Patents

Literature

66results about How to "The equipment is compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

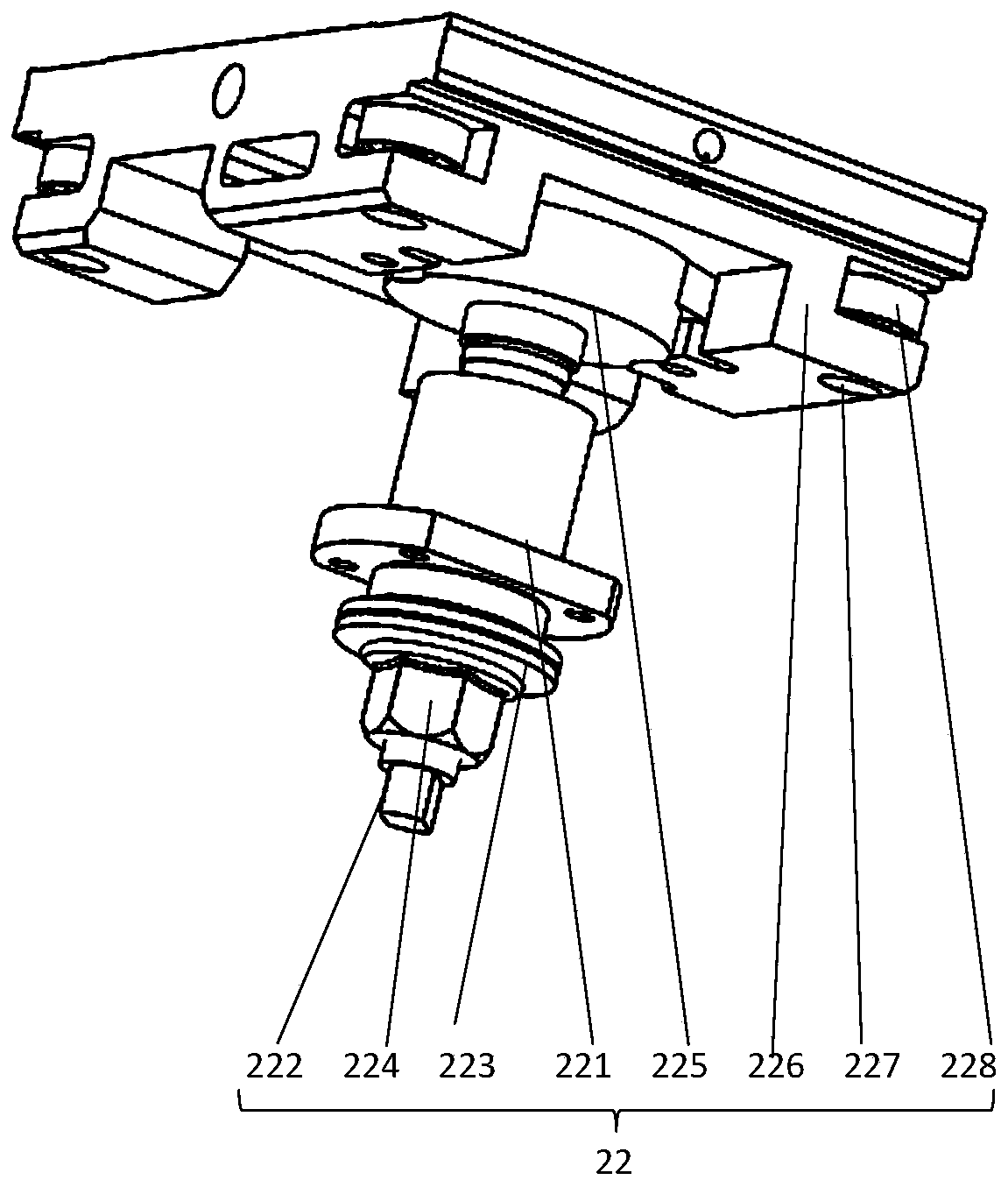

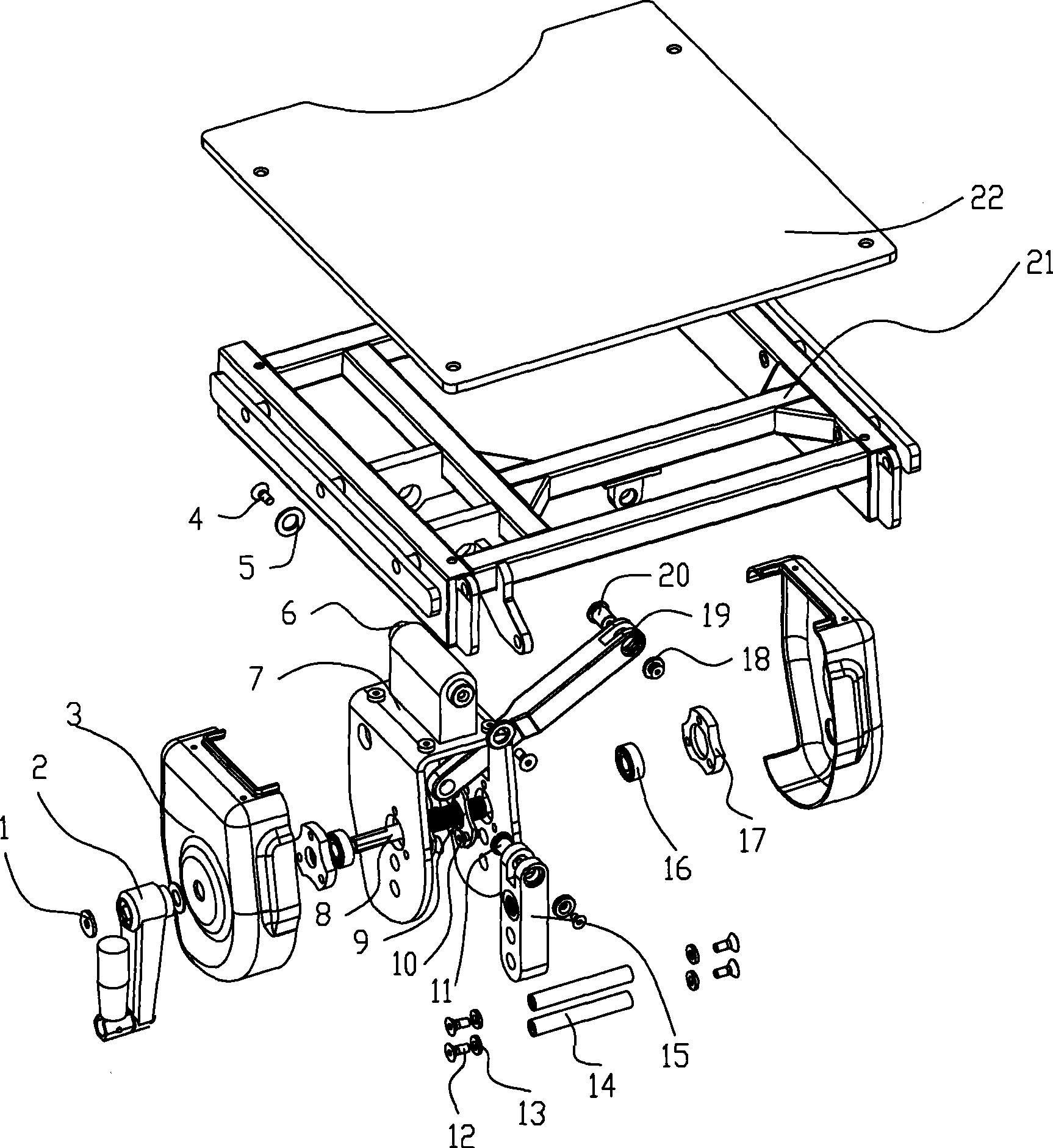

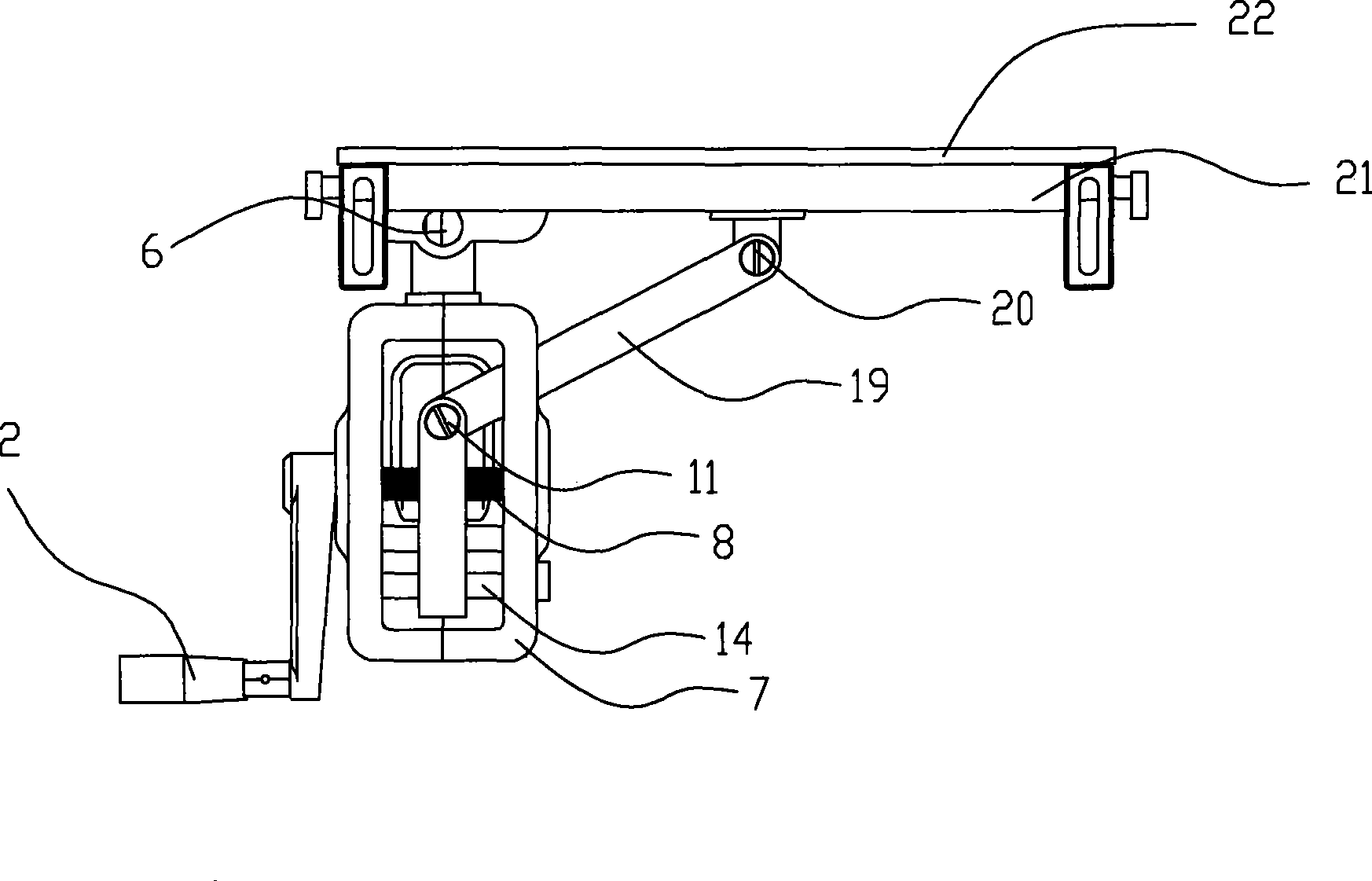

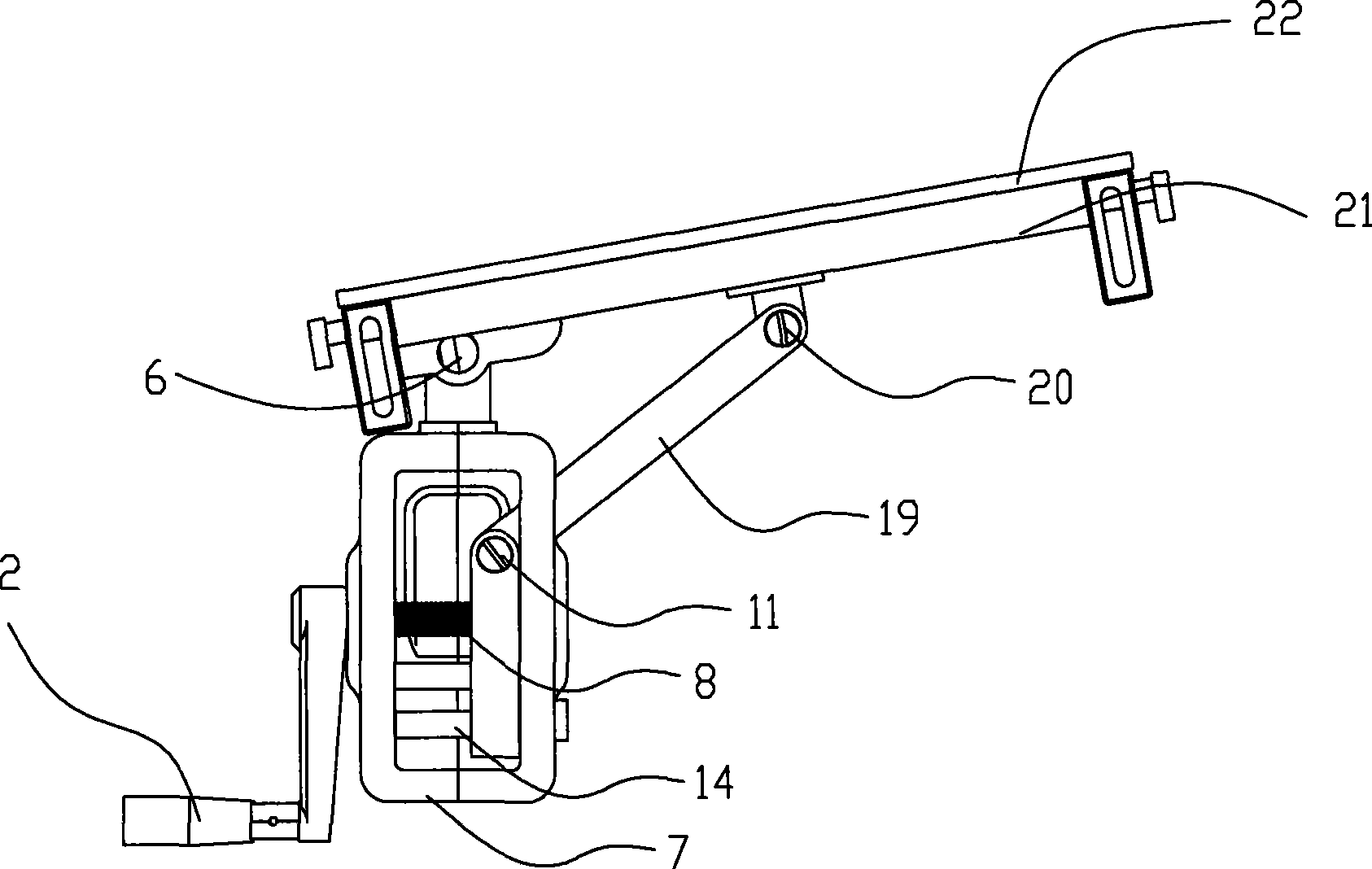

Chip check apparatus

InactiveCN1503340AThe equipment is compactLarge areaSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMicroscopeMechanical engineering

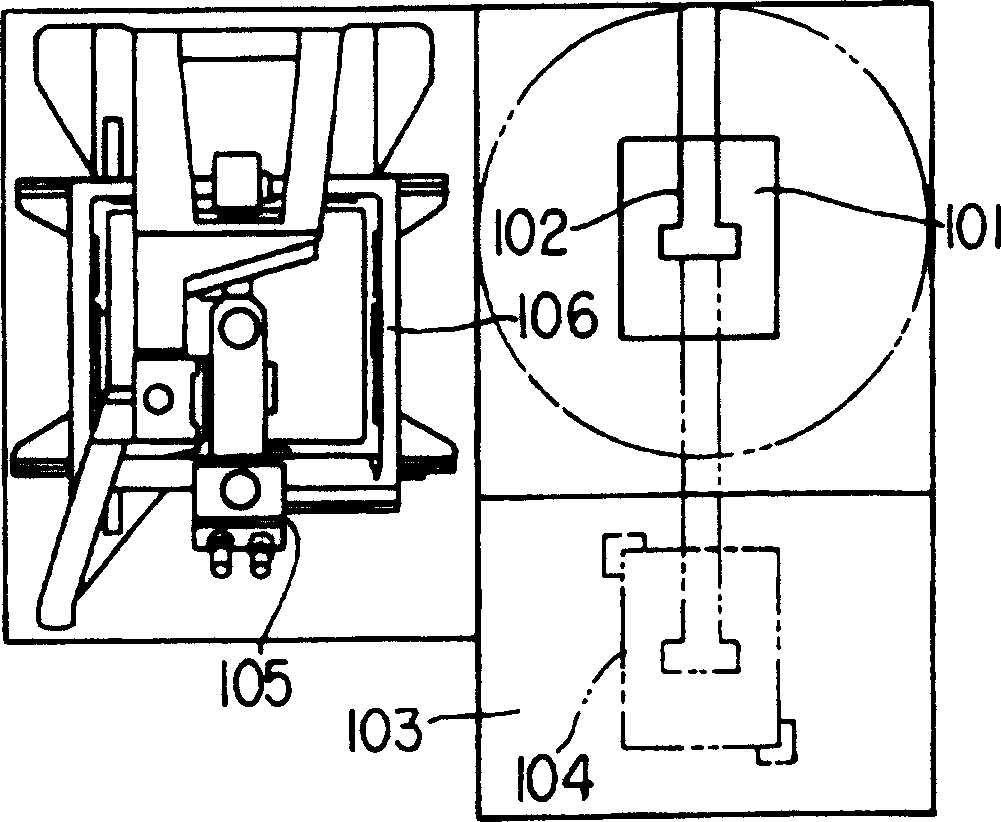

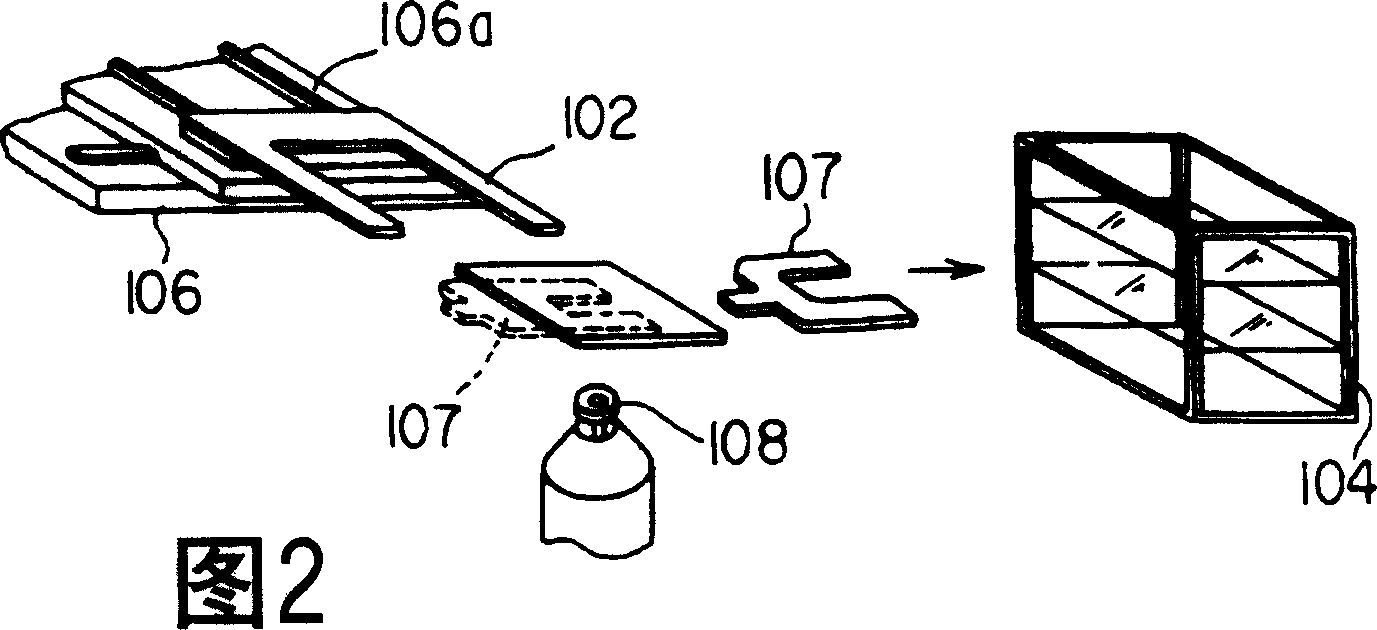

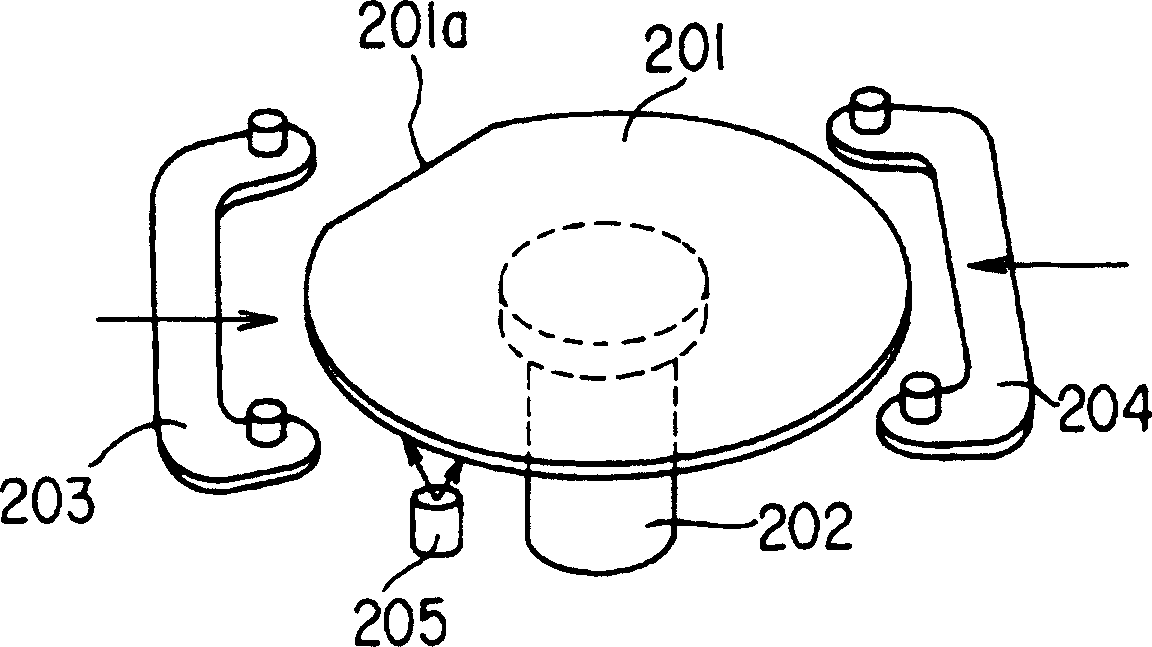

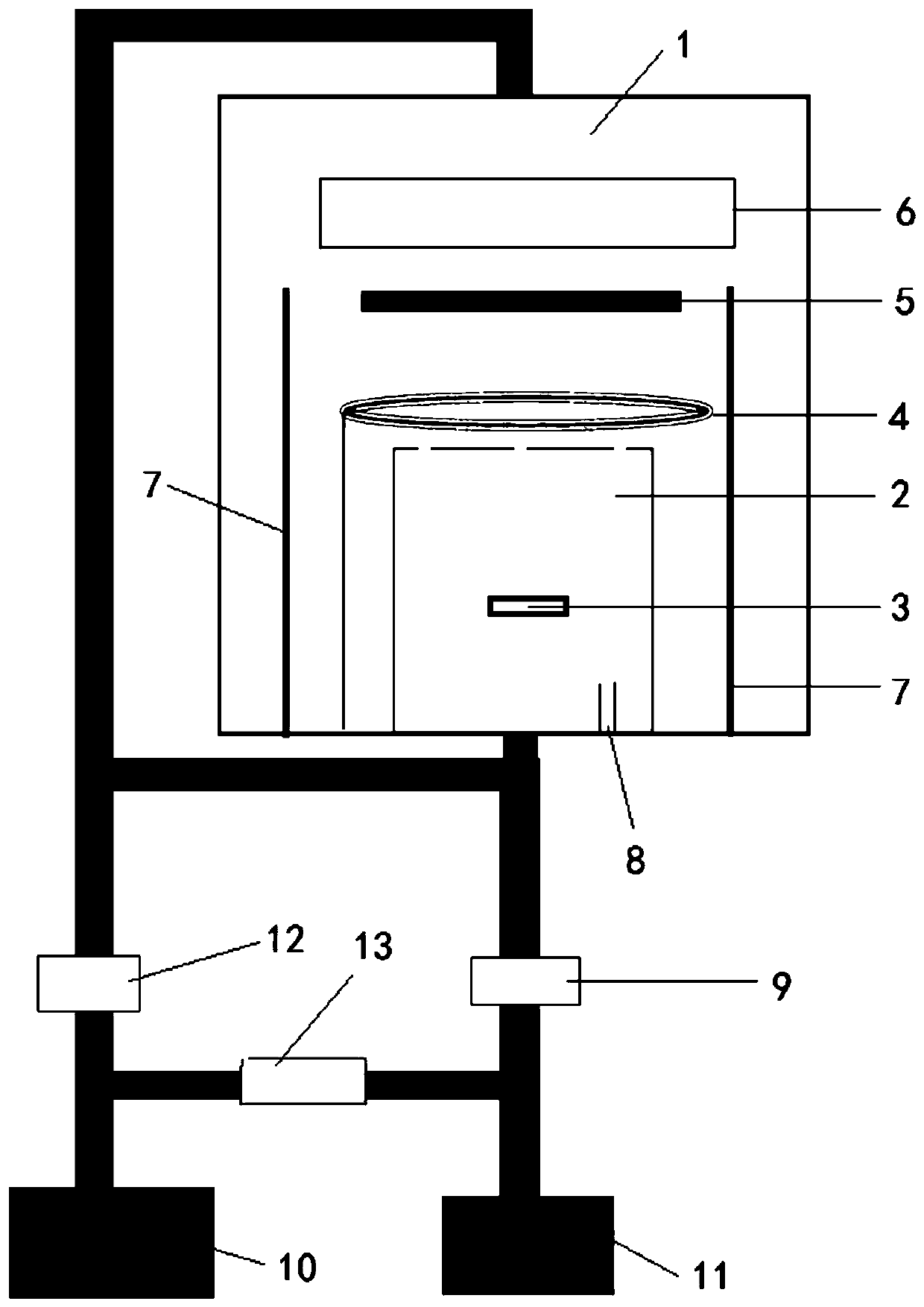

To provide a wafer inspection device which can realize an efficient configuration for suppressing an increase in footprint and can inspect a wafer with high accuracy.The wafer inspection device has a cassette part 2 and a wafer inspection part 3 including a microscope 6 and an XY stage 7 for moving the wafer 10. The cassette part 2 comprises a cassette 4 for holding the wafer 10 and an elevator 5. The wafer inspection part 3 comprises a carrying arm 18 that is arranged on the XY stage 7 to insert / extract the wafer 10 by arm pieces 181, 182 which can linearly move toward an opening of the cassette 4 and can be inserted between wafers 10 in the cassette 4, and a wafer rotary mounting base 22 which is vertically movable above the XY stage 7 to carry-in / carry-out the wafer to the carrying arm 18 by the vertical movement, a centering means for making the center of the wafer 10 and the rotary center of the wafer rotary mounting base 22 coincide with each other, and a detecting means for detecting the orientation of the wafer. (C)2004,JPO.

