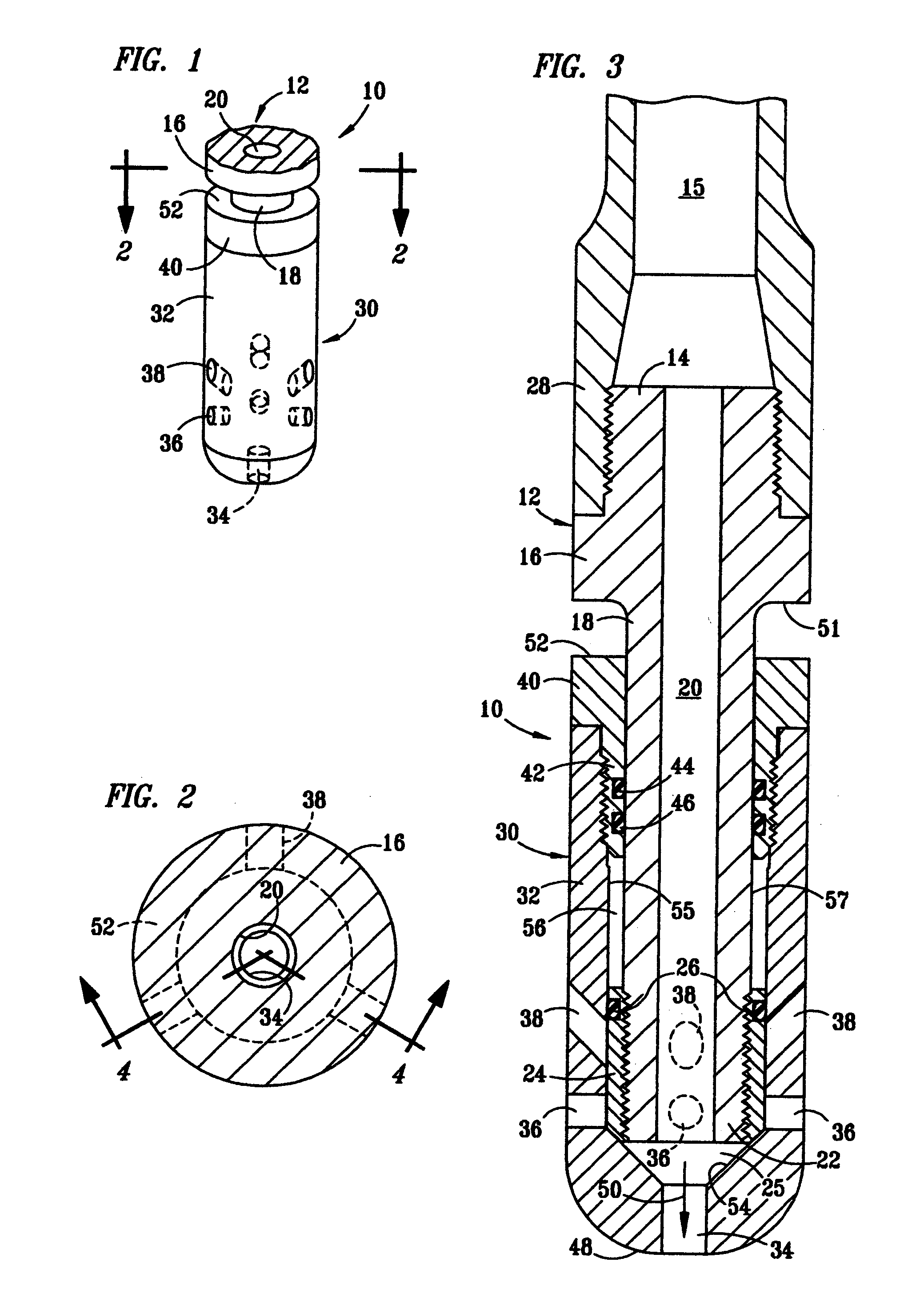

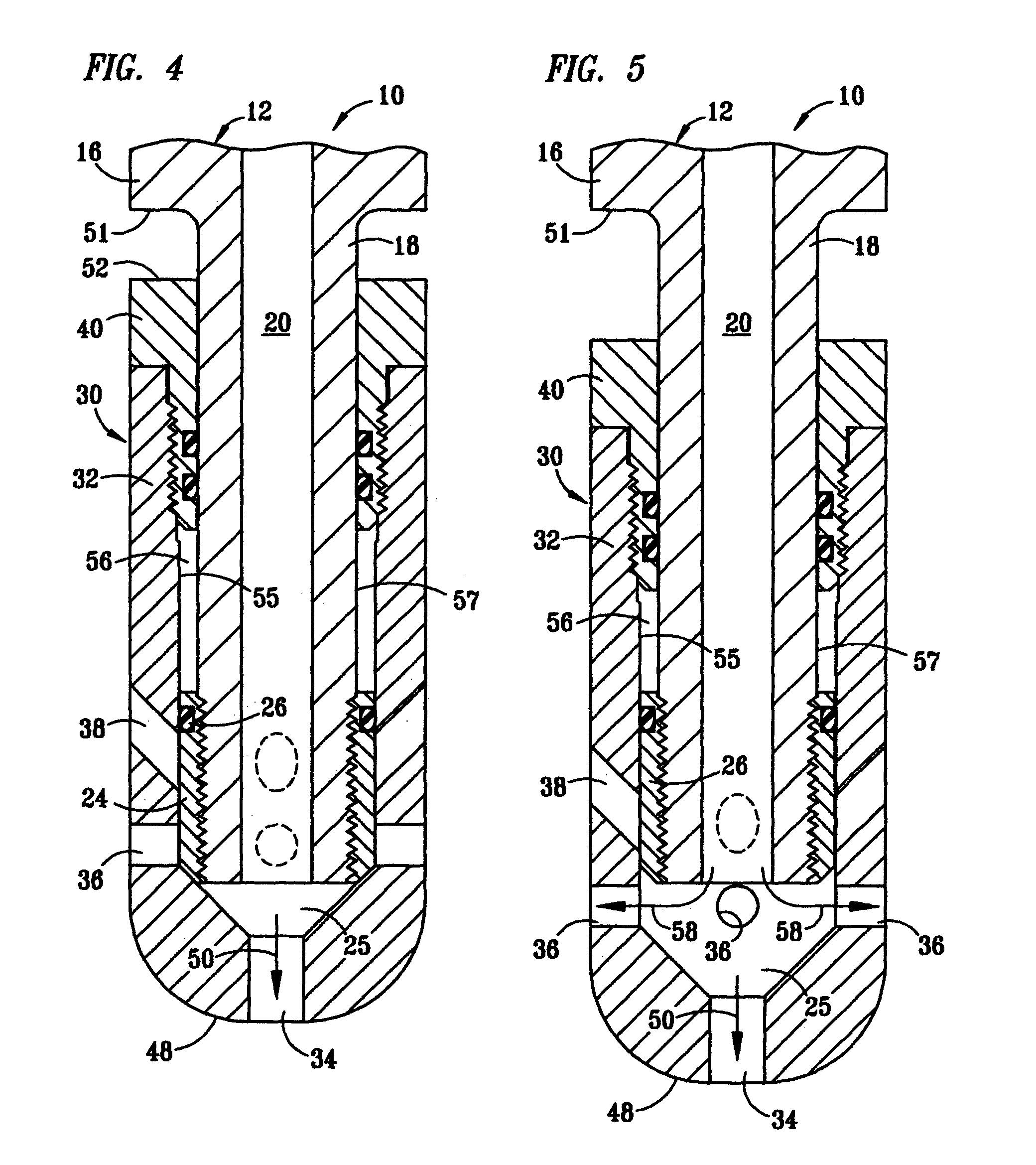

Self-adjusting nozzle

InactiveUS7007865B2Clean effectPrevent liquid leakageMovable spraying apparatusSpray nozzlesReciprocating motionEngineering

A self-adjusting nozzle for use in injecting pressurized, and optionally pulsating, fluid into a well bore or other conduit for the purpose of cleaning out the bore or conduit, the nozzle having slidably engaged mandrel and tool tip sections, each with an axial bore, and the tool tip having a plurality of axially and circumferentially spaced discharge ports communicating with the axial bores, the mandrel being able to reciprocate inside the tool tip without operator intervention in response to obstructions encountered ahead of, around or behind the nozzle as it enters or leaves the well bore or conduit, thereby sequentially blocking or unblocking some of the discharge ports to direct more of the pressurized fluid against the obstruction.

Owner:WAVEFRONT TECHNOLOGY SOLUTIONS

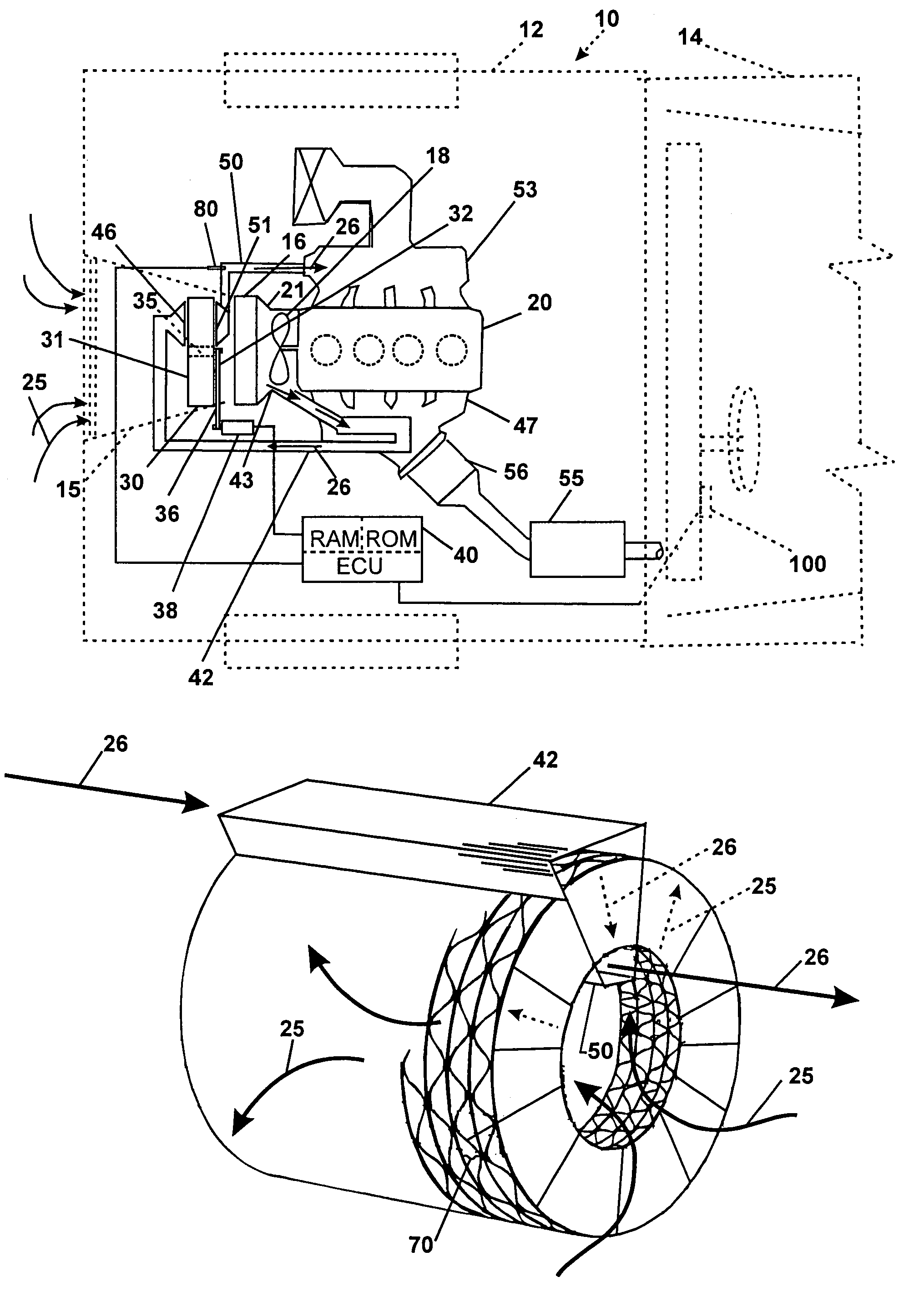

Vehicular atmosphere cleansing method

InactiveUS7080505B2Clean effectGood removal effectCombination devicesGas treatmentActivated carbonSorbent

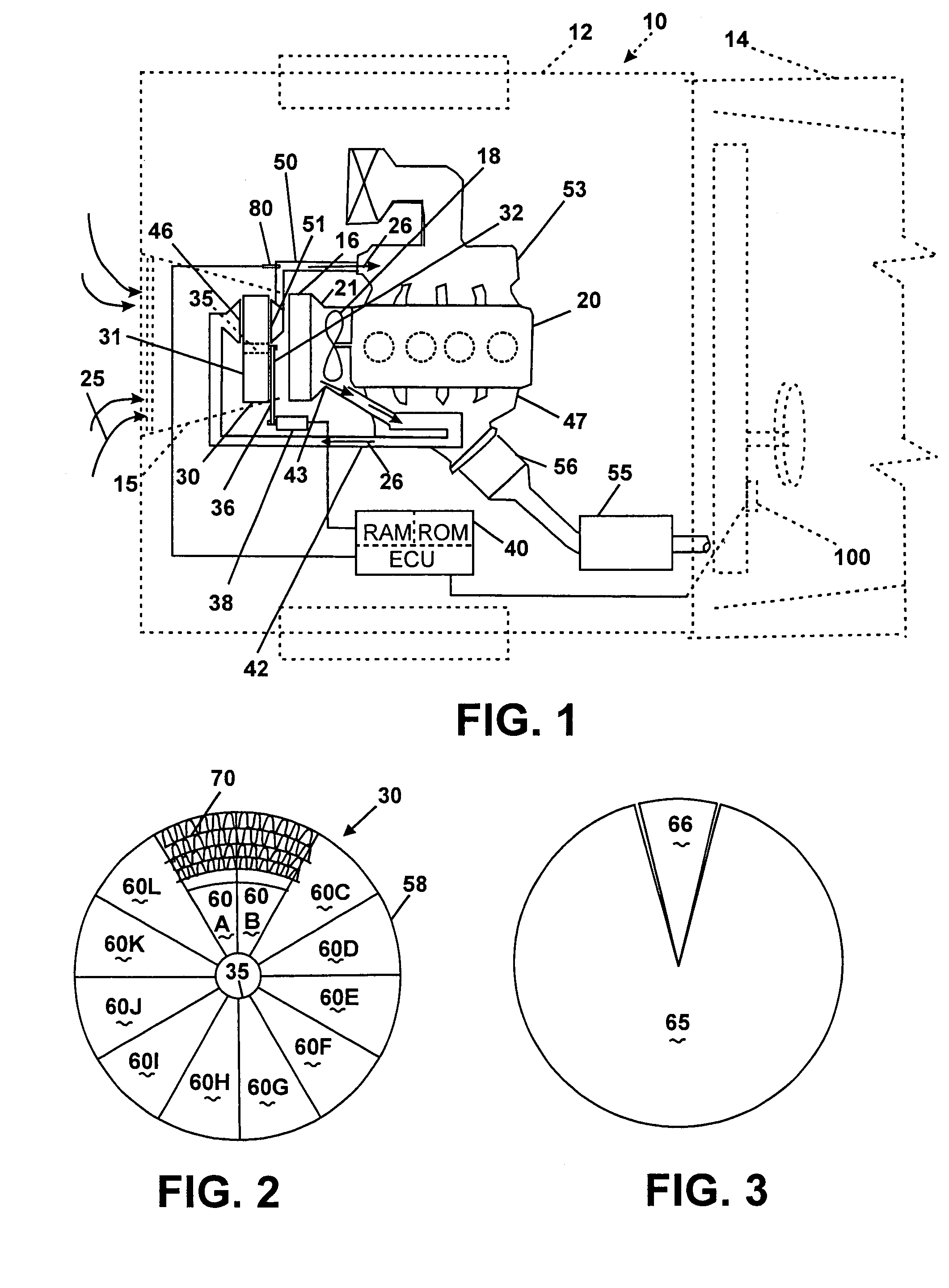

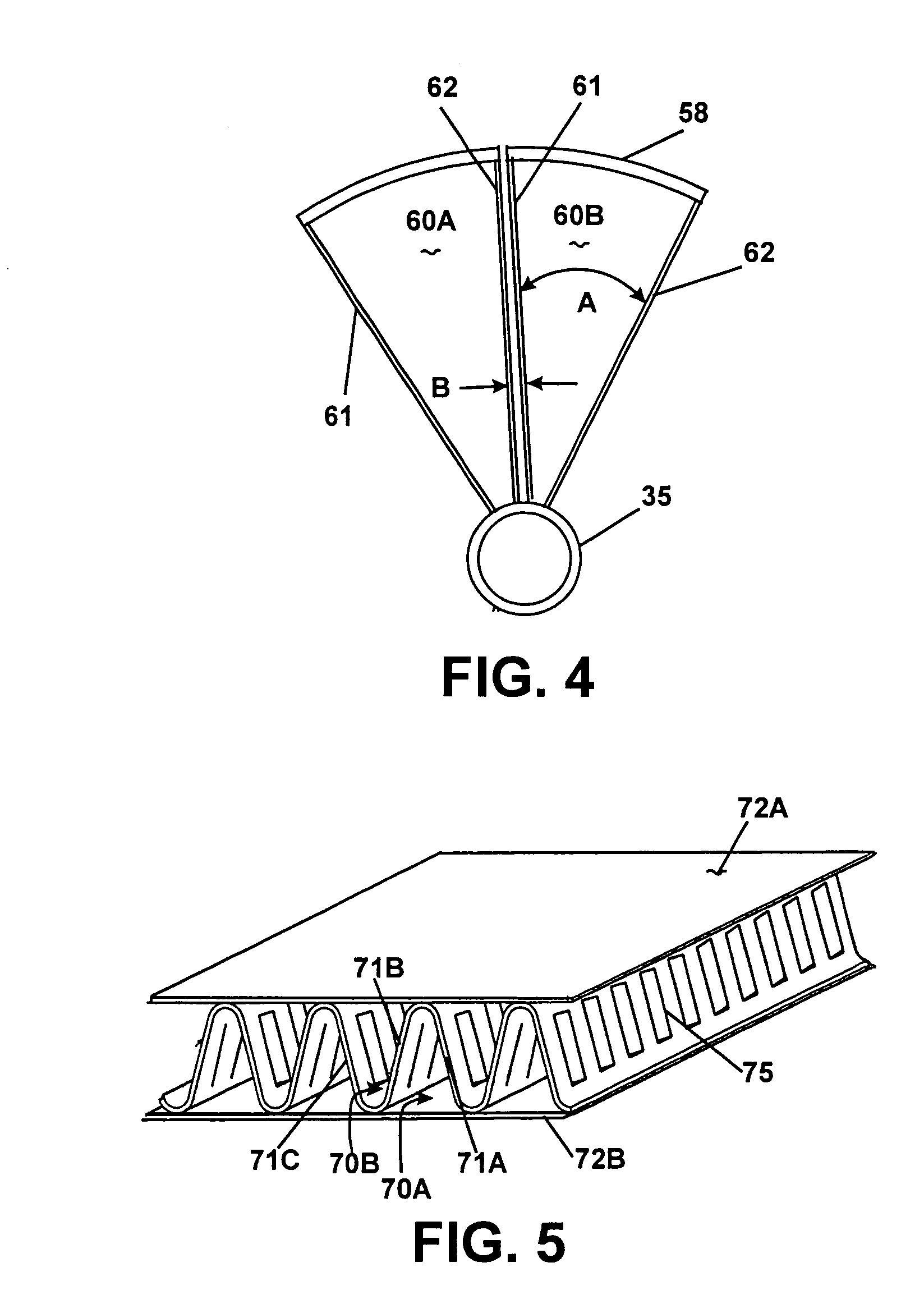

A vehicular atmosphere cleansing system utilizes a regenerative wheel having flow channels extending through the wheel coated with an adsorbant. An atmosphere stream passes through a first position dependent portion of the wheel where VOC's including HC's are adsorbed while a heated atmosphere stream passes through a second position dependent regenerative portion of the wheel whereat VOC's are desorbed. The adsorbant is activated carbon having particles of micropore size adhered to the substrate by a silicone binder producing high adsorption efficiencies while withstanding relatively high regenerative heat temperatures resulting from exhaust gas sensible heat. A hydrocarbon senses HC in the desorbed heated atmosphere stream to rotatively and sequentially index pie shaped, segmented portions of the wheel into the wheel's regenerative region while also functioning as the main component of an OBD device for the system.

Owner:ENGELHARD CORP

AER wet cleaning indicator

A soil standard for monitoring a cleaning process for a medical instrument, employs a soil which contains moisture so as to more accurately mimic soil which may be present upon an instrument to be cleaned in the cleaning process.

Owner:ETHICON INC

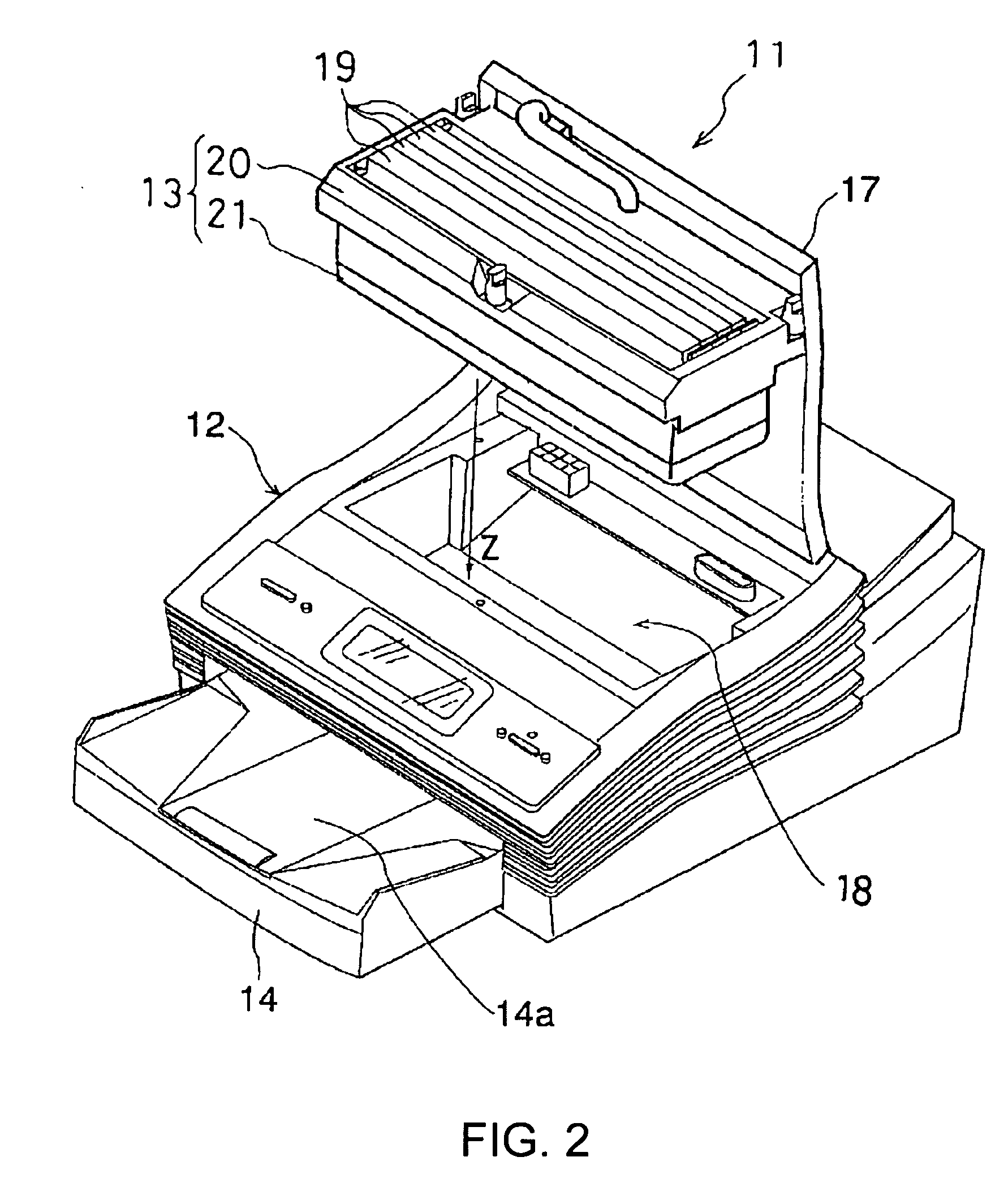

Recording apparatus

InactiveUS20060023050A1Minimize amount of contaminationClean effectTypewritersOther printing apparatusRecording headEngineering

A recording apparatus for effecting recording by a recording head on a recording material which is fed by a plurality of pairs of feeding rollers, the recording apparatus, includes a first feeding roller for feeding the recording material with a first feeding force; a second feeding roller for feeding the recording material with a second feeding force which is smaller than the first feeding force; control means for stopping the first feeding roller with a sheet material nipped to cause rubbing between the second feeding roller and the sheet material to effect cleaning to a peripheral surface of the second feeding roller.

