Automatic assembling machine for plastic nails of fan of machine box

A technology of assembly machines and rubber nails, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to realize simultaneous material supply and corresponding feedback, high labor cost, high labor intensity, and high labor cost, so as to reduce labor force Quantity, convenient maintenance, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

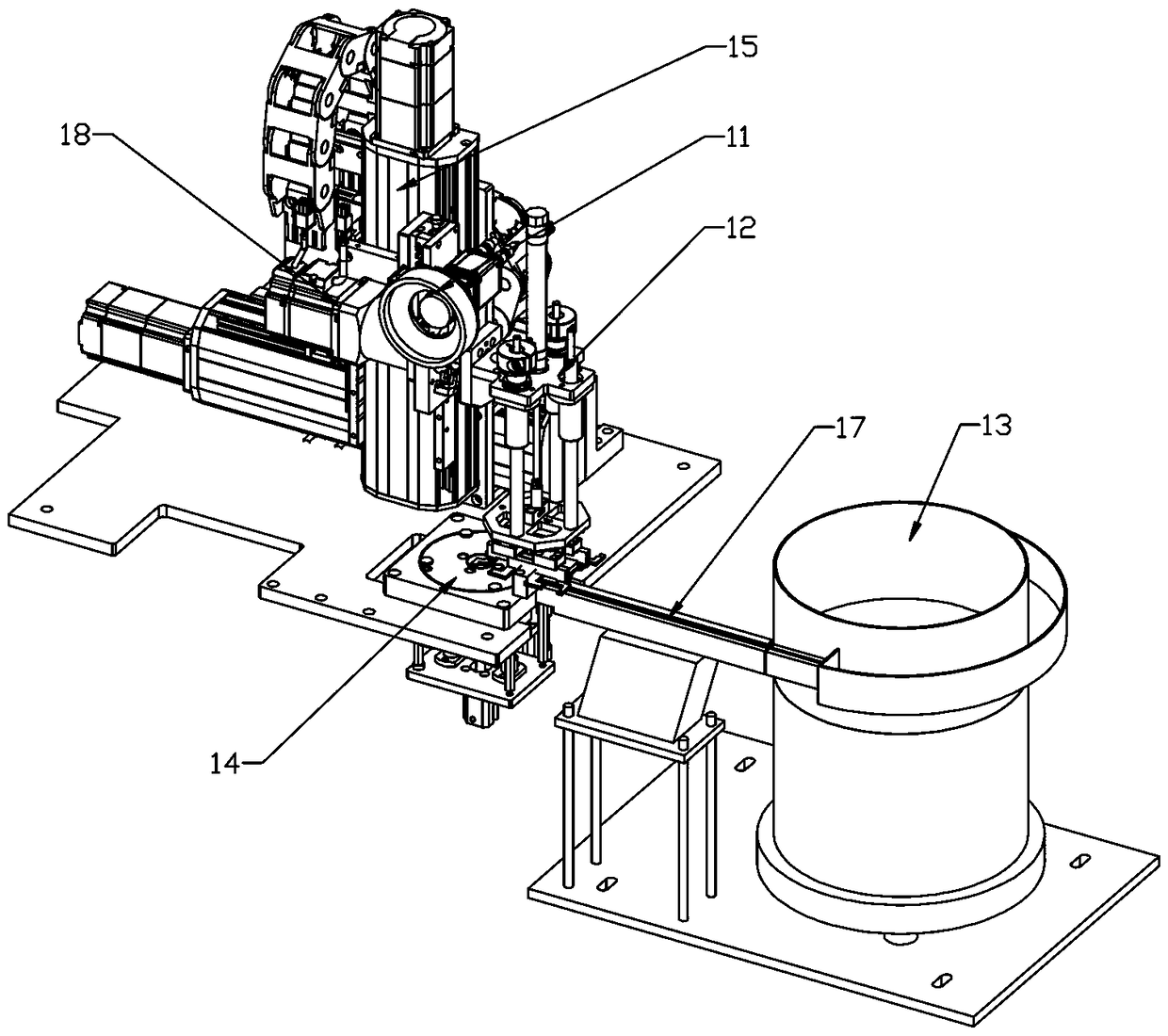

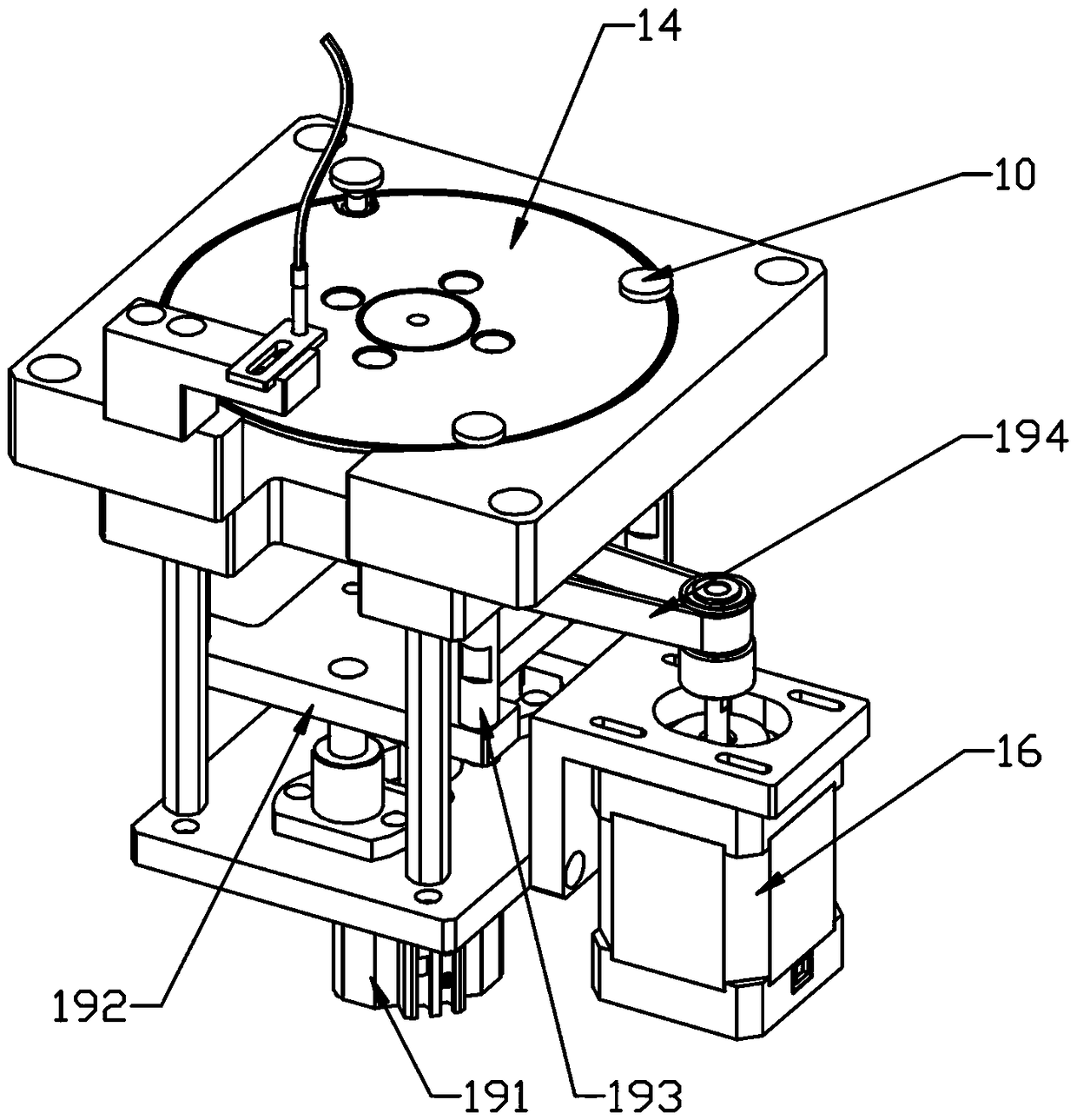

[0029] Such as Figure 1 to Figure 8 As shown, the specific embodiment of the present invention is: the present invention comprises glue nail supply module, and described glue nail supply module comprises CCD camera 11 and takes glue nail manipulator 12, and described glue nail manipulator 12 is used for gripping glue nail 10;