Owner:OLYMPUS CORP

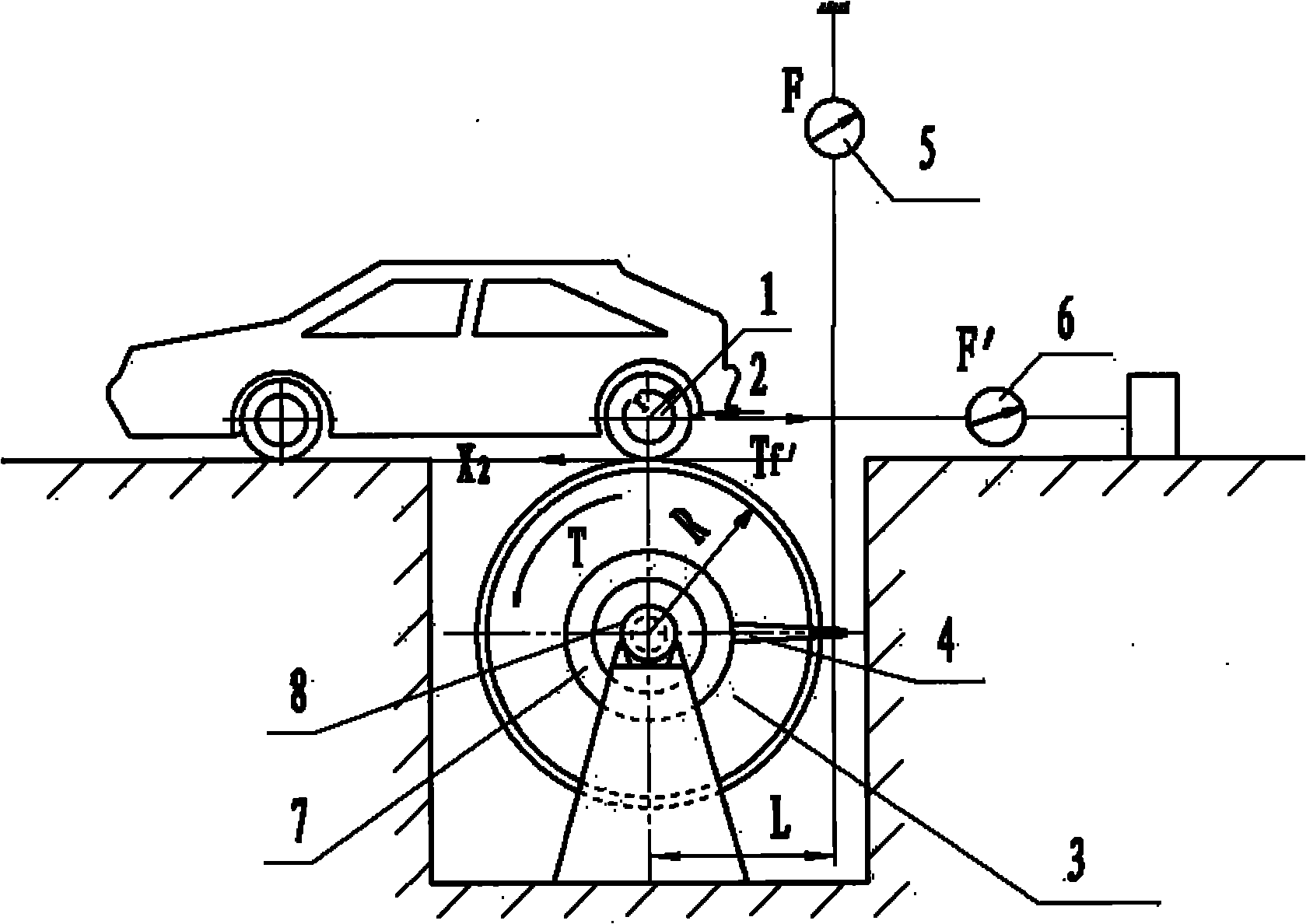

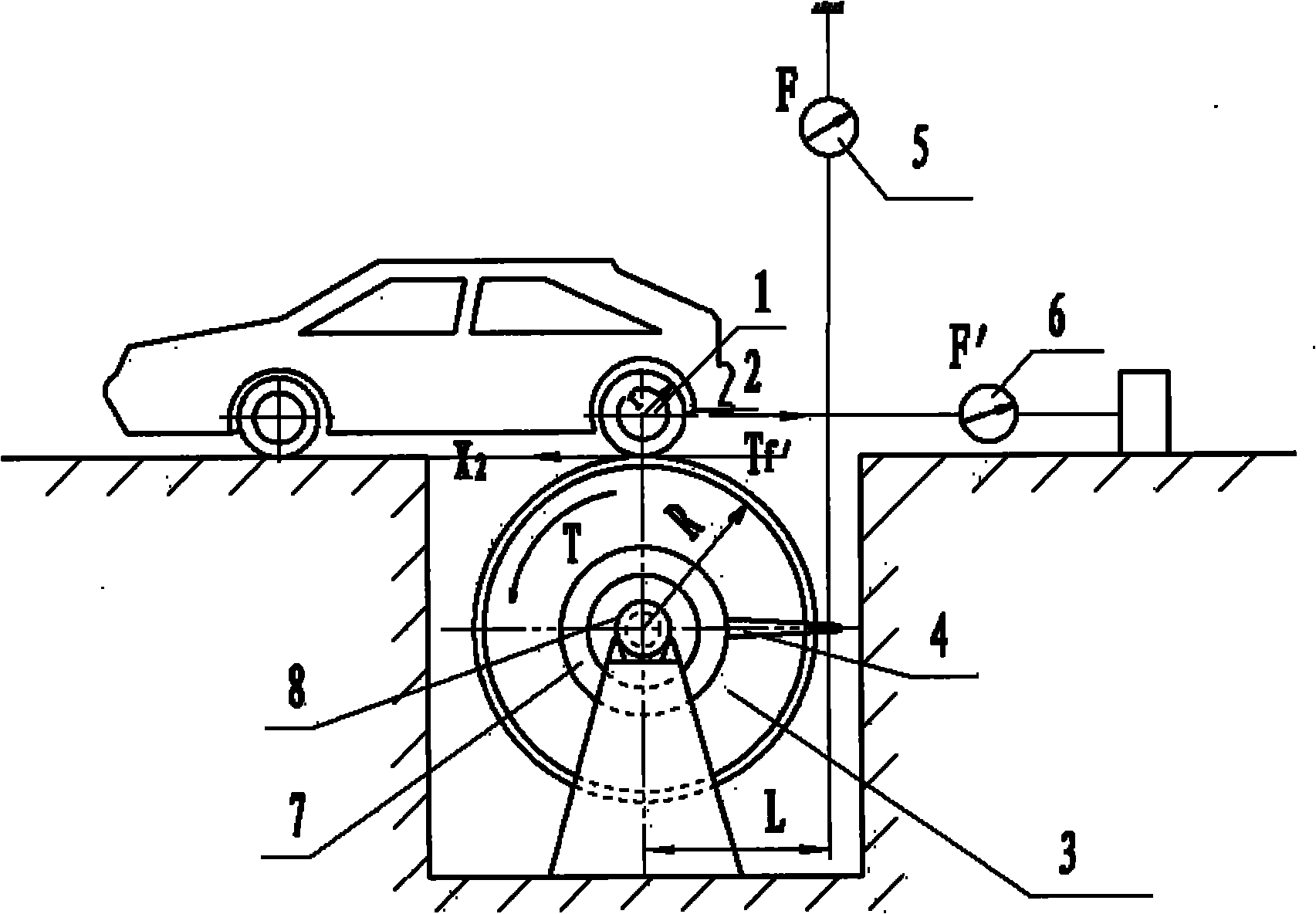

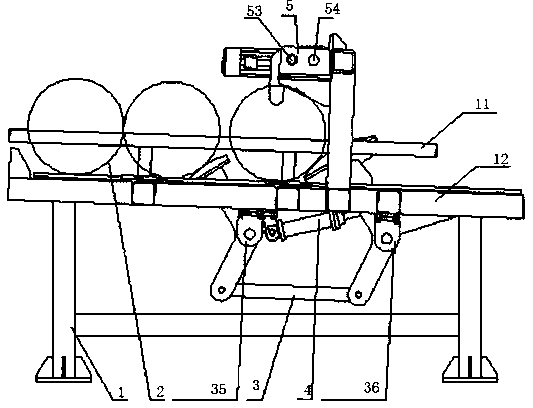

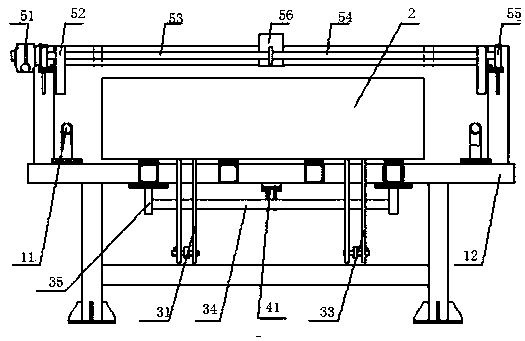

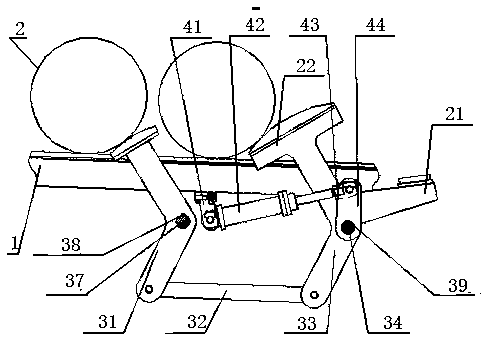

Undetached measurement device and method for transmission efficiency of automotive transmission system

InactiveCN101871845ASimple processThe equipment is compactVehicle testingMachine gearing/transmission testingMeasurement deviceDynamometer

The invention relates to an undetached measurement device and method for transmission efficiency of an automotive transmission system. The device has the advantages of accurate measurement, high efficiency, easy manufacture, and high practical value. The technical scheme of the invention is that: the device consists of a first rotating drum, a second rotating drum, an eddy current dynamometer arm, an eddy current dynamometer, a rotating drum center shaft, and a coupler, wherein the undetached measurement device for the transmission efficiency of the automotive transmission system also comprises an eddy current machine arm dynamometer, an automotive driving force dynamometer, and a speed regulating motor; an automotive rear hook is connected with the automotive driving force dynamometer through a pull rod; and the automotive driving force dynamometer is fixed on a fixed pile. The device and the method have the advantages of solving the problems of undetached measurement of automobile engine dynamic property and economical efficiency, and realizing the rapid detection of the automobile engine dynamic property and economical efficiency detection station. By combining modern computer technology, the device and the method can realize rapid display of the automobile engine dynamic property and economical efficiency detection, and print the results on the spot.