Owner:CANON KK

Pipe cleaner

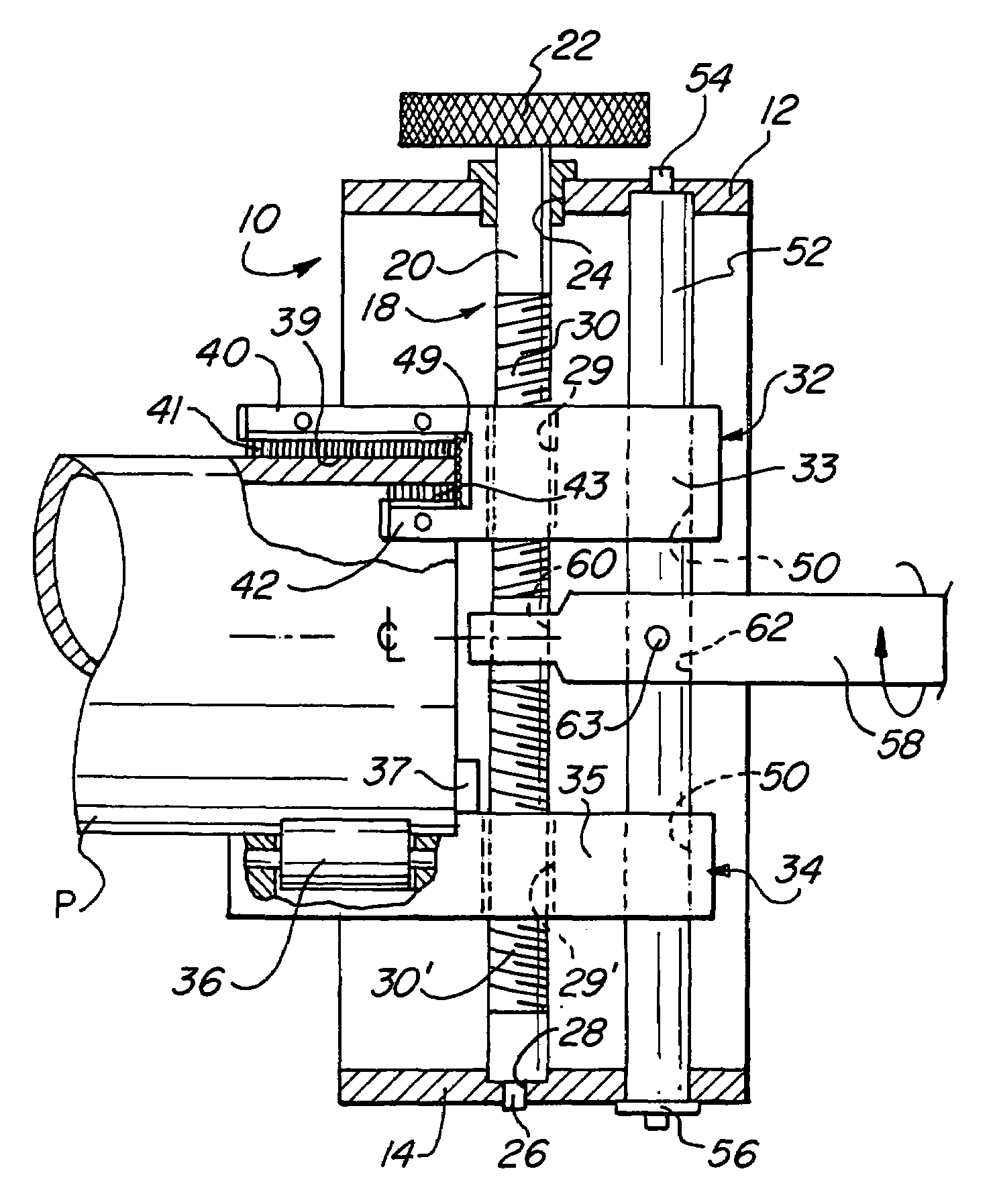

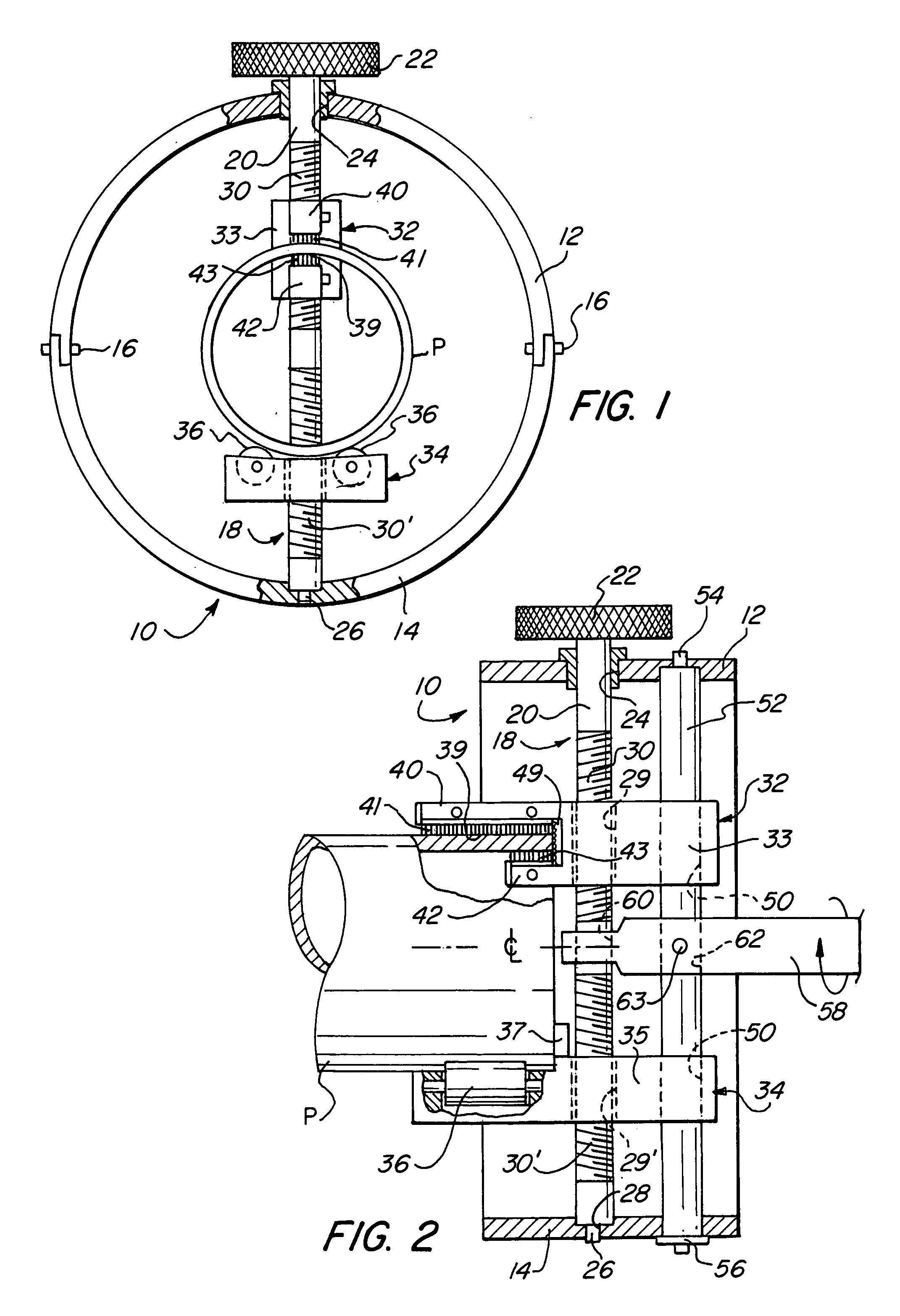

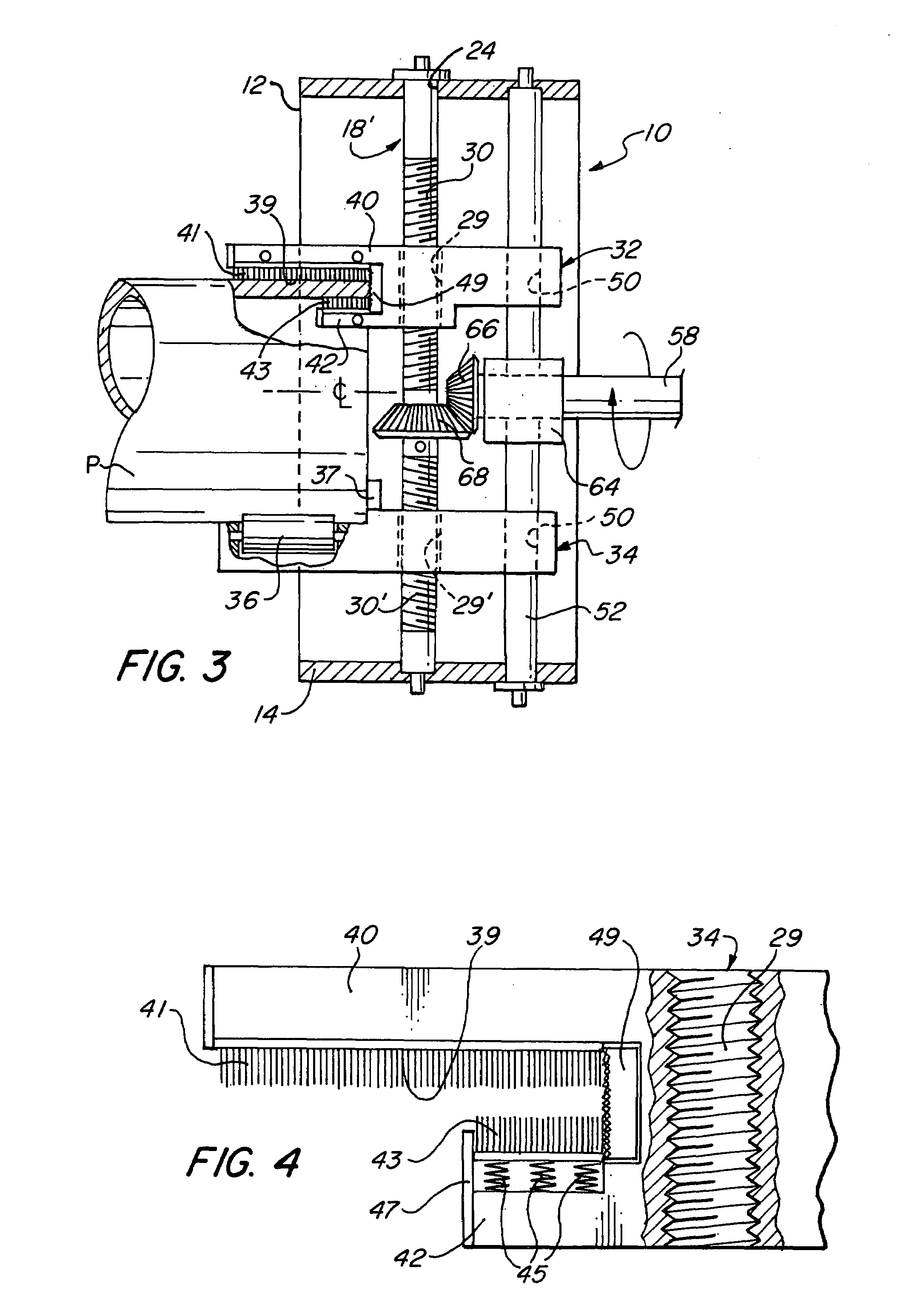

InactiveUS7263737B1Clean effectWide dimensionHollow article cleaningCleaning using toolsEngineeringPipe support

A tool for simultaneously cleaning inside and outside surfaces surrounding an open end portion of a pipe includes a cleaning arm and a pipe-supporting arm mounted in a head for adjustment of the transverse spacing therebetween. Support portions on the cleaning arm have confronting faces spaced transversely from one another and defining a rearwardly extending, forwardly open slot adapted for the receipt of the wall of a pipe supported on the pipe-supporting arm, and a pipe-cleaning element is disposed on each of the confronting faces of the support portions. Relative rotation of the mounting head and a pipe so positioned will cause the cleaning elements to effect simultaneous cleaning of the surrounding inside and outside surfaces of the pipe end portion.

Owner:WALSH RICHARD T +1

Mechanical seal device

A mechanical seal has a seal cover attached to an outer surface of a device body, a fitting surface through which a shaft is insertable, and defines a space further away from a machine than the fitting surface. A quenching path penetrates the space and supplies quenching fluid therein. A first seal ring has a movement surface fitted to the fitting surface and a seal surface inward of the space section. A second seal ring has a relative slide seal surface in tight contact with the seal surface of the first seal ring and a seal surface that faces a restriction surface. A seal collar holds the second seal ring in a sealed state and is sealingly fixed to the shaft. A packing is in tight contact with the seal surface of the second seal ring and the restriction surface to prevent quenching fluid from leaking out of the machine.

Owner:EAGLE INDS

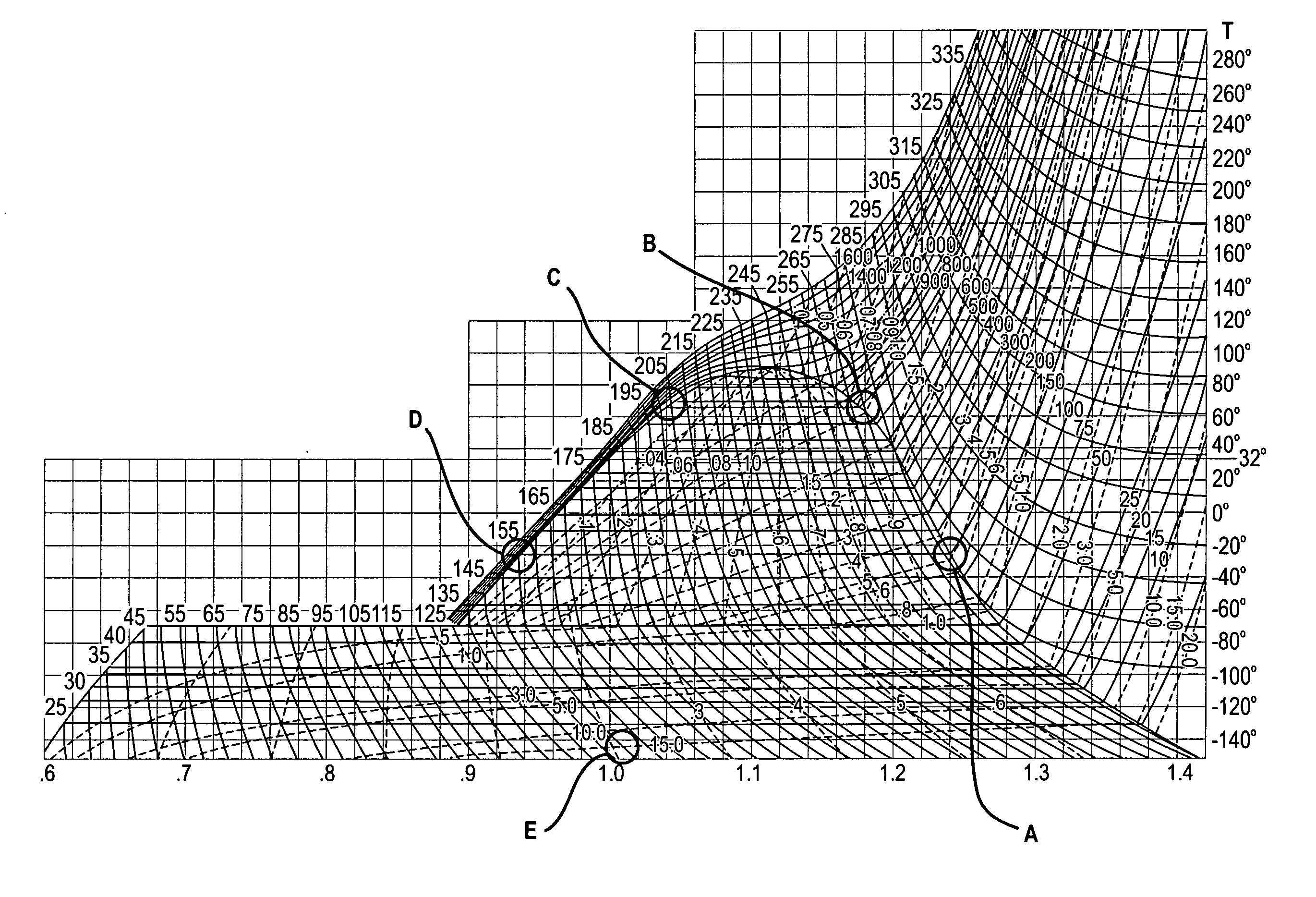

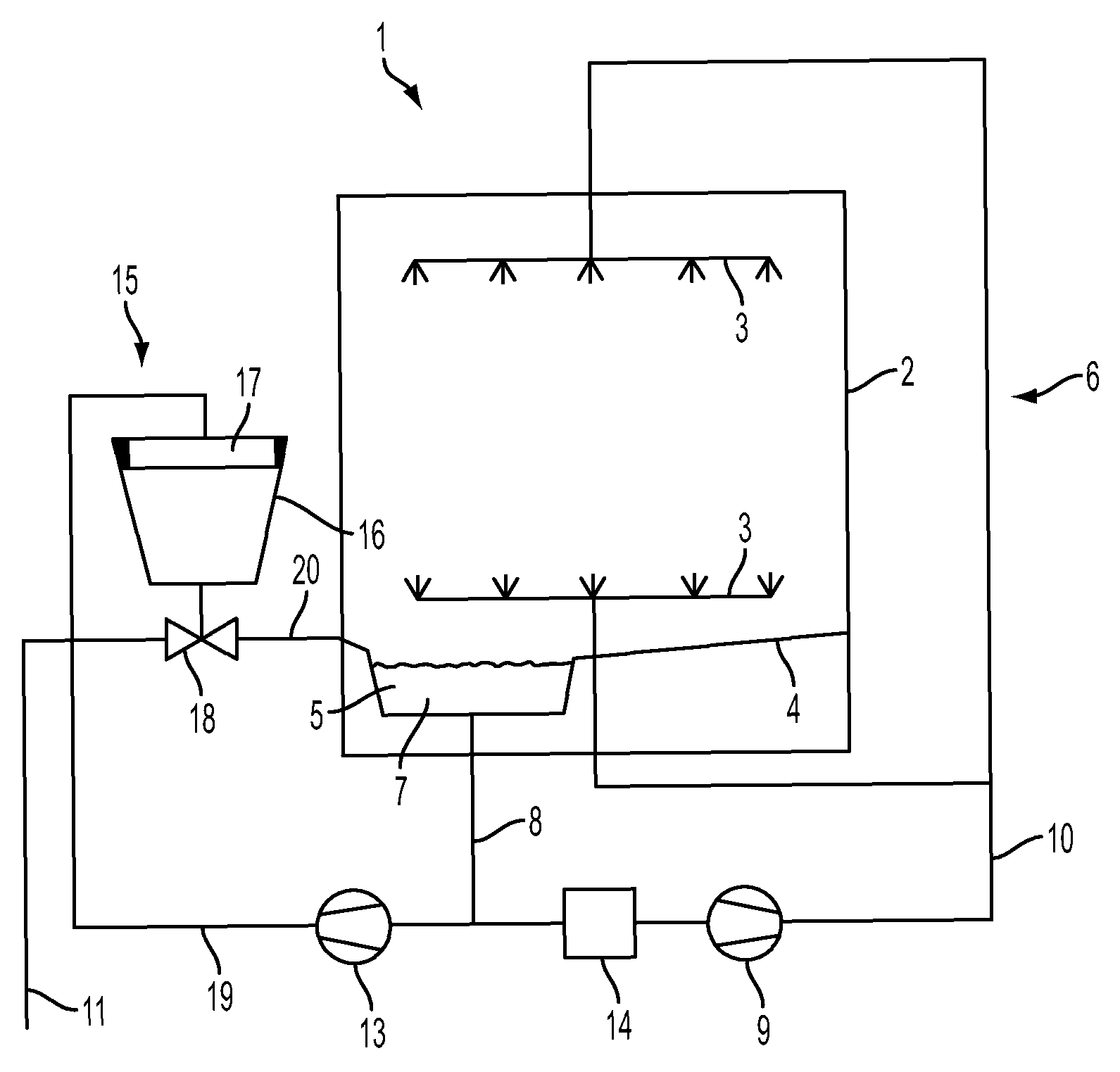

High pressure cleaning and decontamination system

InactiveUS20060089090A1Suitable protectionClean effectAbrasive feedersAbrasive machine appurtenancesTriple pointRoom temperature

Abrasive cleaning and decontamination methods and systems are disclosed. The methods and systems use a high pressure liquefied gas, such as carbon dioxide, which produces insignificant quantities of secondary waste. These principles of the invention exploit the properties of the relatively high triple point of CO2 in order to first pressurize it to 35,000 to 60,000 PSI from a pressurized liquid. In the pressurized state, such a fluid can be at or above room temperature, allowing for transport over long distances in a flexible high pressure hose. At a point of use, a heat exchanger may subsequently chill the liquid, so that after expansion through a small high pressure orifice, a significant fraction of the liquid is converted to solid phase crystals exiting at high velocity to effectively clean and decontaminate. For more aggressive cleaning, abrasive particles and / or small diameter solid CO2 pellets can be entrained into the high pressure CO2 slipstream.