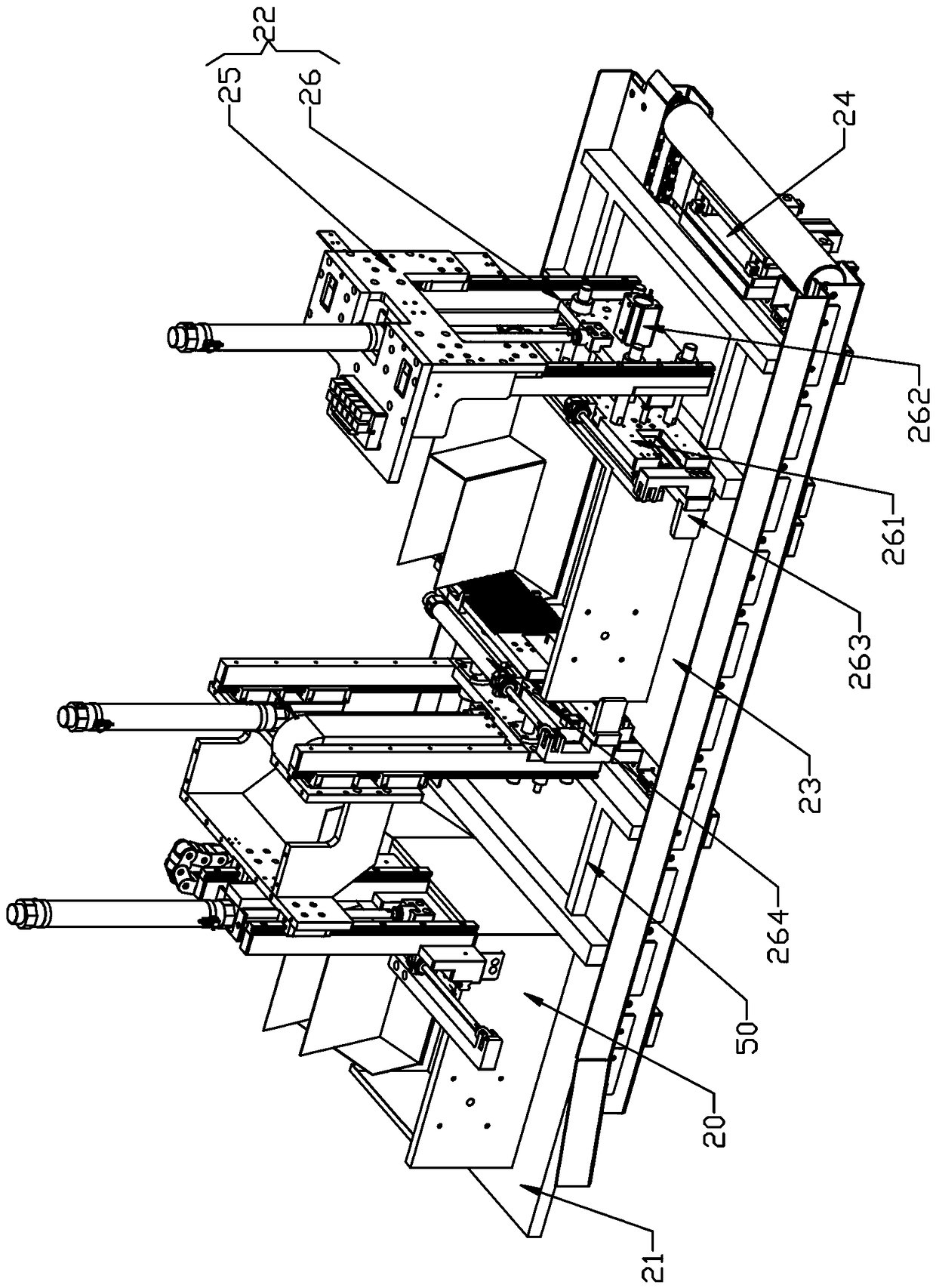

[0030] A chassis feeding module, the chassis feeding module includes a box delivery track 21 and a stopper positioning assembly 22 arranged on the box delivery track 21, and the box delivery track 21 is used to transport the box 20;

[0031] A fan feeding module, the fan feeding module includes a fan discharge positioning assembly 31, and the fan 30 waits for discharge at the fan discharge positioning assembly 31;

[0032] And the glue nail assembly module, the glue nail assembly module includes the fan taking manipulator 41 matched with the fan discharge positioning assembly 31;

[0033] The fan removal manipulator 41 removes the fan 30 from the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com