Organic waste disposal machine

A technology of organic waste and processing machine, applied in the direction of organic fertilizer, climate change adaptation, etc., can solve the problems of treatment effect impact, secondary pollution, uneven heating, etc., improve utilization rate and integrity, and facilitate installation and disassembly , the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

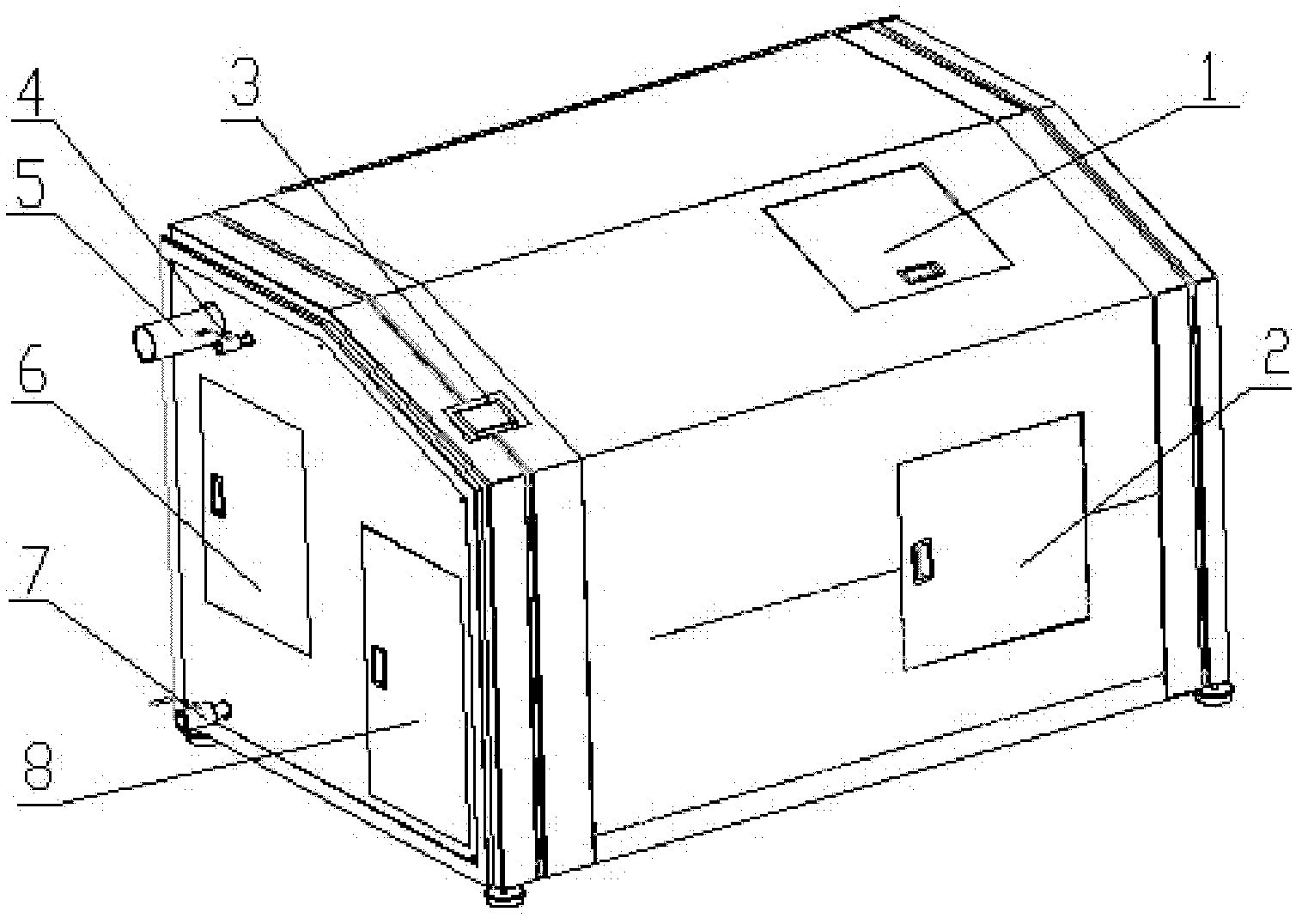