Owner:KURION INC

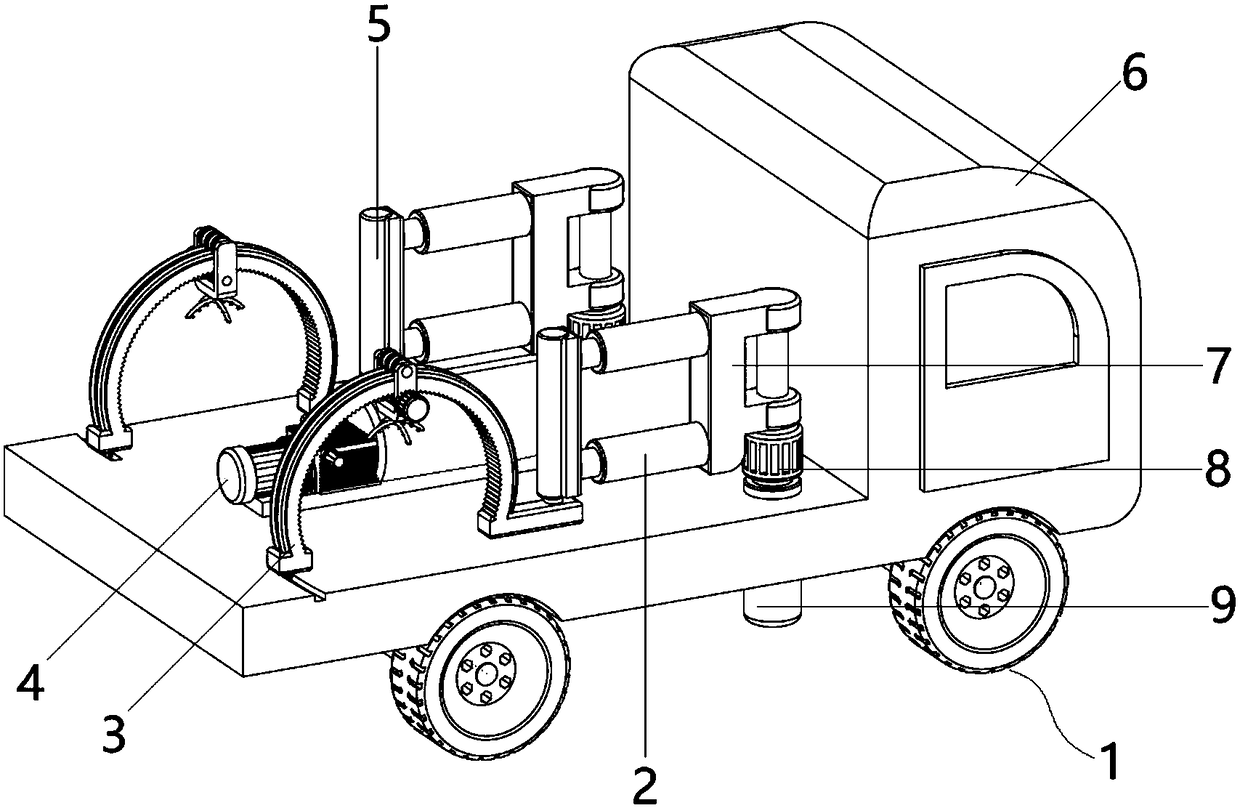

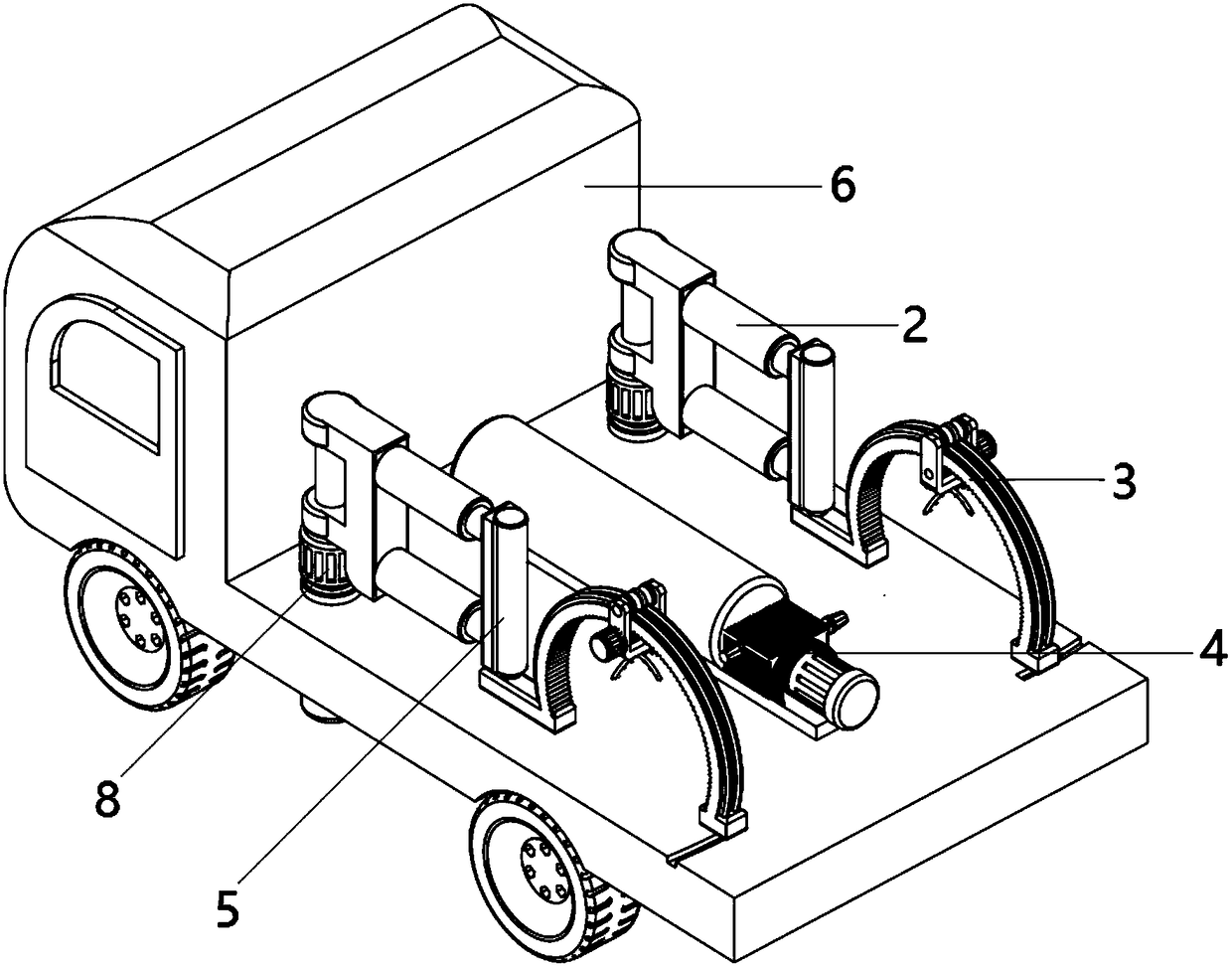

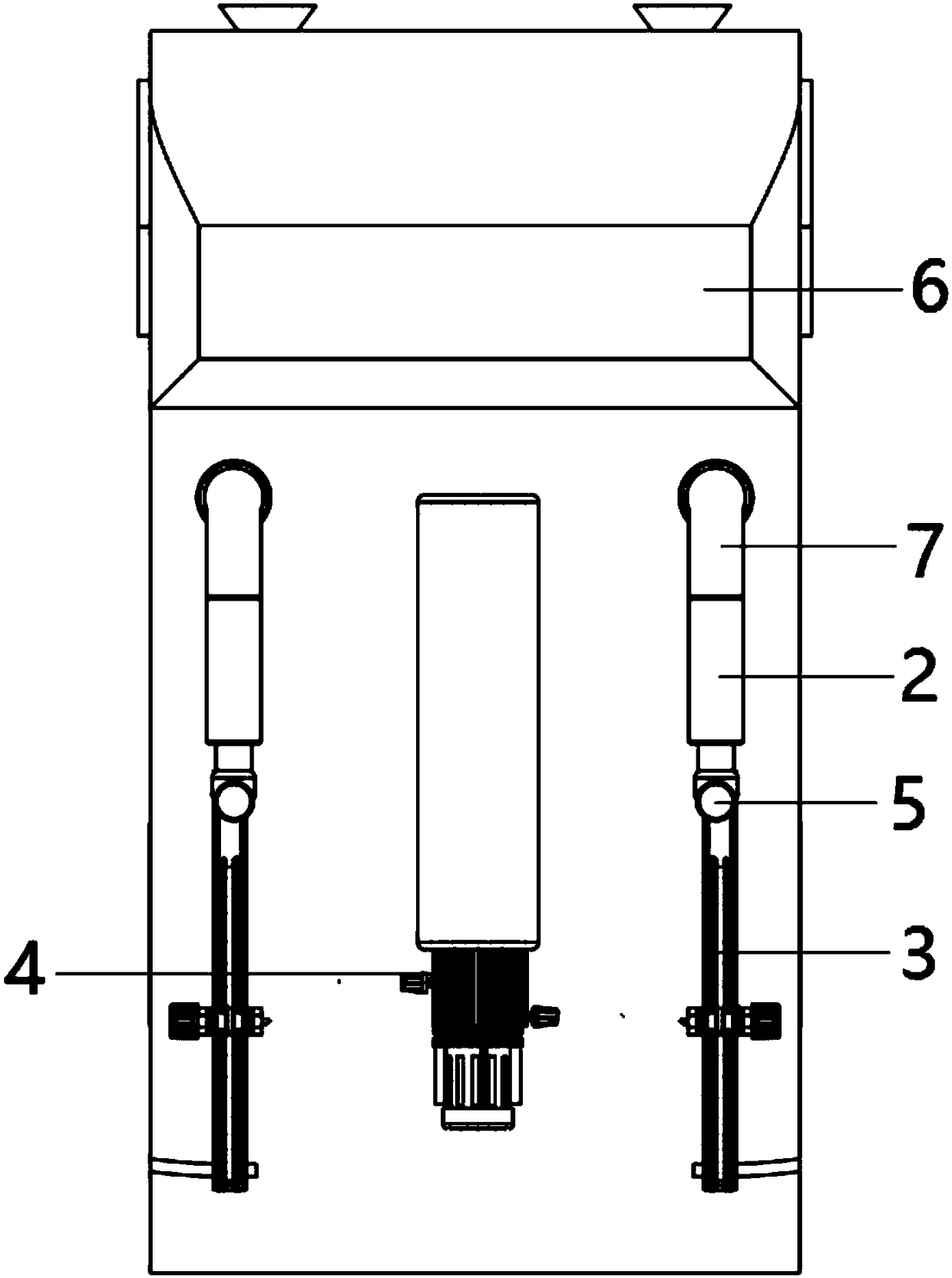

Air blowing type dust removal device for municipal administration landscaping plant surfaces

The invention provides an air blowing type dust removal device for municipal administration landscaping plant surfaces. The air blowing type dust removal device comprises dust removal device bodies, amoving fixing truck and device rotation motors. The moving fixing truck is arranged on the bottom body on the device body. Two second up-down adjustment cylinders are embedded in the front side position of a platform of the moving fixing truck in a symmetric installation manner. The top end of each of the two second up-down adjustment cylinders is fixedly provided with the corresponding device rotation motor through bolts. A front-back cylinder fixing frame is fixedly connected to the top of each of the two device rotation motors. The dust removal device bodies are fixedly arranged at the endpositions of the lower ends of first up-down adjustment cylinders. According to the air blowing type dust removal device for the municipal administration landscaping plant surfaces, dust removal tracks are arranged and are designed in an arc structure manner, the diameter of the arc structure is 2 m, the structure can buckle green belt bushes needing to be cleaned to the inner sides of the dust removal tracks so that the whole green belt bushes can be located in a dust removal range, accordingly, cleaning is more rapid, and the effect of more cleanliness is achieved.

Owner:JIANGSU SHANSHUI ENVIRONMENT CONSTR GRP

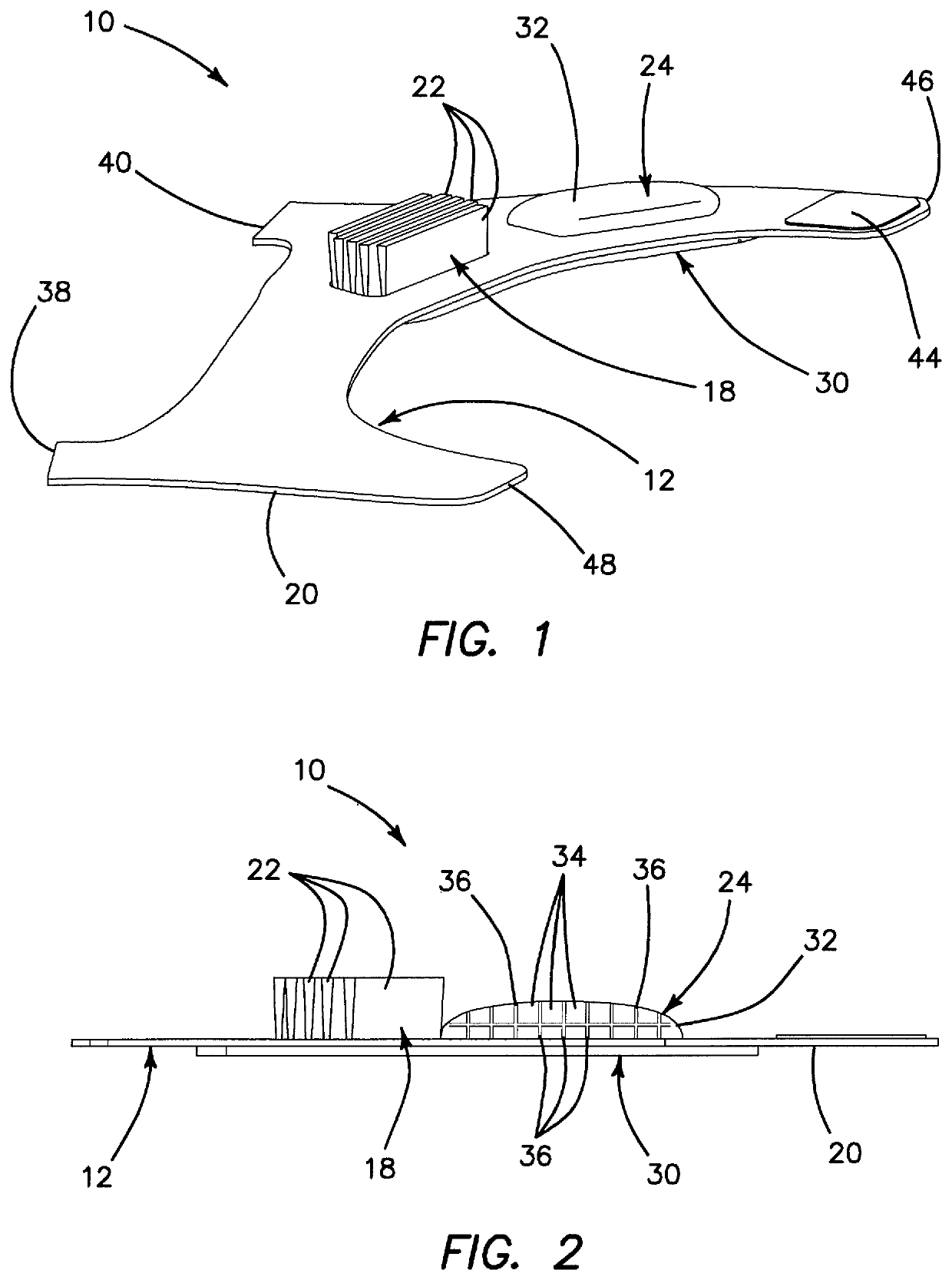

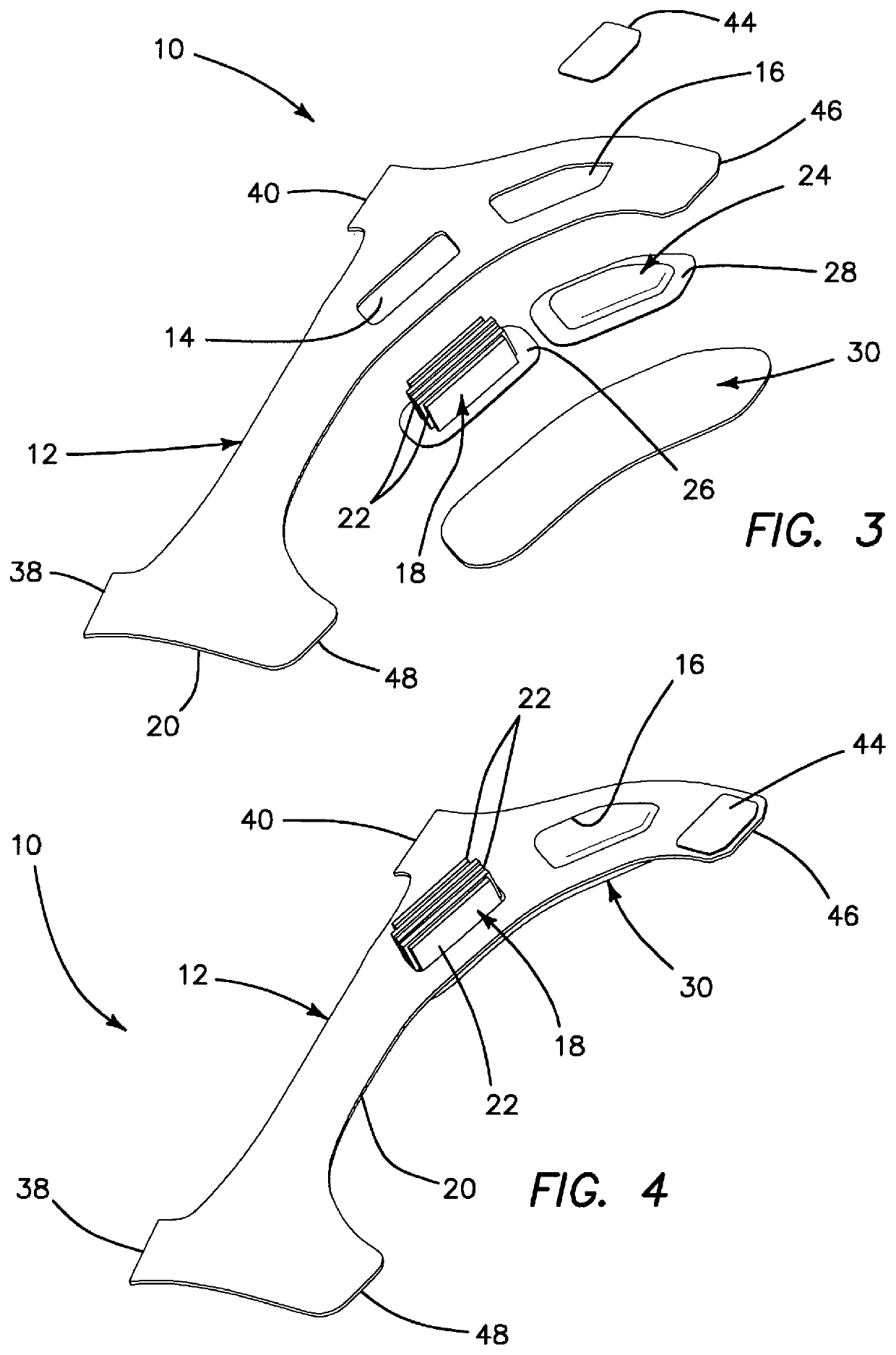

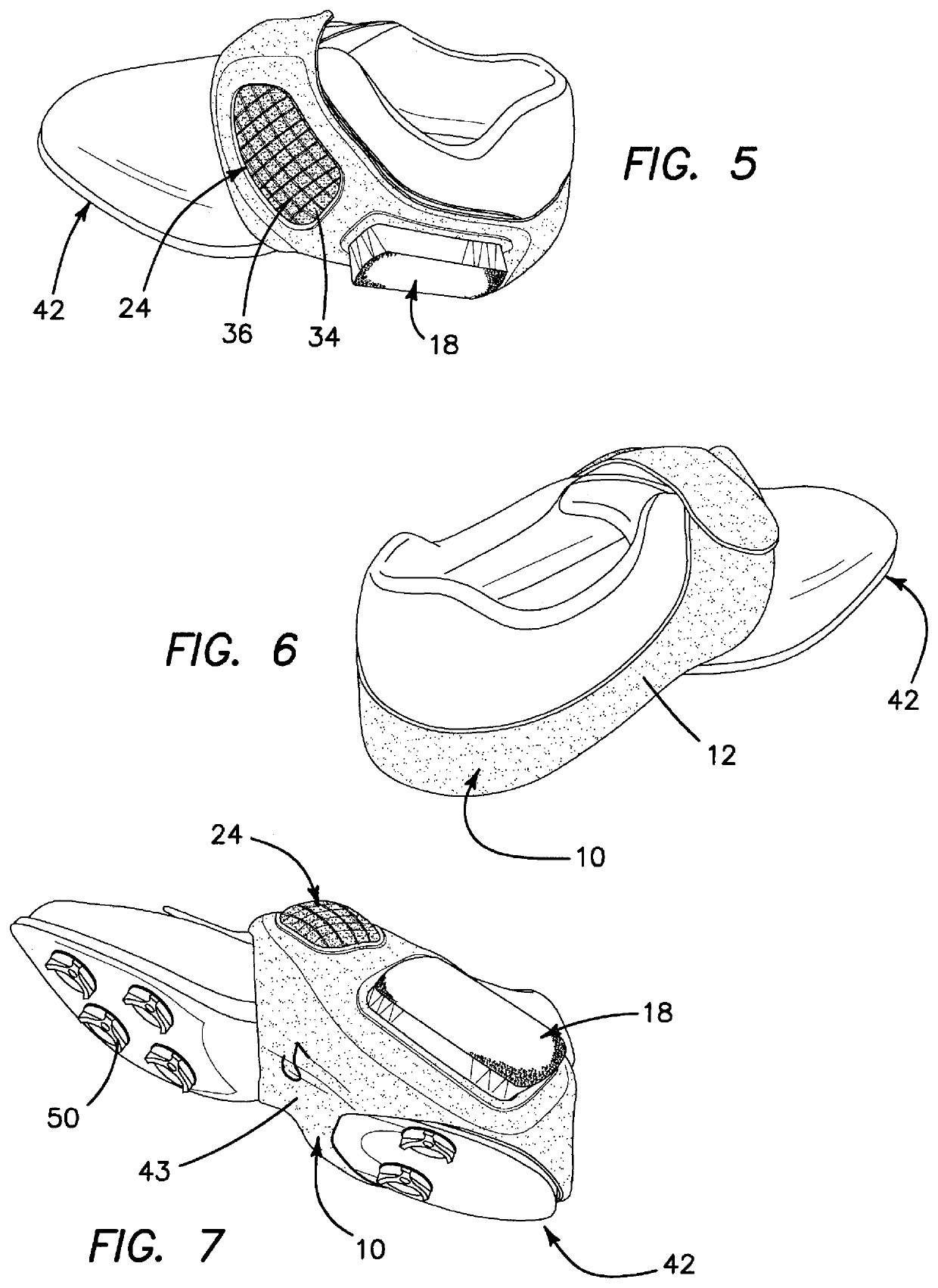

Footwear-based cleaning systems and methods

ActiveUS10576341B2Simple and easy and quick solutionEasy and quick to cleanBristleFootwearEngineeringCleaning methods

