Four-phase cyclone separator

A cyclone separator and flow separation technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problems of rarely reported four-phase cyclone separators, and achieve low operation and maintenance costs. , High separation efficiency, compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

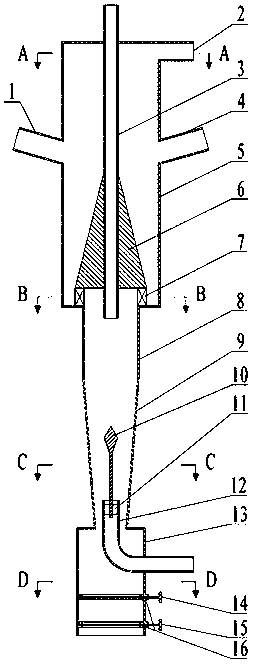

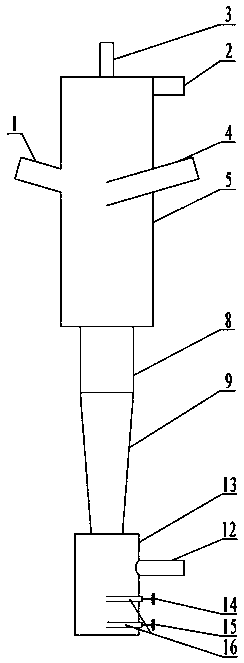

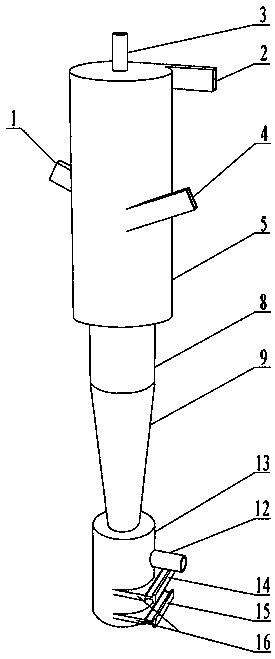

[0023] like figure 1 As shown, a gas, oil, water, and solid four-phase cyclone separator according to an embodiment of the present invention includes a left-side downward-sloping tangential inlet (1), a gas-phase tangential outlet (2), and an oil-phase outlet pipe (3 ), the right downward tangential inlet (4), the gas phase separation chamber (5), the inner cone (6), the tangential flow channel (7), the oil phase separation chamber (8), the water-solid separation chamber (9), Oil core stabilizer (10), fixing ribs (11), water phase outlet pipe (12), solid collection chamber (13), upper deck (14), lower deck (15) and slot (16).

[0024] like figure 1 As shown, the gas phase separation chamber (5), the oil phase separation chamber (8), the water-solid separation chamber (9) and the solid collection chamber (13) are sequentially connected along the axial direction; the gas phase separation chamber (5) and the oil phase The separation chambers (8) are all cylindrical structures; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com