Steam boiler with pressure blowdown thorough-cleaning function

A steam boiler, a thorough technology, applied in the field of boilers, can solve the problem of artificial inability to remove dirt from the drain, and achieve the effect of cleaning the dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

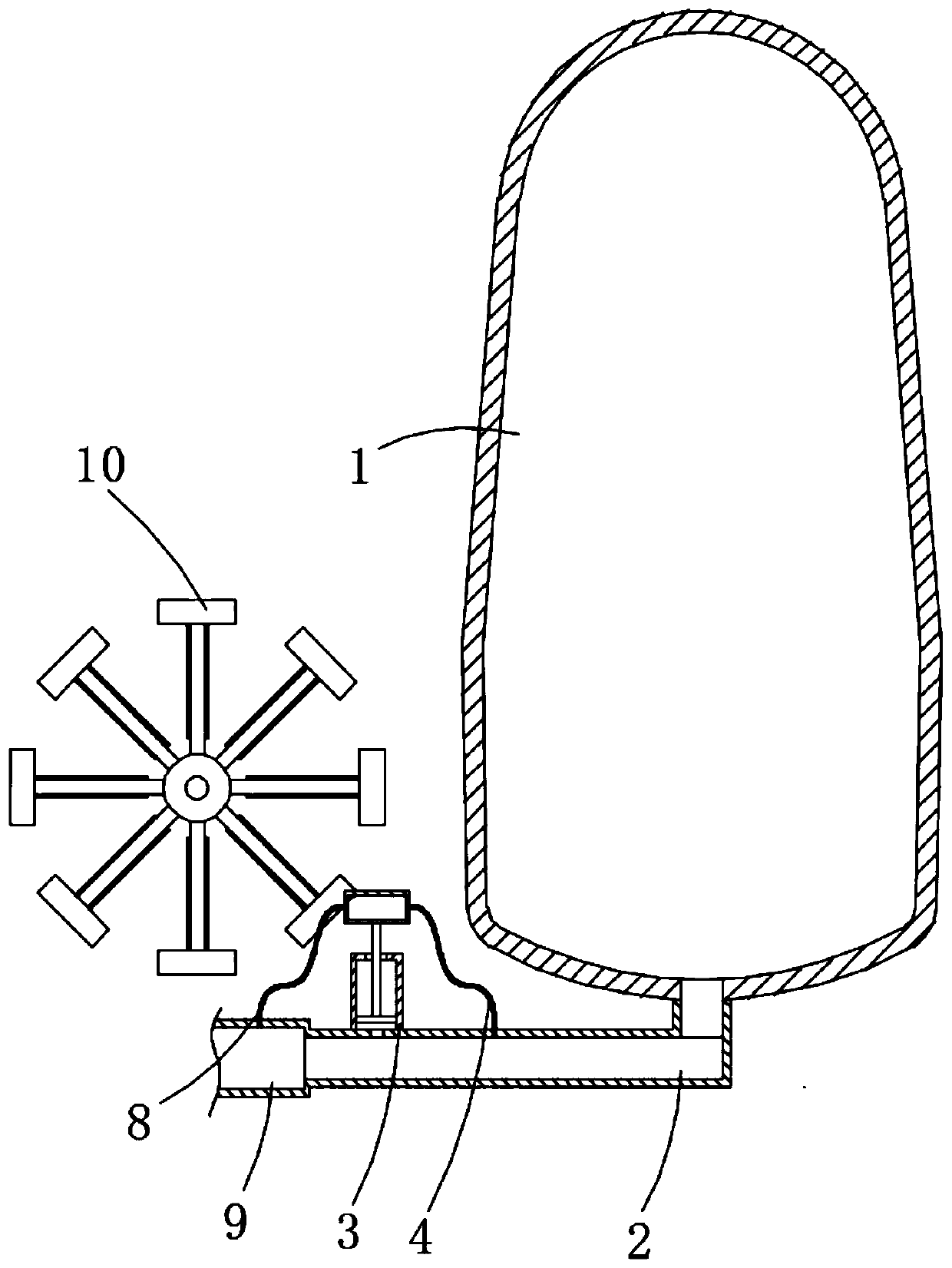

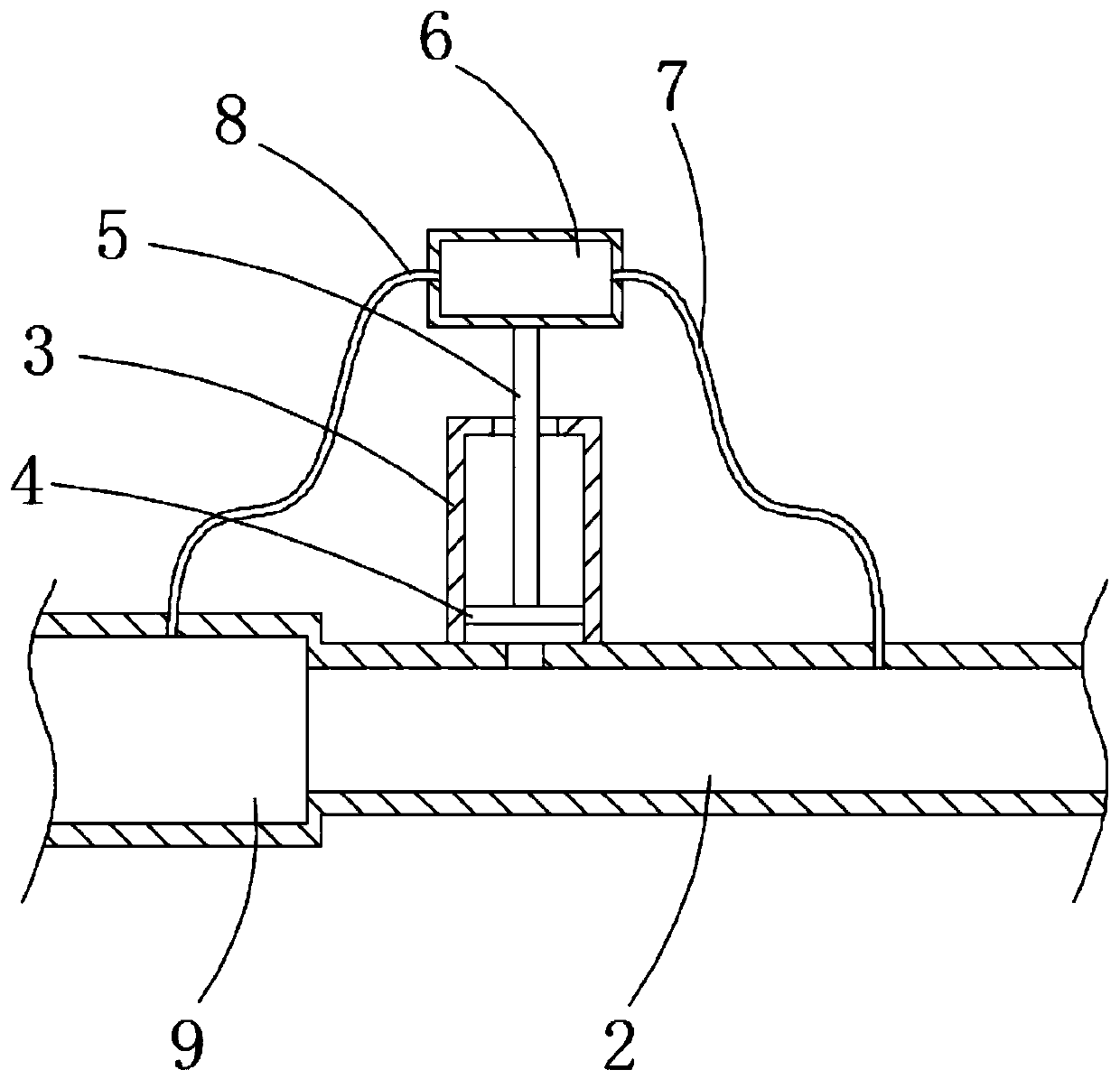

[0021] refer to Figure 1-6 , a thoroughly clean steam boiler with pressurized sewage discharge, including a furnace body 1 and a drain pipe 2 arranged at the bottom of the furnace body 1, the drain pipe 2 is a hard pipe and the diameters of each part are equal, and the drain pipe 2 is connected with a pipe diameter The thick pipe 9 that is larger than the drain pipe 2, the side wall of the drain pipe 2 is connected with a vertical pipe 3, and a piston plate 4 is connected to the vertical pipe 3 for sealing and sliding, and a flat and hollow pipe 4 is fixedly connected to the piston plate 4 through the connecting rod 5. One end of the heat conduction box 6 communicates with the drain pipe 2 through the first hose 7, and the other end of the heat conduction box 6 communicates with the thick pipe 9 through the second hose 8. The side wall of the furnace body 1 is provided with a heat transfer percussion device;