Owner:ENGEL ROBERT P

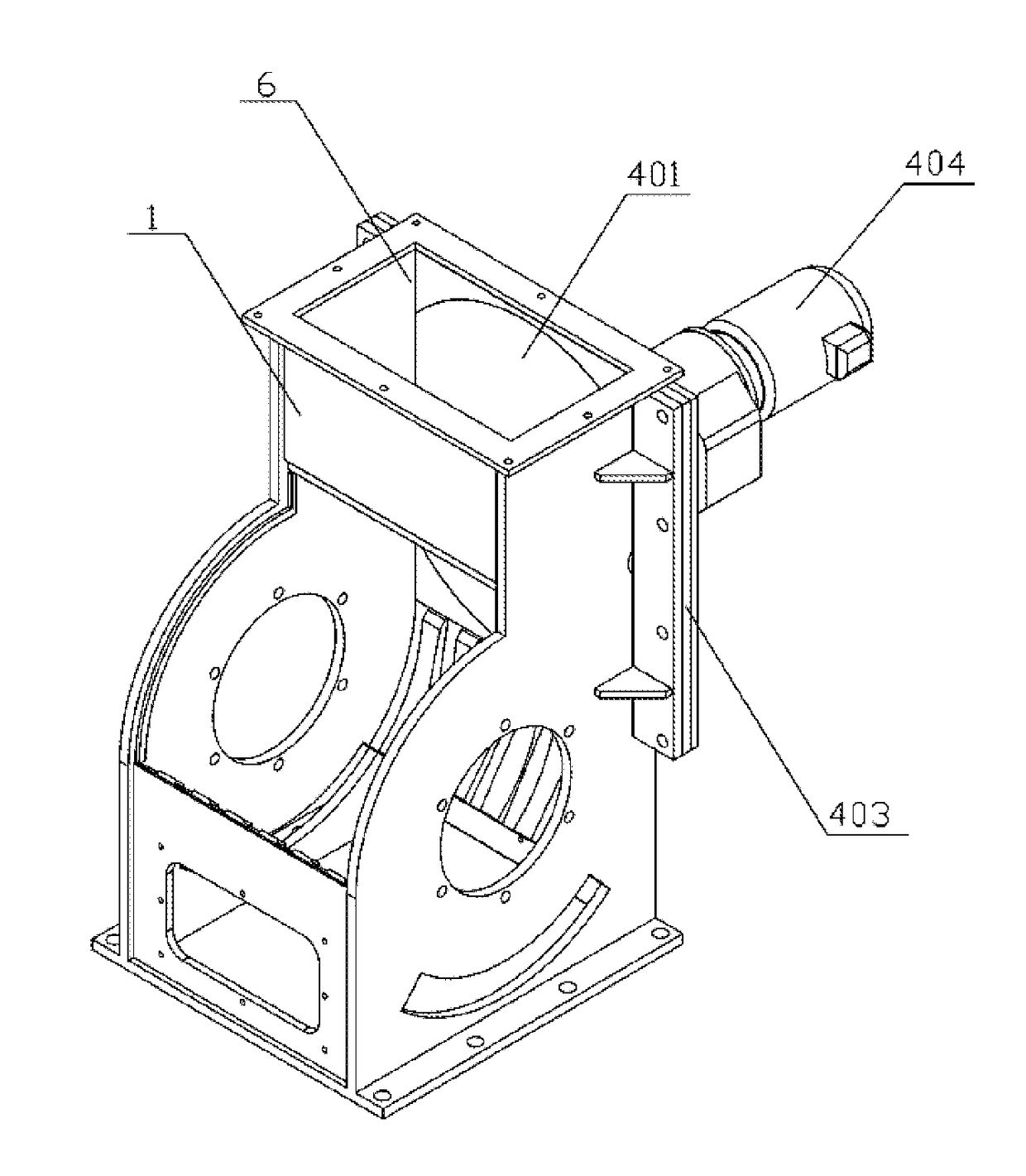

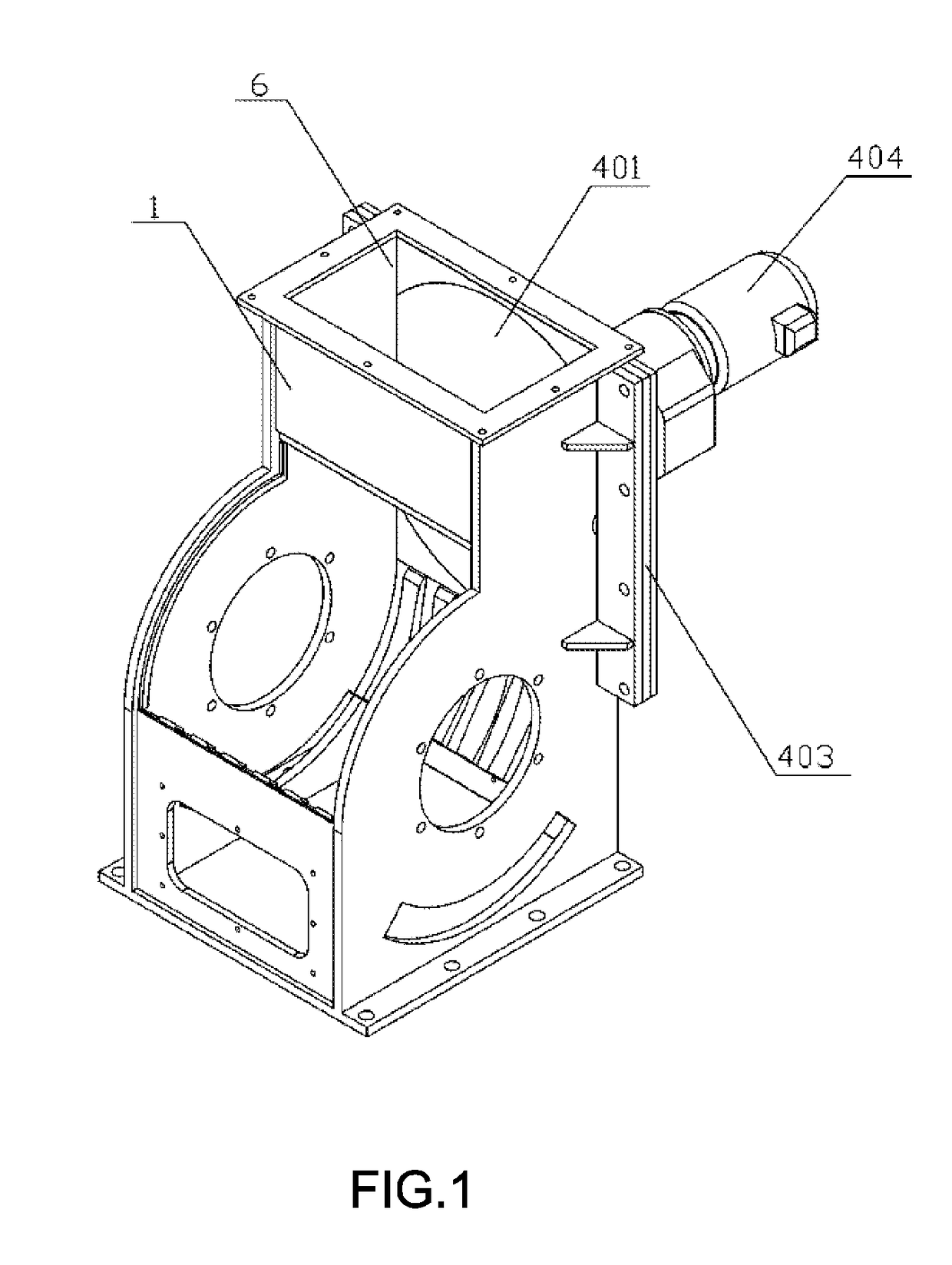

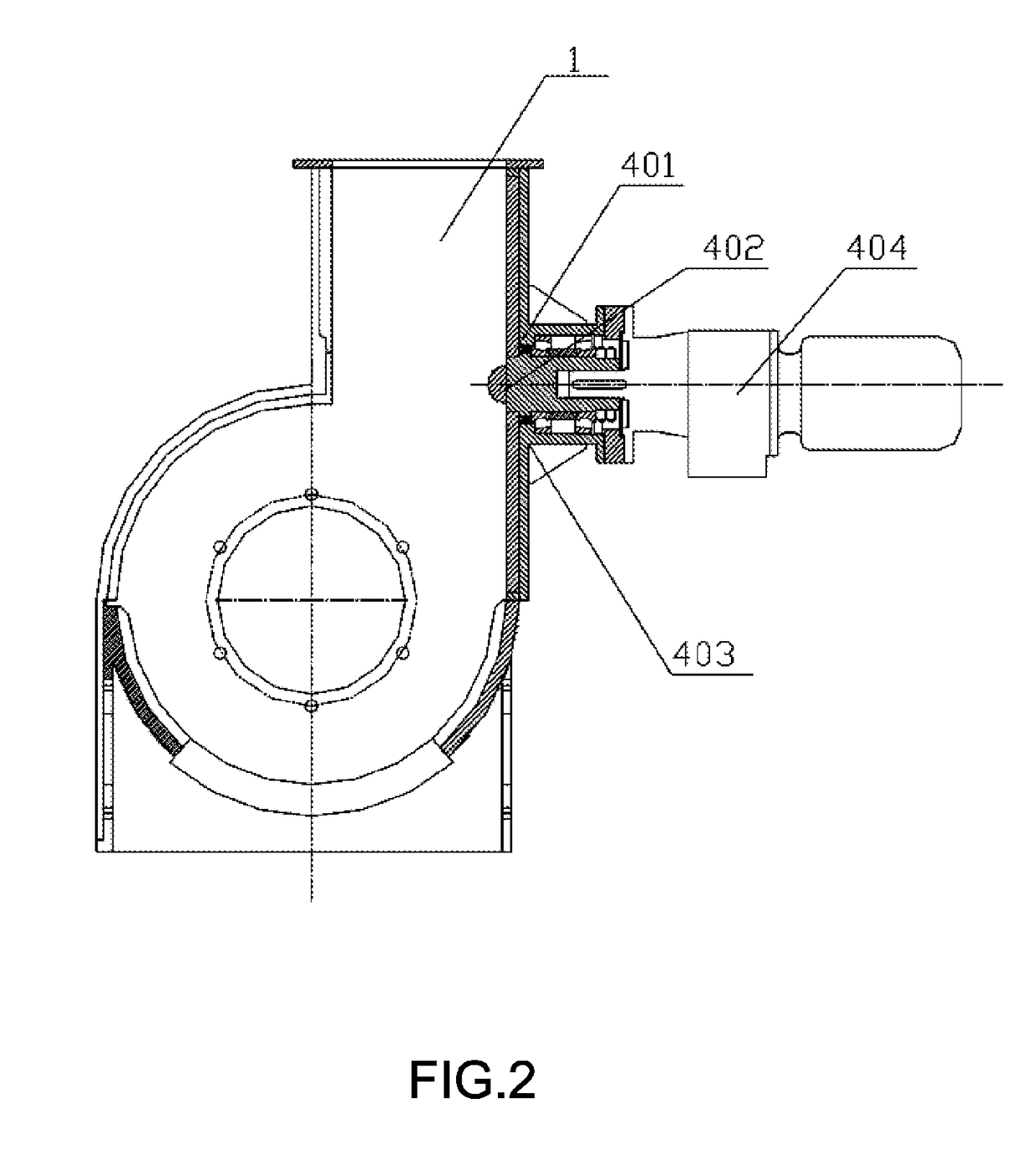

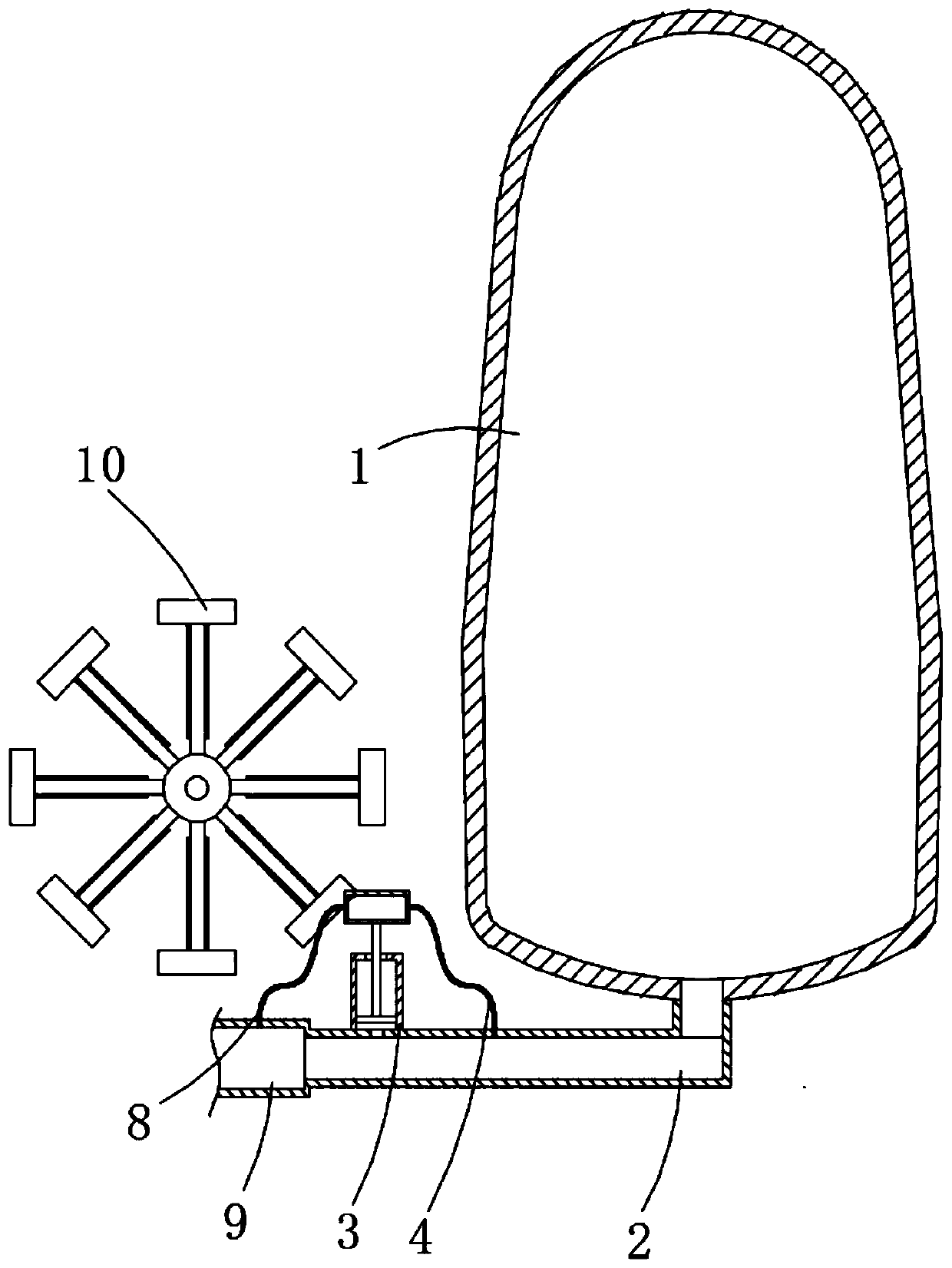

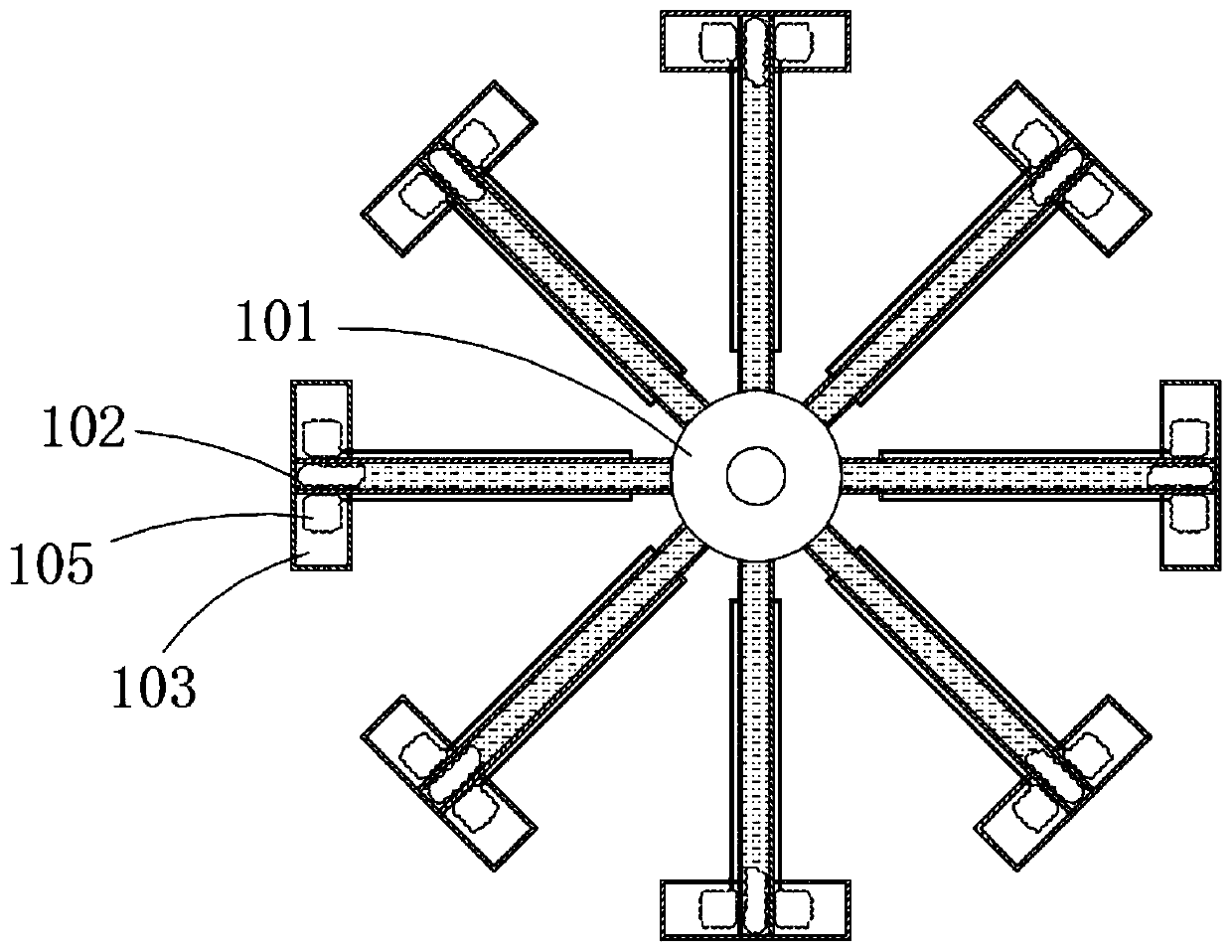

Automatic Cleaning Device for Ring Hammer Crusher, and Ring Hammer Crusher

ActiveUS20170144163A1Simple structureEasy to operateCleaning using toolsGrain treatmentsEngineeringCrusher

An automatic cleaning device for a ring hammer crusher, and a ring hammer crusher having the automatic cleaning device are provided. The automatic cleaning device includes an automatic cleaning assembly at a back side of a feeding opening of a crushing chamber of the ring hammer crusher; the automatic cleaning assembly includes a material meeting disk and a cleaning blocking rod; the material meeting disk is connected to a drive member and is driven by the drive member to rotate, and the cleaning blocking rod is fixed to the crushing chamber and is cooperated with a material meeting surface of the material meeting disk for cleaning. The ring hammer crusher having the automatic cleaning device has a simple structure and convenient operation, thus improving cleaning effect.

Owner:HUNAN SUNDY SCI & TECH DEV

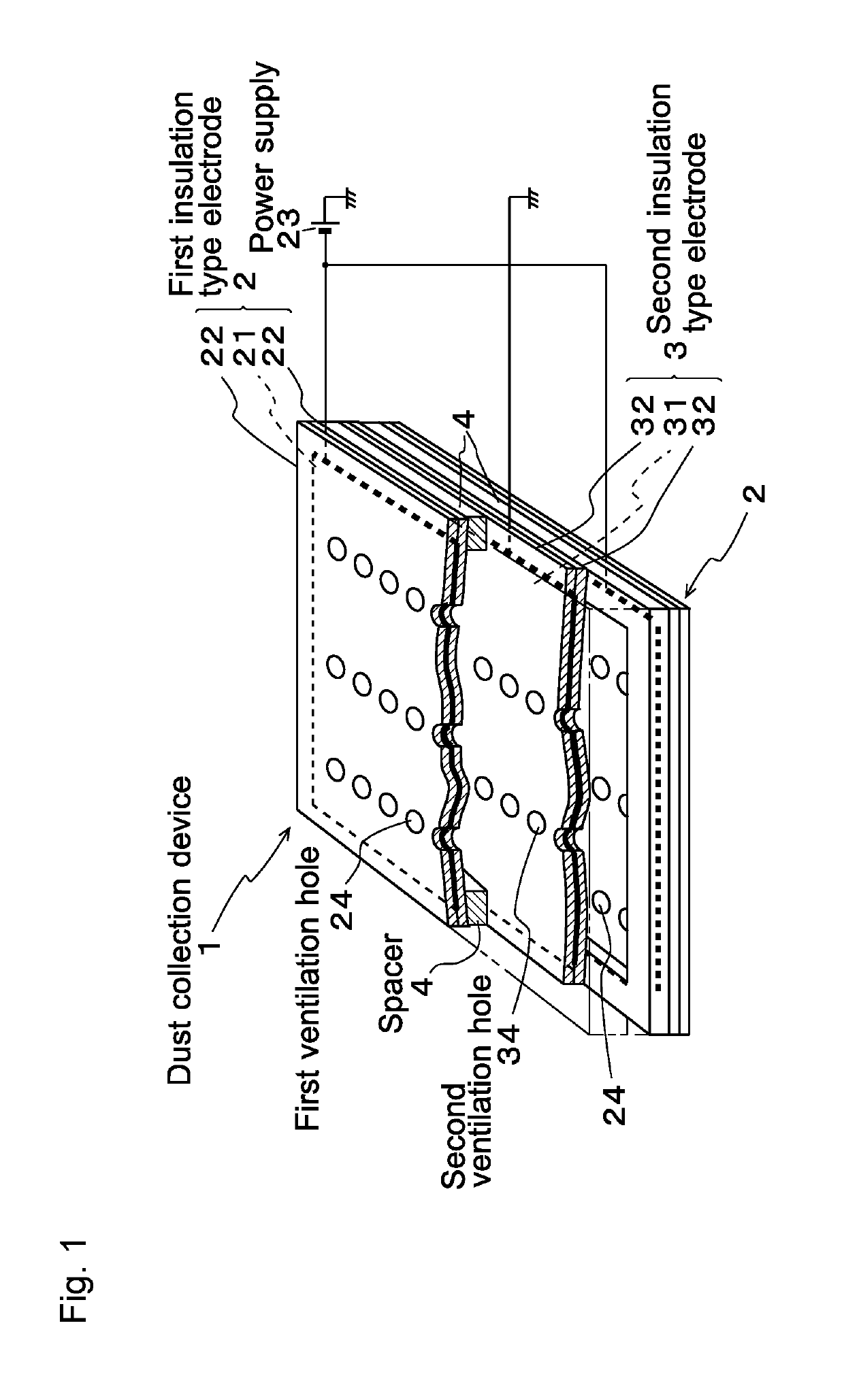

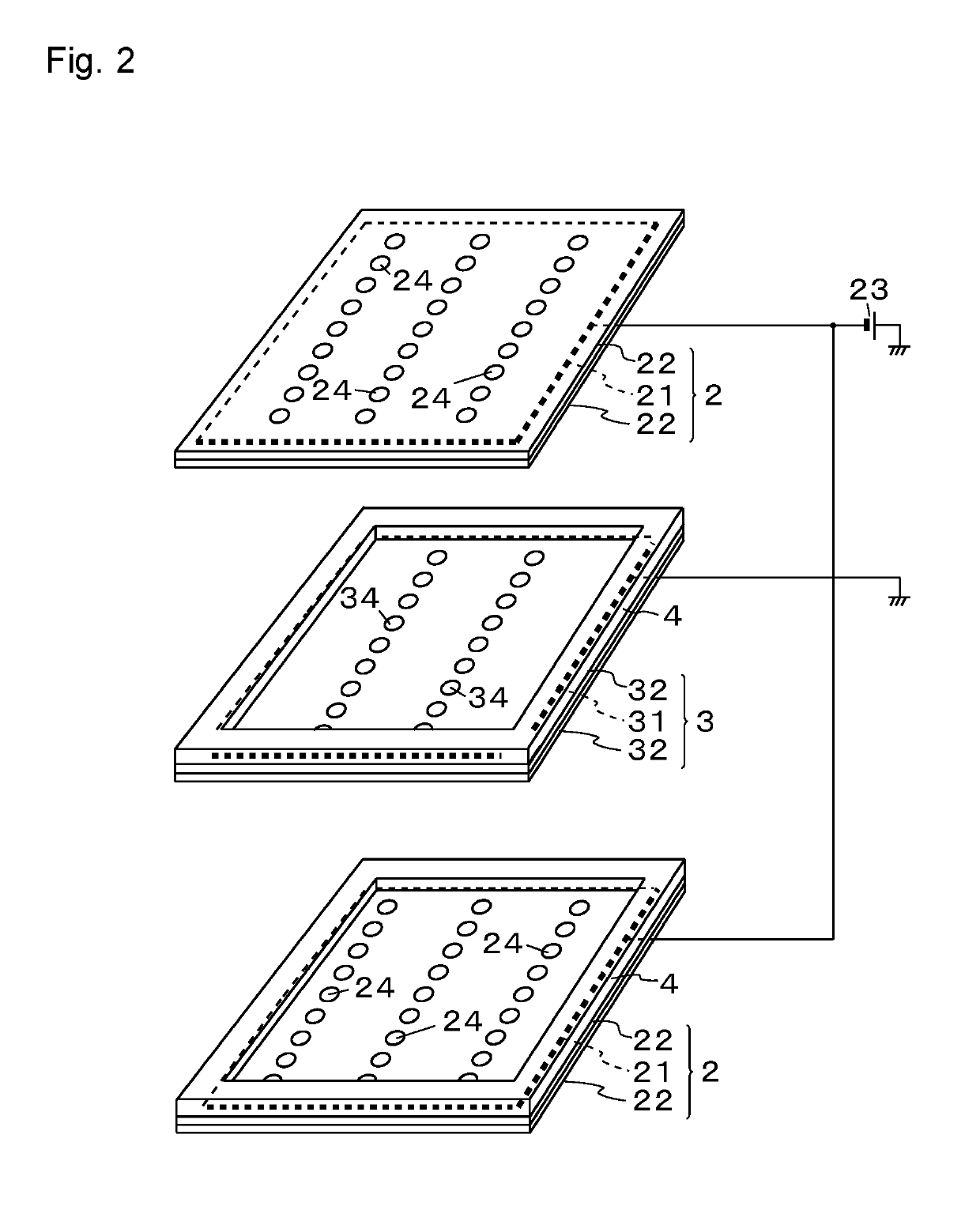

Dust collection device

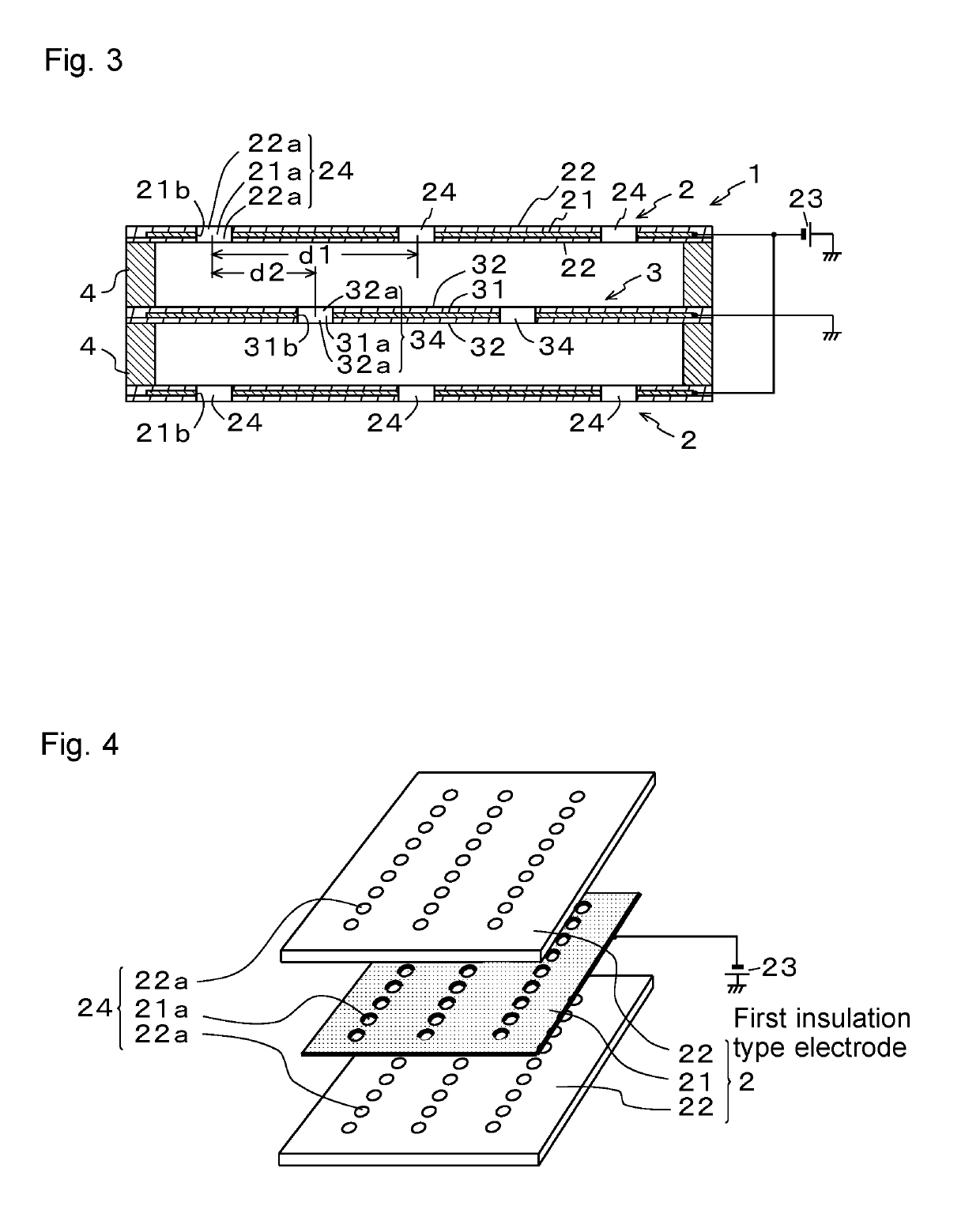

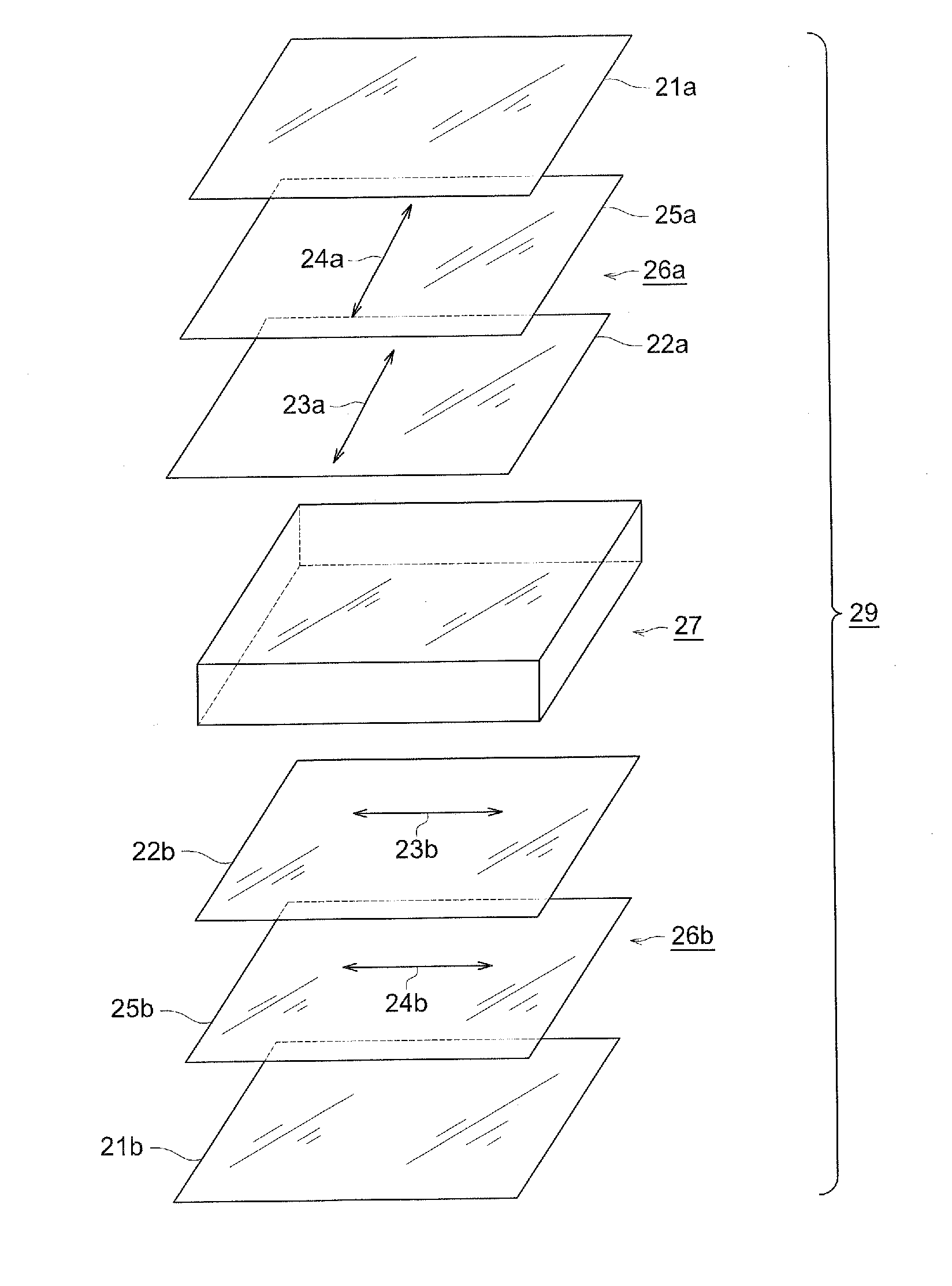

ActiveUS10357781B2Preventing a decrease in oxygen in the room space is obtainedEliminate spaceParticle charging/ionising stationsExternal electric electrostatic seperatorElectrical and Electronics engineeringElectrode

A dust collection device can be fitted to windows in a room, thus not only cleaning air while ventilating air within a space targeted for cleaning but also cleaning air outside of the space. A dust collection device is constructed by laminating first insulation type electrodes and second insulation type electrodes alternately via spacers. The insulation type electrodes have a configuration in which both sides of first electrodes (second electrodes) are coated by first insulating layers (second insulating layers). Furthermore, a power supply is connected to the electrodes, and the electrodes are grounded. In addition, a plurality of first through holes (second through holes) is provided in rows in the insulation type electrodes. Furthermore, the positions of the through holes in the insulation type electrodes are arranged in a plane view so as to be a prescribed distance from the positions of the through holes in the insulation type electrodes.