Owner:EAST CHINA JIAOTONG UNIVERSITY

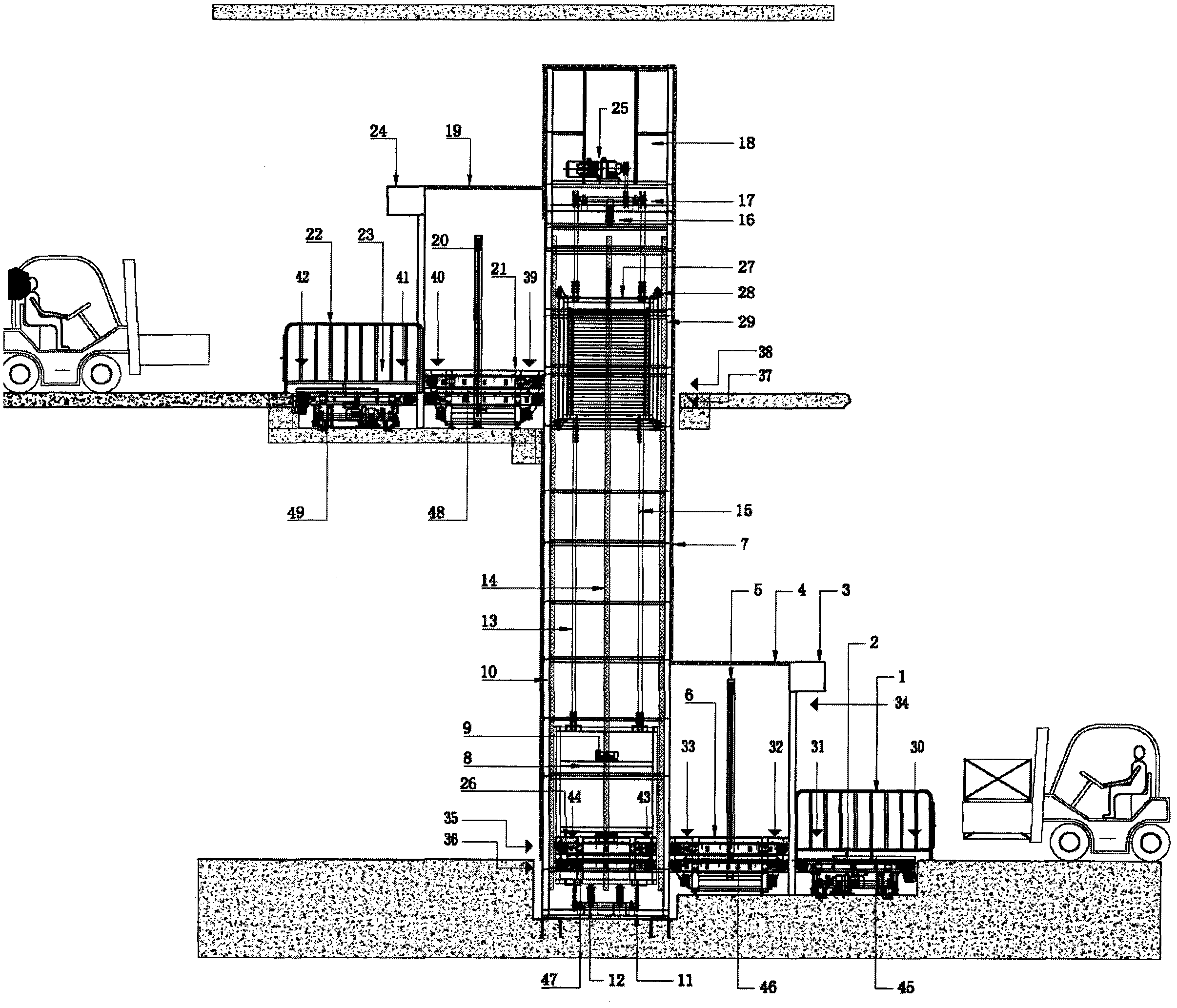

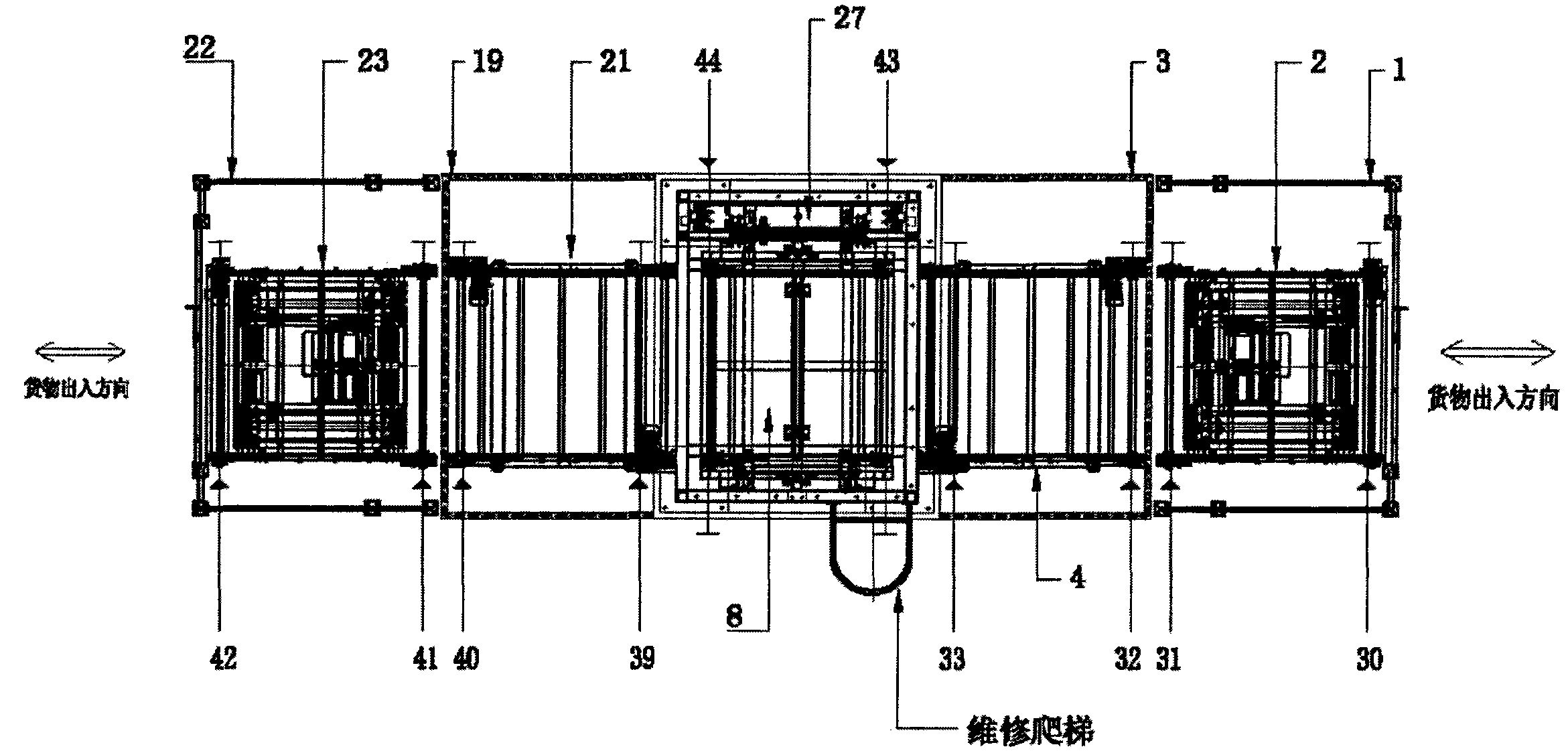

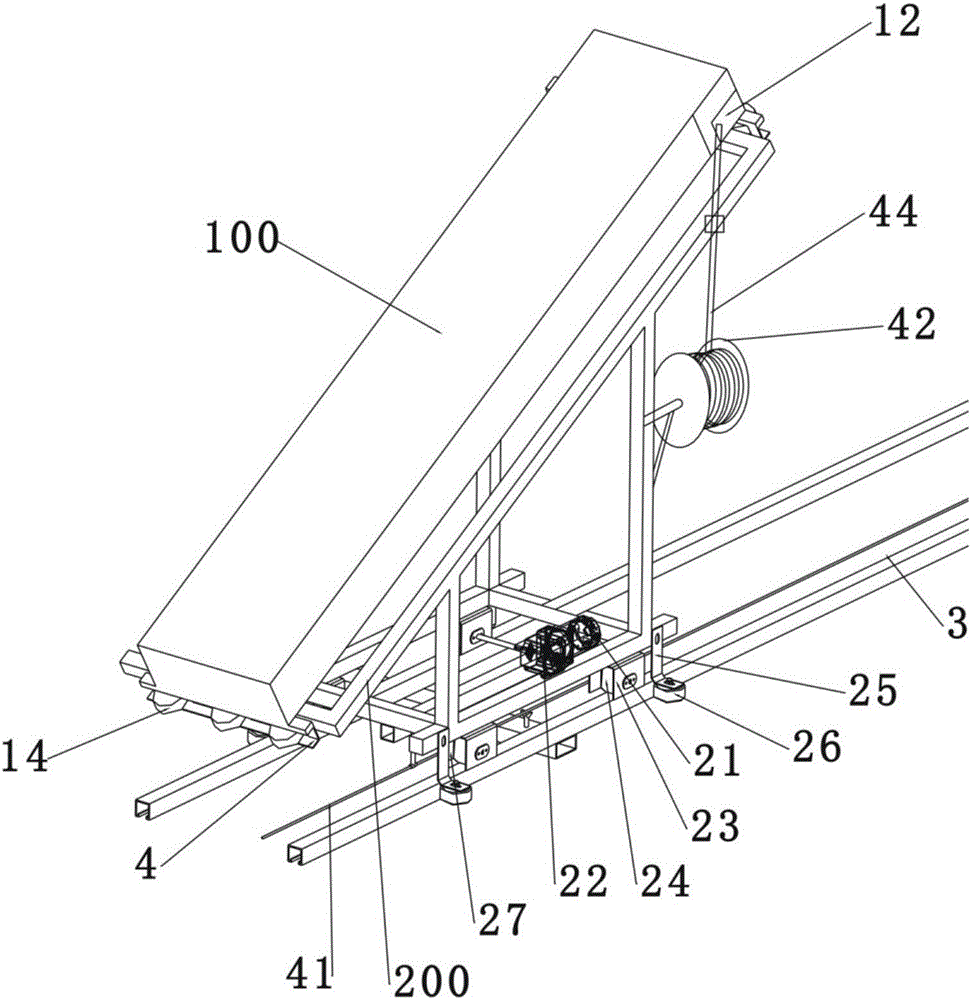

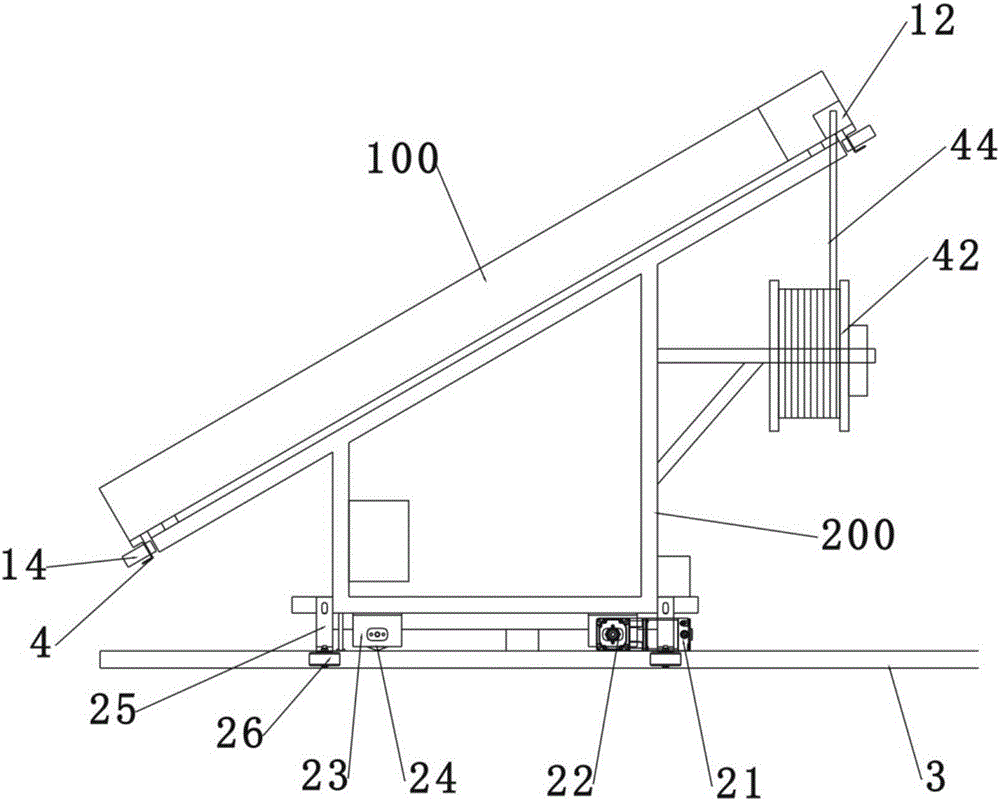

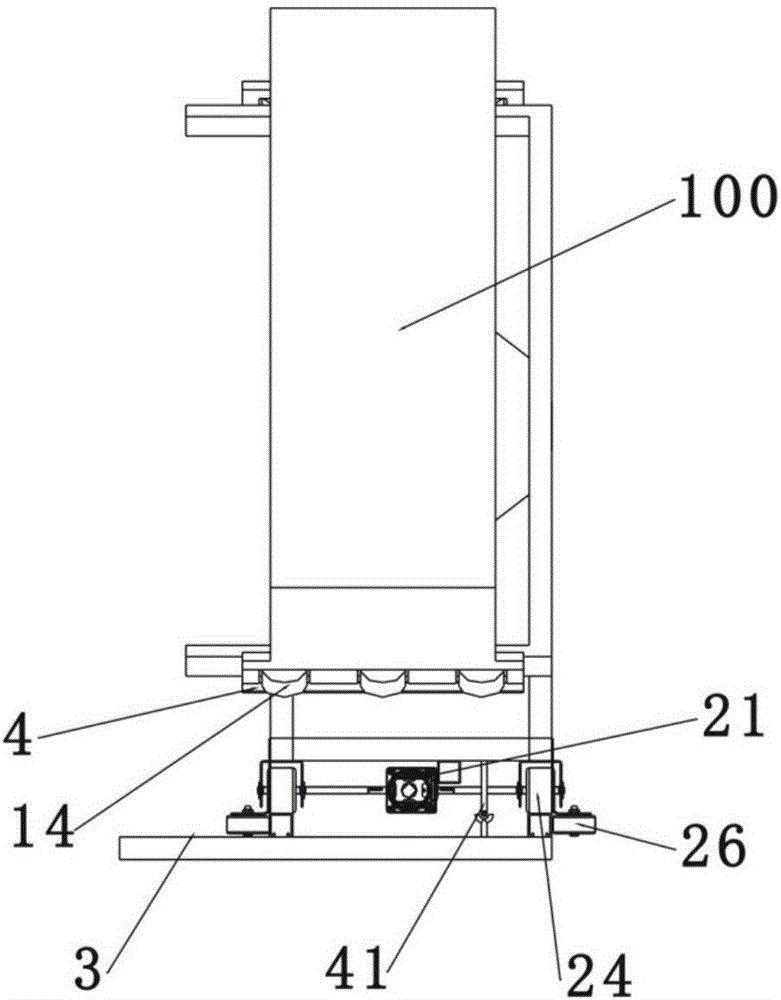

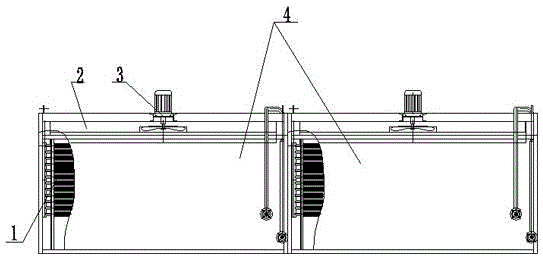

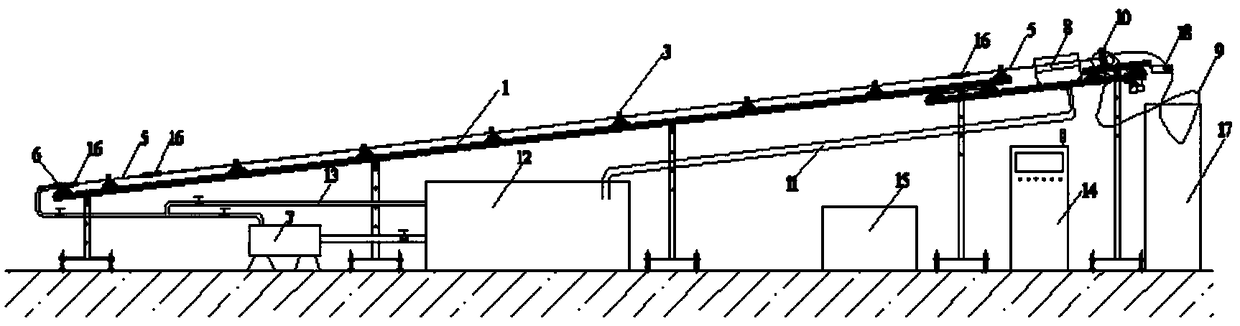

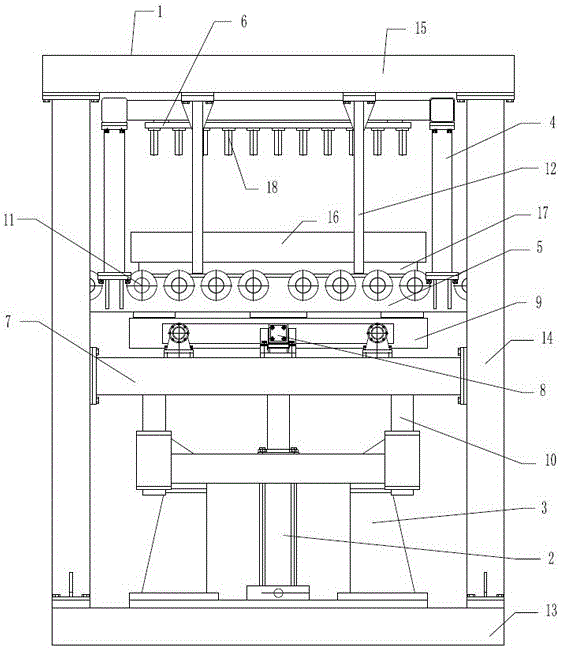

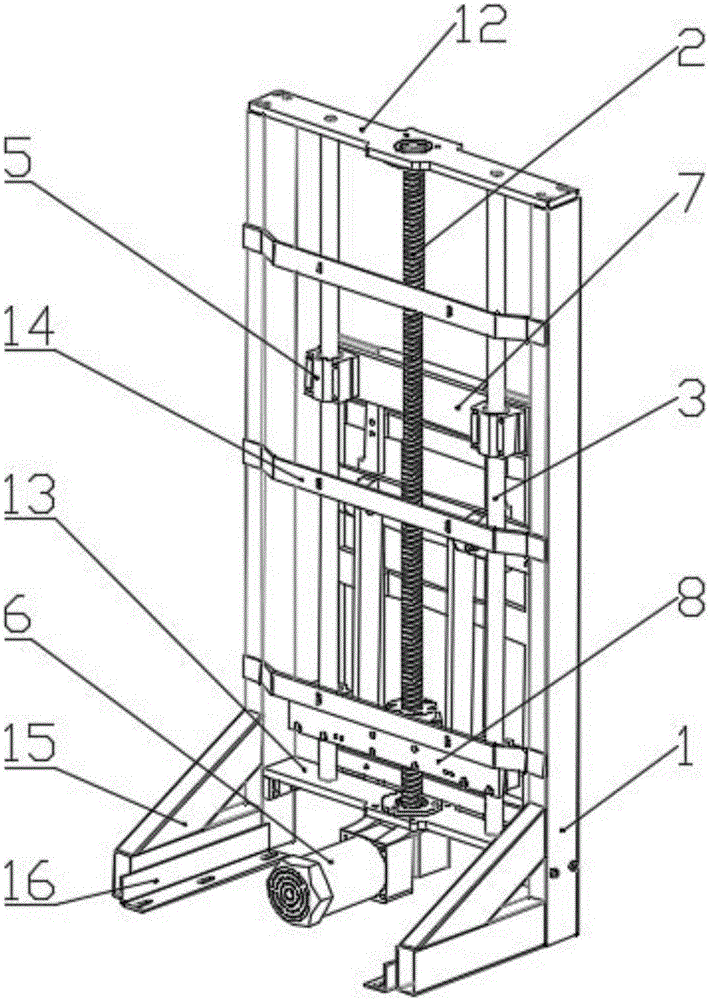

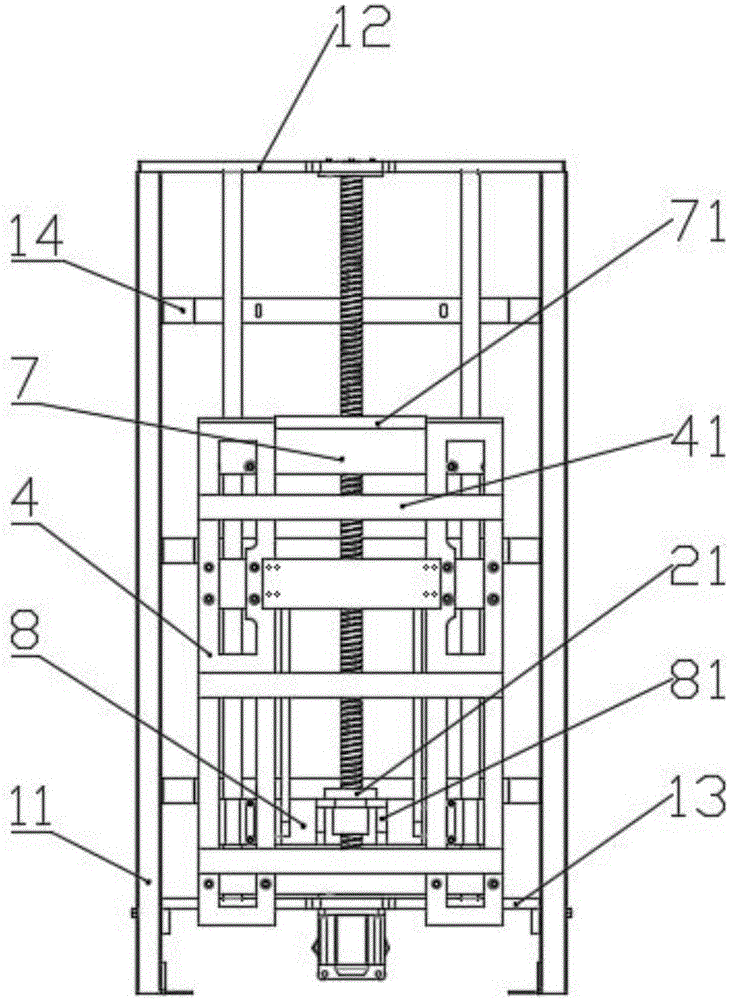

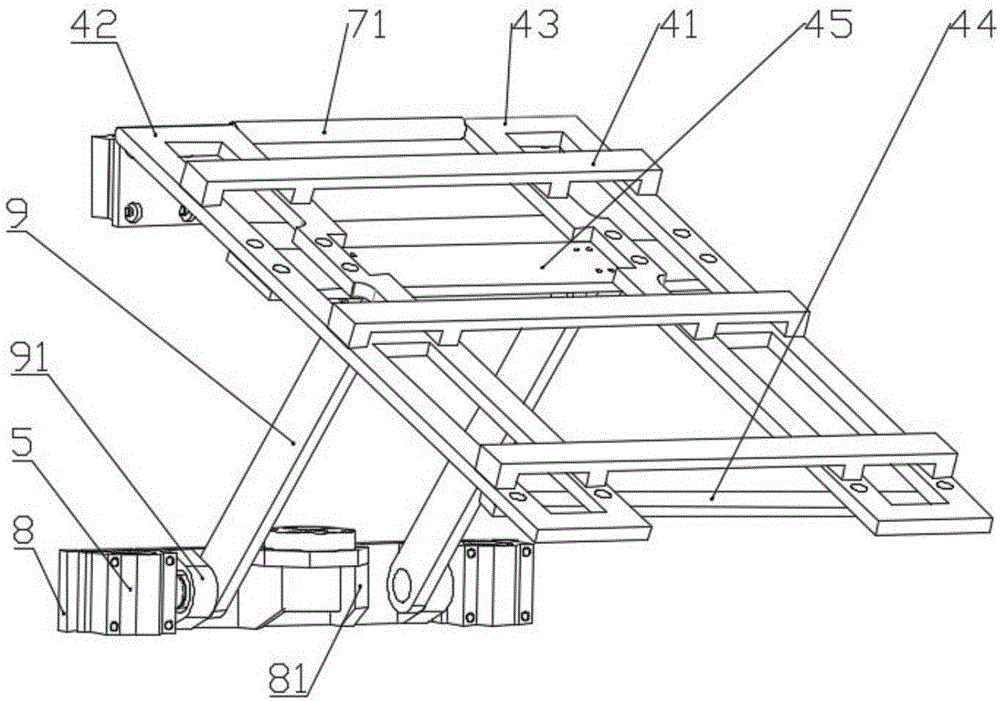

Horizontal automatic cycle tooling plate vertical conveyor

A horizontal automatic cycle tooling plate vertical conveyor comprises two groups of single chain tooling plate lifting conveying sections, two groups of fireproofing devices, two groups of double chain tooling plate lifting conveying sections, a lift car, a lift car guide wheel assembly, a machine frame, a bottom driven sprocket, a bottom anti-collision device, two groups of vertical conveying drive chains, lift car guide rails, a top anti-collision device, a top drive sprocket, a main drive motor, a double chain tooling plate lifting conveying section in the lift car, a photoelectric detection group and a tooling plate group. The horizontal automatic cycle tooling plate vertical conveyor improves the warehouse fireproofing safety and reduces the fire damage to devices and goods effectively; can achieve automatic goods conveying and automatic management of the conveying process; omits a carrying device in the goods conveying process to reduce conveying cost; reduces labors in the conveying process; improves the efficiency and the safety, and reduces the damage to goods; has a compact structure, occupies small areas, and improves the land utilization rate; and achieves vertical conveying of a variety of goods, and solves the problem of three-dimensional storing of certain goods.

Owner:谢刚

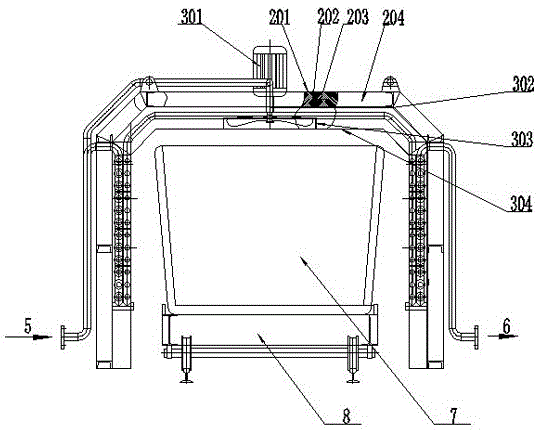

Cleaning equipment and photovoltaic module cleaning system

InactiveCN106424056AThe equipment is compactLow costPhotovoltaicsFlexible article cleaningControl systemAutomation

The invention discloses cleaning equipment and a photovoltaic module cleaning system. The cleaning equipment comprises a cleaning machine, a moving wharf, guide rails and a control system. The moving wharf is used for bearing the cleaning machine and controlled by the control system to advance along the guide rails. The cleaning machine is controlled by the control system to be capable of moving on the moving wharf. The photovoltaic module cleaning system comprises array photovoltaic panels, the array photovoltaic panels are in an m*n matrix, and m and n are each a positive integer. The guide rails are located on one side of the array photovoltaic panels. The moving wharf is located above the guide rails. The cleaning machine is loaded on a bearing frame of the moving wharf and does back and forth movement on the array photovoltaic panels through a walking mechanism. The cleaning equipment and the photovoltaic module cleaning system are simple and compact in structure, high in automation degree and cleaning efficiency and stable in operating, and the problems that in current manual cleaning, time and labor are consumed, and efficiency is low are solved.

Owner:HANGZHOU PINNET TECH CO LTD

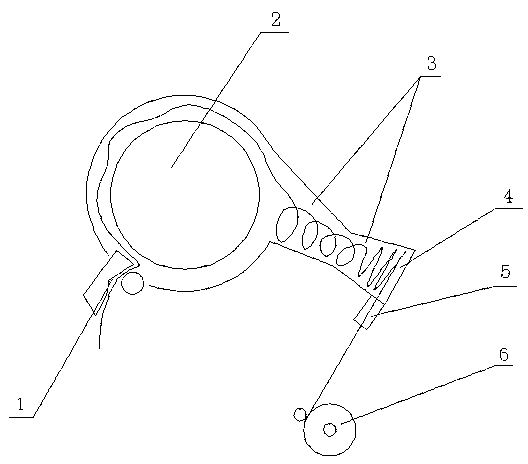

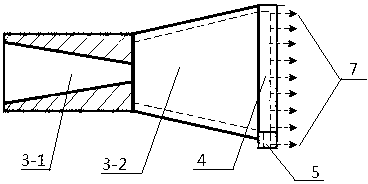

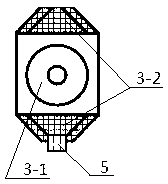

One-step spinning machine capable of conducting entwisting clockwise and one-step spinning method

ActiveCN103060963ACompactReduce power lossContinuous wound-up machinesOpen-end spinning machinesSteel platesYarn

The invention provides a one-step spinning machine capable of conducting entwisting clockwise and a one-step spinning method. The one-step spinning machine comprises a carding roller, a cover, a fiber feeding mechanism, a yarn winding mechanism and an air sucking device. The one-step spinning machine is characterized in that an irregular-shaped pipe formed by a conical pipe and a trapezoid pipe is arranged below the carding roller. The trapezoid pipe is formed by defining two trapezoid steel plates and two trapezoid mesh plates, and a U-shaped fiber cohesion area formed by a semi-circular-arc mesh plate is arranged at the outlet end of the trapezoid pipe so as to achieve cohesion of fiber in the irregular pipe. One side of the cohesion area is connected with a rotation flow entwisting pipe in butting mode, and the inner diameter of the rotation flow entwisting pipe and the U-shaped cohesion area form a straight smooth yarn channel. Compressed air enters along an air inlet hole of a lateral wall of the rotation flow entwisting pipe to form forward rotation flow to finish entwisting of strips and push the yarn to move forward. Fiber is fully separated, stretched, becomes parallel and is combined evenly on one device, and the one-step spinning machine is simple and compact in structure, convenient to machine and manufacture and low in cost. The one-step spinning method achieves purposes of high speed, high yield, high efficiency and high quality.

Owner:吴江赴东扬程化纤有限公司

Heat collection device for recycling waste heat in calcium carbide cooling process

ActiveCN105066715AThe equipment is compactEasy to installIncreasing energy efficiencyHandling discharged materialWorkloadUranium carbide

The invention discloses a heat collection device for recycling waste heat in the calcium carbide cooling process. The heat collection device comprises a heat collection module. The heat collection module comprises a main frame, a heat exchange pipe bundle assembly and a circulating fan assembly. The circulating fan assembly is installed on the top of the main frame. The main frame is fixed to an installation face, and the section of the main frame is of an n structure. A cavity defined by the main frame forms a channel through which a carrier vehicle passes. The tunnel heat collection device for recycling waste heat in the calcium carbide cooling process has the advantages of not changing the original production technology process or production site layout, being compact and reasonable in structure and easy to install, overhaul and replace, saving device maintenance cost and the like; on-site maintenance workloads are reduced, the device maintenance halt time is shortened, and production cost is reduced.

