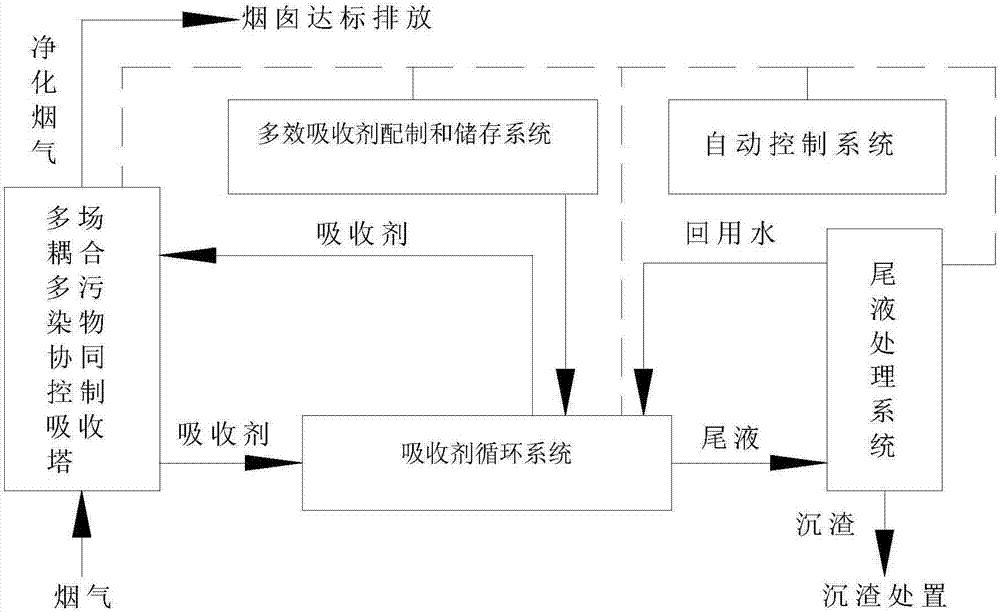

Process system and method for industrial furnace flue gas multi-pollutant multifield-coupling coordination control

A collaborative control, industrial furnace technology, applied in separation methods, chemical instruments and methods, combined devices, etc., can solve problems such as lack of economical and efficient treatment technology, inability to meet NOx emission reduction requirements, and inability to directly apply to the building materials industry. , to achieve the effect of convenient source of raw materials, small footprint, simple preparation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