Owner:CREATIVE TECH CORP

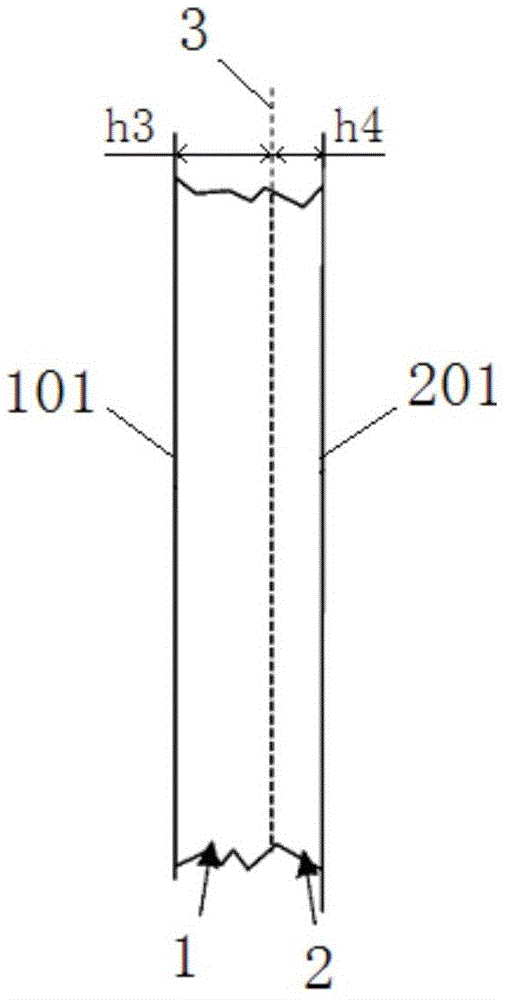

Vitreous System

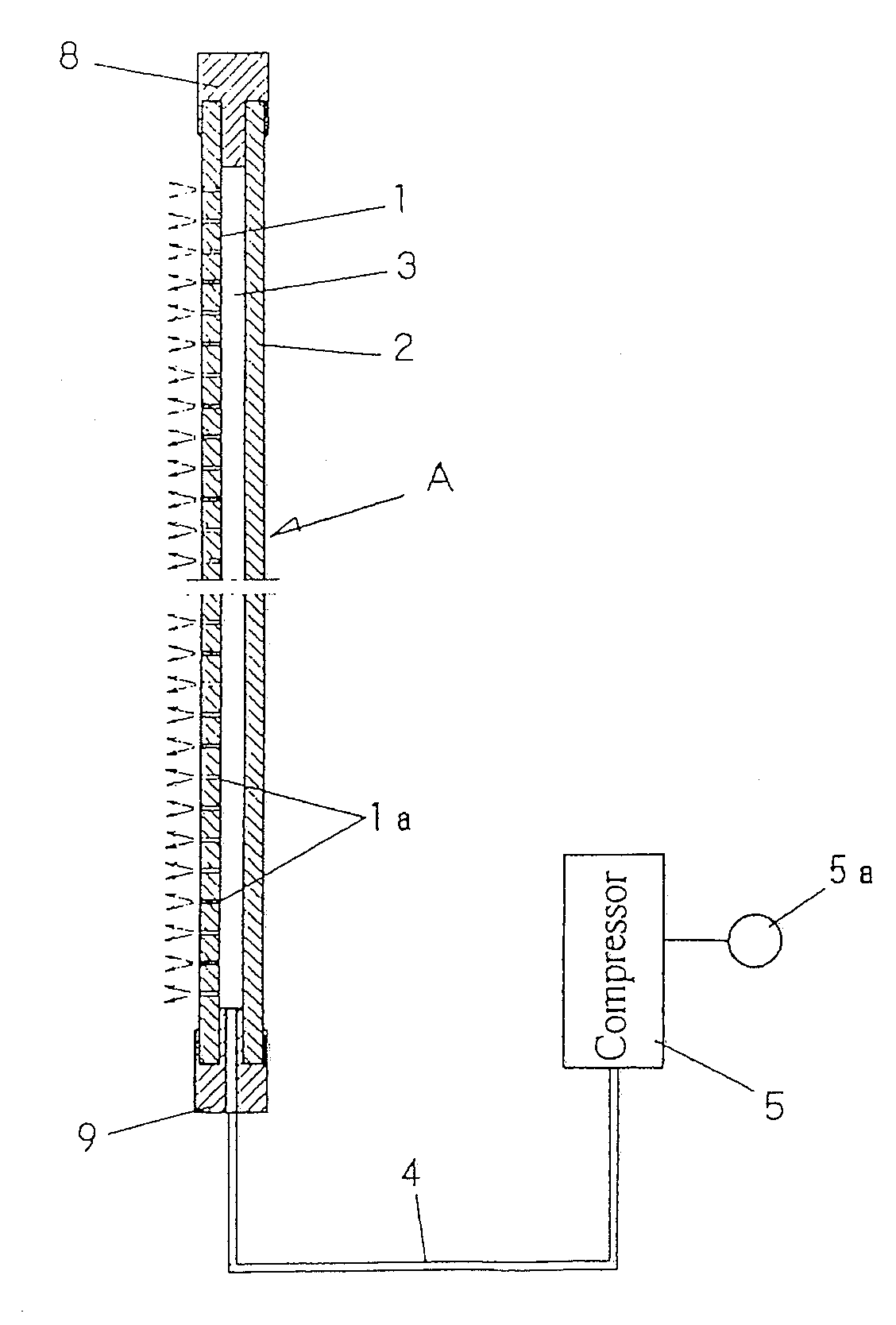

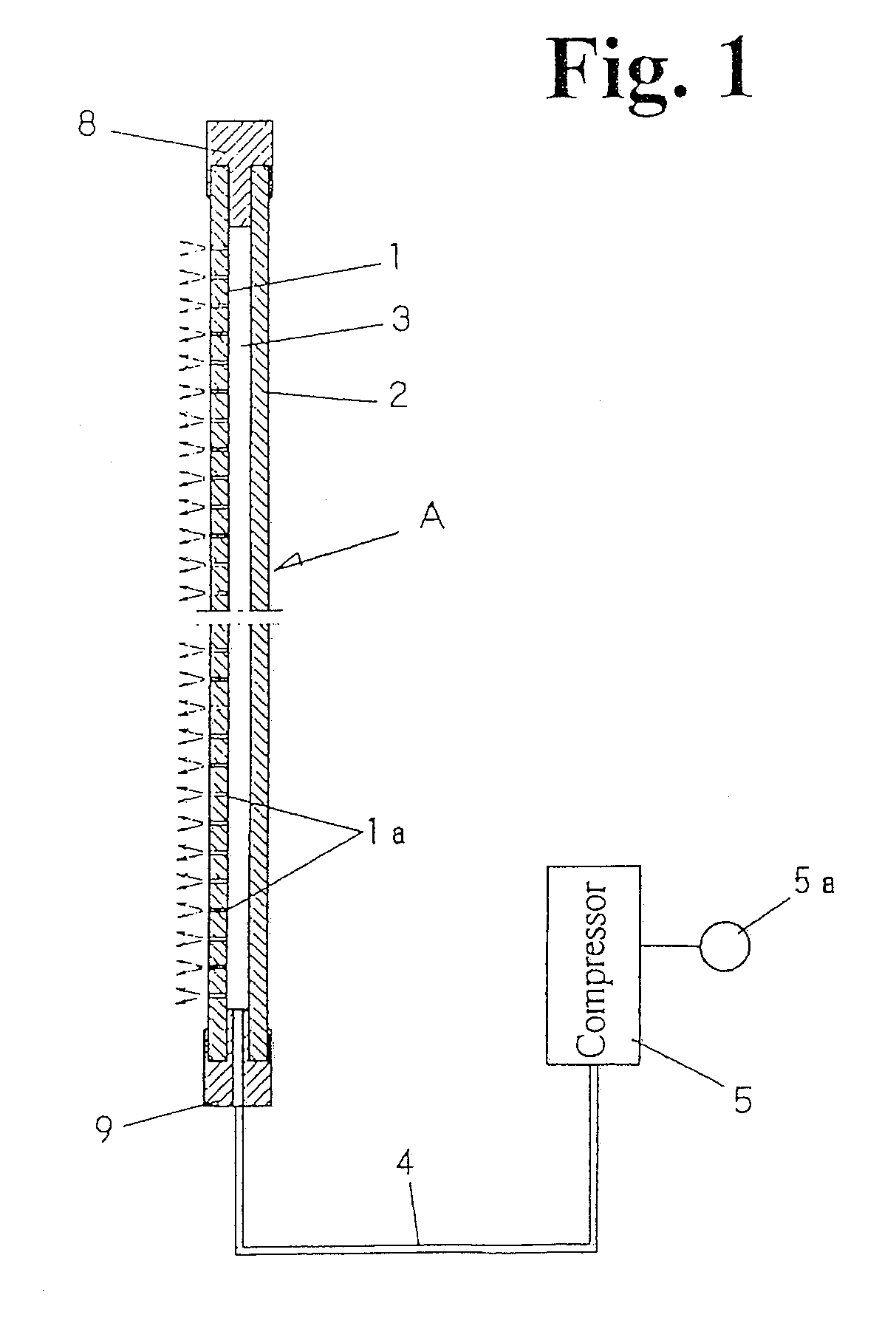

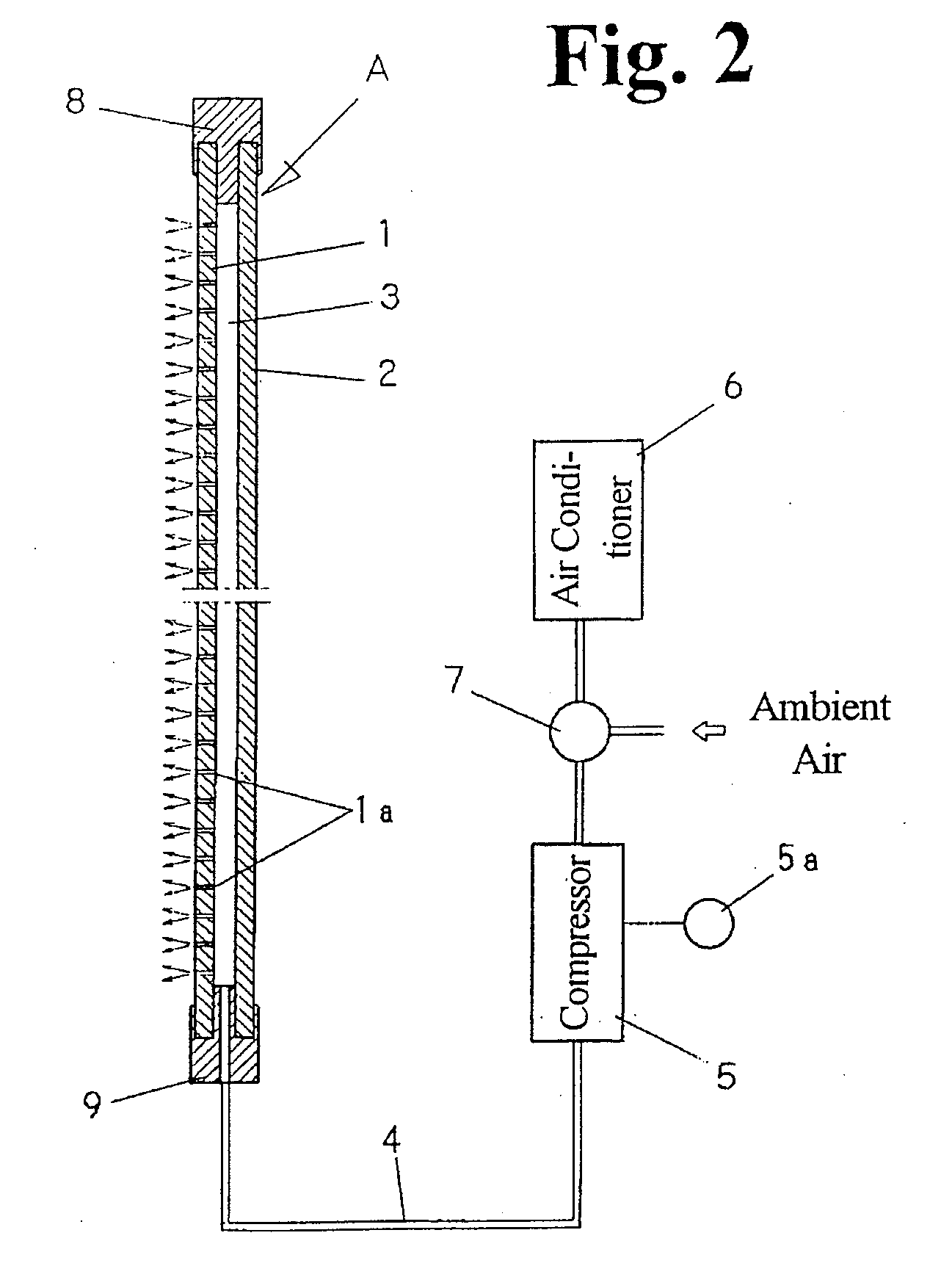

A vitreous system of the invention is provided for use particularly as windowpanes of a car or the like vehicle, and is always kept clean over its whole surface. A multi-layer vitreous body ‘A’ forming the system is composed of an outside glass plate (1), an inside glass plate (2) and a stratified air space (3) defined between the inside and outside plates. A number of jetting orifices (1a) are formed to penetrate the outside plate (1), and a compressor (5) is connected through a piping (4) to the air space (3) so as to charge it with a compressed air, so that this air is blown out through the orifices (1a).

Owner:NAKAI KOMUTEN

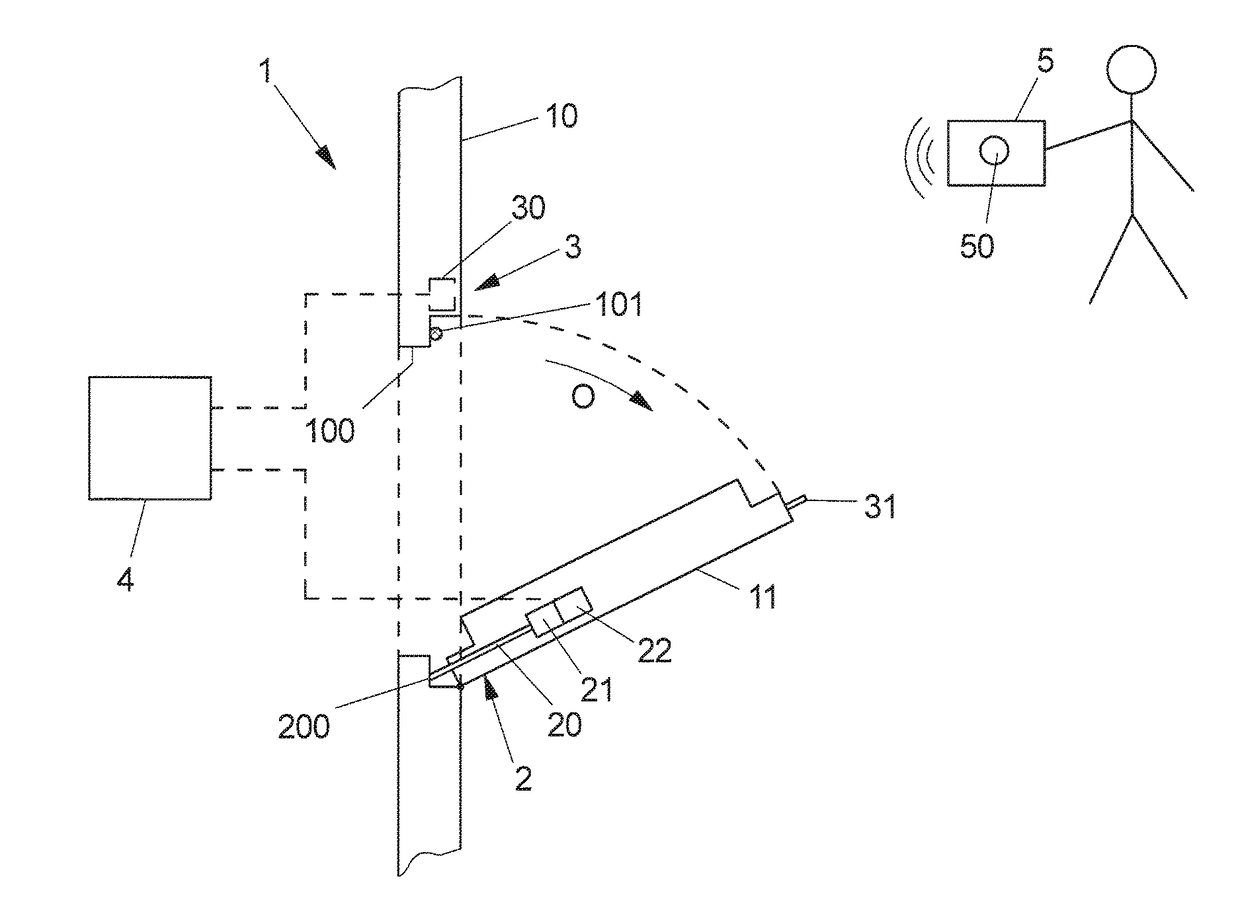

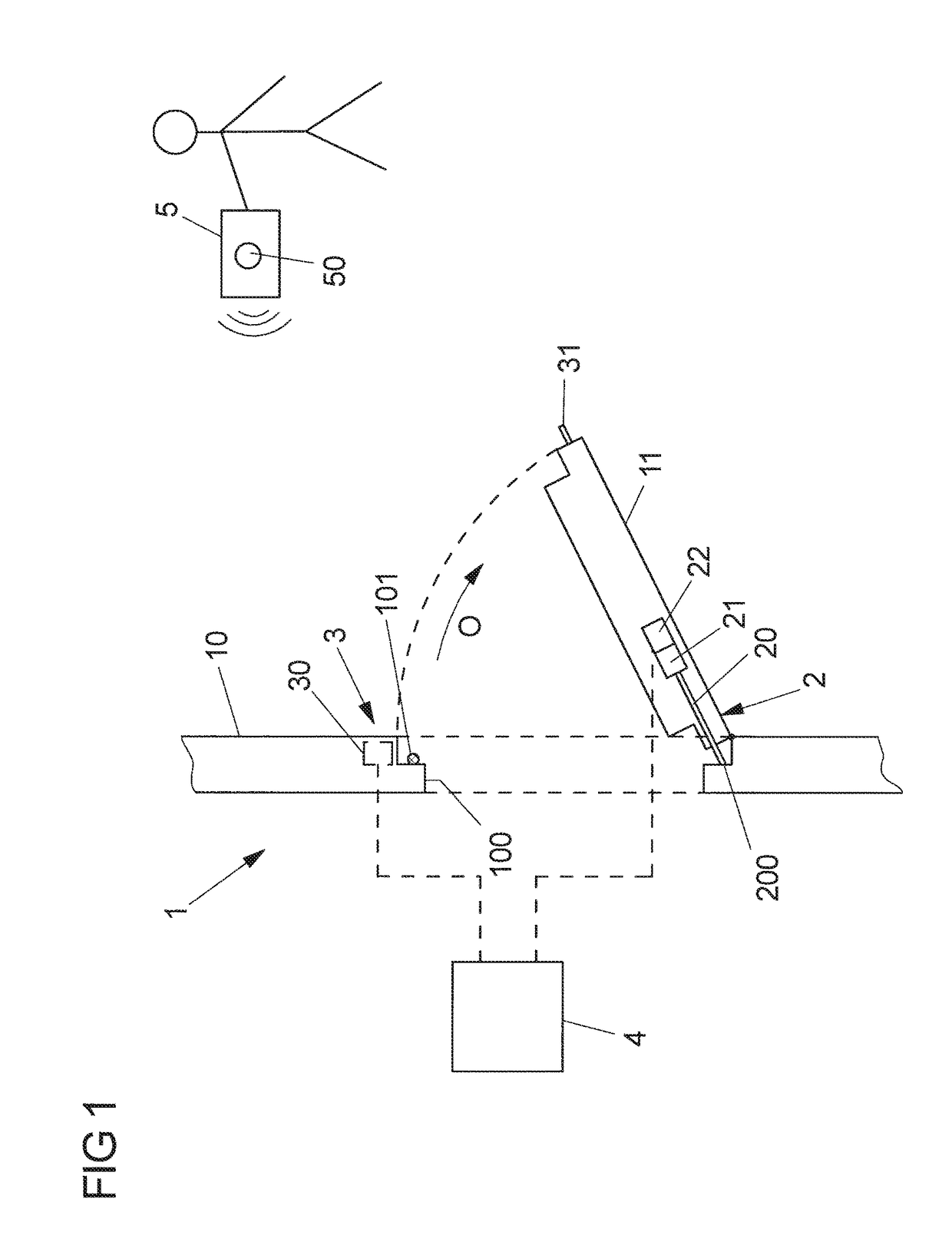

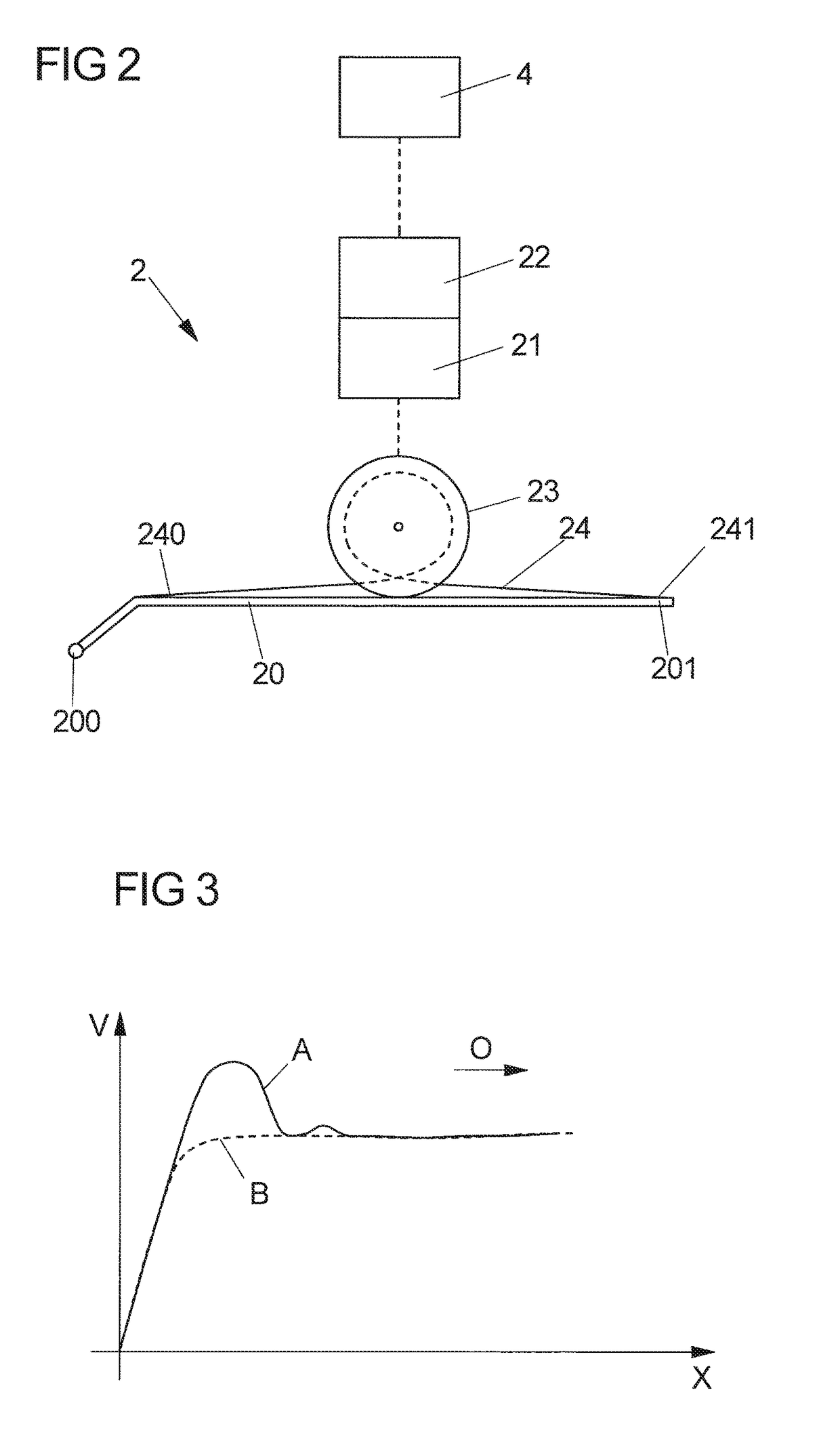

Assembly for adjusting an adjustment element relative to a stationary portion of a vehicle

