Chlorine leakage absorption device and method

An absorption device and chlorine release technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of large floor area, low absorption efficiency, and many pipelines, and achieve reduced floor space and high reaction efficiency. Improvement, the effect that the absorption reaction is sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

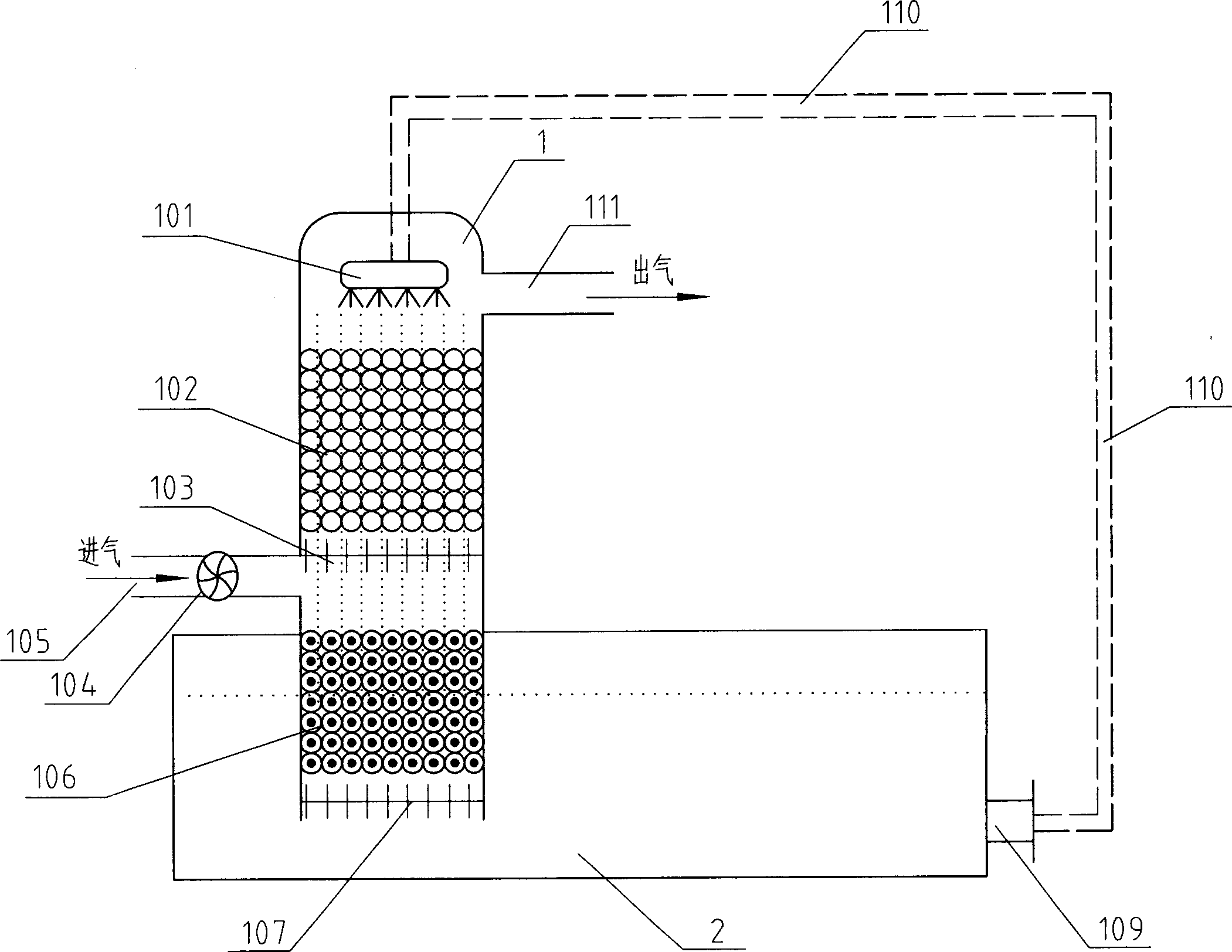

[0029] like figure 1 As shown, the chlorine release absorption device includes a blower 104 , a chlorine delivery pipe 105 , a reaction tower 1 , a liquid storage tank 2 , an acid-resistant pump 109 and a delivery pipe 110 .

[0030] Wherein, one end of the blower 104 passes through the chlorine delivery pipe 105 and imports the chlorine discharge to be absorbed (generally from the chlorination room, not shown in the figure), and the other end of the blower 104 passes through the chlorine delivery pipe 105 and the air inlet of the reaction tower 1 Connected; Reaction tower 1 comprises spraying device 101, chlorine reaction absorption layer 102, dividing plate 103 (for isolation between the upper and lower layers), ferric chloride replacement reaction layer (106) and filter grid successively from top to bottom (107), the chlorine reaction absorbing layer 102 is positioned on the reaction tower inlet, and the shower device 101 is positioned at the chlorine reaction absorbing lay...

