One-step spinning machine capable of conducting entwisting clockwise and one-step spinning method

A spinning machine and forward technology, which is applied in the field of forward multi-twist one-step spinning machine and one-step spinning, can solve the problems of high consumption, inability to achieve high-count, high-quality spinning, etc., and achieve reasonable structure and reduce spinning. The number of yarn processes and the effect of compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

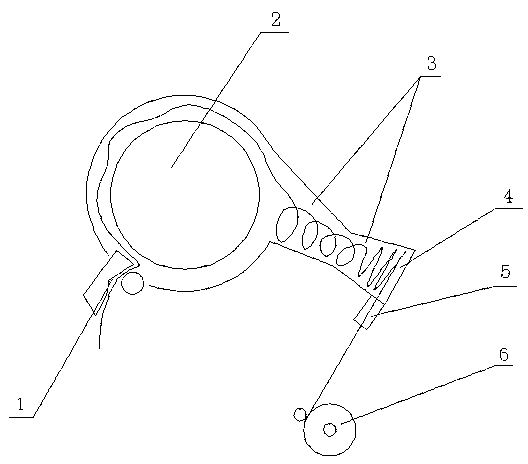

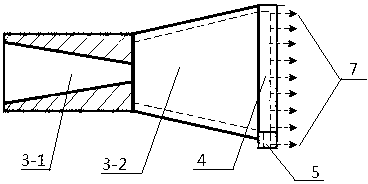

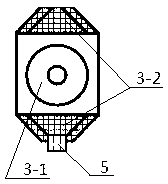

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment: See Figure 1-Figure 8 , an embodiment of a forward polytwisting one-step spinning machine of the present invention, comprising a frame, a carding roller 2, a carding roller cover, a fiber feeding mechanism 1, a forward cohesive twisting mechanism, and a yarn winding mechanism 6 And the air suction device, the opening roller 2 and the opening roller cover are arranged on the frame, the fiber feeding mechanism 1 is arranged on one side of the opening roller 2, and the other side of the opening roller 2 is provided under the other side which is connected with the opening roller cover. Shaped tube 3. The fiber feeding mechanism 1 is a cotton feeding roller and a cotton feeding board or a pair of wool feeding rollers. The special-shaped pipe 3 is formed by butt jointing of a tapered pipe 3-1 and a trapezoidal pipe 3-2, the large-diameter end of the taper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outlet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com