ActiveUS20170335615A1Clean effectError is generatedPower-operated mechanismElectrical locking circuitsDrive motorCar door

An assembly for adjusting an adjustment element relative to a stationary portion of a vehicle, in particular of a vehicle door relative to a vehicle body comprises a drive motor for electromotively adjusting the adjustment element and an electrically actuatable locking device for locking the adjustment element with the stationary portion of the vehicle in a closed position, wherein the locking device has a locked condition in which the locking device is locked relative to the stationary portion for blocking the adjustment element in the closed position, and an unlocked condition in which the locking device is unlocked for adjusting the adjustment element relative to the stationary portion. A control device serves for controlling the drive motor and the locking device. It is provided that the control device is formed to actuate the drive motor for executing a diagnostic routine, while the locking device is in the locked condition.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

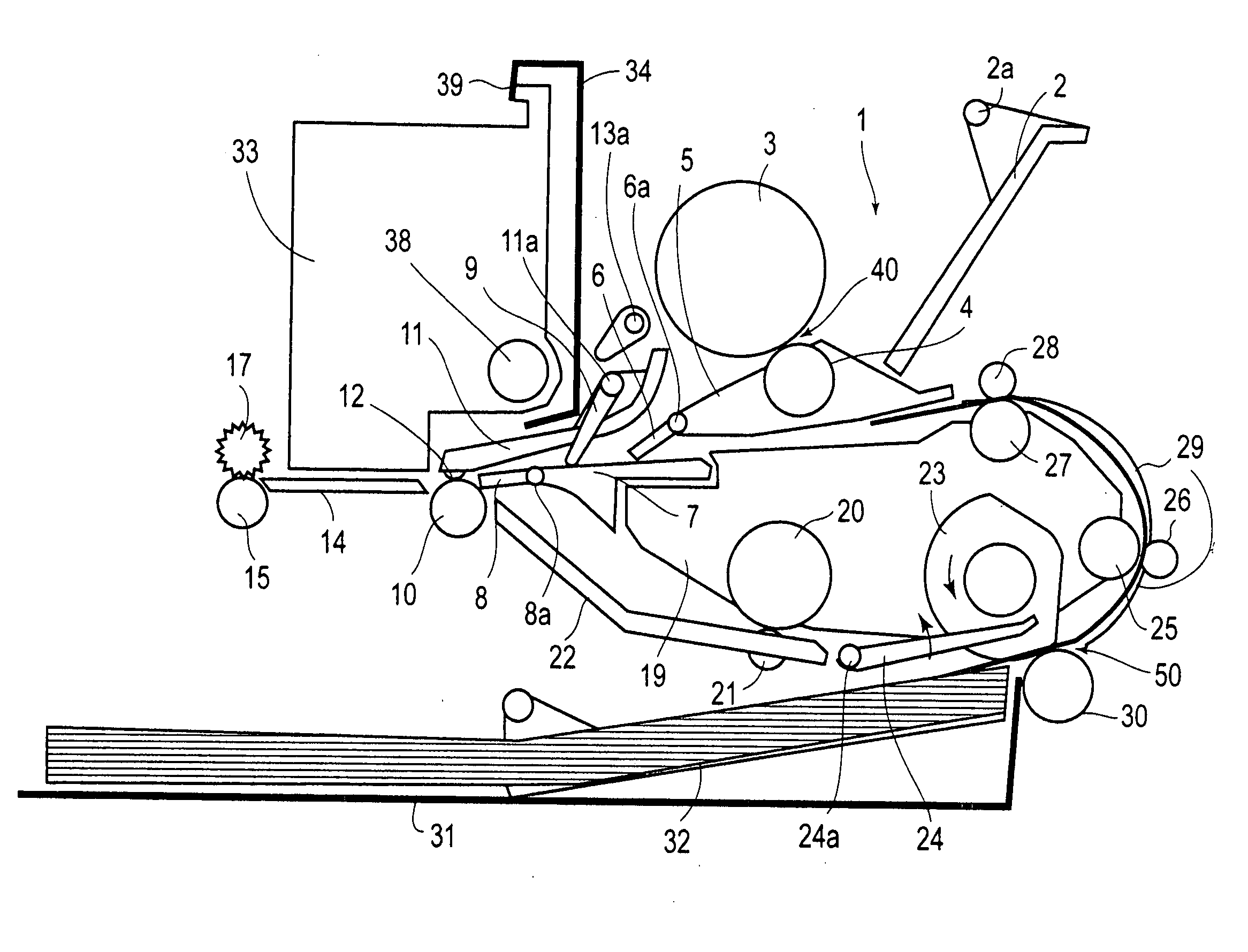

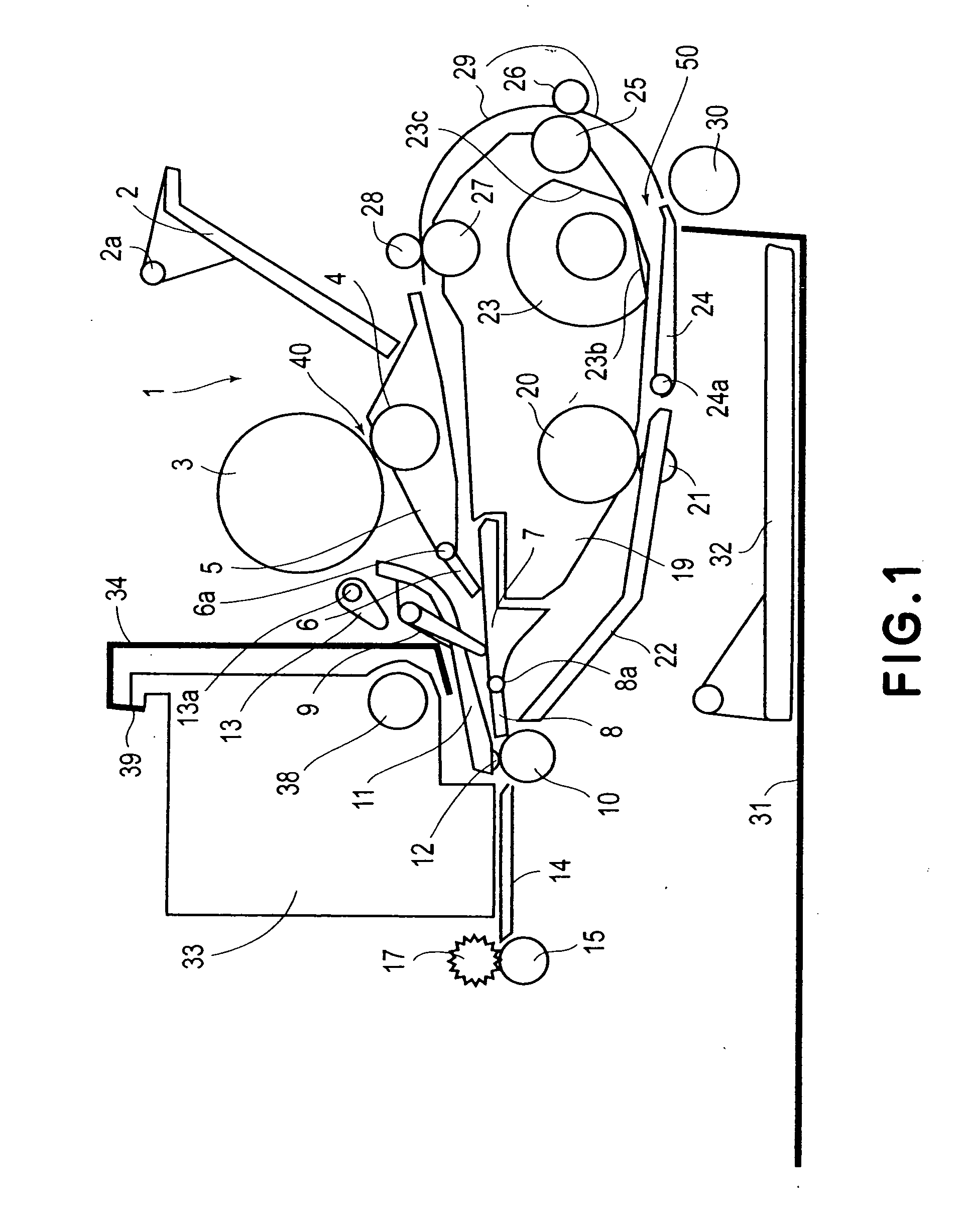

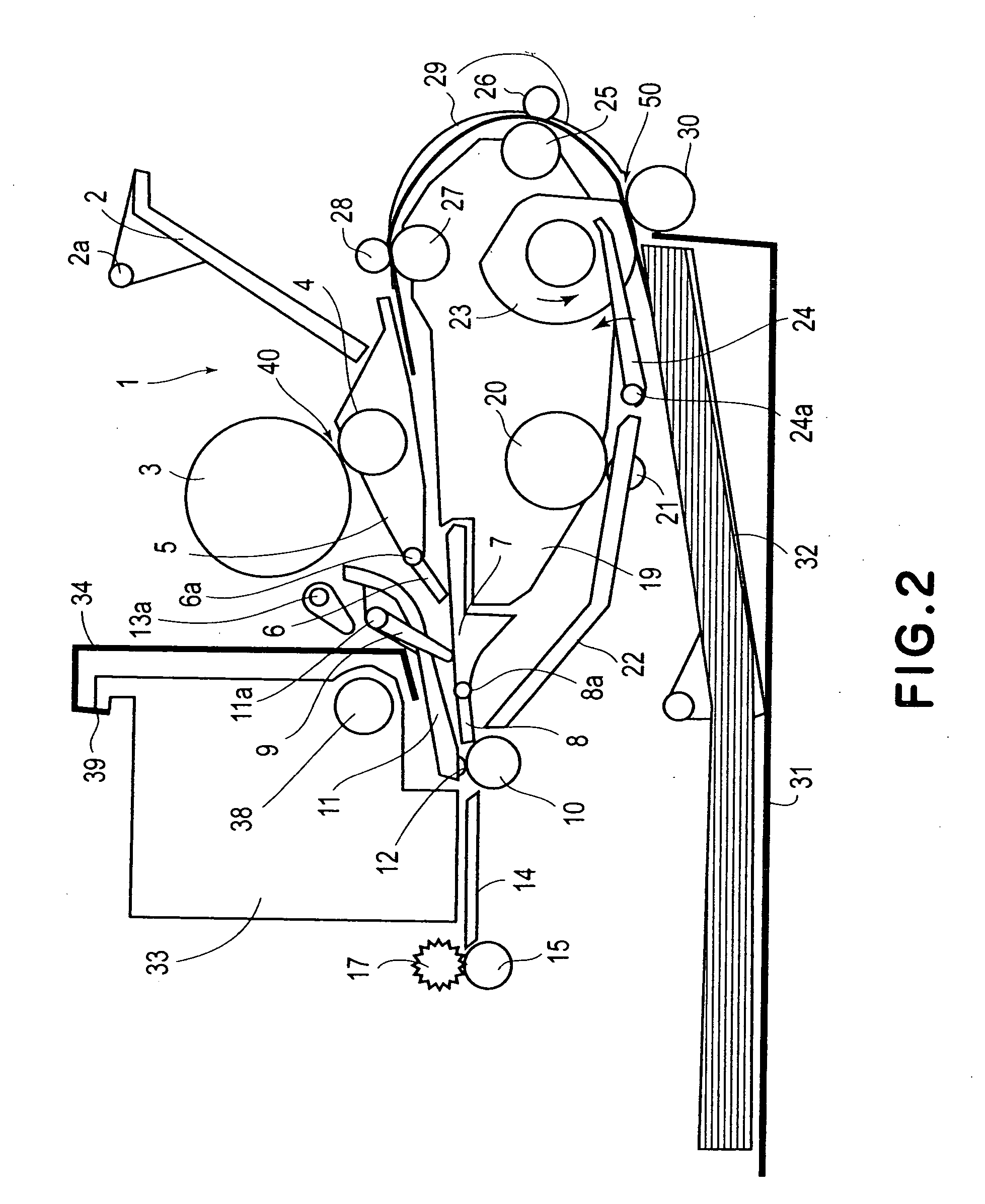

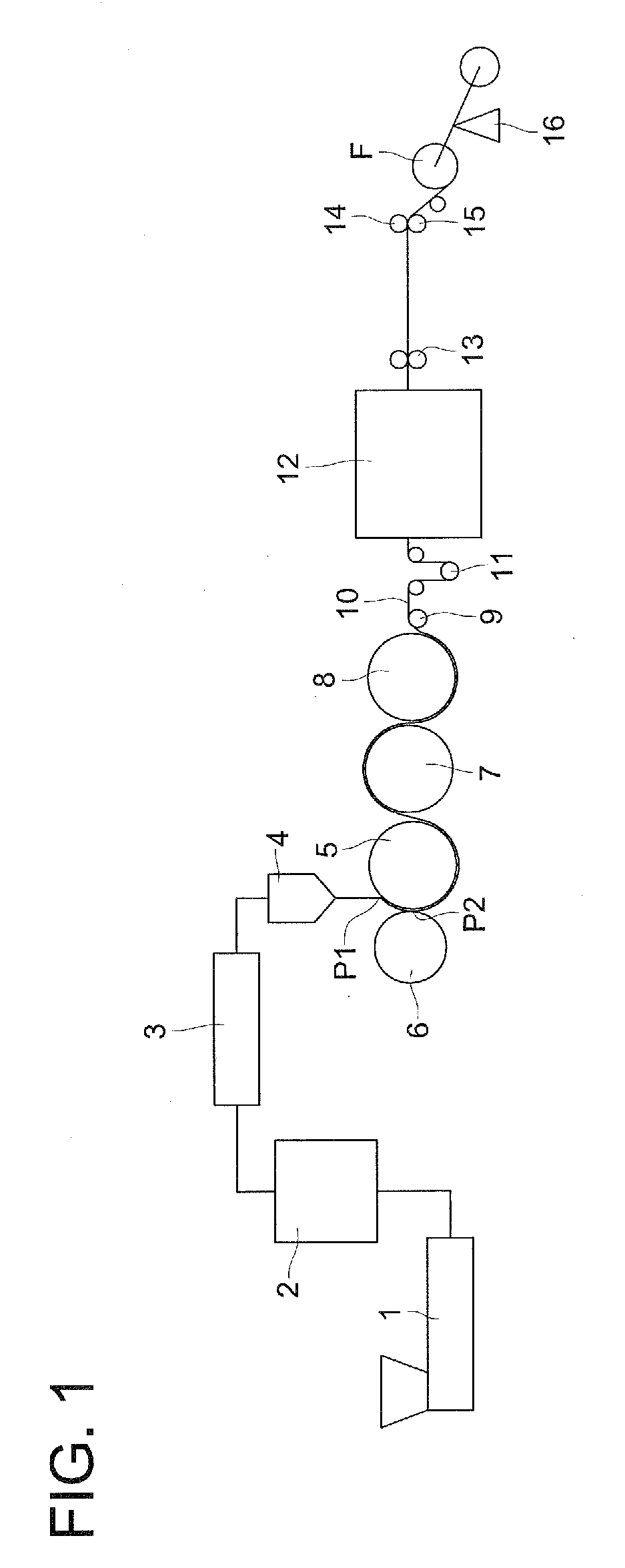

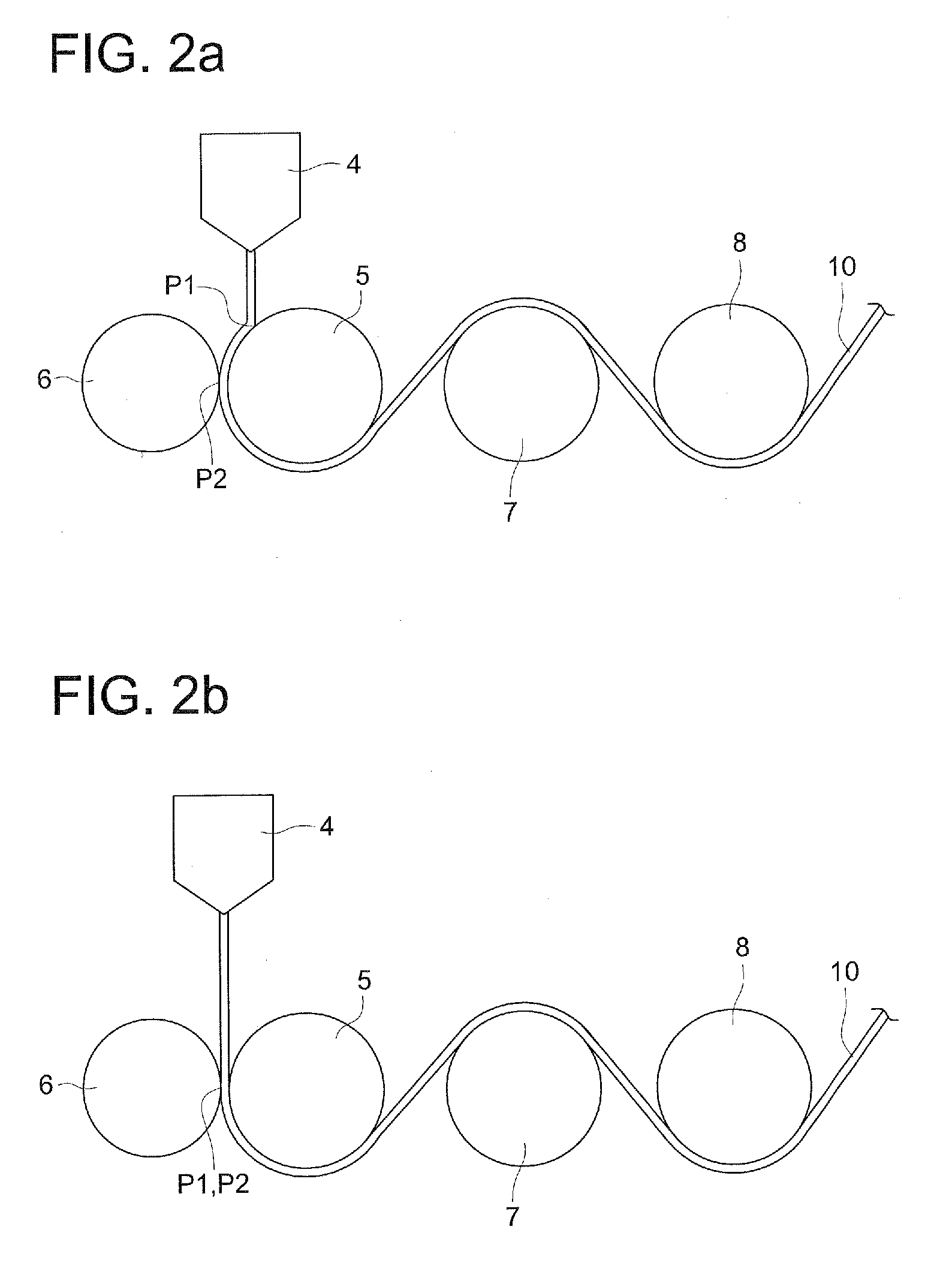

Optical film and process for producing the same

InactiveUS20100179263A1Efficient productionImprove flatnessOptical articlesDomestic articlesVitrificationLiquid-crystal display

An optical film of high planarity that even in the use of an optical film material containing a non-resinous additive in an amount of 5 mass % or more, would exhibit inexpensive satisfactory roll cleaning effects, and that would find application in, especially, various functional films such as a retardation film and a protective film for polarization plate for use in a liquid crystal display apparatus, etc.; and a process for producing the optical film. There is disclosed a process for producing an optical film according to a melting casting film forming method, including extruding a melt of resin blend containing a resin and 5 mass % or more of non-resinous additive through a casting die into a film form, wherein a first roller (5) for cooling has a temperature of the melting point of the additive to the glass transition temperature (Tg) of the resin blend. Preferably, the first roller (5) for cooling has a peripheral speed (S1) exhibiting a ratio between the same and the peripheral speed (S3) of a third roller (7) for cooling, S3 / S1, of 1.001 to 1.05. Preferably, a filmlike molten blend is pressed against the first roller (5) for cooling at a linear pressure of 0.5 to 50 N / mm by means of a second roller (6) for pressure application.

Owner:KONICA MINOLTA OPTO

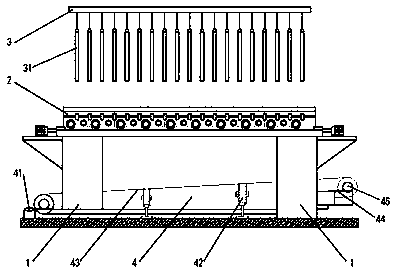

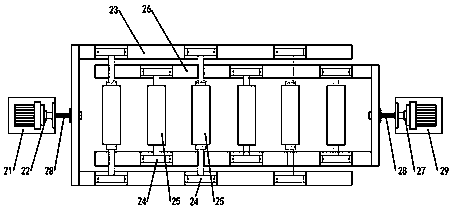

Nickel anode plate cleaning machine

PendingCN108754547AEasy to cleanShorten the timePhotography auxillary processesElectrolysis componentsEngineeringMetallic Nickel

The invention discloses a nickel anode plate cleaning machine. The nickel anode plate cleaning machine comprises a foundation platform, a cleaning mechanism, a crane mechanism and an anode slime recovery mechanism. The foundation platform is fixedly connected with the cleaning mechanism. The anode slime recovery mechanism is arranged below the cleaning mechanism directly. The crane mechanism hoists nickel anode plates from a workshop electrolytic platform to the upper portion of the cleaning mechanism. The nickel anode plate cleaning machine disclosed by the invention has the characteristics of being simple in structure, high in efficiency and easy to operate and has broad market prospects.