Embodiment 2

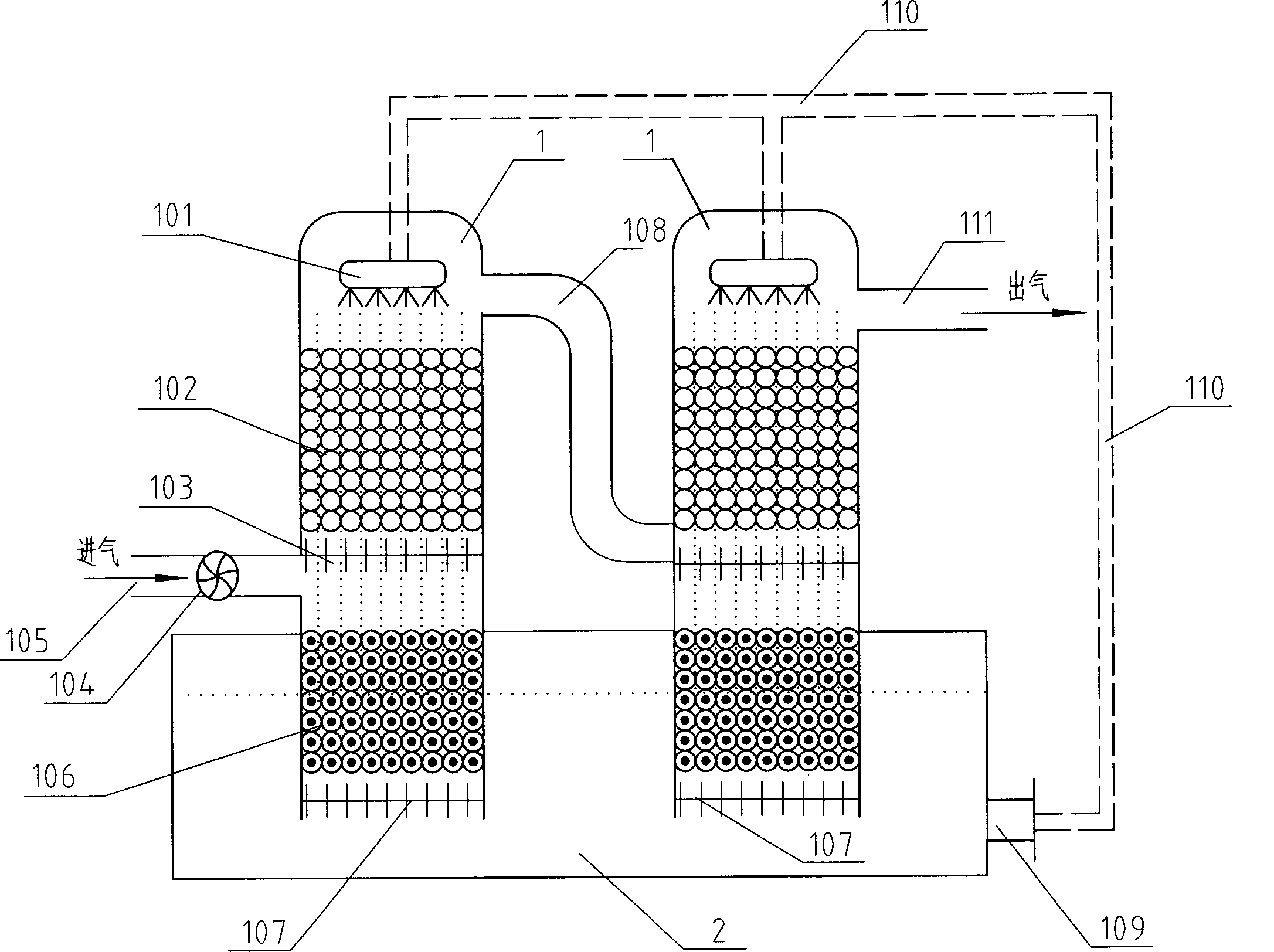

[0039] like figure 2 As shown, in order to increase the absorption rate of chlorine, on the basis of embodiment one, a next-level reaction tower and a chlorine delivery connecting pipe 108 are added, and one end of the chlorine delivery connecting pipe 108 is connected to the gas outlet of the upper-level reaction tower, and the chlorine delivery The other end of the connecting pipe 108 is connected to the air inlet of the next-stage reaction tower. The interior setting of the next-stage reaction tower is the same as that of the reaction tower. The spray device of the first-stage reaction tower is connected with the outlet of the ferrous chloride infusion pipe, and the lower part of the next-stage reaction tower is placed in the liquid storage tank 2 and communicated with the liquid storage tank 2.

[0040] Working process, the difference with embodiment one is:

[0041] The air containing chlorine enters the next reaction tower from the gas outlet of the reaction tower thro...