Owner:LONGHUA TECHNOLOGY GROUP (LUOYANG) CO LTD

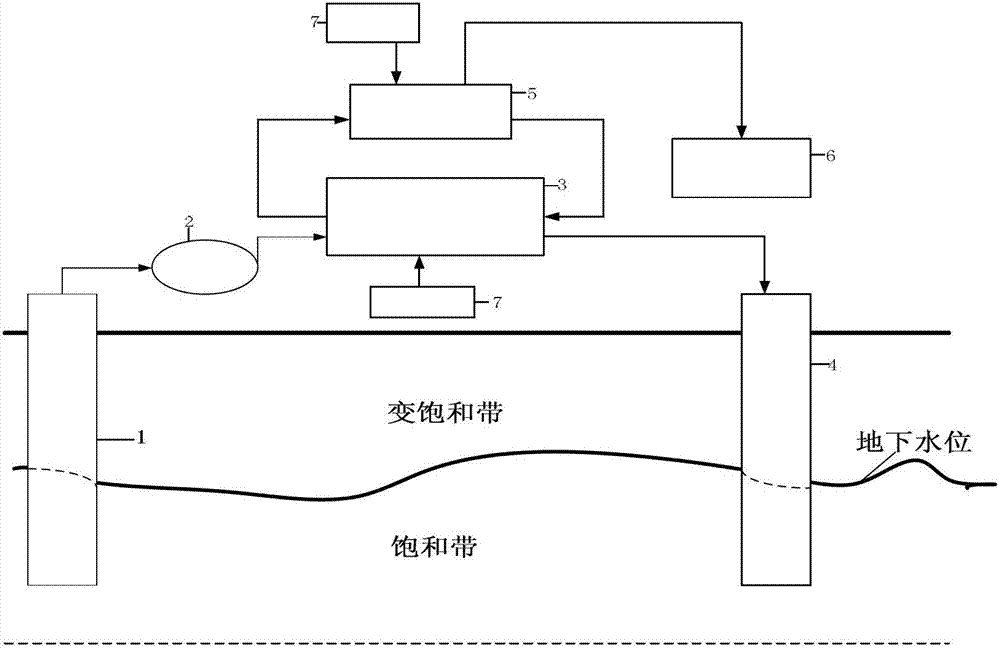

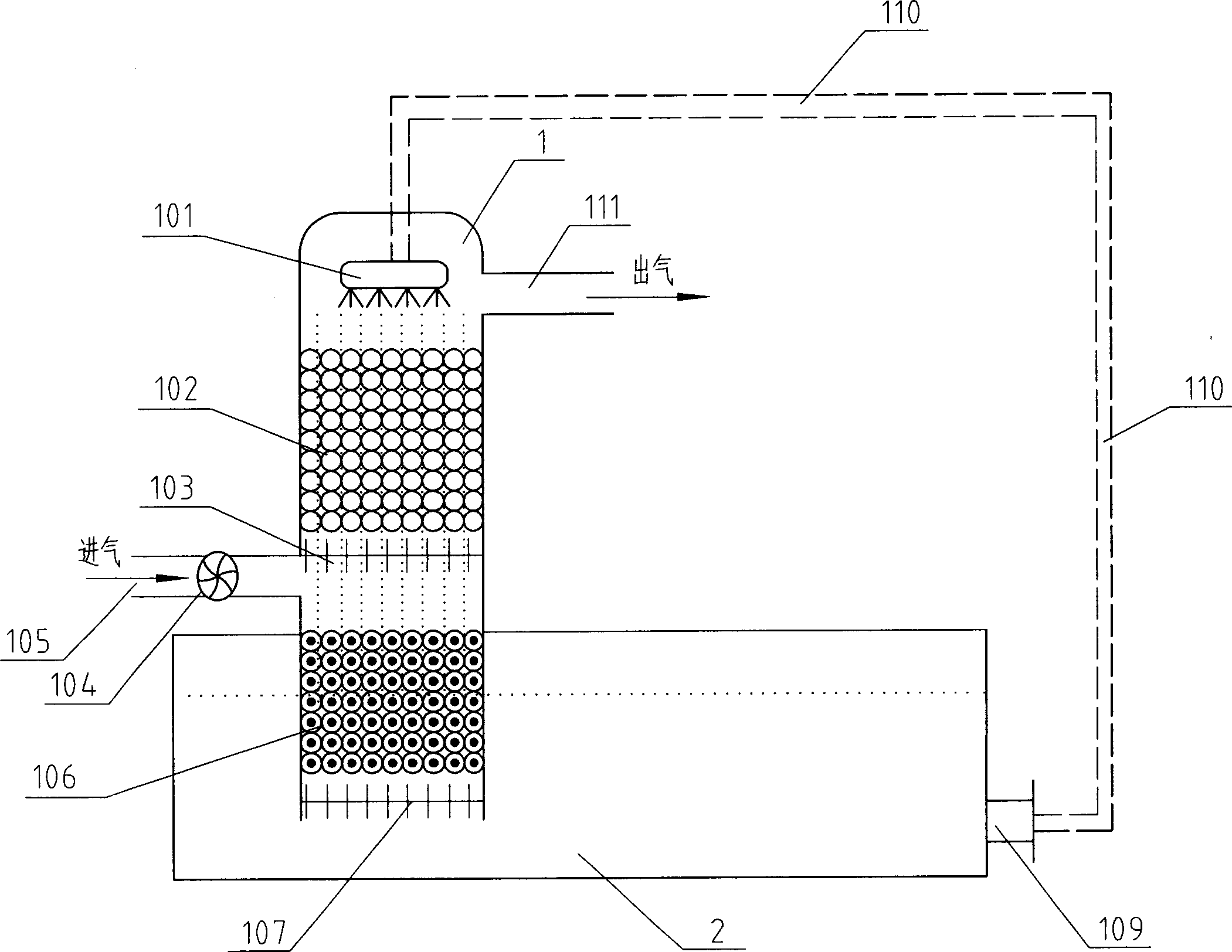

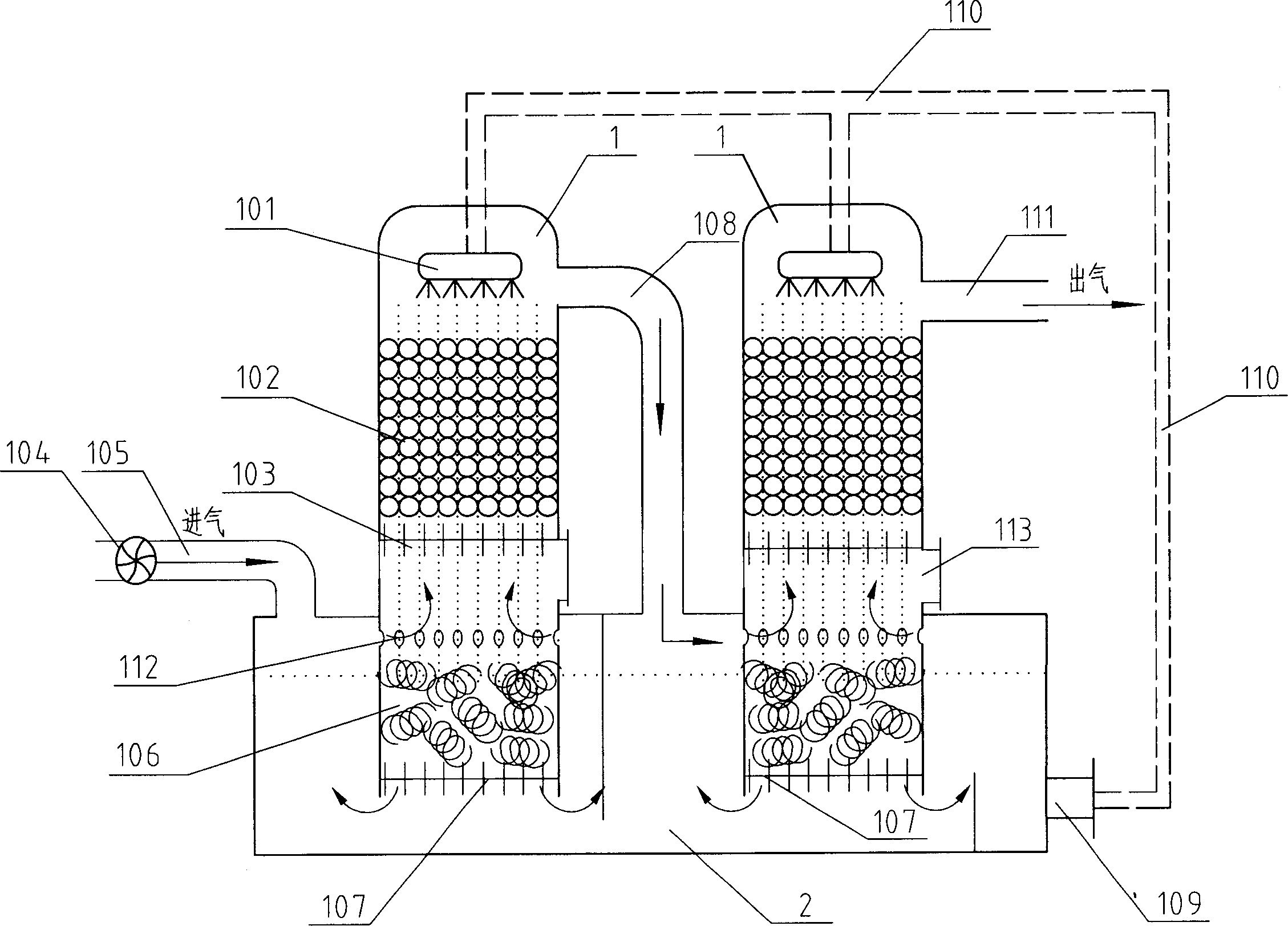

Ectopic pump circular processing system and method for reactive additives of tea saponin

ActiveCN103043822AThe equipment is compactEasy to operateMultistage water/sewage treatmentContaminated groundwater/leachate treatmentChemistryWater delivery

The invention belongs to the technical field of repair of environment polluted by heavy metal, and particularly relates to an ectopic pump circular processing system and method for reactive additives of tea saponin. The invention adopts the scheme that a pumping well is connected with a circular reactor through a transmission pump, and a water delivery well is connected with the circular reactor; the circular reactor is connected with a decomplexing separation and recovery reactor through two pipelines; the circular reactor and the decomplexing separation and recovery reactor are respectively connected with a dosing device; and the decomplexing separation and recovery reactor is connected with a heavy metal collector. According to the invention, heavy metal sewage reacts with the tea saponin, the tea saponin is separated from the heavy metal through heavy metal catching agent N-915, NH3-N type heavy metal precipitator or alkali in a decomplexing way, and heavy metal sewage is delivered to the heavy metal collector for sedimentation and collection. The method is suitable for processing the quality of groundwater polluted by heavy metal, outlet water after being processed has good quality, the removal rate of heavy metal is more than 96%, and main pollution indexes conform to first grade of National Comprehensive Wastewater Discharge Standard.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

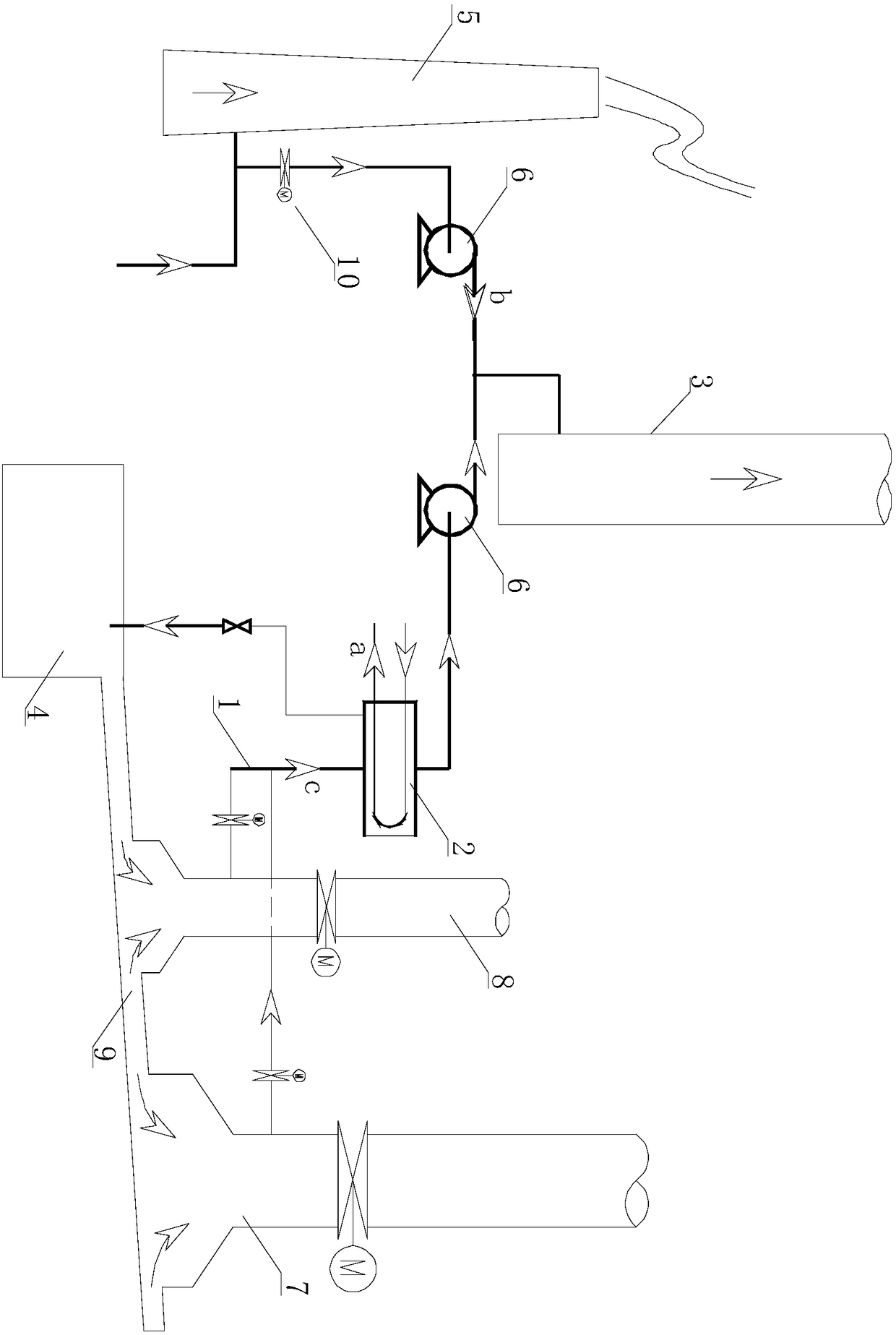

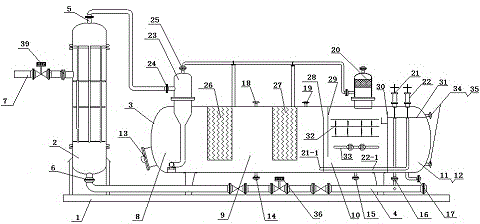

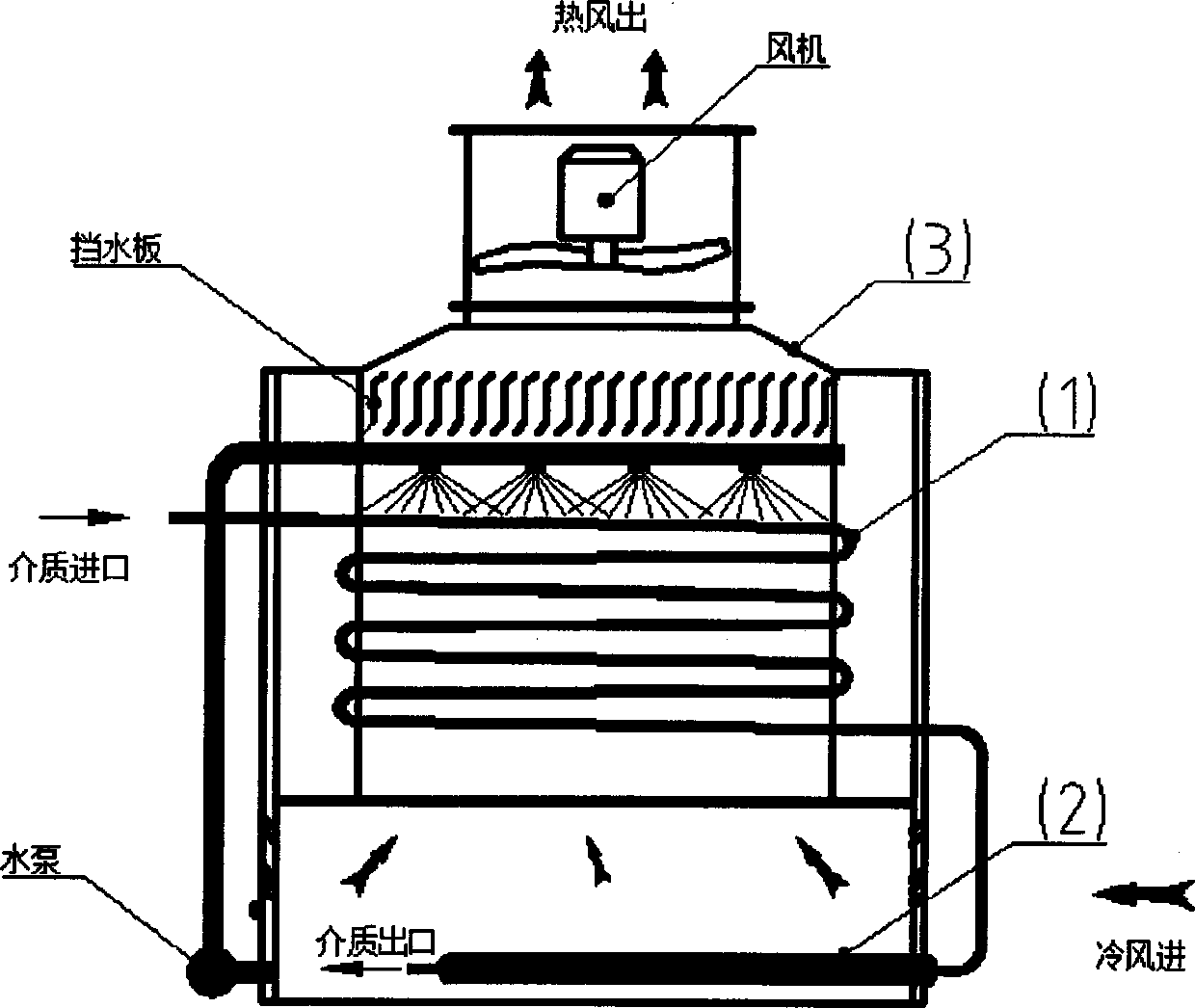

Blast furnace slag flushing steam white elimination system

InactiveCN108411055AGood effectThe equipment is compactExhaust gas handlingProcess efficiency improvementQuenchingSlag

The invention relates to the field of steel plant smoke plume white elimination, in particular to blast furnace slag flushing steam white elimination system which comprises a slag flushing steam collection pipe section, a slag flushing steam condenser and a slag flushing steam discharge chimney; the slag flushing steam collection pipe section is used for collecting slag flushing steam; the slag flushing steam condenser is connected with the slag flushing steam collection pipe section and introducing a cold medium to condense the slag flushing steam introduced by the slag flushing steam collection pipe section; and the slag flushing steam discharge chimney is connected with a slag flushing steam outlet of the slag flushing steam condenser and is used for introducing a mixed hot gas to be mixed with the slag flushing steam and discharging the mixed gas. For the blast furnace slag flushing steam white elimination system, by utilizing blast furnace wall cooling water to cool the slag flushing steam and utilizing a hot air furnace smoke to be mixed with the slag flushing steam which is not cooled to form unsaturated smoke, the technical problem that white smoke plume is eliminated in the water slag flushing treatment technology by adopting a water quenching method is solved, and the environmental protection problem is solved.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

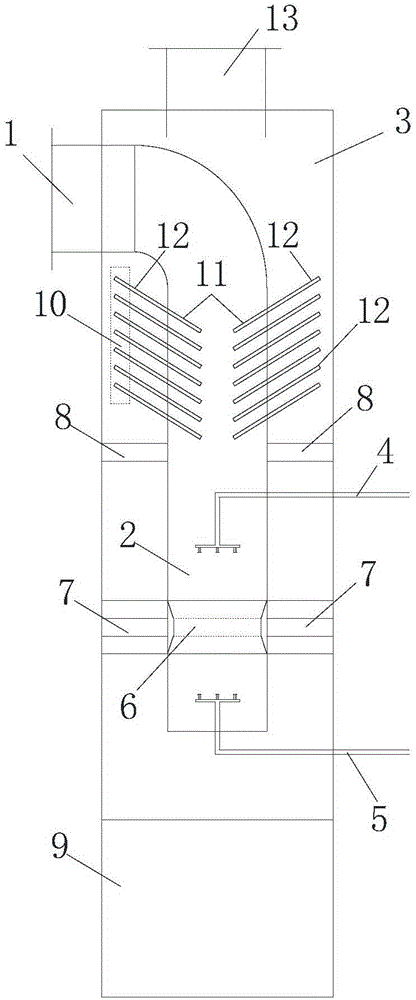

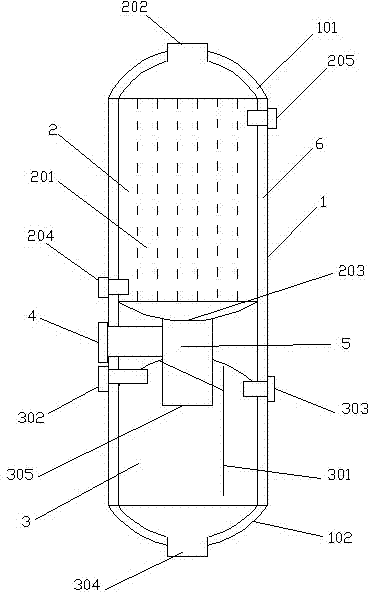

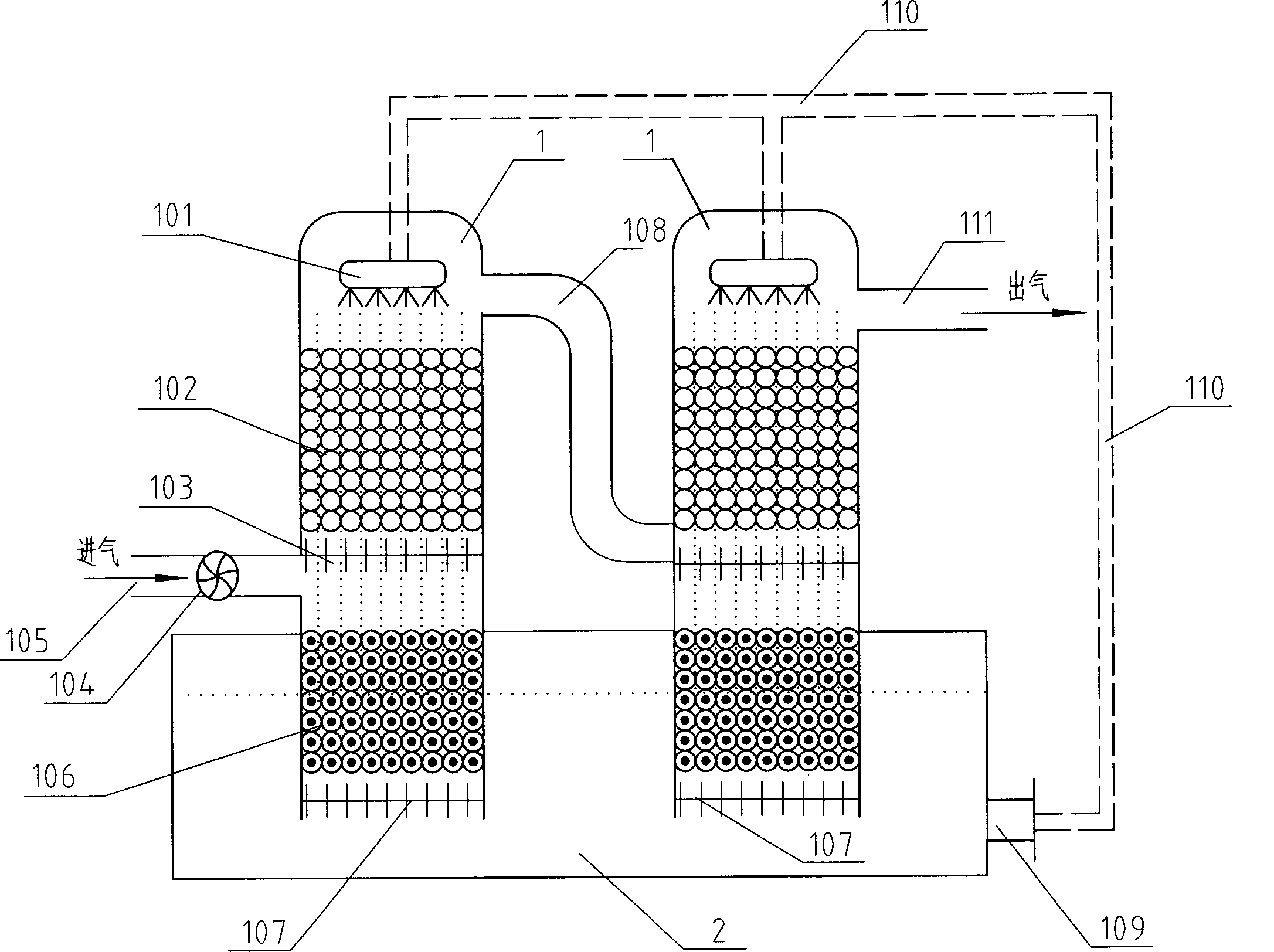

Wet smoke self-temperature returning integrated smoke purification device and application thereof

The invention relates to a wet smoke self-temperature returning integrated smoke purification device and an application thereof. The device comprises a washing tower outer barrel, a smoke outlet, an absorbing liquid storing cavity and a gas inlet flue extending barrel, the smoke outlet is disposed at the top of the washing tower outer barrel, the absorbing liquid storing cavity is arranged below the washing tower outer barrel, the gas inlet flue extending barrel is connected with the side of the washing tower outer barrel and extends to inside of the washing tower outer barrel, a smoke inlet is arranged at the front end of the gas inlet flue extending barrel, a same-direction fair current spraying head and a reverse spraying head are arranged inside the gas inlet flue extending barrel, directions of liquid drop sprayed by the same-direction fair current spraying heads and smoke flowing direction are the same, vertical opposite spraying is formed with the reverse spraying heads, and foam induction rings are arranged between the same-direction fair current spraying heads and the reverse spraying heads. According to the wet smoke self-temperature returning integrated smoke purification device and the application thereof, multiple functions such as dust removing, desulfuration, defogging and smoke heat exchange are integrated, device structure is compact, the floor space is small, the problems of 'white smoke' or chimney rain of wet purification smoke can be remarkably eliminated, and influence of smoke discharging on surroundings or vision can be reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

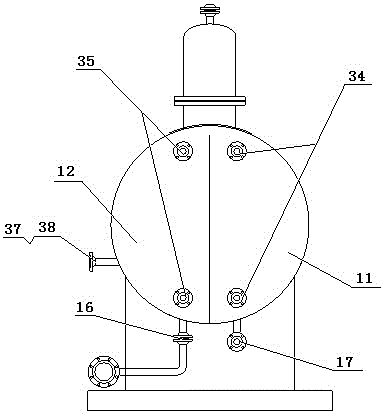

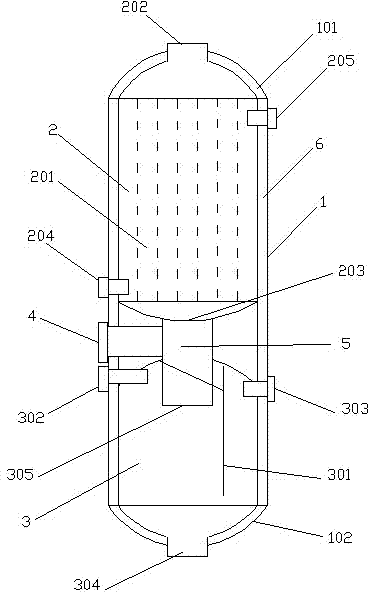

High-frequency electric coalescence type high-efficiency oil-gas-water three-phase separator

PendingCN106032473AThe equipment is compactImprove dehydration efficiencyTreatment with plural serial refining stagesElectric fieldSettling chamber

The invention provides a high-frequency electric coalescence type high-efficiency oil-gas-water three-phase separator. The separator comprises the following components: a base (1), a cyclone (2), a horizontal tank (3) and a pollution discharge system. The cyclone (2) is placed at an inlet side of the horizontal tank (3), and a cyclone oil phase outlet (5) is connected to a separating cylinder inlet (24); the horizontal tank (3) is separated into a primary separation chamber (8), a settling chamber (9), an electric dehydration chamber (10), an oil chamber (11), and a water chamber (12); and the pollution discharge system (4) is connected to a cyclone water outlet (6) and a water outlet (16). The volume of the separator tank is effectively reduced, and the separator has the advantages of compact structure, high dehydration efficiency, etc. The phenomenon 'reserved electric field' which is easy to appear in conventional electric dehydrators is overcome, and at the same the problem that the treatment effects do not reach the standard existed in the conventional oil-gas-water three-phase flow separator is solved.