Owner:李文斌

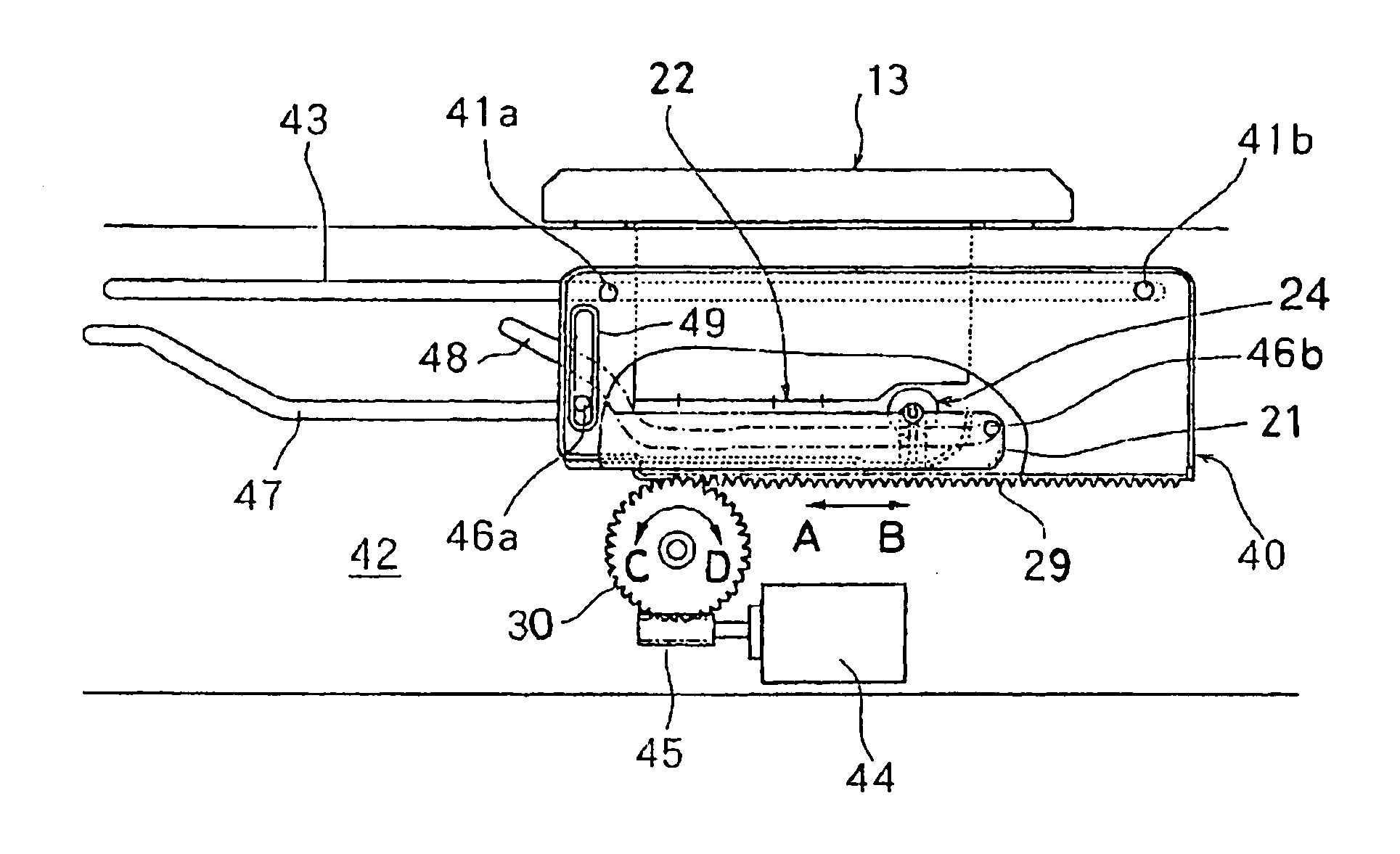

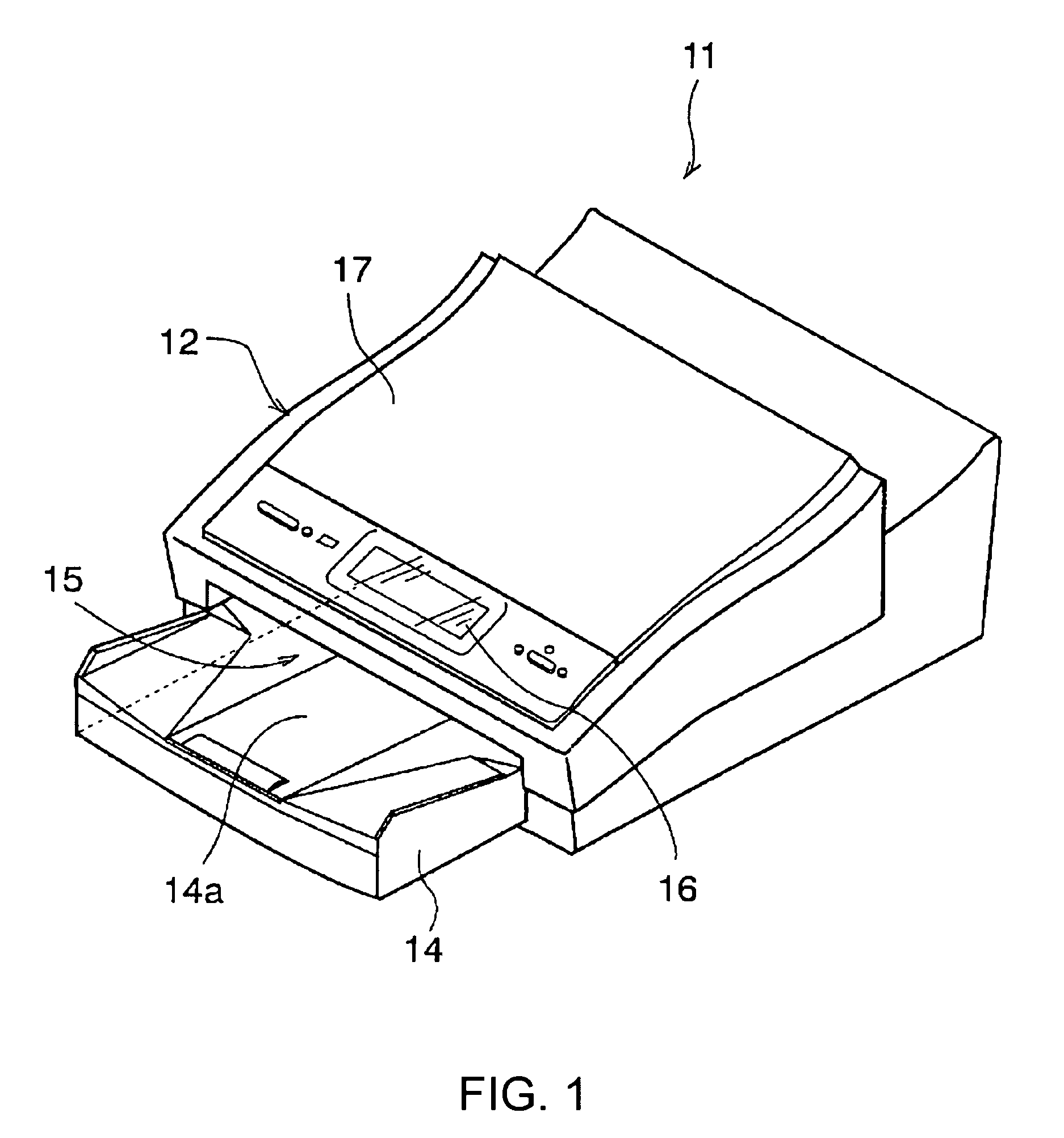

Liquid discharging apparatus and control method therefor

In a liquid discharging apparatus for discharging droplets from a liquid discharge nozzle to a discharge object to be discharged and in a method for controlling the liquid discharging apparatus, cleaning effects for the ink discharge nozzle and the adjacent areas can be enhanced, and the time required for a series of performance maintaining operations can be reduced. The apparatus includes a platen plate for supporting recording paper as the discharge object, defining a positional relationship between the discharge object and the liquid discharge head, and receiving the droplets discharged from the liquid discharge head. Ink droplets are preliminarily discharged from the ink discharge nozzle to the platen plate.

Owner:SONY CORP

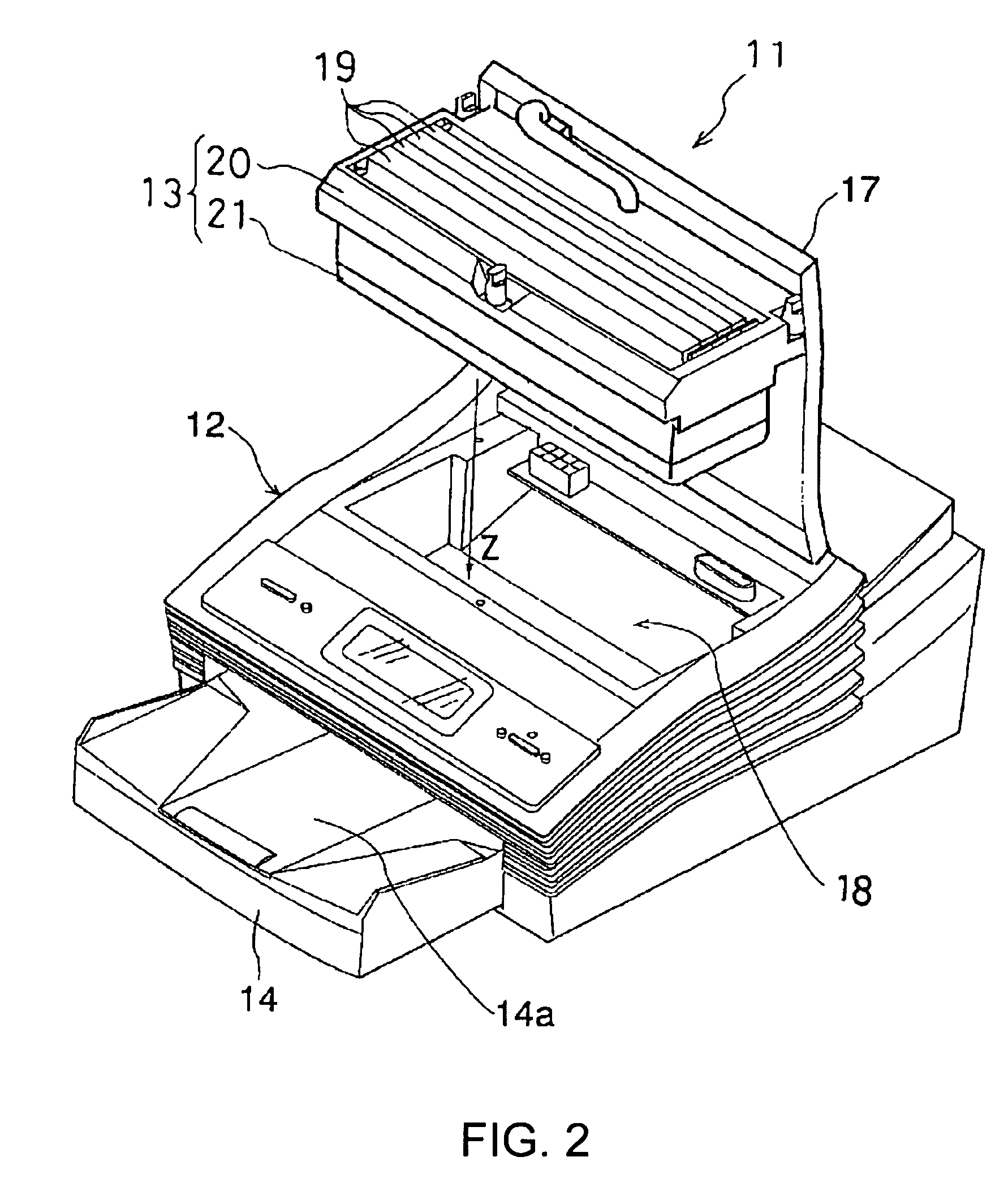

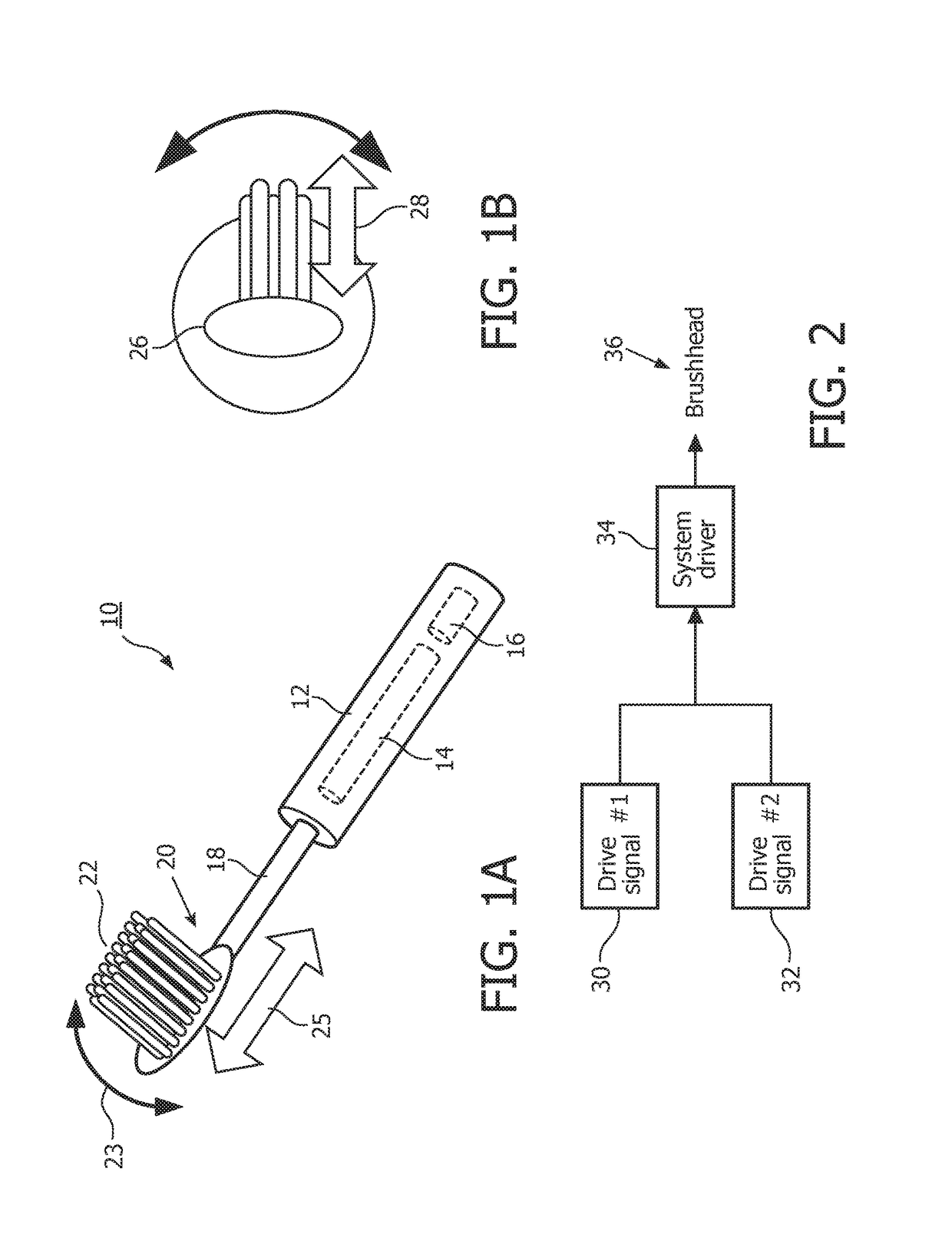

Power toothbrush with multiple bristle motions producing an audible sound

ActiveUS9844260B2Efficient actionClean effectBristleTooth cleaningBristleElectrical and Electronics engineering

A power toothbrush includes a handle having a driving system therein. The driving system is responsive to two drive signals. One drive signal produces a clinically effective cleansing action for the teeth, while the other drive signal is arranged to produce audible sounds from the toothbrush which are cognitively stimulating or relaxing.

Owner:KONINKLJIJKE PHILIPS NV

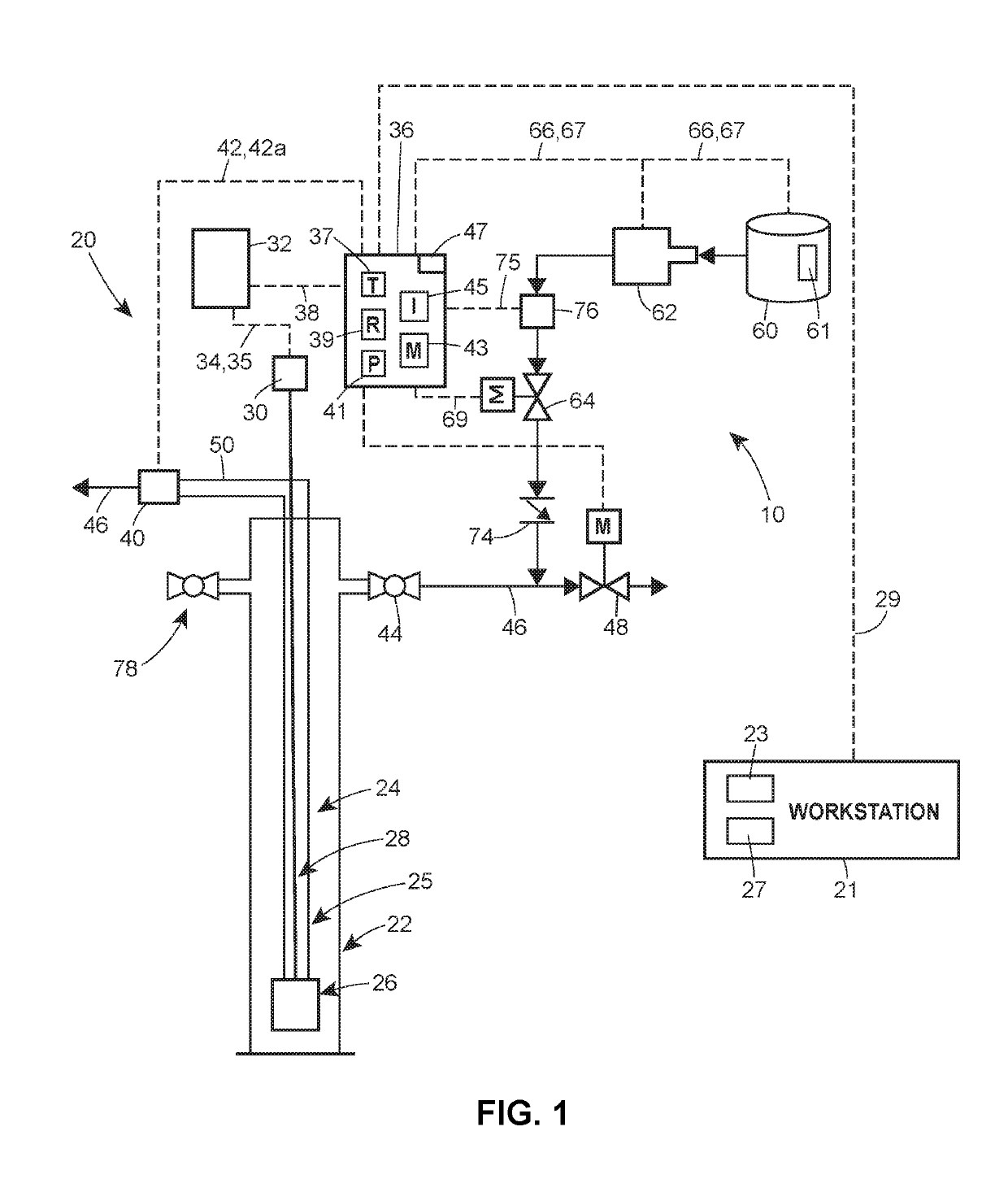

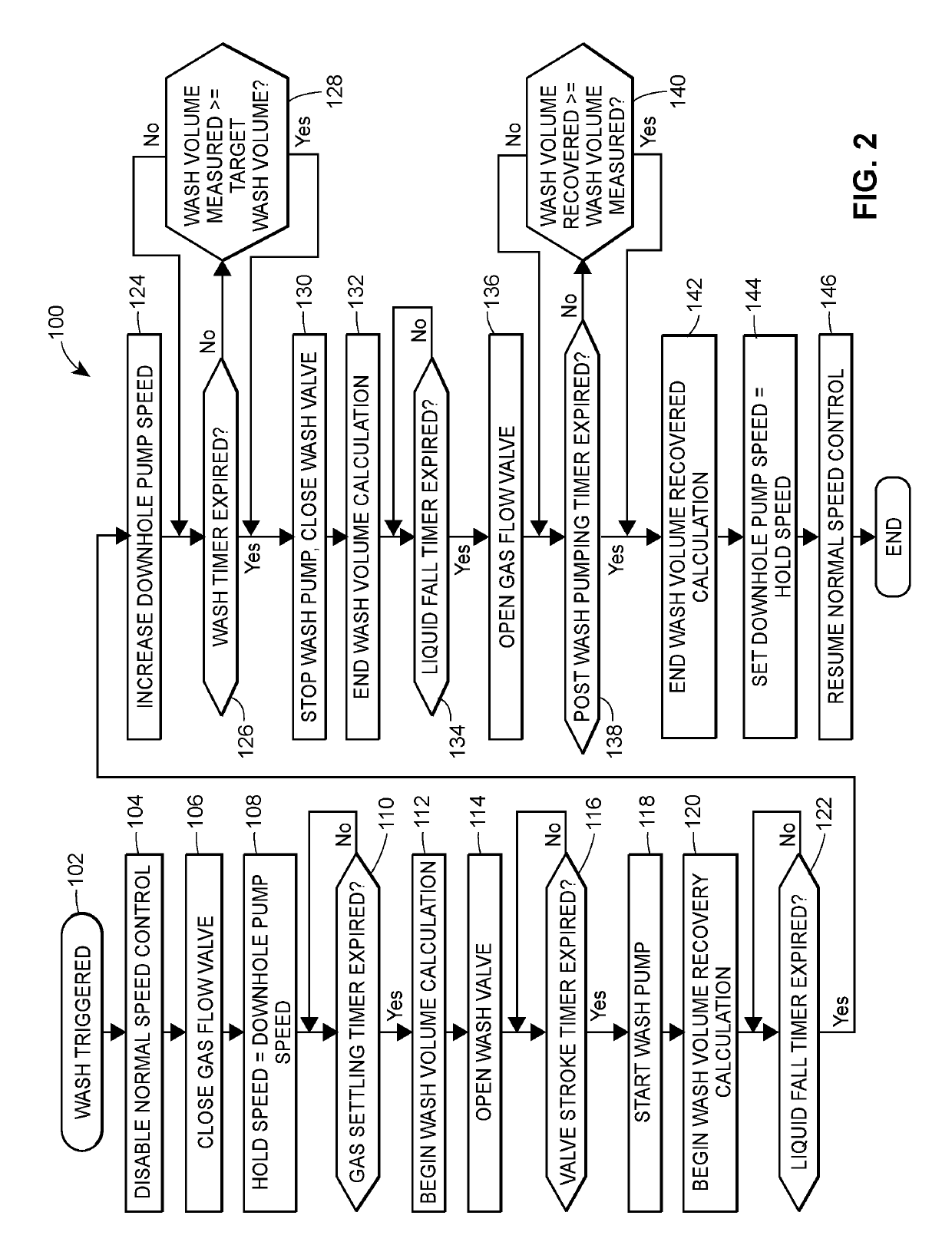

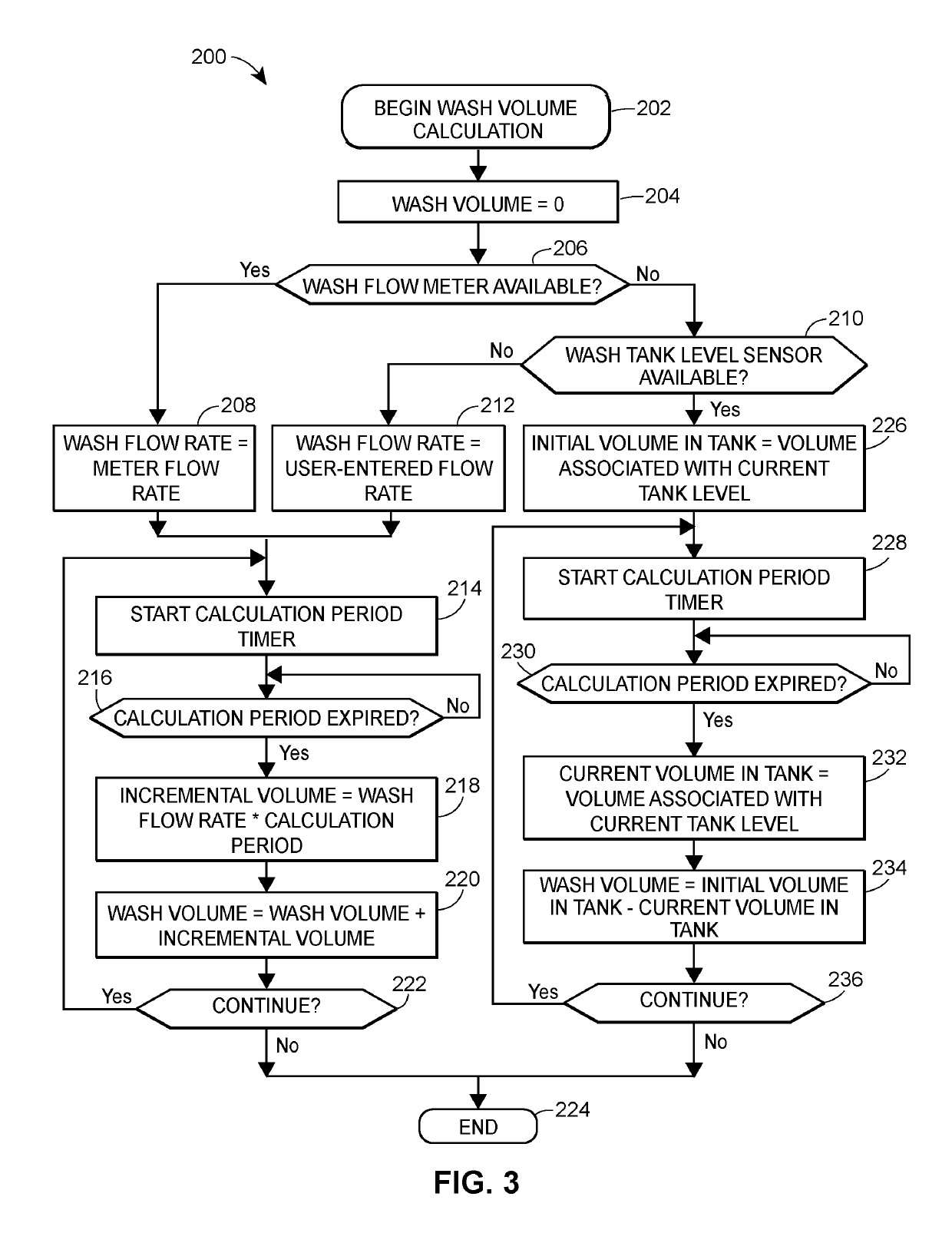

Automated wash method for a progressing cavity pump system

ActiveUS10465493B2Clean effectSurveyVolume measurement apparatus/methodsMechanical engineeringMechanics

A method of automatically washing a well casing of a progressing cavity (PC) pump system. The method includes disabling, via a controller, a normal speed control of a progressing cavity (PC) pump of the PC pump system, and closing, via the controller, a gas flow valve to stop upward fluid flow in an annulus of the well casing. The method further includes opening a wash valve to allow fluid from the wash fluid source into the well casing. Upon wash fluid accumulation within the annulus, the method further includes increasing the speed of the pump to begin flushing the well casing, and closing the wash valve.

