Plate-shell type middle fluid type gasifier

A technology of plate-shell type and vaporizer, which is applied in the direction of pressure vessels, non-pressure vessels, fixed-capacity gas storage tanks, etc., and can solve the problems of low heat exchange efficiency, high manufacturing cost, and large volume of shell-and-tube heat exchangers , to achieve the effects of reducing manufacturing costs, installation and maintenance costs, compact weight, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

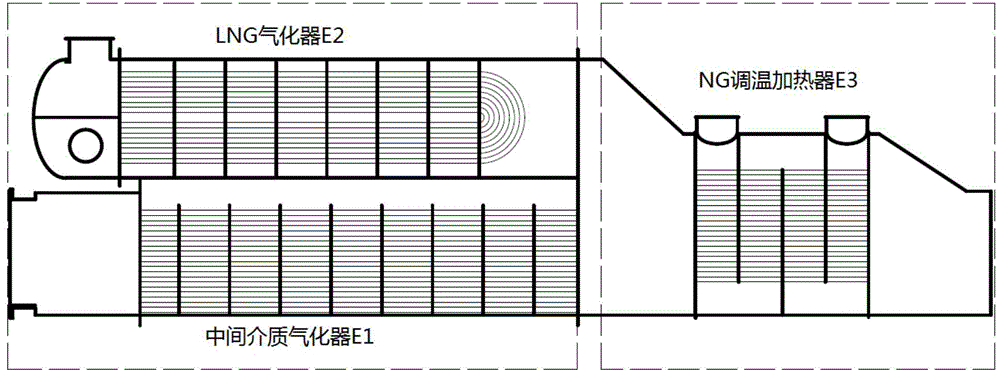

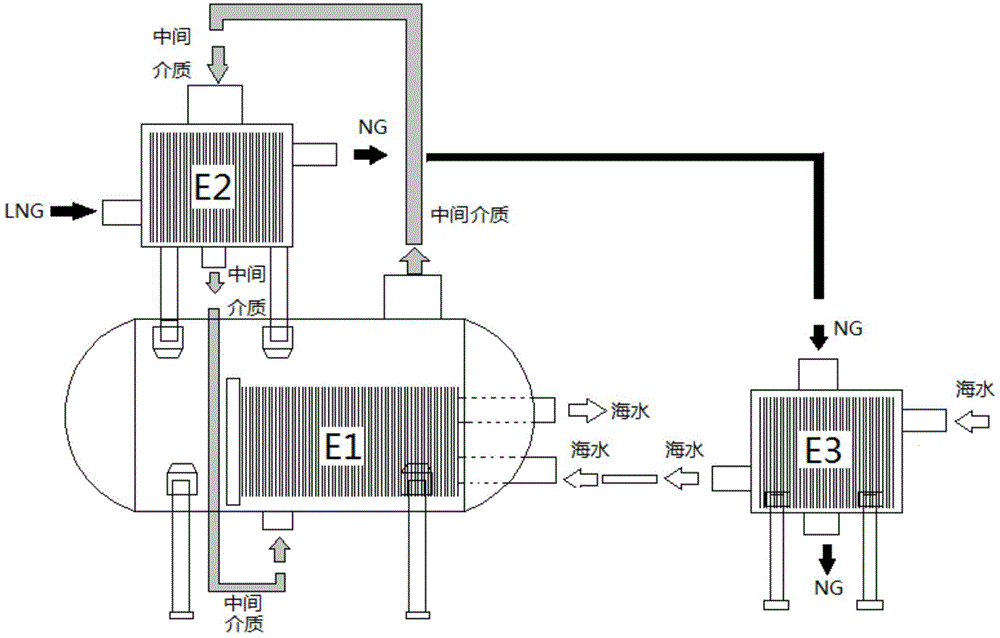

[0021] This embodiment provides a plate-shell type intermediate fluid vaporizer, which is composed of three-stage plate-shell heat exchangers. Compared with the traditional shell-and-tube IFV, it is small in size, light in weight, low in equipment cost, and can improve equipment reliability and lifespan.