Owner:李庆银

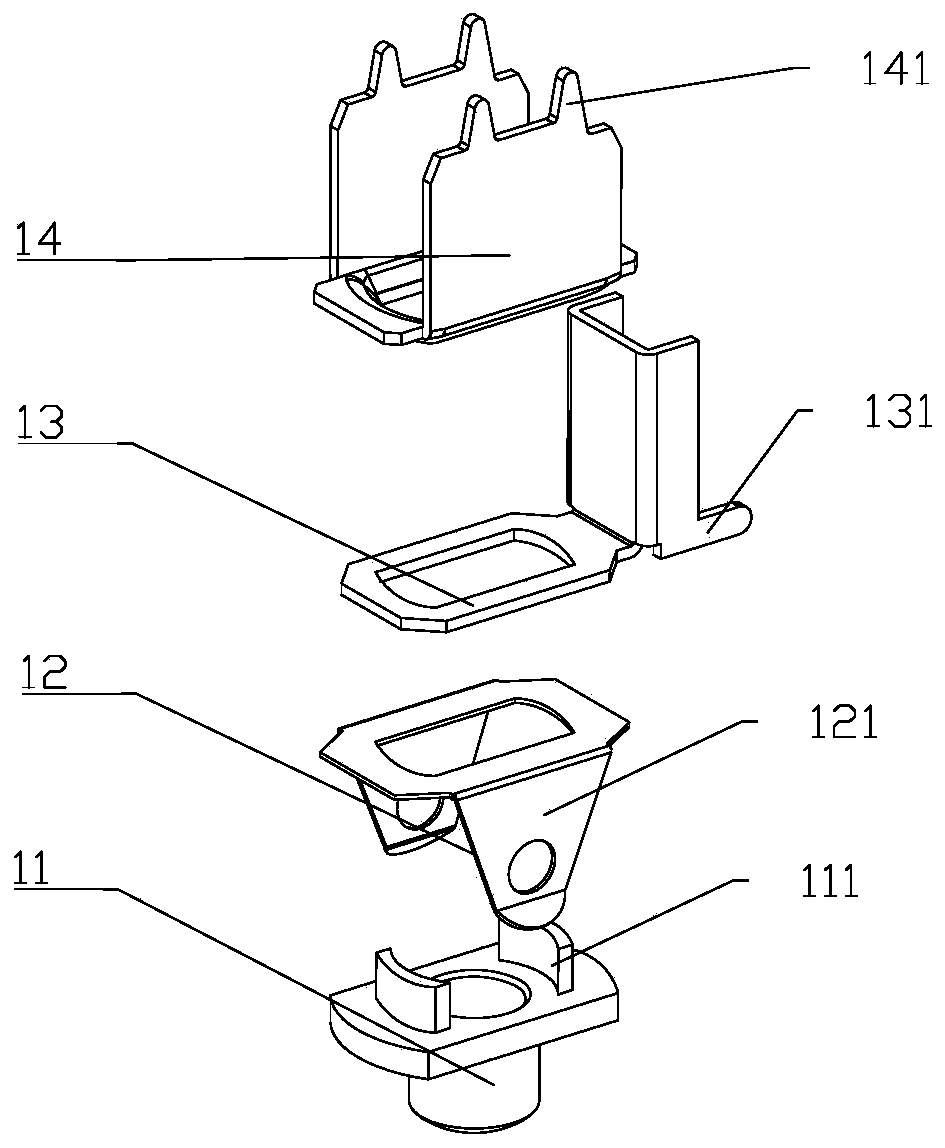

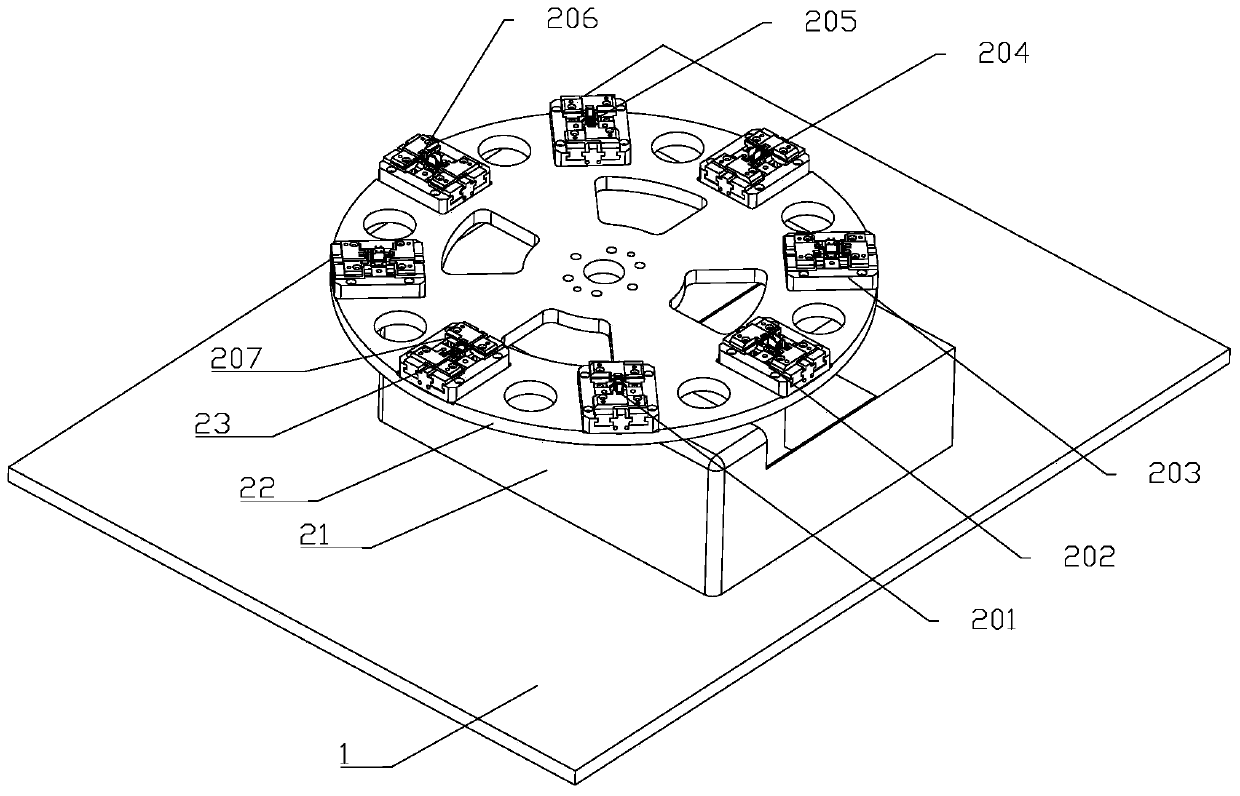

Turntable jig device of wire connector production equipment

ActiveCN110802401AThe equipment is compactEfficient transportAssembly machinesMetal working apparatusEngineeringManufacturing engineering

The invention relates to the technical field of electronic connector production. A turntable jig device of wire connector production equipment comprises a divider, a turntable and a plurality of groups of jigs, wherein the divider is mounted on a rack; the turntable is mounted at the output end of the divider; the jigs are uniformly distributed on the periphery of the turntable; and a wire connector mounting station, a positioning piece mounting station, a side clamping piece mounting station, a bottom clamping piece mounting station, a detection station, a riveting station and a discharging station are correspondingly arranged on the turntable jig device. The turntable jig device adopts turntable type assembly, the jig positioning precision is high, and the stations are efficiently switched.

Owner:楼显华

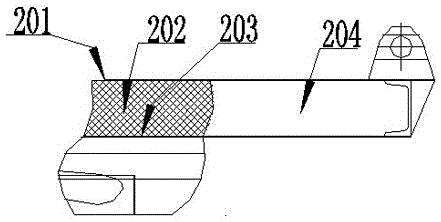

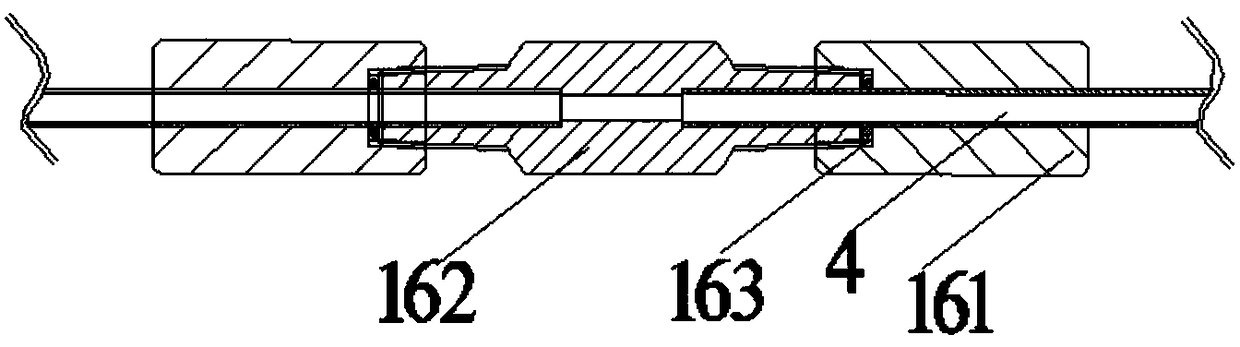

Novel sleeve isolating and releasing device and using method thereof

PendingCN109650132AThe equipment is compactEasy to operateConveyor partsWebs handlingAction functionEngineering

The invention discloses a novel sleeve isolating and releasing device and a using method thereof. The device is composed of a rack, a sleeve, a connecting rod mechanism, a power source and a centeringmechanism, wherein the sleeve is stored on the rack, the upper surface of the rack is an inclined surface, and the connecting rod mechanism is arranged on the rack; an oil cylinder is arranged belowthe rack and is used for driving the connecting rod mechanism to move; and the centering mechanism is arranged above the sleeve and the rack, and is used for carrying out centering operation on the sleeve at the isolation position. According to the device, one power source and one connecting rod mechanism are utilized to achieve two action functions of isolating and releasing of the sleeve at thesame time, so that the device is simple, convenient and reliable to operate, and compact in structure; and meanwhile, the device cost is reduced, and the economic benefits of factories are improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

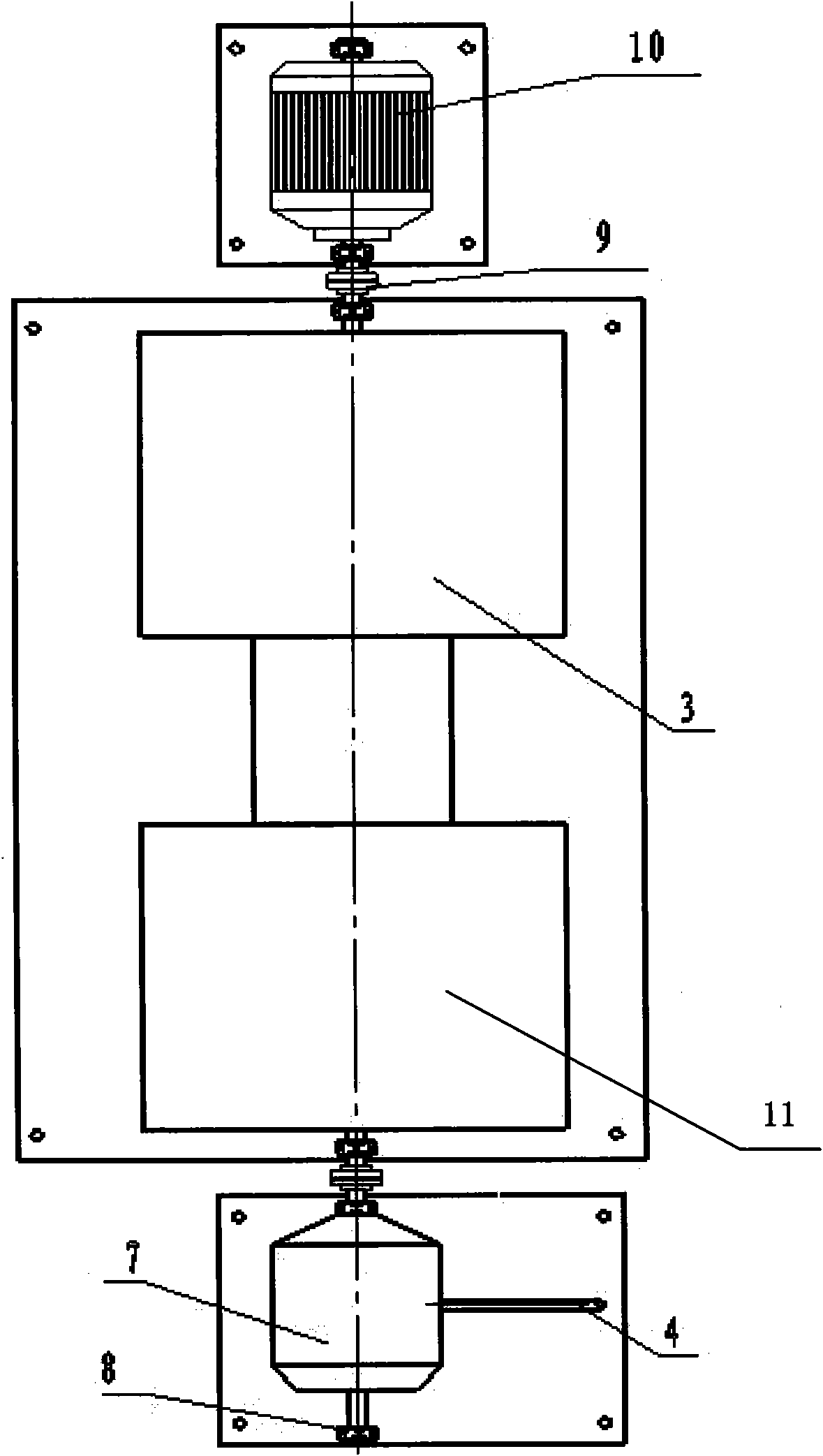

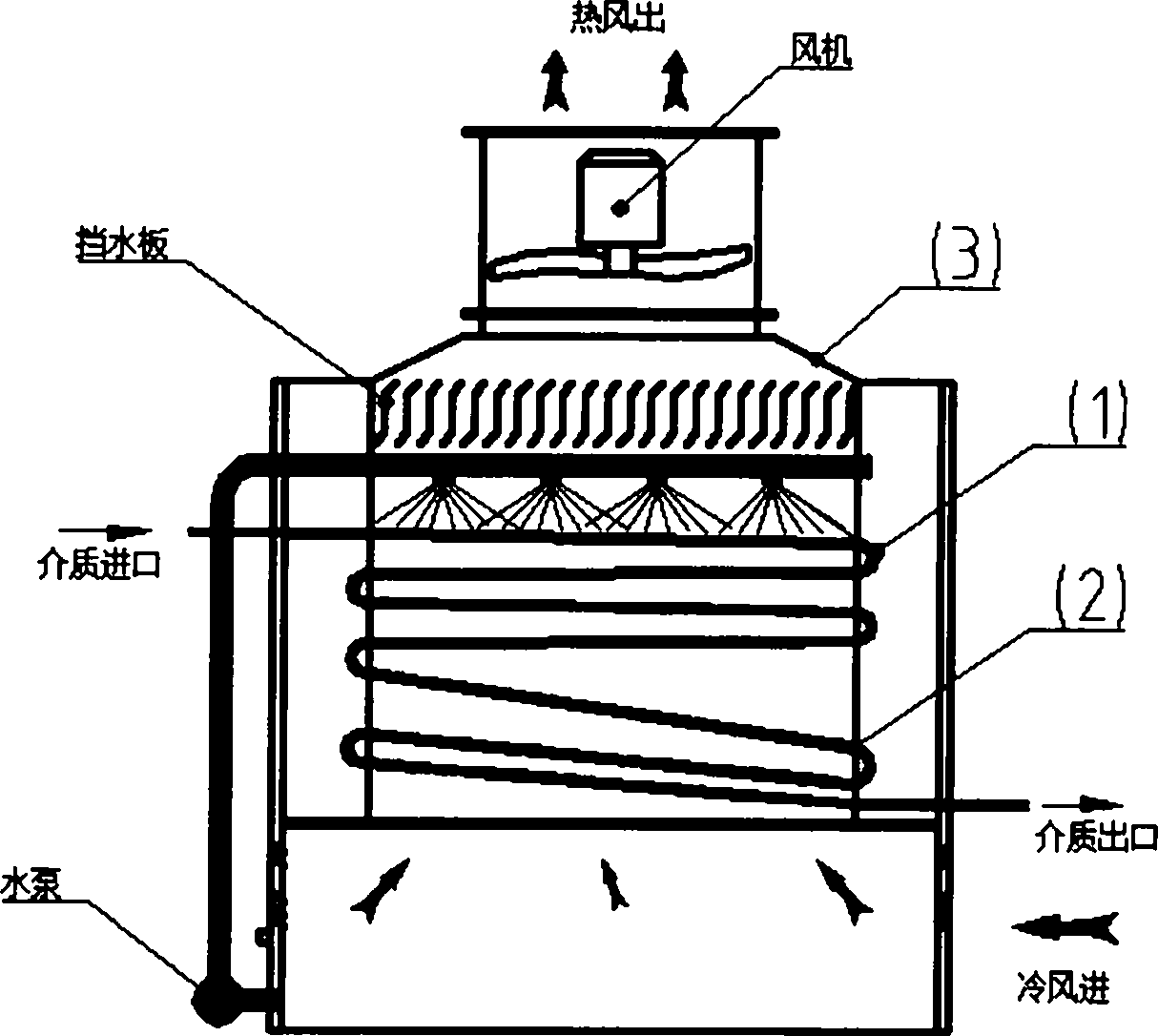

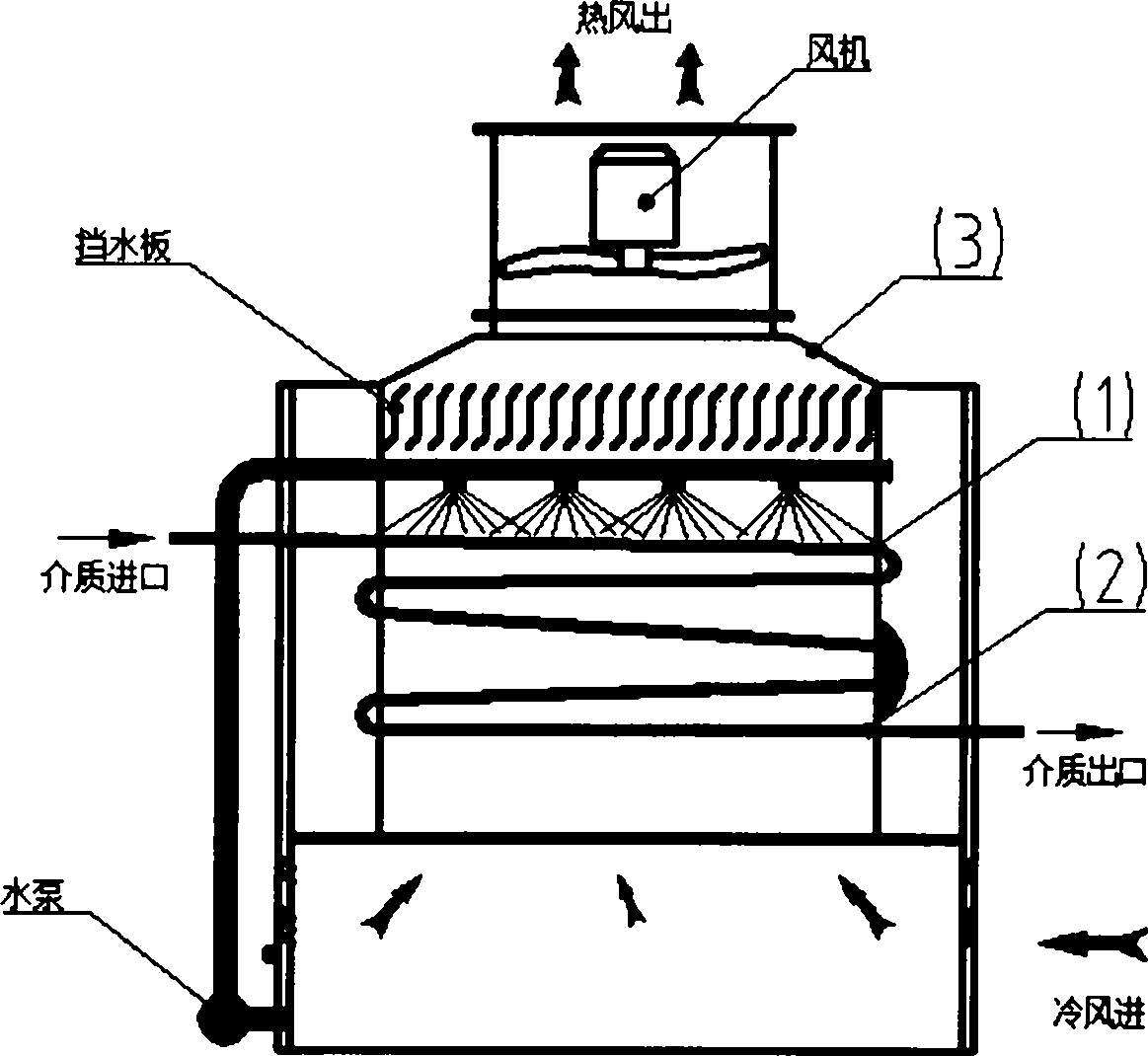

Condenser with cooler

InactiveCN104197738AThe equipment is compactSmall footprintSteam/vapor condensersEngineeringSupercooling

A condenser with a cooler allows supercooling of a medium is characterized in that a supercooler is serially connected to the rear of a condensing coil and serves as the cooler for use after medium condensation, and the cooler continues to cool the medium which is condensed by the condensing coil. The condenser is generally composed of a coil inclining down, all parts of the coil are equal in flow sectional area, gaseous fluid and liquid fluid flow by an outlet necessarily, and the medium requiring all-condensation and supercooling is not cooled but condensed. The condenser with the cooler is a novel device integrating the condensing coil and the supercooler in a series manner; the novel device is capable of continuing to cool the medium on the premise that the medium is all-condensed, and the design requirements are met accordingly.

Owner:CHONGQING SHUDONG TIANYI AIR COOLER

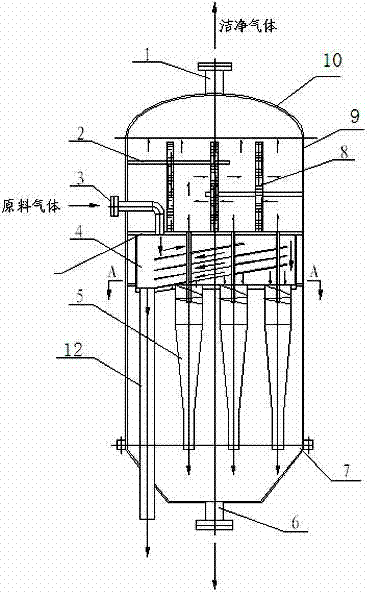

Agglomerate cyclone separator

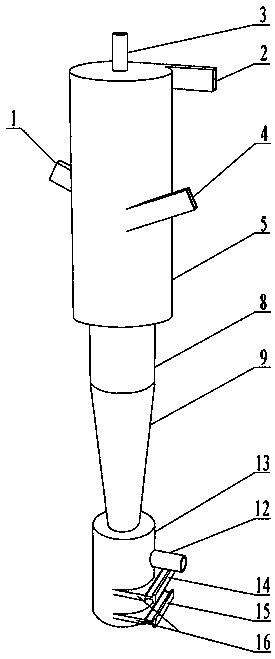

ActiveCN102872668AImprove separation efficiencyThe equipment is compactCombination devicesCyclonic separationSmall footprint

The invention relates to an agglomerate cyclone separator which is characterized by comprising a vertical outer cylinder body, a louver separator, a plurality of cyclone pipes and a plurality of agglomerate filter elements, wherein the outer cylinder body is axially divided into an agglomerate filtering area, an inertial separating area and a cyclone separating area from top to bottom; the louver separator is internally arranged in the inertial separating area; a natural gas inlet which stretches out of the side wall of the outer cylinder body is arranged at the top end of the louver separator, and a louver separator exhaust port is arranged at the bottom of the louver separator; the cyclone pipes are arranged vertically and are internally arranged in the cyclone separating area; an air inlet of each of the cyclone pipes is communicated with an exhaust port of the louver separator, a bottom flow port of the cyclone pipe stretches into an ash bucket, and an overflow port of the cyclone pipe stretches into the agglomerate filtering area; the agglomerate filter elements are arranged in the agglomerate filtering area; and the agglomerate filter elements are arranged at overflow ports of the cyclone pipes. Through skillful combination of various separators, the agglomerate cyclone separator disclosed by the invention can be applied to occasions in which larger particles and liquid drops can appear suddenly, and in addition, the agglomerate cyclone separator is high in separation efficiency, compact in equipment structure, and small in occupied area.

Owner:MORIMATSU (JIANGSU) HEAVY IND CO LTD

Electropolishing device for inner wall of stainless steel pipe

ActiveCN108570705AThe equipment is compactSmall footprintElectrolysis componentsCentrifugal pumpSmall footprint

The invention provides an electropolishing device for inner wall of stainless steel pipe, the upper end of the device is provided with a copper anode unit frame, the copper anode unit frame has an inclination angle of 5 to 15 degrees, and extension steel pipes are connected to both ends of a steel pipe, the left end of the extension steel pipe at the left end is provided with an electrolyte distributor, the electrolyte distributor is connected with a high-lift centrifugal pump through a pipeline, the right end opening of the extension steel pipe at the right end is connected with a collector,a flexible cathode is arranged in the steel pipe, a return pipe connected with an electrolyte tank is arranged at the bottom of the collector, a pressure relief pipeline is arranged between the upperend of the electrolyte tank and the outlet of the high-lift centrifugal pump, and a fully automatic control host and a high frequency pulse rectifier are arranged at the bottom of the right side of the copper anode unit frame. The device has compact structure, small floor space, high processing efficiency, good processing quality, convenient assembly and disassembly of components, long service life of the device and good economic benefits.

