Case separating, hole ejecting and casting pushing machine

A technology for producing castings and top holes, which is applied in the field of equipment and foundry machinery and equipment, can solve problems such as the inability to use top holes, and achieve the effects of small footprint, compact equipment structure and improved operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0018] Example.

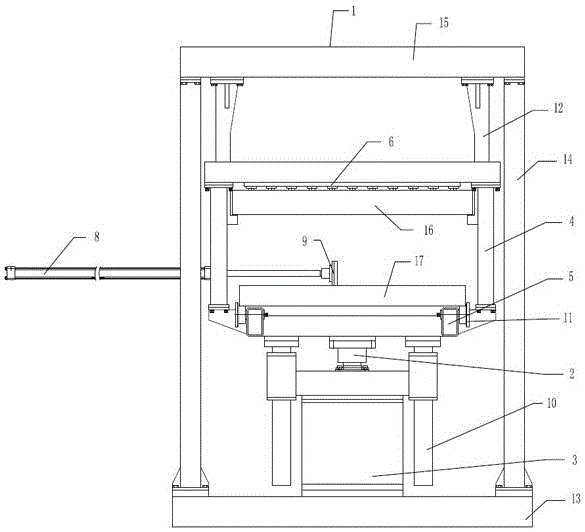

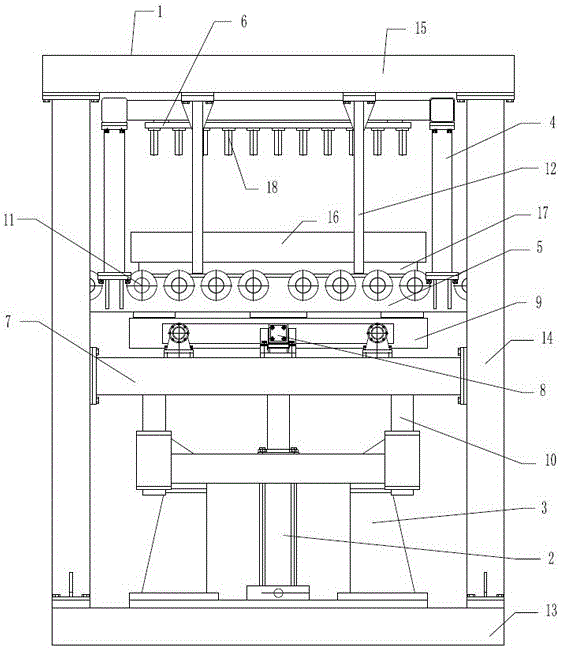

[0019] see Figure 1 to Figure 2 In this embodiment, the boxing, jacking and casting machine mainly includes a main body frame 1, a lifting cylinder 2, a guide rod support 3, a thimble plate frame 4, a roller frame 5, a thimble plate 6, a cross brace 7, and a casting pusher. Cylinder 8, push plate 9, guide rod 10, roller 11, upper box hook 12 and thimble 18.

[0020] This embodiment provides a case dividing, punching and casting machine, that is, the three functions of the case dividing machine, punching machine and casting machine can be realized sequentially on one piece of mechanical equipment.

[0021] The main body frame 1 of this embodiment is made up of base 13, column 14 and upper beam 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com