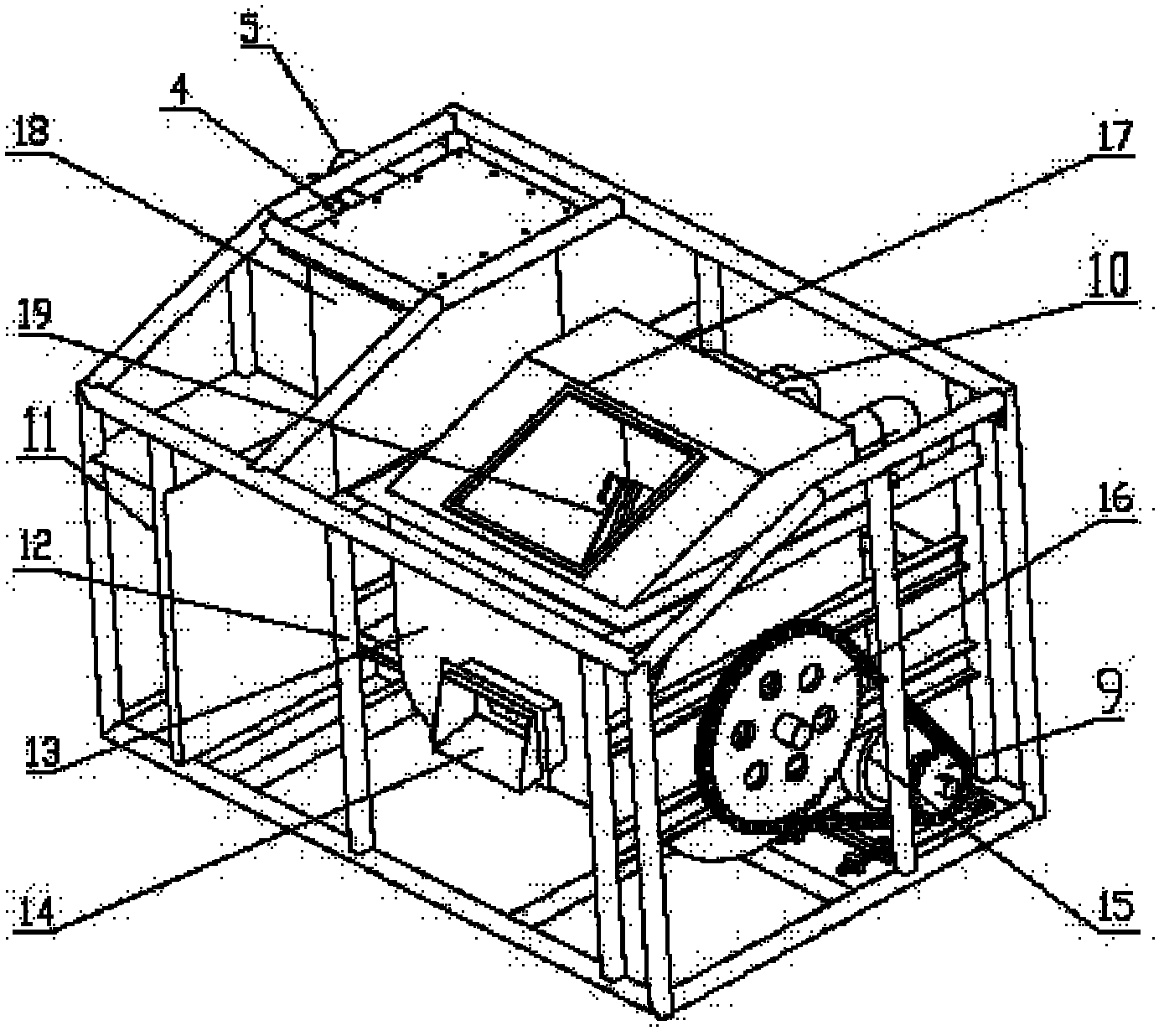

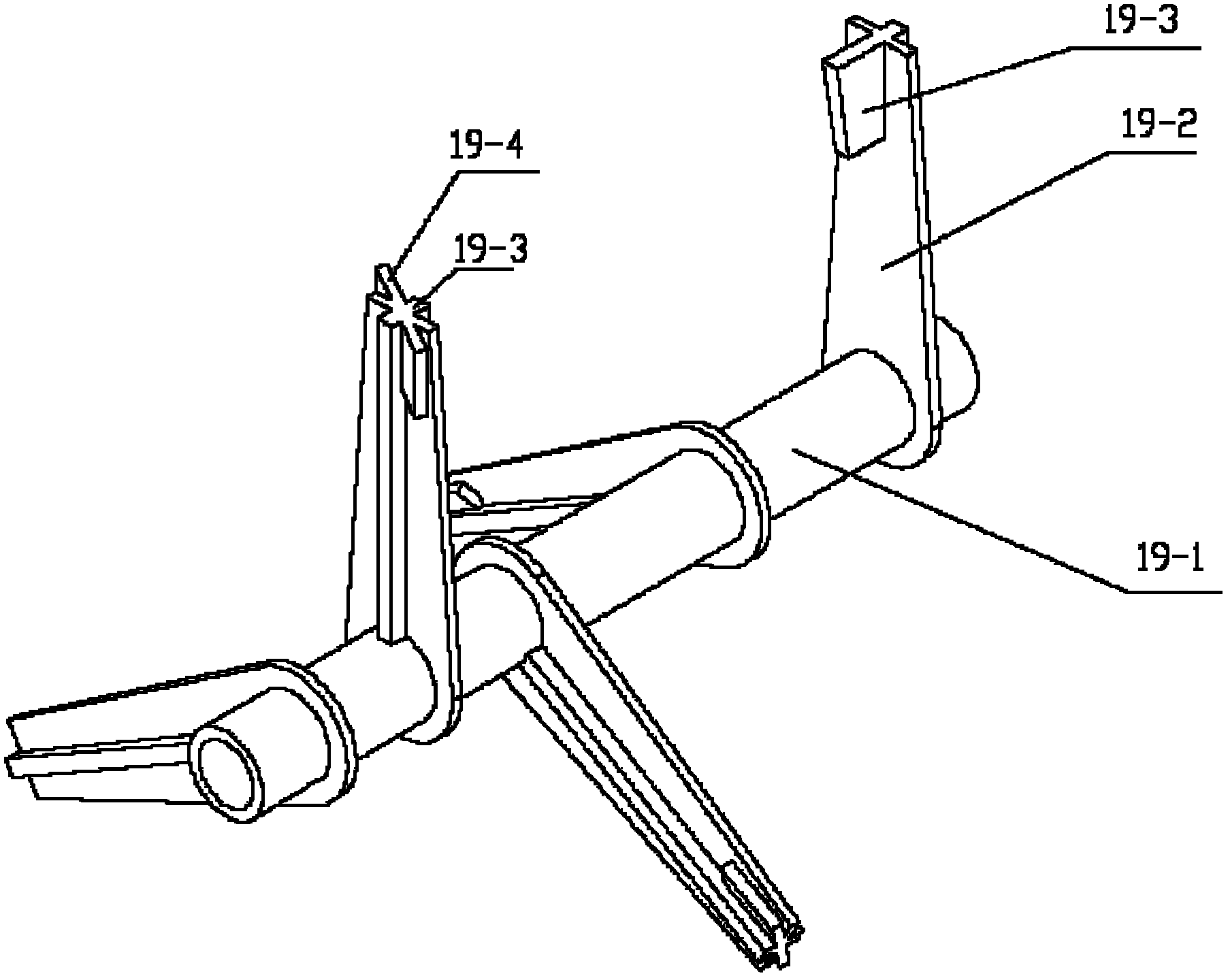

[0027] See Figure 1 ~ Figure 3 , an organic waste processing machine, comprising a main frame body 12, the main frame body 12 is the support of the main part of the whole machine, panels are fixedly installed on each surface of the main frame body 12, wherein the upper panel is provided with a sealed flip cover, made The feed port 1 is convenient for the pouring of organic waste such as kitchen waste and microbial treatment agents. A display screen 3 is arranged on the left side of the upper panel; a water inlet 4 and an air outlet 5 are arranged on the upper part of the side panel, and a There is a water outlet 7, and the middle part is provided with an activated carbon discharge port 6 and an electrical control port 8; the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com