Owner:宣城品宙洁净科技有限公司

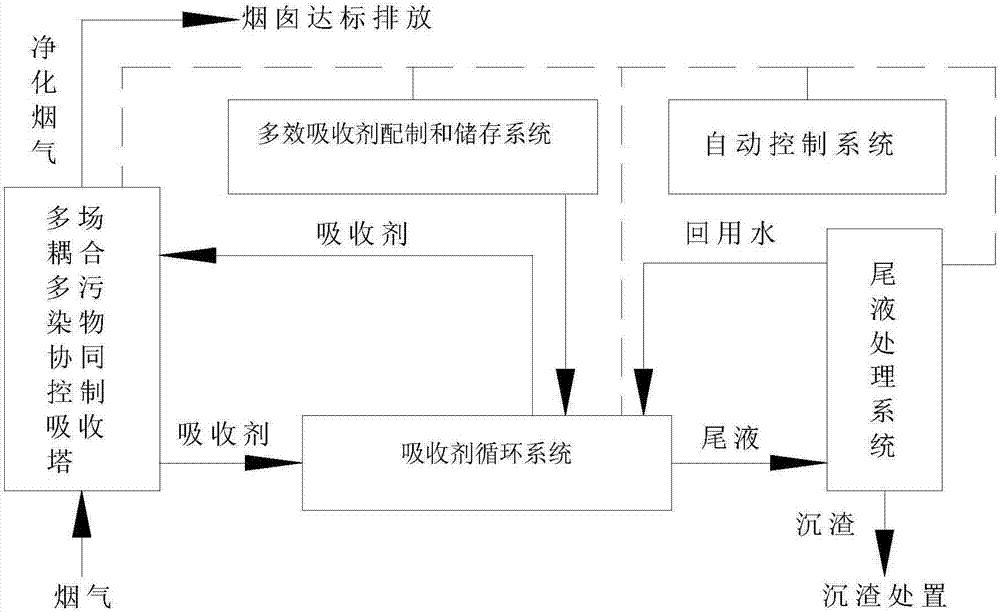

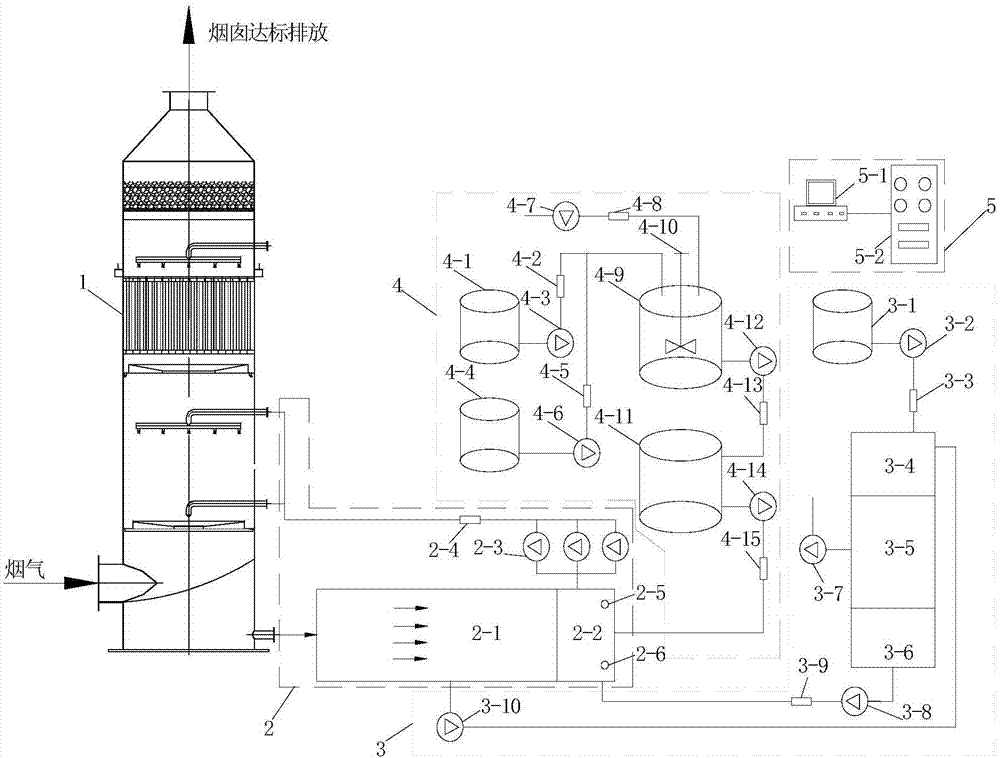

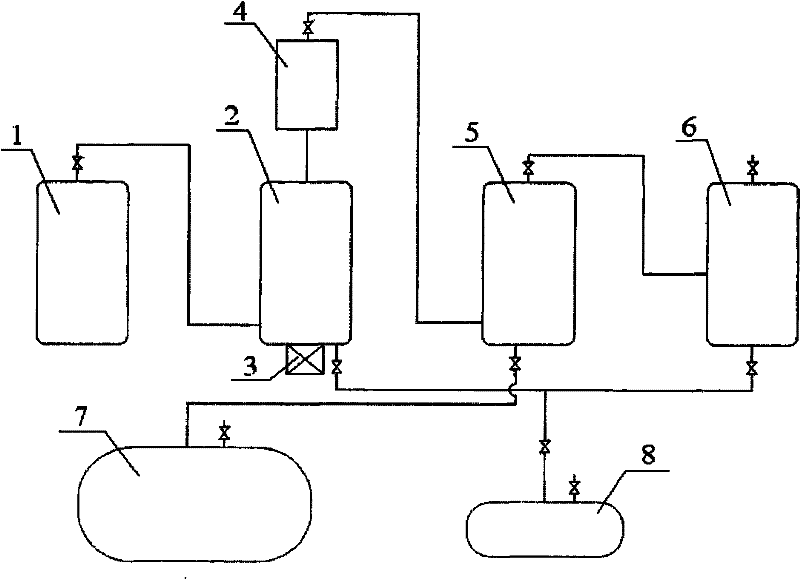

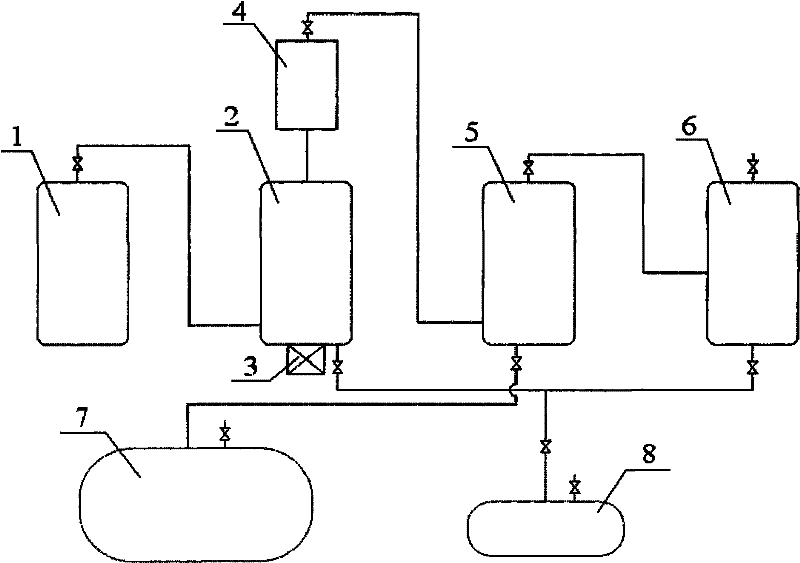

Process system and method for industrial furnace flue gas multi-pollutant multifield-coupling coordination control

InactiveCN107233798AThe equipment is compactEasy to operateCombination devicesGas treatmentAutomatic controlProcess systems

The invention discloses a process system and a method for industrial furnace flue gas multi-pollutant multifield-coupling coordination control. The process system comprises a multifield-coupling multi-pollutant coordination control absorption tower, a multi-effect absorbing agent preparation and storage system, an absorbing agent circulation system, an end solution treatment system and an automatic control system, wherein the multi-effect absorbing agent preparation and storage system, the absorbing agent circulation system and the multifield-coupling multi-pollutant coordination control absorption tower are sequentially connected; the absorbing agent circulation system and the end solution treatment system are sequentially connected; the automatic control system is respectively connected with the multi-effect absorbing agent preparation and storage system, the absorbing agent circulation system and the end solution treatment system. The process system and the method for industrial furnace flue gas multi-pollutant multifield-coupling coordination control provided by the invention have the advantages of high pollutant removal efficiency, simple process equipment, low investment and operation cost, easiness in control and management and the like, and are economic and high-efficient industrial furnace flue gas pollution control technologies.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

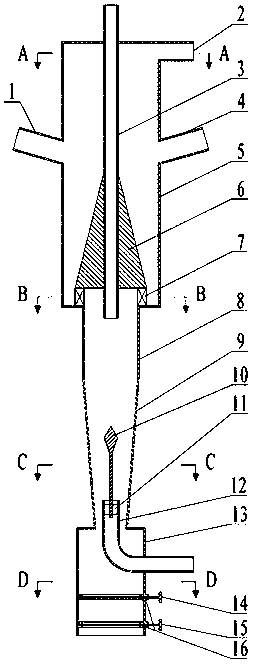

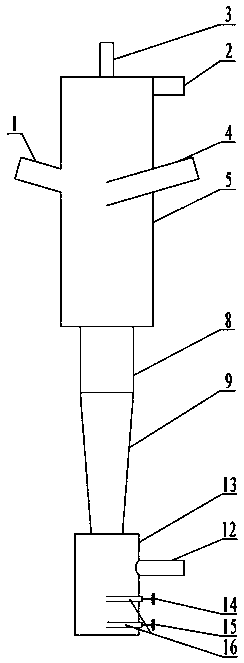

Multifunctional separation equipment for high-temperature biological mixed gas

InactiveCN102517095AThe equipment is compactSmall footprintBiofuelsPyroligneous acid productionTarBiogas

The invention relates to multifunctional separation equipment for high-temperature biological mixed gas. A heat exchange chamber and a static separating chamber are arranged in a shell; both ends of heat exchange pipes in the heat exchange chamber are respectively communicated with a biological gas outlet at the top part of the heat exchange chamber and a biological mixed liquor outlet at the bottom part of the heat exchange chamber; a high-temperature biological mixed gas inlet arranged in the side wall of the shell is communicated with the bottom ends of the heat exchange pipes; the static separating chamber is divided into a left chamber and a right chamber by a partition plate in the static separating chamber; the lower parts of the two chambers are communicated; a biological mixed liquor inlet is located above one of the two chambers; a biological light tar outlet is arranged above the side wall of the chamber provided with a biological mixed liquor inlet; a biological acetic acid outlet is arranged above the side wall of the other chamber; and the bottom part of the static separating chamber is provided with a biological heavy tar outlet. As corollary equipment of a pyrolysis comprehensive conversion and utilization system for biomass waste resources, because solid purification and separation equipment, liquid purification and separation equipment and gas purification and separation equipment are integrated, the multifunctional separation equipment for the high-temperature biological mixed gas has a compact structure and less occupied space. Secondary pollution and wastes of secondary transformation resources in the transformation process are eliminated.

Owner:LUOYANG JUNTENG ENERGY TECH +1

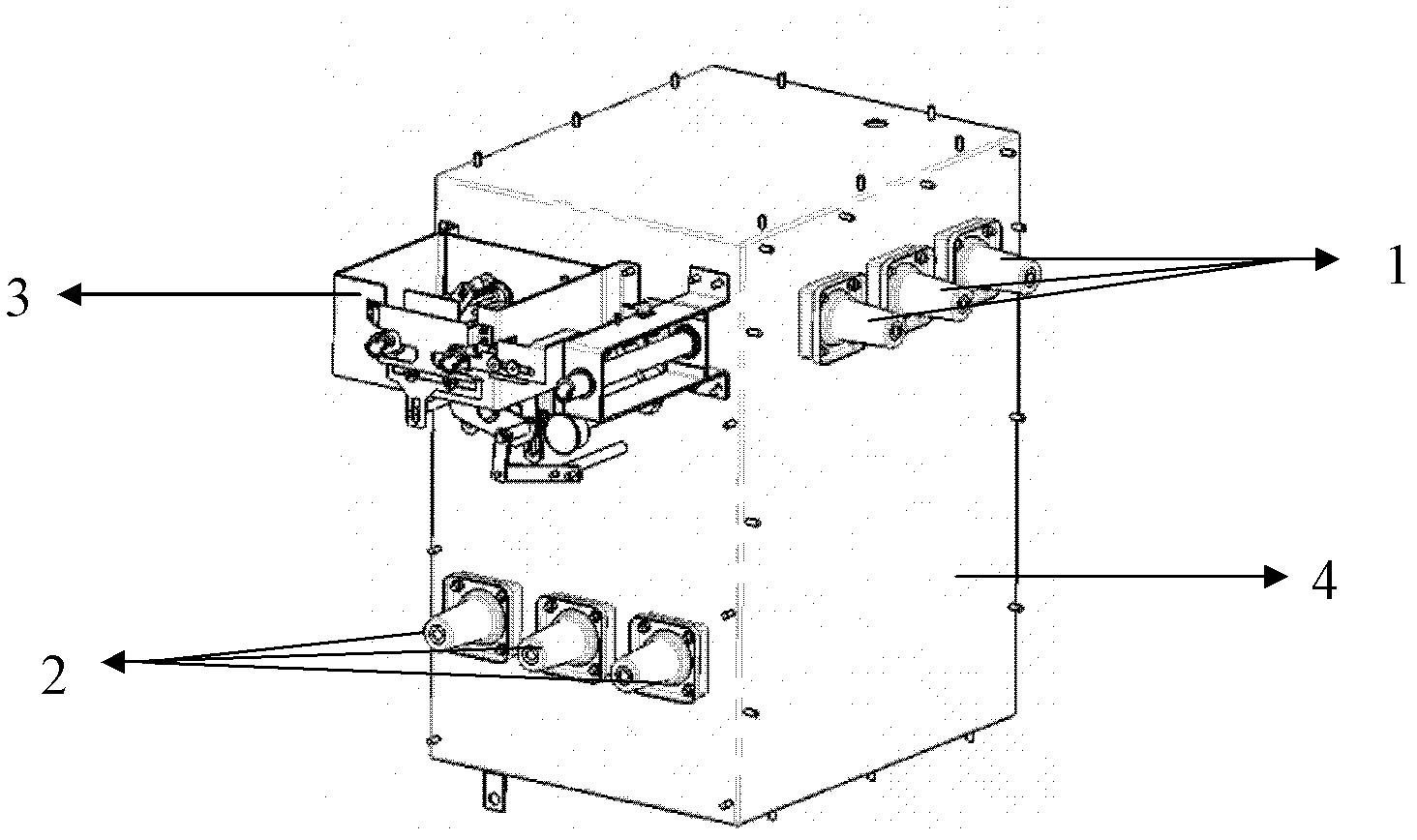

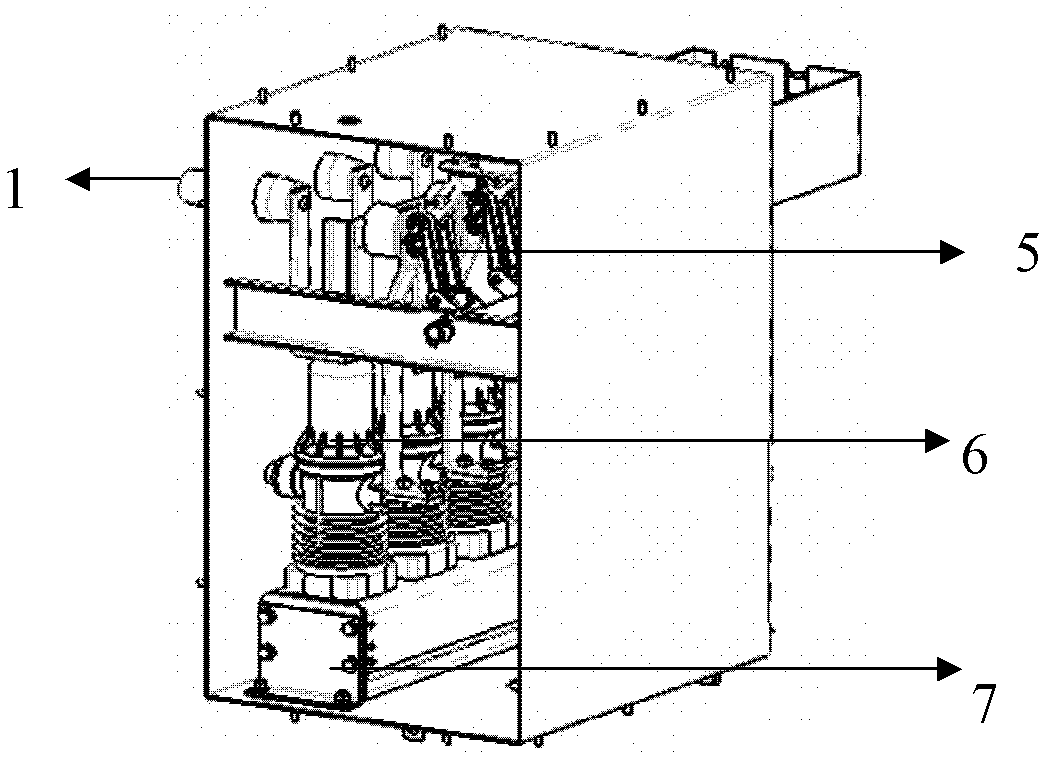

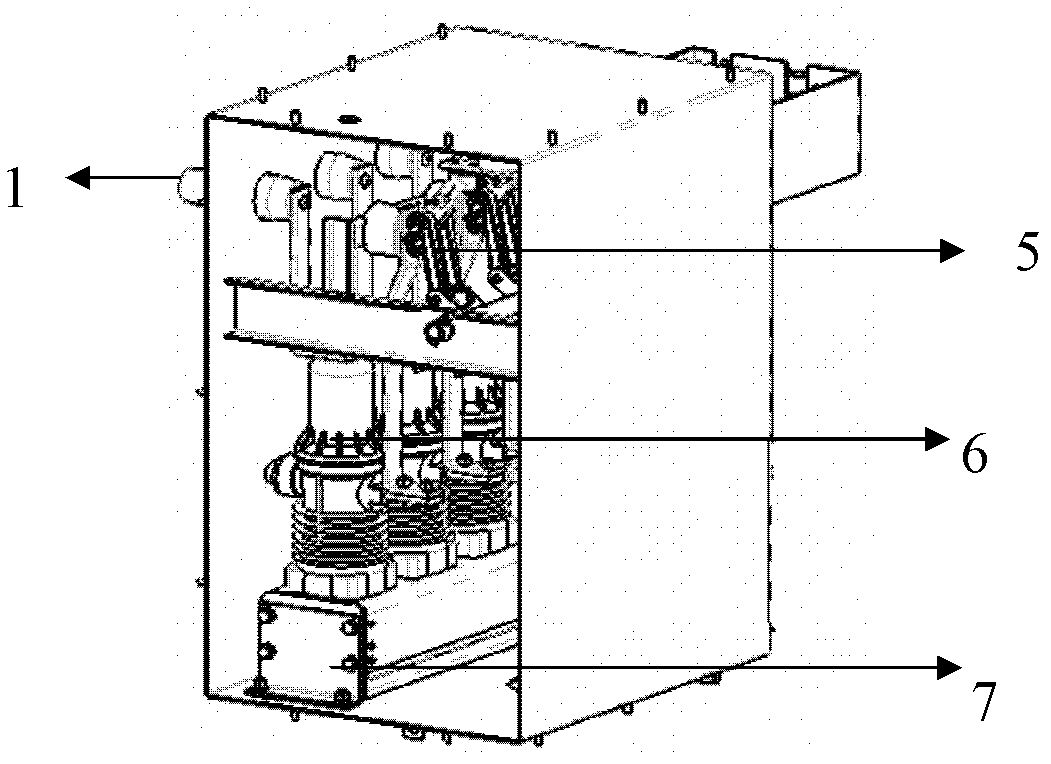

Aerated switch cabinet

InactiveCN102306913AThe equipment is compactReduce volumeSwitchgear arrangementsHigh voltageVacuum switch

The invention discloses an aerated switch cabinet, at least comprising an aerated cabinet, a high-voltage component, a permanent-magnetic vacuum switch and a isolating-grounding three-position switch, wherein the permanent-magnetic vacuum switch and the isolating-grounding three-position switch are connected integrally and arranged in the aerated cabinet in a closed mode. In the aerated switch cabinet, the permanent-magnetic vacuum switch and the integral design are used, thus realizing the good safety, the high reliability, the strong adaptability and the maintenance-free effect. The aerated switch cabinet is applied to 10-35kV power distribution networks with ungrounded neutral points, neutral points grounded by arc suppression coils and neutral points grounded by resistance.

Owner:武汉百楚科技有限公司

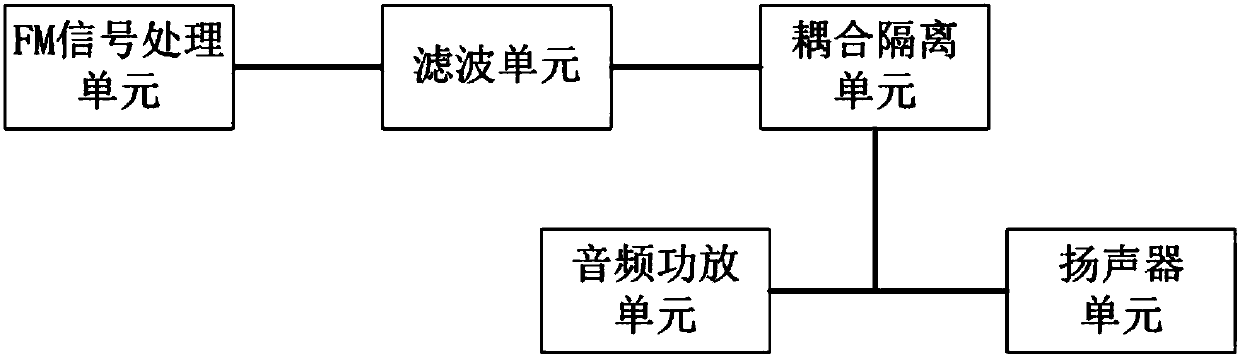

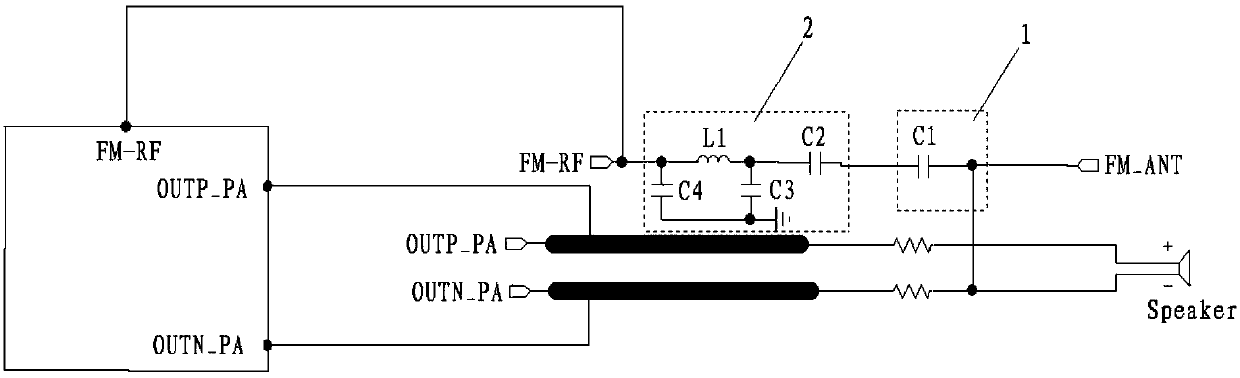

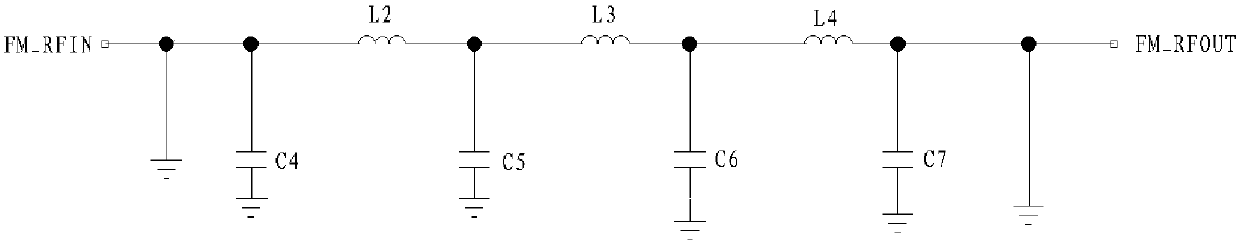

FM receiving circuit

InactiveCN109525261AReduce space consumptionThe equipment is compactTransmissionTelephone set constructionsLoudspeakerVIT signals

The invention provides an FM receiving circuit. The FM receiving circuit comprises an FM signal processing unit, a filtering unit, a coupling and isolation unit, and a loudspeaker unit. The negative pole of the speaker unit is connected to the negative output end of an audio power amplifier unit, and the positive pole of the speaker unit is connected to the positive output end of the audio power amplifier unit. The input end of the coupling and isolation unit is coupled to the negative end of the loudspeaker unit, and the output end of the coupling and isolation unit is connected to the inputend of the filtering unit. And the output end of the filtering unit is connected to the input end of the FM signal processing unit. According to the FM receiving circuit, the circuit has the beneficial effects that the circuit using the coil of a speaker as an FM antenna is provided, so that the FM radio reception effect of the device can be realized without an additional chip or a matching circuit; the space occupation of the circuit board of the device is greatly reduced; and the structure of the device can be more compact.