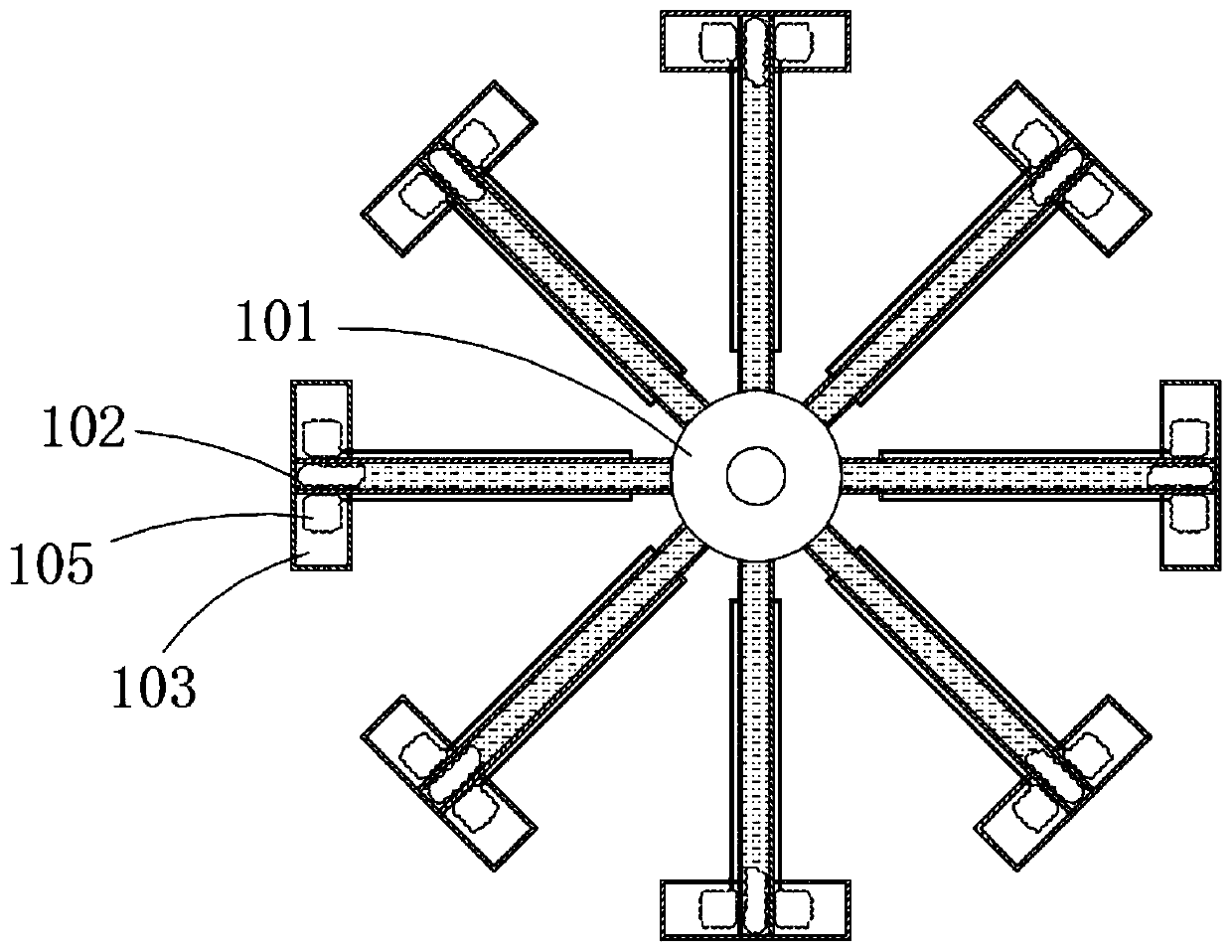

[0022] The heat-rotating knocking device includes a rotating mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com