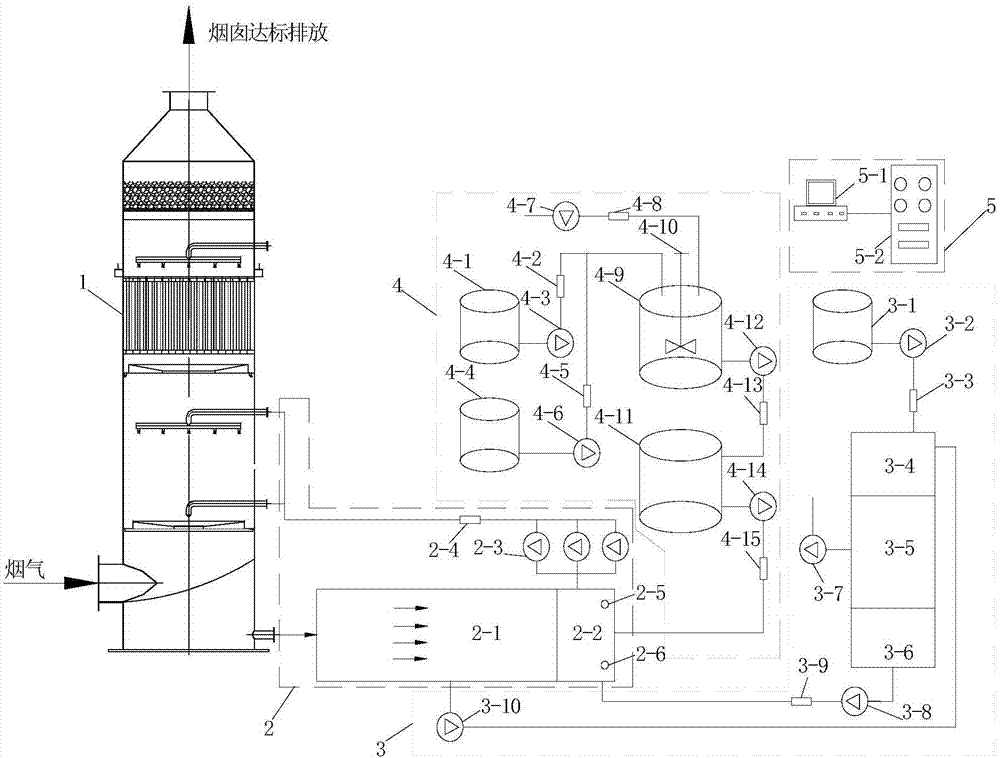

Embodiment 1

[0042] The flue gas of a finished kiln in a ceramic factory, the air volume is 50000m 3 / h, main component SO 2 The average concentration is 250mg / m 3 ;The average concentration of NOx is 180mg / m 3 ;The average concentration of HF is 5mg / m 3 ;The average concentration of HCl is 25mg / m 3 , Pb concentration is 1.5mg / m 3 .

[0043] 1) Start the power supply of the automatic control system, and the automatic control system outputs instructions to the lye pump, lye electronic flow meter, oxidant pump, oxidant electronic flow meter, clean water electronic flow meter, mixer, absorbent pump; NaOH lye, NaClO 2 +Ca(ClO) 2 Oxidant (composite molar ratio is 10:1) and clear water are respectively input into the medicament mixing tank after being measured by an electronic flow meter; the mixer is turned on to prepare a multi-effect absorbent with a pH of 6 and an oxidant concentration of 0.5%; the absorbent pump is turned on to The prepared multi-effect absorbent is delivered to the ...

Embodiment 2

[0049] A cement factory kiln flue gas, the air volume is 350000m 3 / h, main component SO 2 The average concentration is 500mg / m 3 ;The average concentration of NOx is 800mg / m 3 ;The average concentration of HF is 35mg / m 3 ; The average concentration of Hg is 0.5mg / m 3 .

[0050] 1) Start the power supply of the automatic control system, and the automatic control system outputs instructions to the lye pump, lye electronic flow meter, oxidant pump, oxidant electronic flow meter, clear water electronic flow meter, mixer, absorbent pump; Ca(OH) 2 Lye, NaClO 2 +Ca(ClO) 2 Oxidant (composite molar ratio is 15:1), clear water is input medicine mixing tank after being measured by electronic flowmeter respectively; Turn on mixer, preparation pH is 8, and the multi-effect absorbent that oxidant concentration is 1.0%; Turn on absorbent pump, will The prepared multi-effect absorbent is delivered to the absorbent storage tank.

[0051] 2) Turn on the induced draft fan, the programma...

Embodiment 3

[0056] Flue gas from a glass kiln in a special glass factory with an air volume of 10,000m 3 / h, main component SO 2 The average concentration is 4500mg / m 3 ;The average concentration of NOx is 3200mg / m 3 ;The average concentration of HF is 17mg / m 3 ;The average concentration of HCl is 37mg / m 3 , Pb concentration is 0.2mg / m 3 .

[0057] 1) Start the power supply of the automatic control system, and the automatic control system outputs instructions to the lye pump, lye electronic flow meter, oxidant pump, oxidant electronic flow meter, clean water electronic flow meter, mixer, absorbent pump; NaOH lye, NaClO 2 +Ca(ClO) 2 Oxidant (composite molar ratio is 20:1), clear water is input medicine mixing tank after being measured by electronic flowmeter respectively; Turn on mixer, preparation pH is 7, and the multi-effect absorbent that oxidant concentration is 2.0%; Turn on absorbent pump, will The prepared multi-effect absorbent is delivered to the absorbent storage tank.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com