Owner:深圳市展睿智能科技有限公司

Chlorine leakage absorption device and method

InactiveCN1803255AThe equipment is compactSmall footprintDispersed particle separationIron(II) chlorideIron chloride

The invention discloses an absorbing device and method of leaked chlorine, which comprises the following parts: reaction tower, chlorine transmission pipe, aerator, ferric dichloride spout, acid-resisting pump and reservoir, wherein the reaction tower contains spray device, chlorine reaction absorption layer, escape pipe and reaction layer in the rear part of reaction tower; the reservoir connects the other end of ferric dichloride spout; the bottom of reaction tower extends in the reservoir. The method comprises the following steps: forcing the ferric dichloride into the replacement reaction layer by itself gravity; producing iron chloride; making the solution pierce the replacement reaction layer; circulating the solution in the reservoir under the reaction tower. The invention saves the absorber reaction tank and iron trichloride outlet pipe, which places the reaction part of ferric dichloride and iron under the bottom of reaction tower directly.

Owner:刘树伟

A method for producing ultrapure ammonia

InactiveCN102275951ASafe and reliable processThe equipment is compactAmmonia preparation/separationChemistryLiquid ammonia

The invention relates to a method for producing ultrapure ammonia water. The liquid ammonia is gasified and the ammonia gas is introduced into an ultrasonic purification tower. The ultrasonic purification tower is provided with an ultrasonic nebulizer and ultrapure water. The ultrasonic nebulizer produces fine ammonia water particles for adsorption Impurities in the ammonia gas, the obtained purified ammonia gas is filtered through a filter and enters the product absorption tower, and the ammonia gas is combined with the ultrapure water in the product absorption tower to obtain ultrapure ammonia water. Compared with the prior art, the invention is suitable for producing ultra-pure ammonia water products, and at the same time by-products industrial grade ammonia water products. The ultra-pure ammonia water product obtained by adopting the present invention meets the following indicators: ammonia water content ≥ 28%, single anion impurity ≤ 10ppb, single cation impurity ≤ 0.1ppb, industrial grade ammonia water content ≥ 28%, safe and reliable process, compact equipment structure, low energy consumption, At the same time, there is no discharge of three wastes in production, which meets the requirements of environmental protection.

Owner:SHANGHAI HABO CHEM TECH

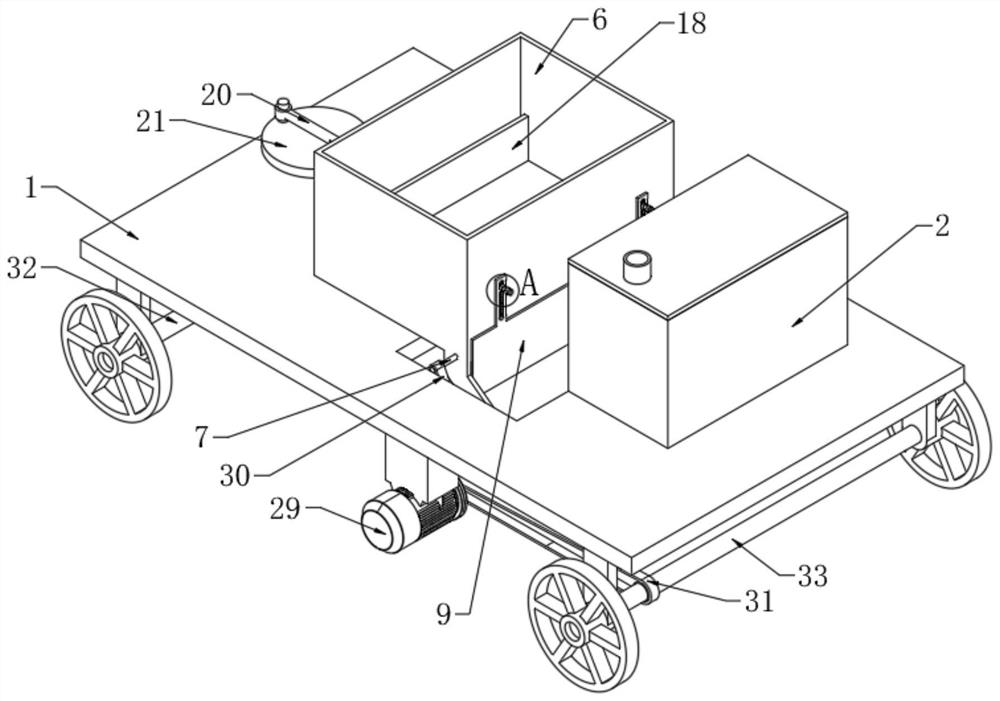

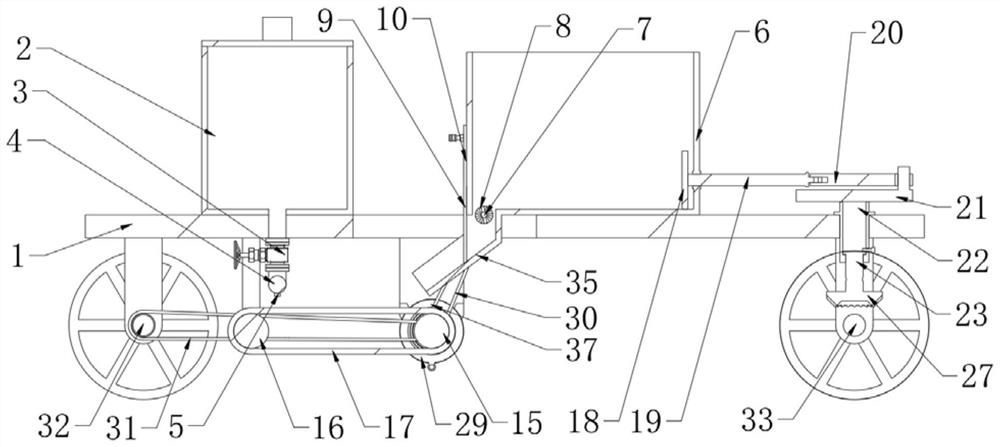

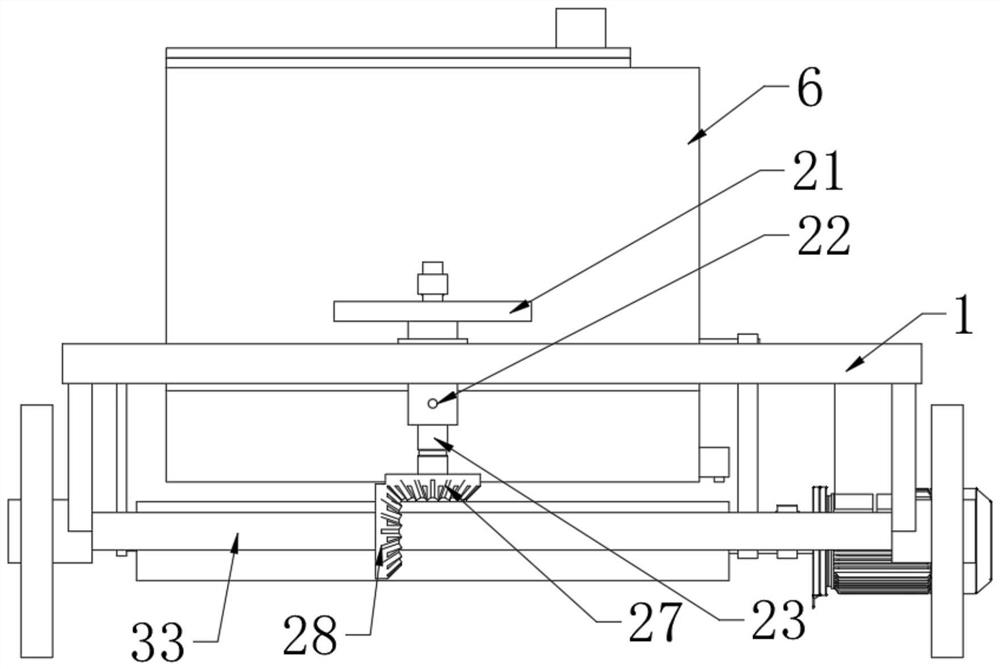

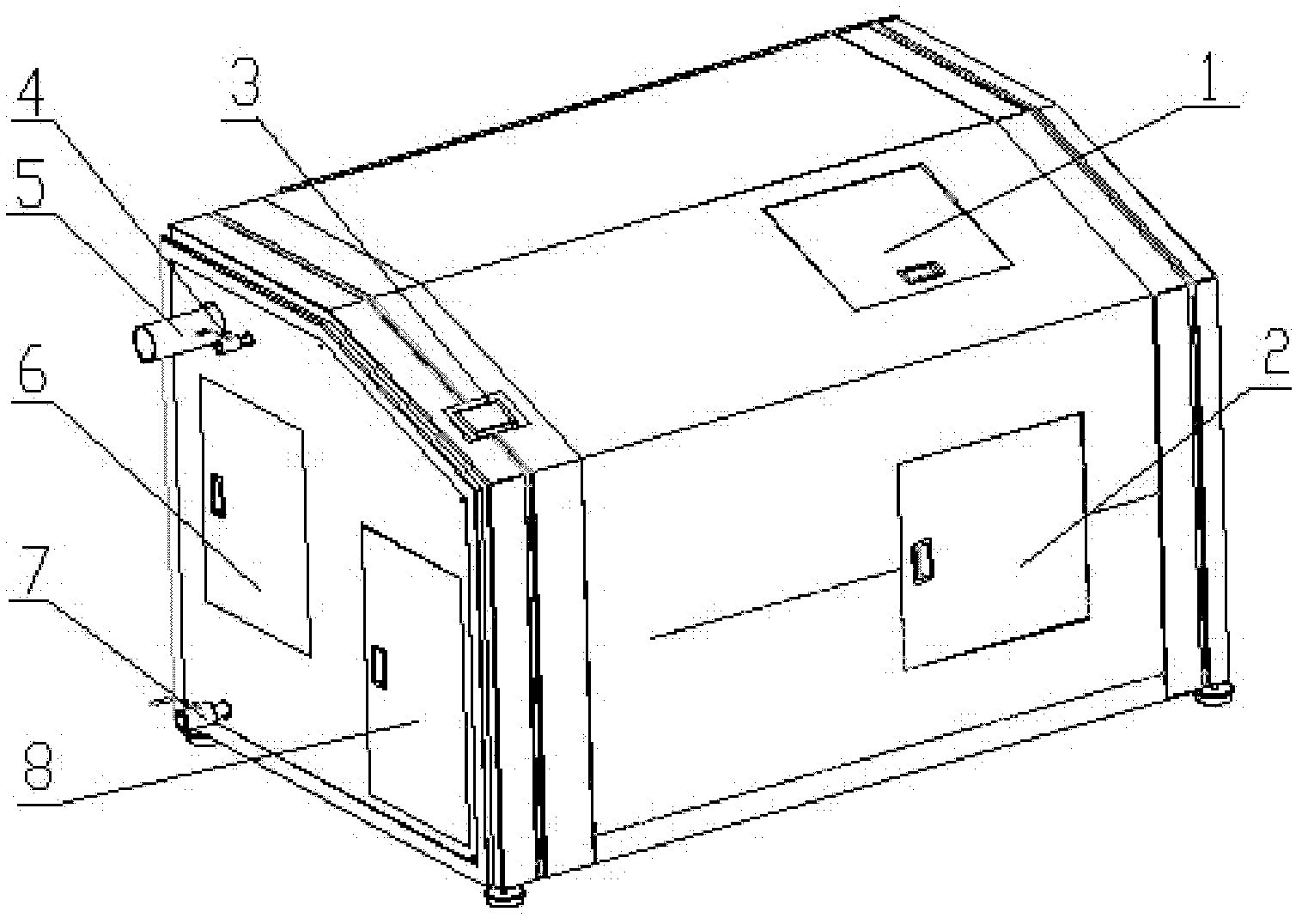

Rice spreading and planting device

PendingCN111771481AThe equipment is compactLow manufacturing costSeed depositing seeder partsBroadcast seedersAgricultural engineeringSowing

The invention discloses a rice spreading and planting device. The rice spreading and planting device comprises a movable frame, a water spraying unit, a storage unit, a conveying unit, a material pushing reciprocating unit and a power unit. The water spraying unit and the storage unit are both installed on the movable frame; the storage unit comprises a turnover mechanism; the conveying unit is installed at the bottom of the movable frame; the feeding end of the conveying unit is located below the discharging end of the storage unit, and the discharging end of the conveying unit is located below the water outlet end of the water spraying unit; the material pushing reciprocating unit is installed on the movable frame and is in transmission through a second wheel shaft of the movable frame;the power unit is installed at the bottom of the movable frame; and the power output end of the power unit is connected with the power input ends of the conveying unit, the turnover mechanism and themovable frame. During sowing, seeds in the storage unit slide onto the conveying unit, the water spraying unit humidifies the seeds and forwards conveys the seeds to enable the seeds to fall into a sowing field, and when the number of the seeds in the storage unit is smaller than a preset value, the material pushing reciprocating unit moves to push the seeds to a discharging port of the storage unit.

Owner:卓志杰

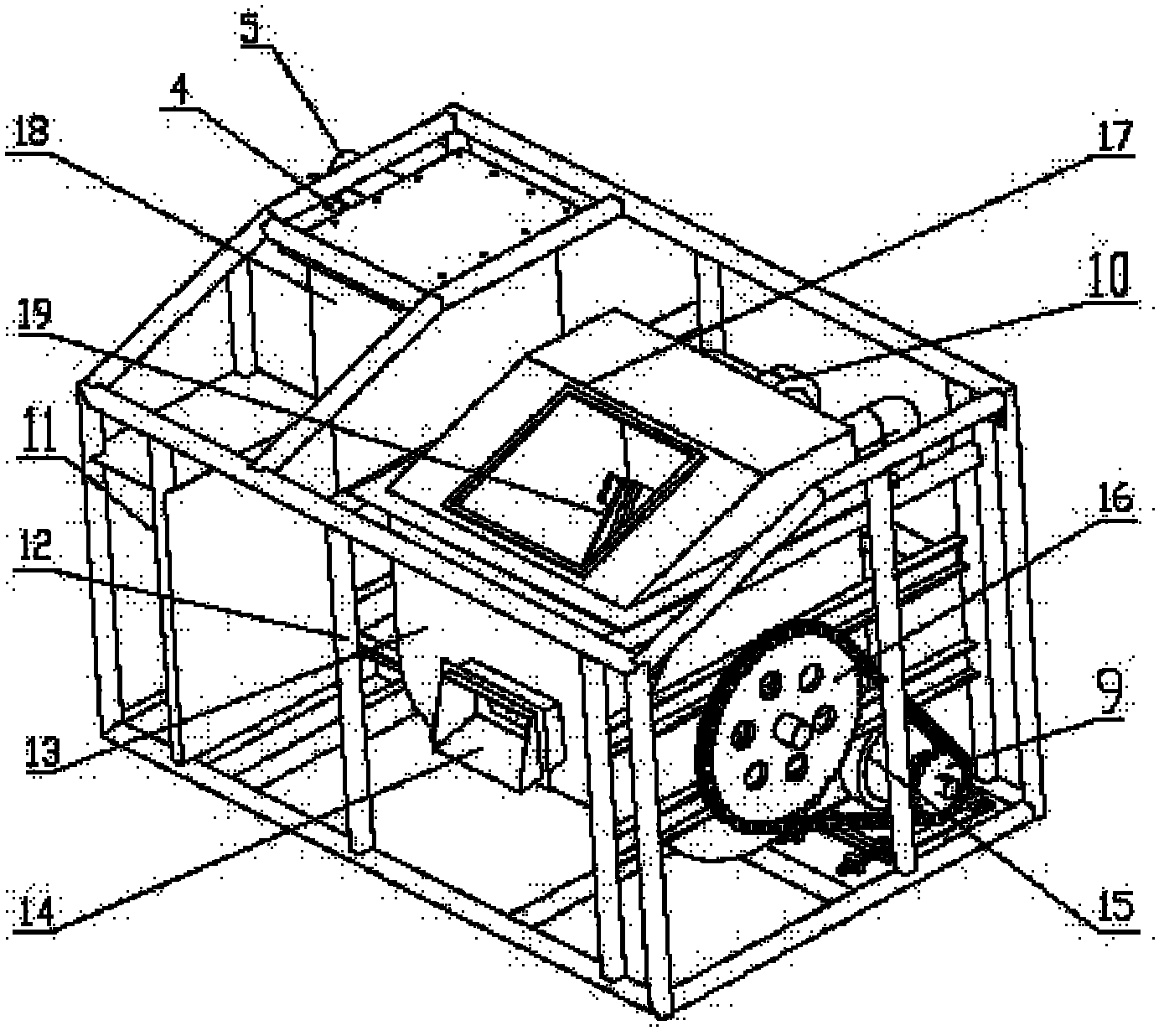

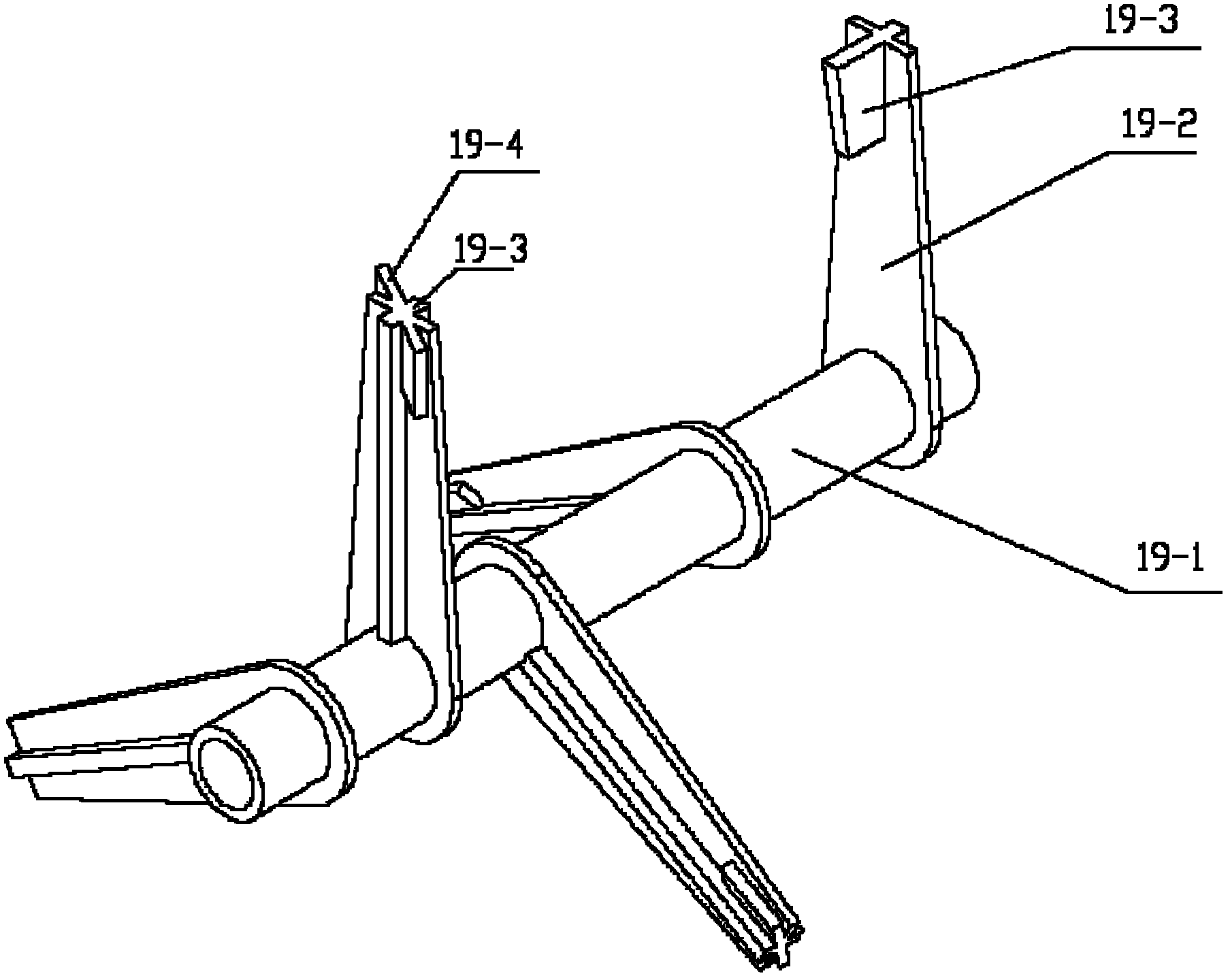

Organic waste disposal machine

ActiveCN102399093BStir wellAdequate responseClimate change adaptationOrganic fertilisersOrganic manureOrganic fertilizer

Owner:天津百利阳光环保设备有限公司

Four-phase cyclone separator

PendingCN109382223AImprove separation efficiencyThe equipment is compactReversed direction vortexEngineeringOil phase

The invention relates to a four-phase cyclone separator, and solves the problem of separation of mediums of integrated four phases of crude oil, water, an associated gas and sediment in a similar produced liquid of an oil field. The four-phase cyclone separator is characterized in that two tangential inlets inclining downwards are symmetrically arranged on the side wall of the cyclone separator; agaseous phase tangential inlet is arranged at the top end of the cyclone separator; an oil phase outlet pipe is inserted into the cyclone separator; the outer surface of an inner cone and the inner wall of the cyclone separator form a gaseous phase separation cavity; a tangential runner is arranged at the lower end of the inner cone, the oil phase separation cavity is arranged between the gaseousphase separation cavity and a water solid separation cavity; a solid collecting chamber is arranged at the lower end of the water solid separation cavity, and an aqueous phase outlet pipe is arrangedon the side wall of the solid collecting chamber. The four-phase cyclone separator has the advantages that the four phases of insoluble mediums of oil, gas, water and solid having density differencesare separated at the same time, the separation efficiency is high, the structure of equipment is compact, and the operation and maintenance costs are low.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