Embodiment 3

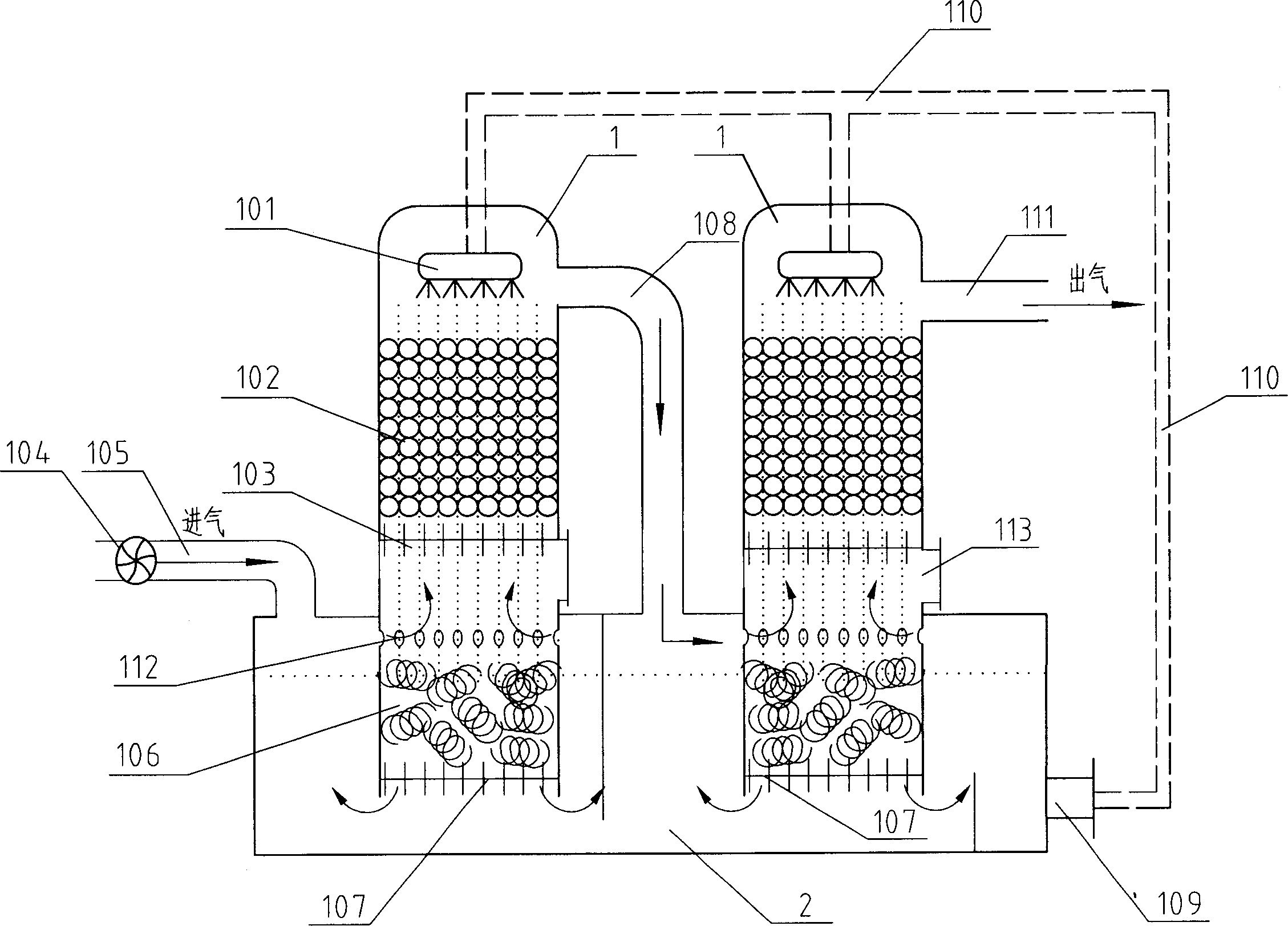

[0044] like image 3 As shown, this embodiment has been improved on the basis of embodiment two, mainly:

[0045] First, the chlorine delivery pipe 105 is not directly connected to the reaction tower, but is connected to the opening on the upper part of the liquid storage tank 2, and chlorine gas is sent into the cavity inside the liquid storage tank and above the liquid level; correspondingly, in the The part of the reaction tower 1 protruding into the liquid storage tank and above the liquid level is provided with an air intake guide hole 112 . In this way, the scheme of pressing chlorine gas into the upper cavity of the liquid storage tank first, and then entering the reaction absorption layer through the air guide hole in the middle of the reaction tower can buffer and homogenize the rising momentum of chlorine gas, thereby making the absorption reaction more sufficient.

[0046] Second, a feeding port 113 is provided in the middle of the reaction tower 1, which is conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com