[0022] The structure of the plate-shell intermediate fluid gasifier is as follows: figure 2 As shown, it is composed of intermediate medium vaporizer E1, LNG vaporizer E2 and NG thermostat heater E3.

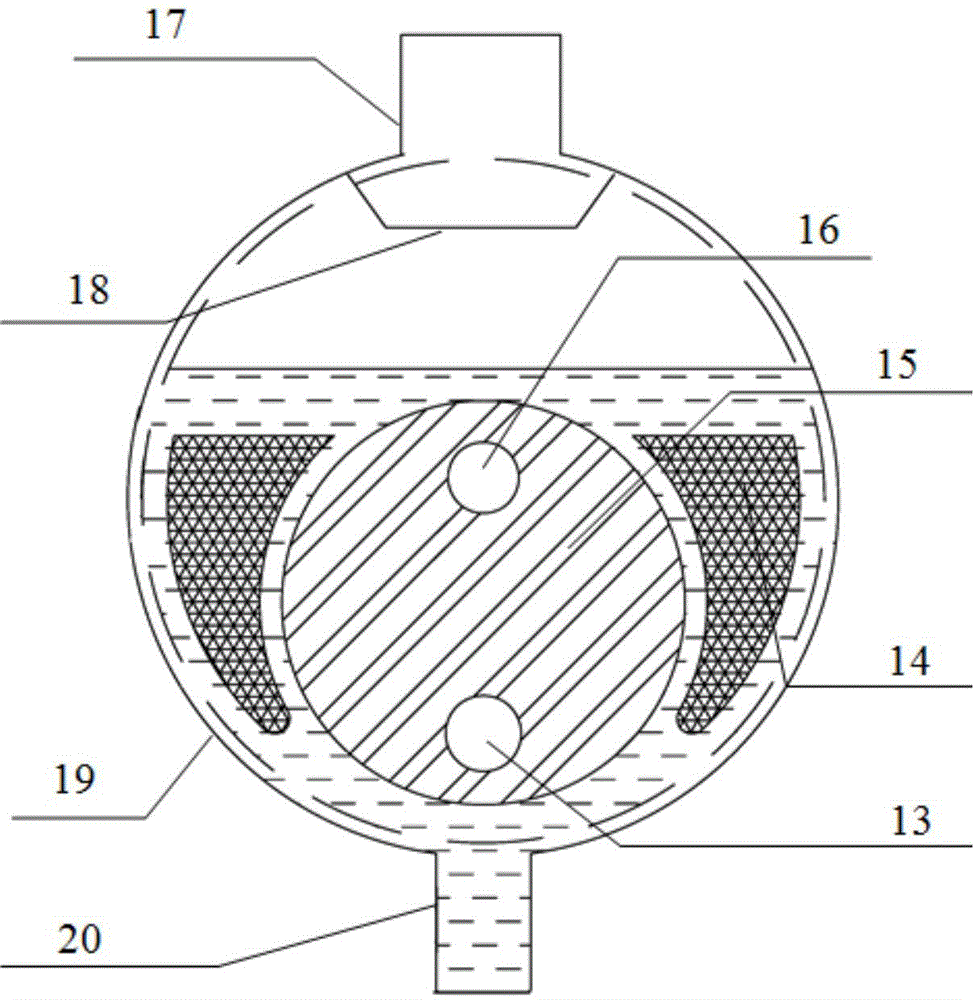

[0023] Among them, the intermediate medium vaporizer E1 adopts a flooded evaporator, such as image 3 shown. It includes an evaporator shell 19 and a heat exchange core 15; wherein the evaporator shell 19 is made of carbon steel or stainless steel, and the heat exchange core 15 is made of titanium. The evaporator shell 19 is a cylindrical structure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com