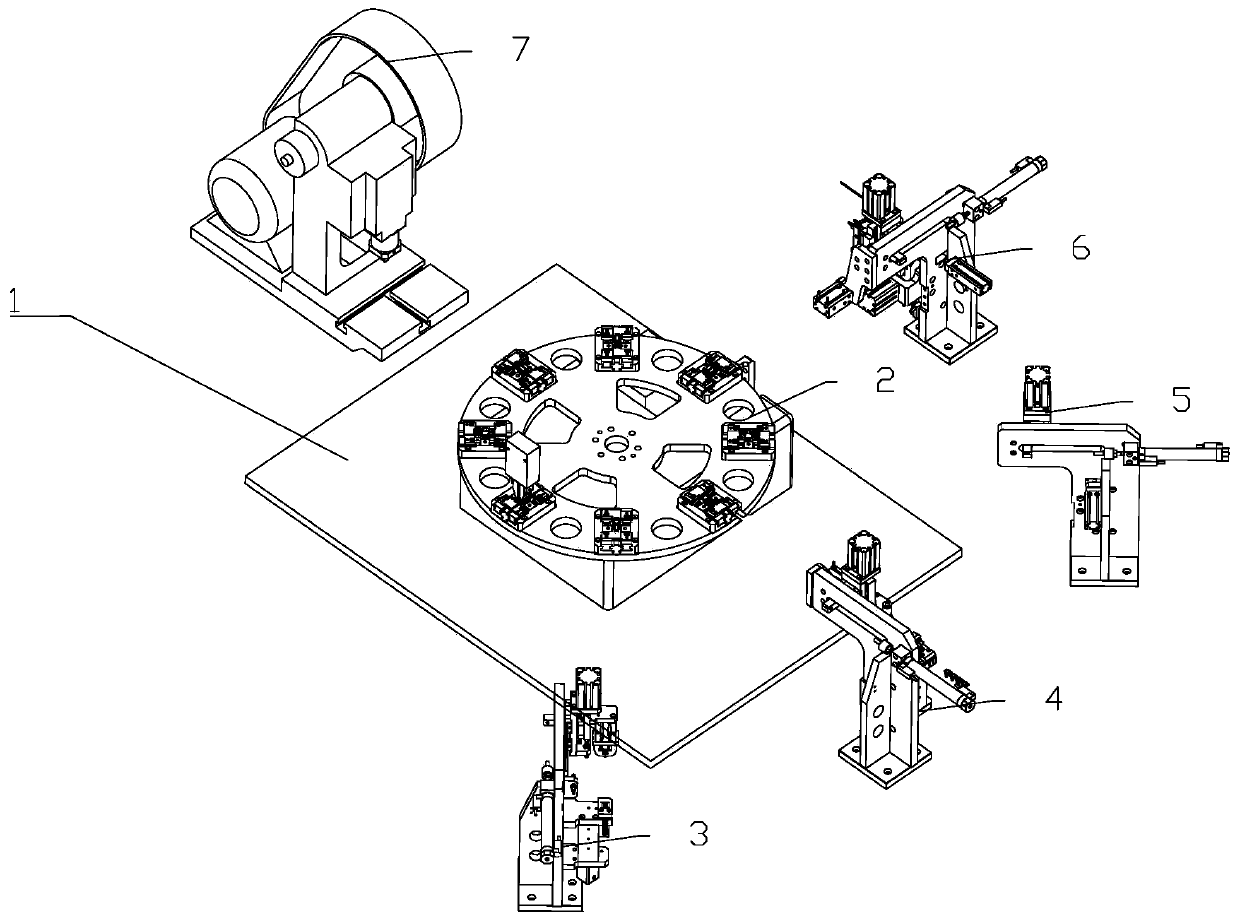

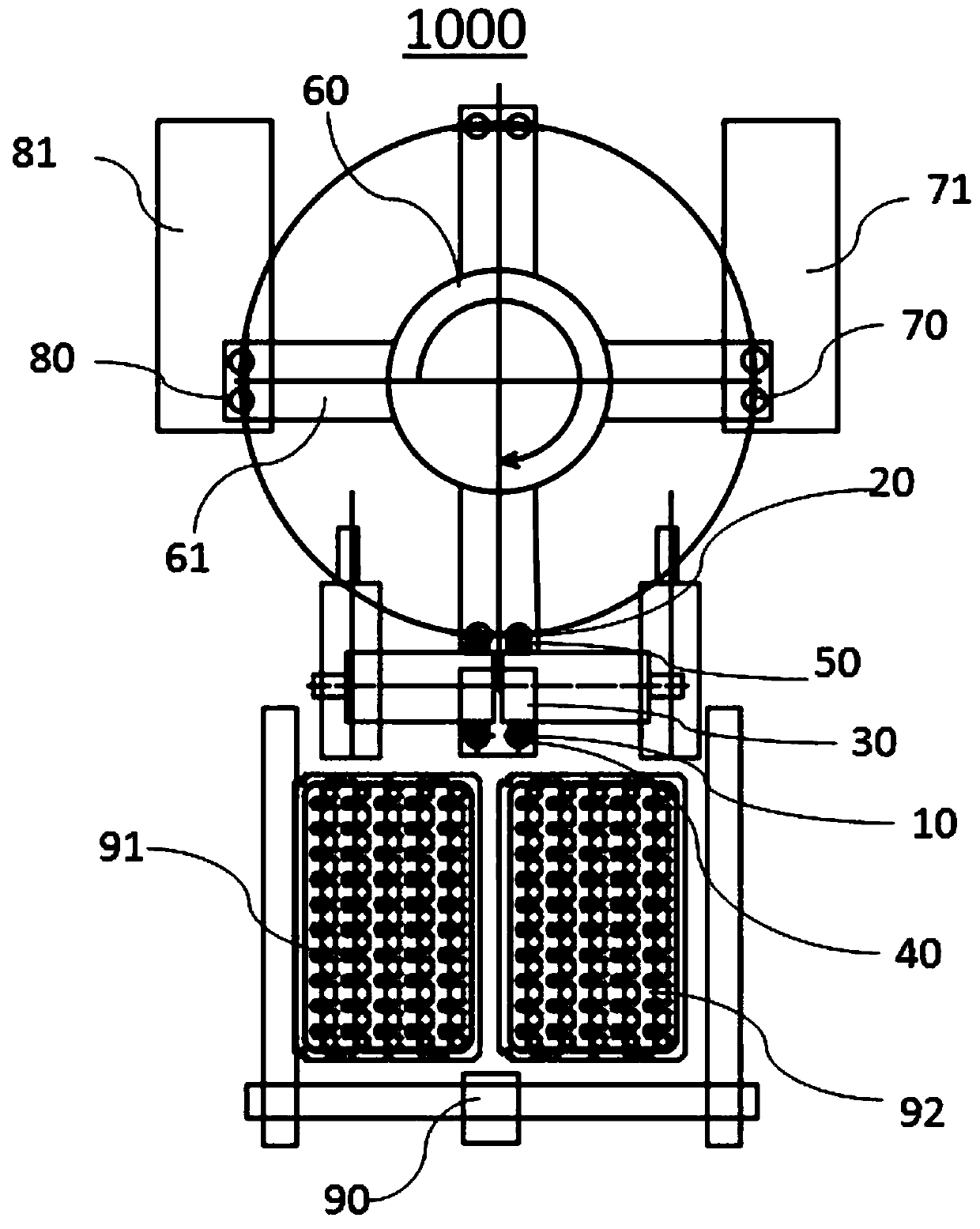

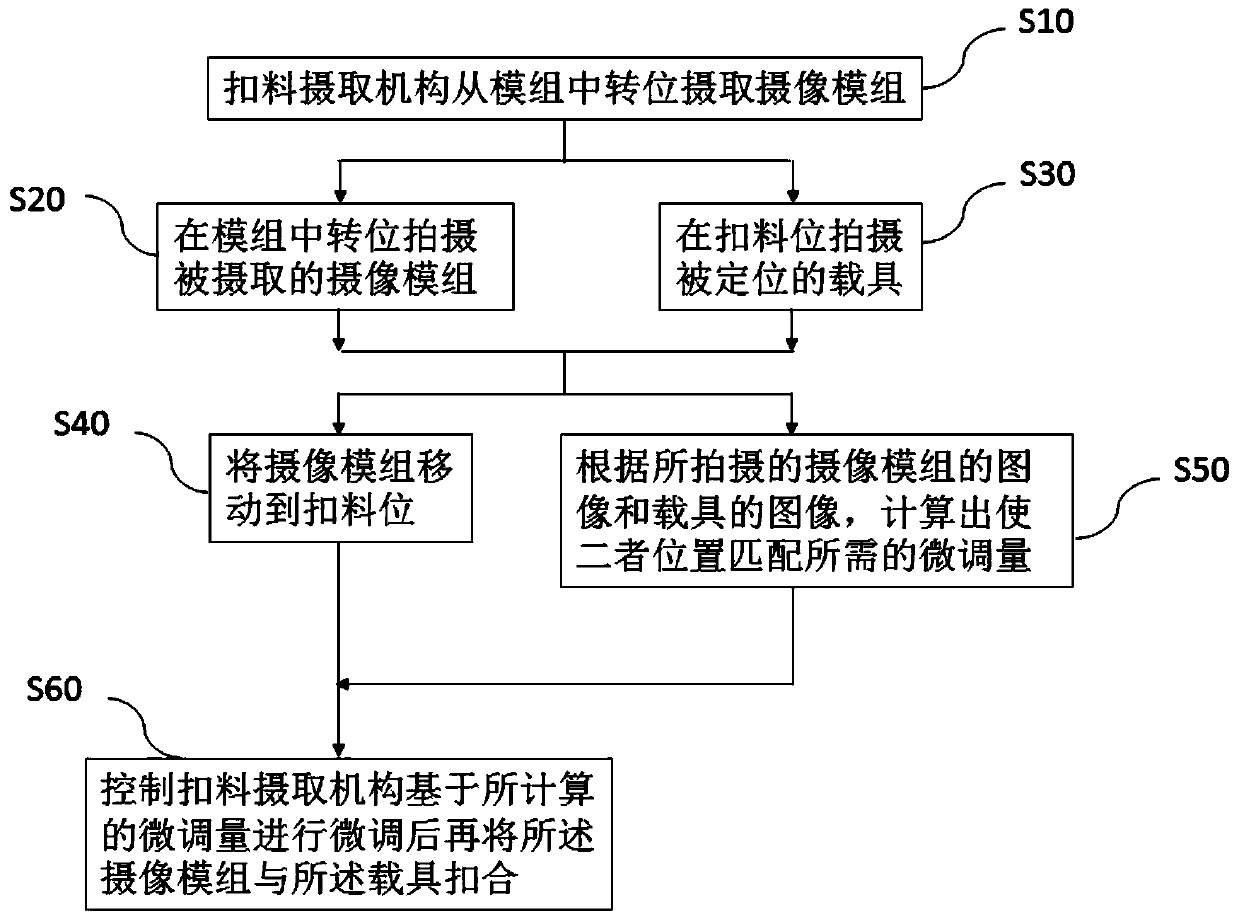

Automatic buckling system and method

The invention provides an automatic buckling system which comprises a module transfer station, a buckling station, a buckling uptaking mechanism, a module photographing device, a carrier photographingdevice and computing equipment, wherein a to-be-buckled carrier can be moved to the buckling station; the buckling uptaking mechanism is suitable for uptaking a camera shooting module in the module transfer station and moving the camera shooting module to the buckling station; and the computing equipment is used for controlling the module photographing device and the carrier photographing deviceto photograph at the same time, computing a fine adjustment amount needed to match the photographing module and the carrier in position according to a photographed image of the camera shooting moduleand a photographed image of the carrier and controlling the buckling uptaking mechanism to adjust finely based on the fine adjusting amount and buckling the camera shooting module to the carrier. Theinvention further provides a corresponding automatic buckling method. According to the automatic buckling system and method, a camera shooting module connector is automatically buckled with high efficiency by executing multiple steps in parallel.

Owner:NINGBO SUNNY OPOTECH CO LTD

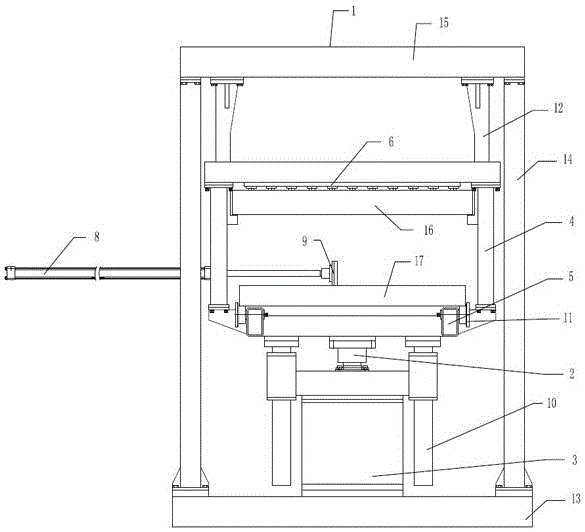

Case separating, hole ejecting and casting pushing machine

ActiveCN105108113AReasonable structural designThe equipment is compactMoulding machinesPistonEngineering

The invention relates to a case separating, hole ejecting and casting pushing machine and belongs to the field of casting mechanical equipment. The case separating, hole ejecting and casting pushing machine comprises a main body frame, a lifting cylinder, a guide rod support, an ejector pin plate frame, a roller way frame, an ejector pin plate, a cross support, a casting pushing cylinder, a pushing plate, multiple guide rods, multiple rollers and multiple upper case hooks. The main body frame comprises a base, stand columns and an upper beam. The lifting cylinder and the guide rod support are both arranged on the base, and the multiple guide rods are arranged in the guide rod support. The ejector pin plate frame, the piston end of the lifting cylinder and the flange ends of the guide rods are all fixed to the roller way frame. The ejector pin plate is fixed to the ejector pin plate frame, and multiple ejector pins are arranged on the ejector pin plate. The multiple rollers are arranged on the roller way frame. The cross support is fixedly connected with the stand columns, the casting pushing cylinder is arranged on the cross support, and the pushing plate is arranged at the head end of the casting pushing cylinder. The upper case hooks are fixed on the lower bottom face of the upper beam. The case separating, hole ejecting and casting pushing machine is safe and reliable, and three functions are achieved on one machine, so that the site area and the invest cost of equipment are reduced, and the production efficiency is high.

Owner:浙江省机电设计研究院有限公司

Vacuum coating equipment and vacuum coating method

InactiveCN111575652AImprove mechanical propertiesThe equipment is compactVacuum evaporation coatingSputtering coatingRadio frequencyThin membrane

The invention discloses vacuum coating equipment and a vacuum coating method. The vacuum coating equipment comprises a coating vacuum chamber, an evaporation source, a sample table, a heating source and an air exhaust system, the vacuum coating equipment is also provided with a small vacuum chamber communicating with the coating vacuum chamber, and the coating molecular or atomic kinetic energy isimproved by utilizing the pressure difference, so that the mechanical property of a thin film is improved. The vacuum coating method comprises the steps of cleaning a substrate, placing a base plate,loading a preparation material, performing vacuumizing coating, and performing annealing. According to the vacuum coating equipment and the vacuum coating method, the pressure difference between thetwo connected vacuum chambers is utilized to provide additional directional kinetic energy for coating molecules, and the combination of a radio frequency power supply and a bias power supply can be utilized to provide assistance in deposition when necessary. A new method for optimizing the mechanical property of the vacuum thin film by improving the hardness of the thin film by adding directionalmolecular or atomic kinetic energy is provided, and the method is expected to provide a new way for improving the mechanical property of the vacuum thin film. The preparation method is simple, easy to operate, low in cost and suitable for popularization and application.

Owner:SHANGHAI UNIV

Polyhedral groove grease coating equipment

ActiveCN110918400AThe equipment is compactEasy to operateLiquid surface applicatorsCoatingsAutomotive engineeringSemi automation

The invention provides polyhedral groove grease coating equipment and relates to the field of special elevator guide rails. The polyhedral groove grease coating equipment comprises a butting assembly,an oiling mechanism assembly and a pneumatic oiling machine. The oiling mechanism assembly comprises a power trolley assembly and a single-shaft transmission oiling assembly. The single-shaft transmission oiling assembly comprises a linear bearing B, a stepped shaft B, a butterfly spring, a locknut B, a self-aligning bearing and bearing block, oiling sliding blocks, butting screws and micro bearings. The deformation of the butterfly spring is changed by adjusting the locknut B. The polyhedral groove grease coating equipment is simple and compact in structure and convenient to operate. The problems that the operation space is narrow and small, and the labor intensity is large through manual grease coating are solved. The polyhedral groove grease coating equipment is low in cost and realizes safe and reliable semi-automation. Meanwhile, the problem of working limitation of flammable and combustible articles is solved through pneumatic drive, and the polyhedral groove grease coating equipment realizes equal-thickness grease coating on cylinders and polyhedrons to be coated with grease, greatly reduces the working intensity of working staff, thereby improving the grease coating efficiency and quality.

Owner:BEIJING UNIV OF TECH

Mechanism for sloping table-board to right or left

Owner:TAICANG KANGHUI TECH DEV

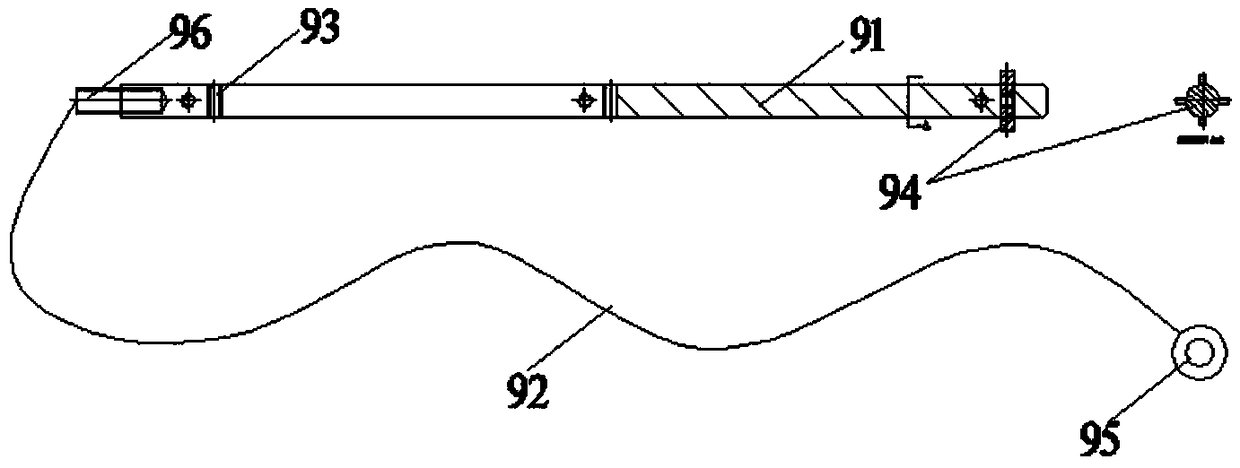

Automatic bobbin lifting and feeding equipment for spinning frame collective doffing bobbins

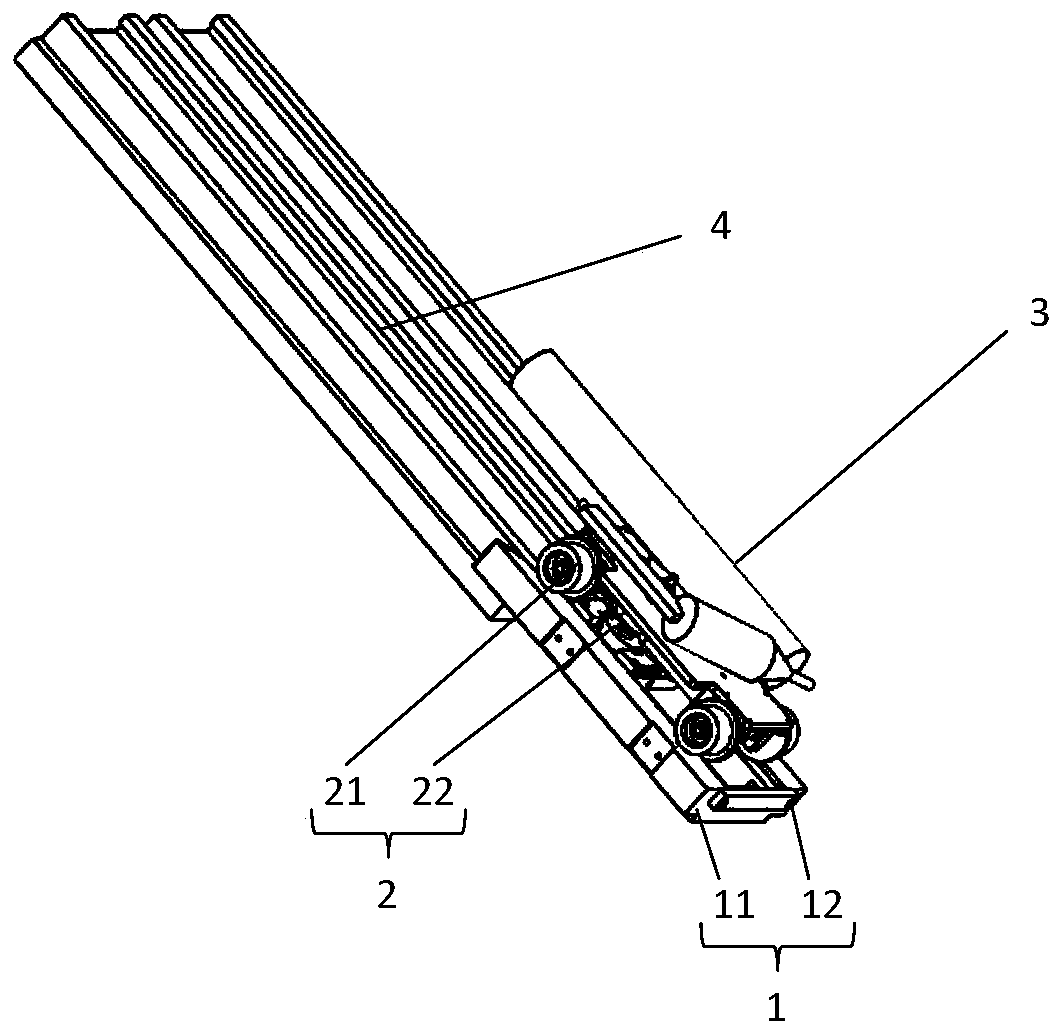

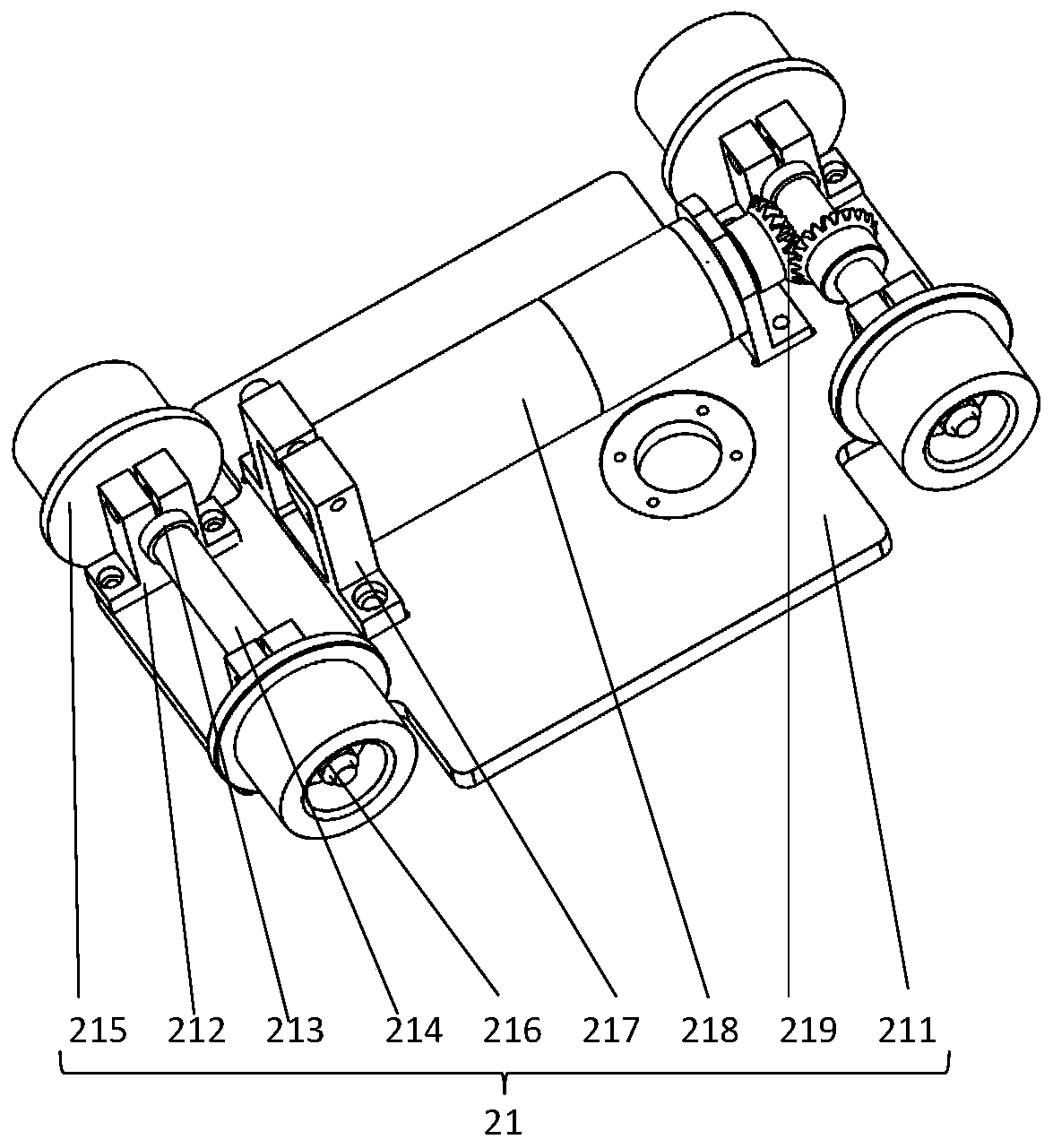

InactiveCN106629099AEfficient conveying and finishingThe equipment is compactBottle emptyingLoading/unloadingLocking plateEngineering

The invention discloses automatic bobbin lifting and feeding equipment for spinning frame collective doffing bobbins. The automatic bobbin lifting and feeding equipment comprises a bobbin arranging machine, a lifting device and a revolving car; the bobbin arranging machine comprises a machine head and a bobbin storing box; the bobbin storing box is located in front of the machine head and provided with a front installation plate away from the machine head, a lower installation plate is installed on the lower portion of the bobbin storing box, a square hole is formed over the lower installation plate; the lifting device is installed in front of the bobbin arranging machine, and an upper-rear locking plate of the lifting device is opposite to the front installation plate and fixed on the front installation plate through a bolt; an obliquely-pulling support of the lifting device and a base plate fixing plate are inserted into the square hole and fixed on the lower installation plate through a bolt; and the revolving car is located in front of the lifting device, and a groove is formed in the face, close to the lifting device, of the revolving car and can be inserted into a hanging arm of the lifting device in a matched mode. According to the automatic bobbin lifting and feeding equipment for the spinning frame collective doffing bobbins, the structure is compact and reasonable, the workload and labor intensity of workers are lowered, production efficiency is improved, and production cost is lowered.

Owner:江苏海马纺织机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com