Owner:BRISTOL

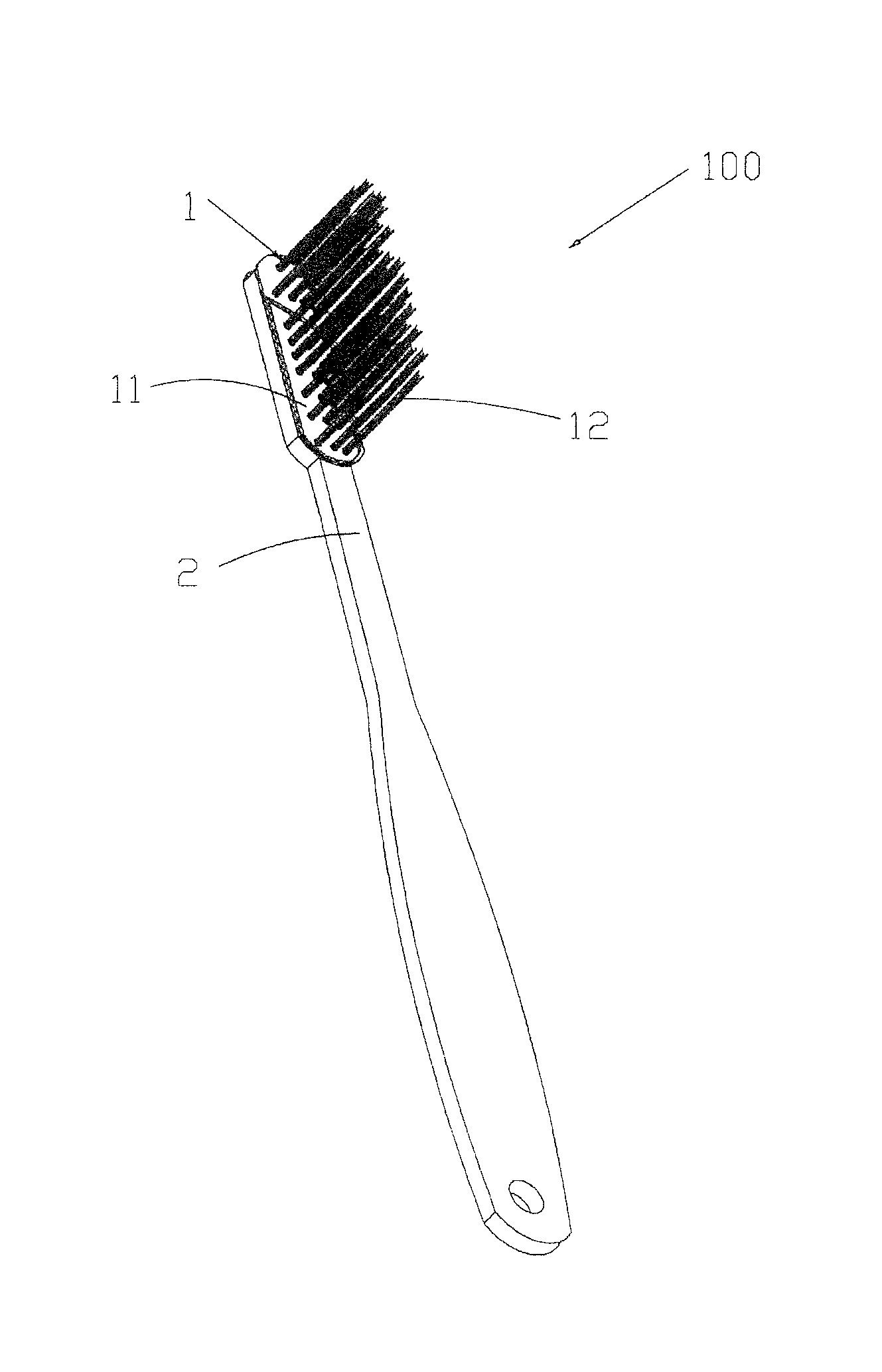

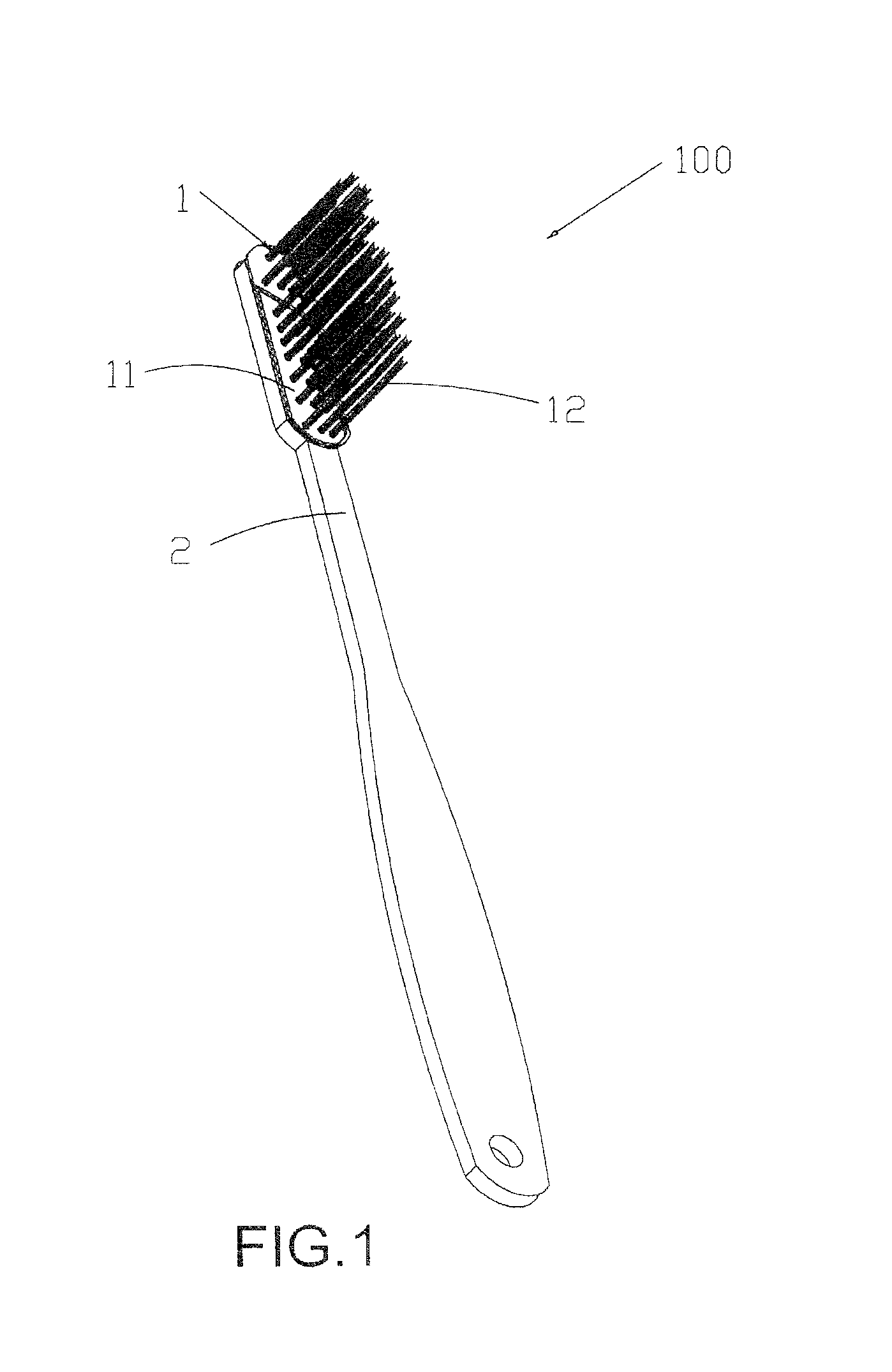

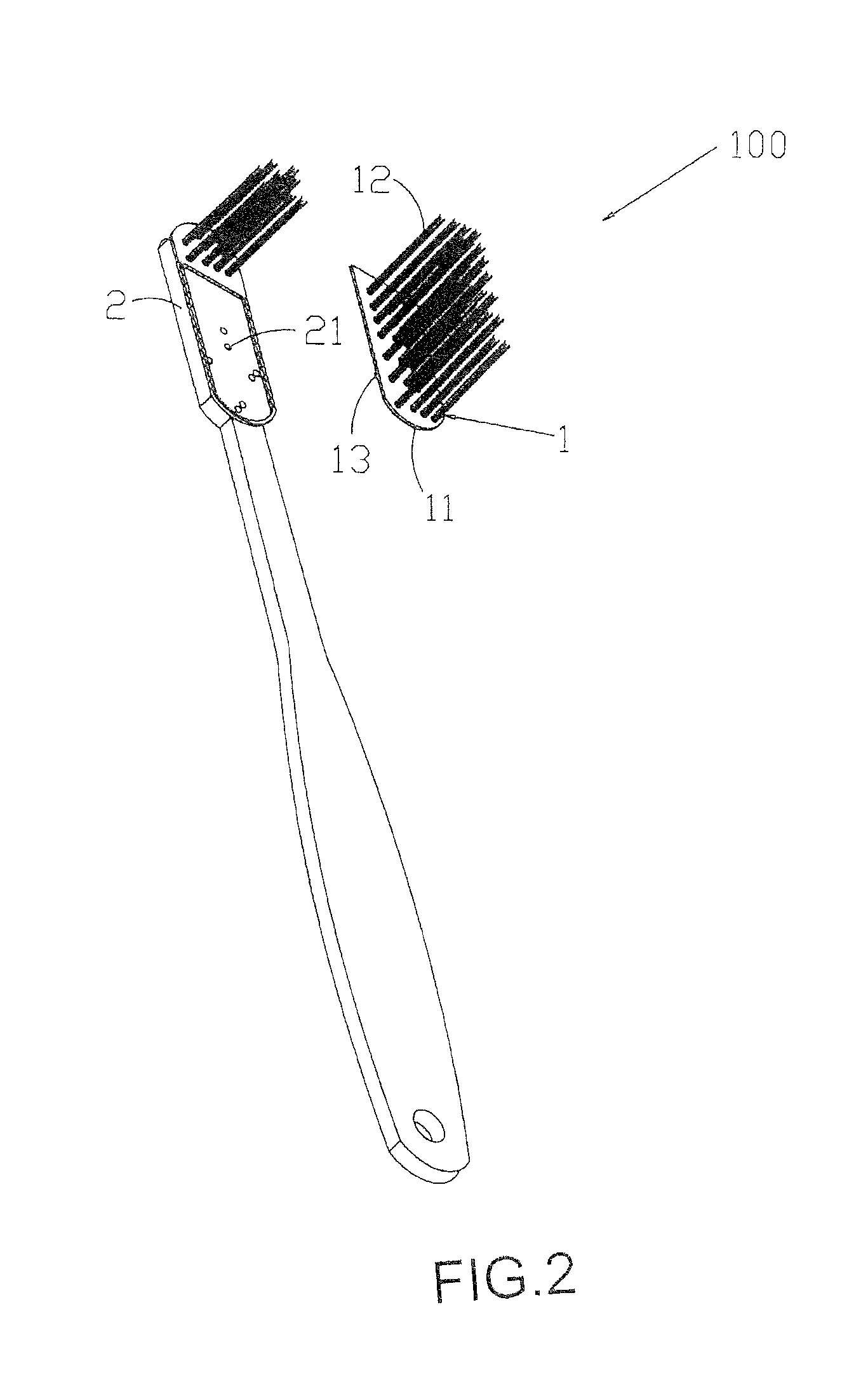

Brush Head and Producing Device Thereof

InactiveUS20120304407A1Extend product lifeGentle but effective brushing effectCarpet cleanersBrush bodiesBristleVolumetric Mass Density

A brush for cleaning a surface of a cleaning object includes a brush body and a brush head unit connected to the brush body arranged for providing a brushing surface for cleaning the surface of the cleaning object in a gentle but effective manner, wherein the brush head unit comprises a plurality of bristle units aligned and connected in layer to formed the brush head unit, wherein each the bristle unit comprises a plurality of bristle members which are welded together to integrally forming the bristle unit, thereby a density and a distribution of the bristle members in the brush head unit are capable of being increased to a level at which gentle but effective cleaning is realized.

Owner:YU HOIPO

Water-conducting household appliance and method for the operation thereof

InactiveUS7909941B2Clean effectGood for removing dirtTableware washing/rinsing machine detailsCleaning using liquidsEngineeringHome appliance

A dishwasher includes at least one substantially closed water circuit in which rinsing liquid is circulated according to a program control unit, the rinsing liquid being conveyed through a filter element while circulating in order to filter out dirt. Another water circuit is provided through which the rinsing liquid is circulated according to the program control unit when the filter element is covered with dirt in order to cause the filter element to be cleaned.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

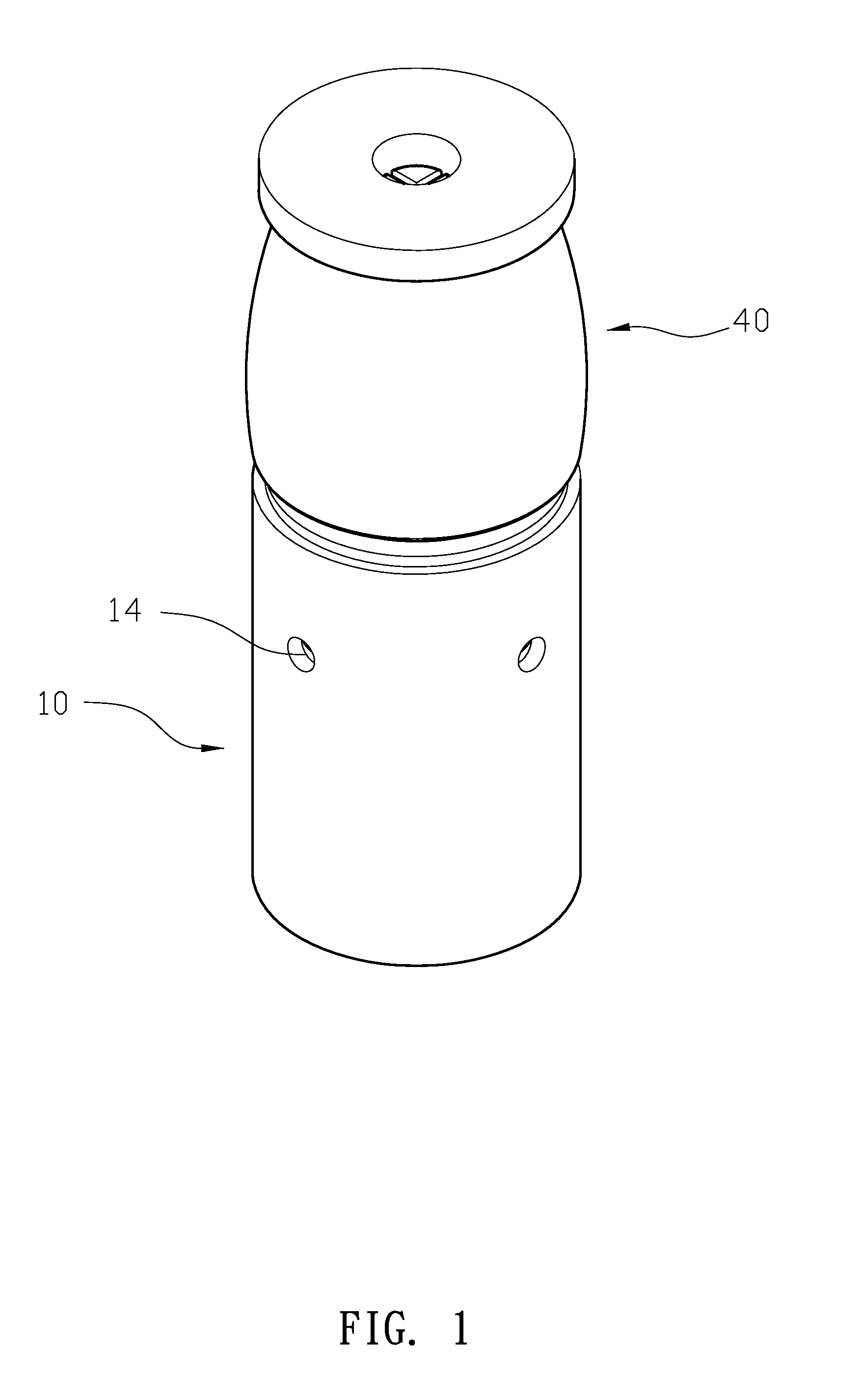

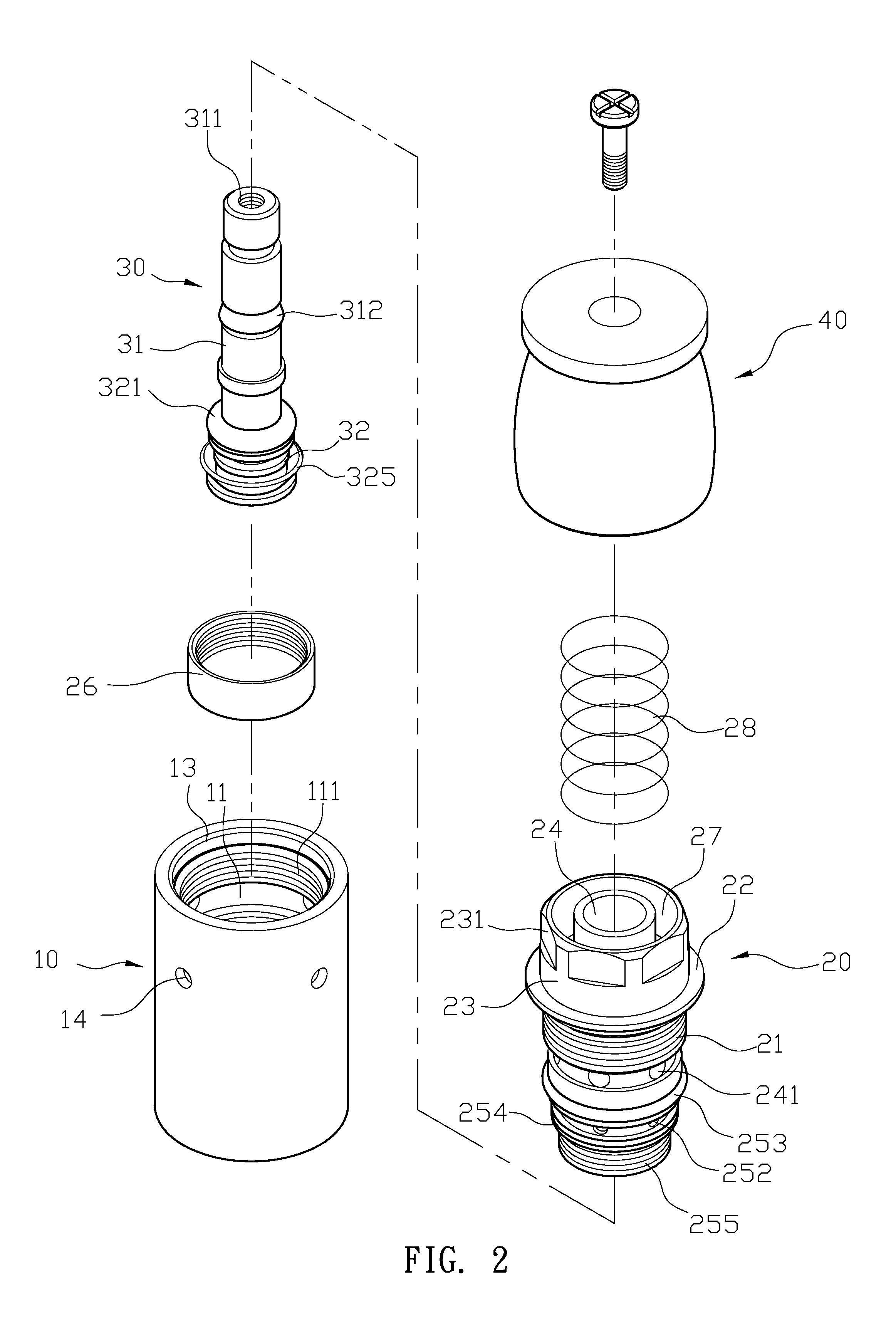

Self-shut valve for faucet

InactiveUS20170037981A1Clean effectAccurate returnDomestic plumbingFluid-delivery valvesEngineeringMechanical engineering

A self-shut valve for a faucet may include a valve body, a valve base, a control shaft and a top cap. The control shaft includes a sealing portion that comprises a ducting pipe and a slot which can prevent the space between the valve base and the control shaft from entering into a vacuum state to enable the control shaft to return to its initial position precisely.

Owner:GEANN IND

Sewing method of linen clothes

ActiveCN105615095AAvoiding Fragmentation ProblemsClean effectClothes making applicancesMechanical engineeringSuture line

The invention relates to the technical field of garment sewing, in particular to a sewing method of linen clothes. The sewing method comprises the steps of enabling the edges of a cutting piece A and a cutting piece B which are to be sewn to be respectively stuck with a lining strip A and a lining strip B; sewing the cutting piece A and the cutting piece B by a suture line, wherein the distance from the suture line to the edge of the cutting piece A is greater than that from the suture line to the edge of the cutting piece B; parting the cutting piece A and the cutting piece B, and respectively locking the edges of the cutting piece A and the cutting piece B; folding the cutting piece A towards the direction of the cutting piece B in a turnover way for the first time, and enabling the cutting piece A to be overlapped with the cutting piece B; folding part of the cutting piece A towards the direction of the cutting piece B in a turnover way for the second time, wherein the folded part of the cutting piece A is wider than the cutting piece B, and enabling the cutting piece B to be wrapped in the cutting piece A; pressing a line at a part close to the edge of the cutting piece A, and sewing the cutting piece A and the cutting piece B together. After the sewing method is adopted, the problems such as stitch slipping, tearing down and the like which are caused in the sewing process of linen fabrics can be avoided, so that the stitch slipping degree of linen fabrics is effectively avoided.

Owner:报喜鸟控股股份有限公司

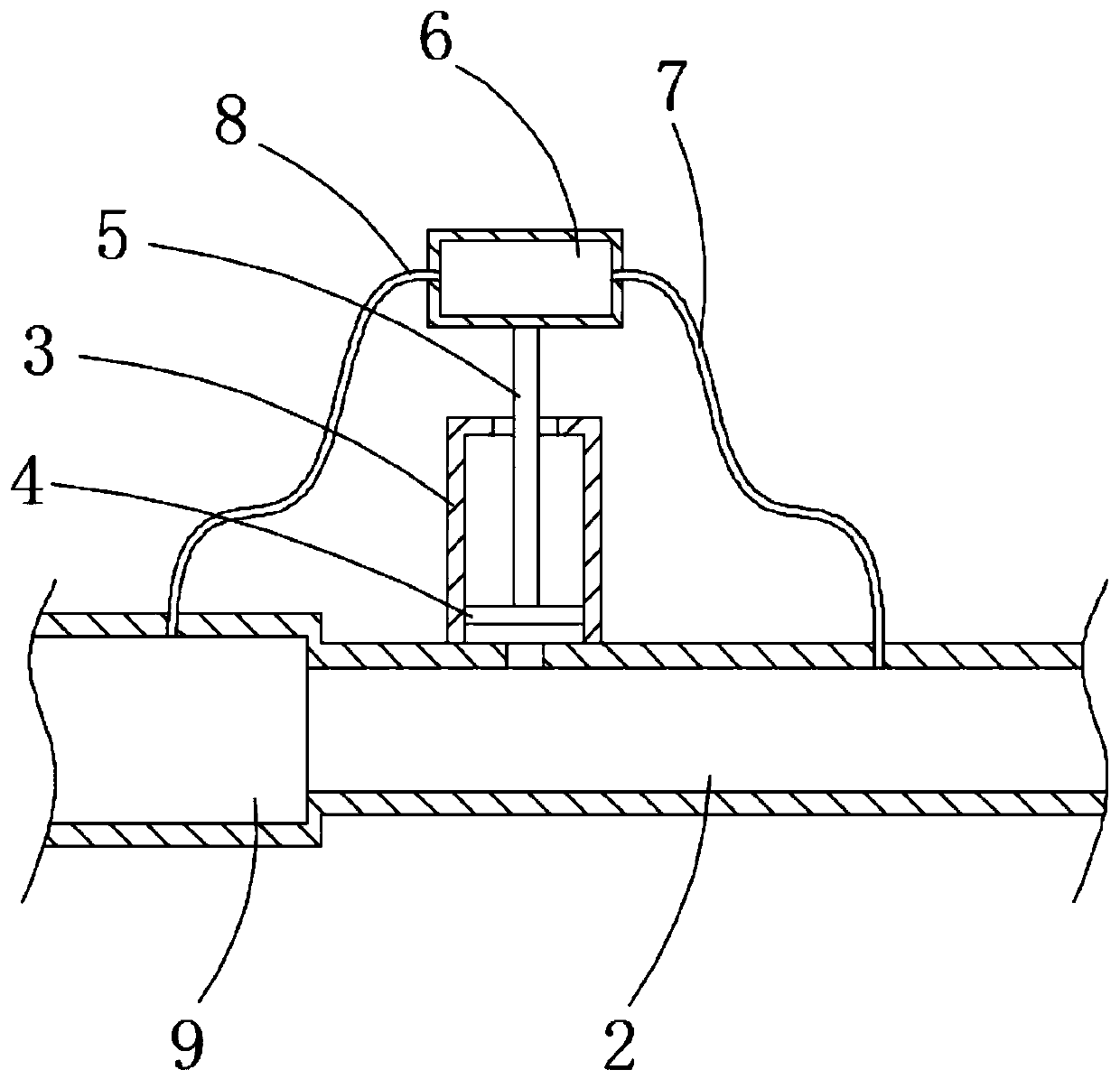

Steam boiler with pressure blowdown thorough-cleaning function

The invention discloses a steam boiler with a pressure blowdown thorough-cleaning function. The steam boiler with the pressure blowdown thorough-cleaning function comprises a furnace body and a waterdischarging pipe arranged at the bottom of the furnace body, wherein the water discharging pipe is a rigid pipeline, pipe diameters of all sections of the water discharging pipe are equal, the water discharging pipe communicates with a thick pipe of which the pipe diameter is larger than that of the water discharging pipe, a vertical pipe communicates with the side wall of the water discharging pipe, a piston plate is connected in the vertical pipe in a sealing and sliding mode, a flat and hollow heat conduction box is fixedly connected to the piston plate through a connecting rod, and one endof the heat conduction box communicates with the water discharging pipe through a first hose. The steam boiler with the pressure blowdown thorough-cleaning function has the advantages that the waterpressure is large in a boiler water discharging initial stage, the water pressure in the water discharging pipe enables the heat conduction box to move upwards to make contact with a fluid pipe, and arotary mechanism is driven to rotate and compress a torsion spring; and when the water pressure in the boiler is reduced, the torsion spring drives a knocking device to rotate reversely, when reverserotation of the knocking device is accelerated, a limiting block is separated from a limiting groove under the acceleration action of the knocking device so that a collision block impacts the furnacebody, then residual dirt in the furnace body can be knocked down, and the effect that the dirt in the boiler is treated more thoroughly is achieved.

Owner:广州强昇热能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com