Hoist motor closed type hydraulic system for preventing pipelines from bursting and control method thereof

A hoisting motor and closed motor technology, applied in the field of safety systems, can solve the problems of poor dynamic braking effect of parking brakes, difficult to put down heavy objects, and hose bursts, etc. Strong flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

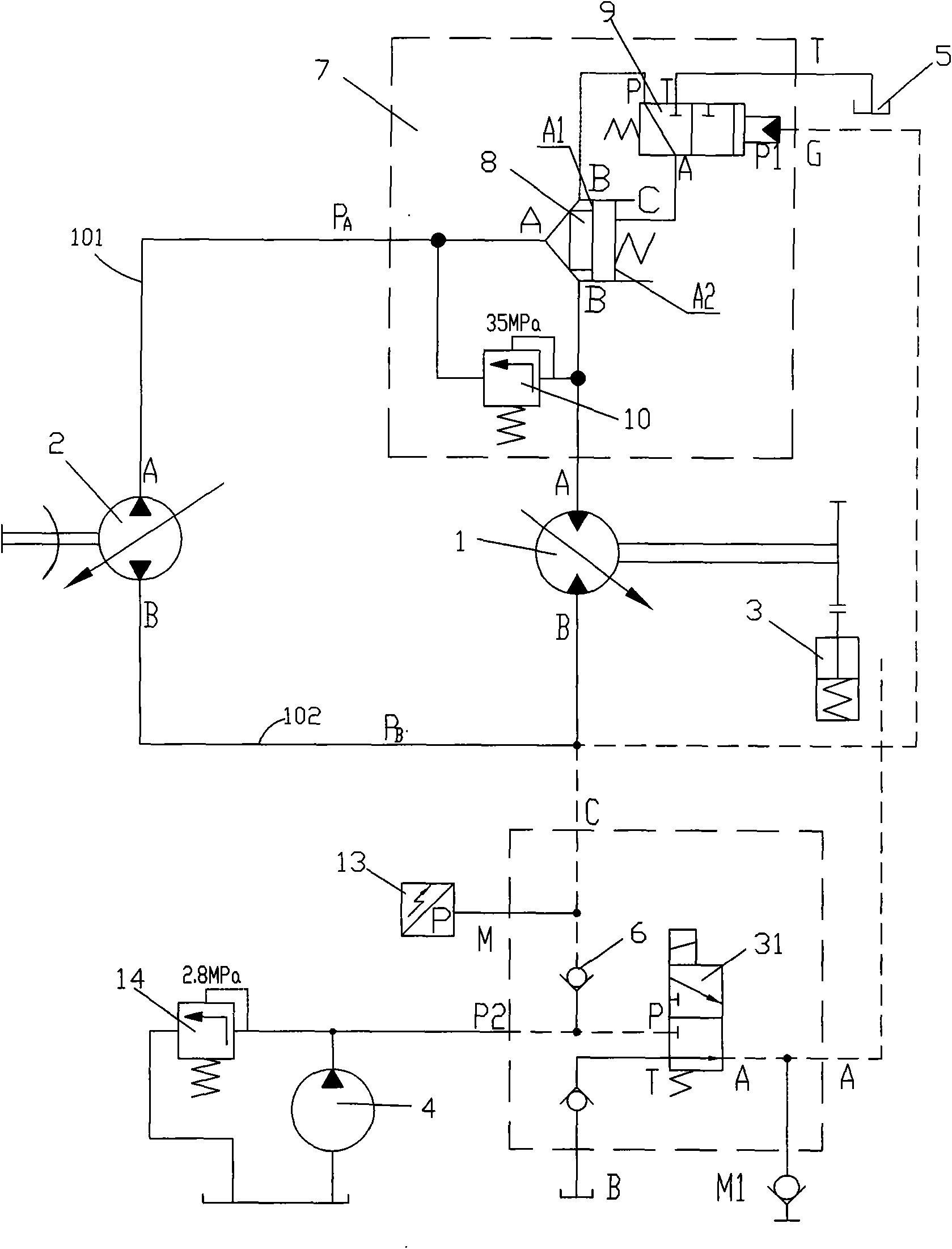

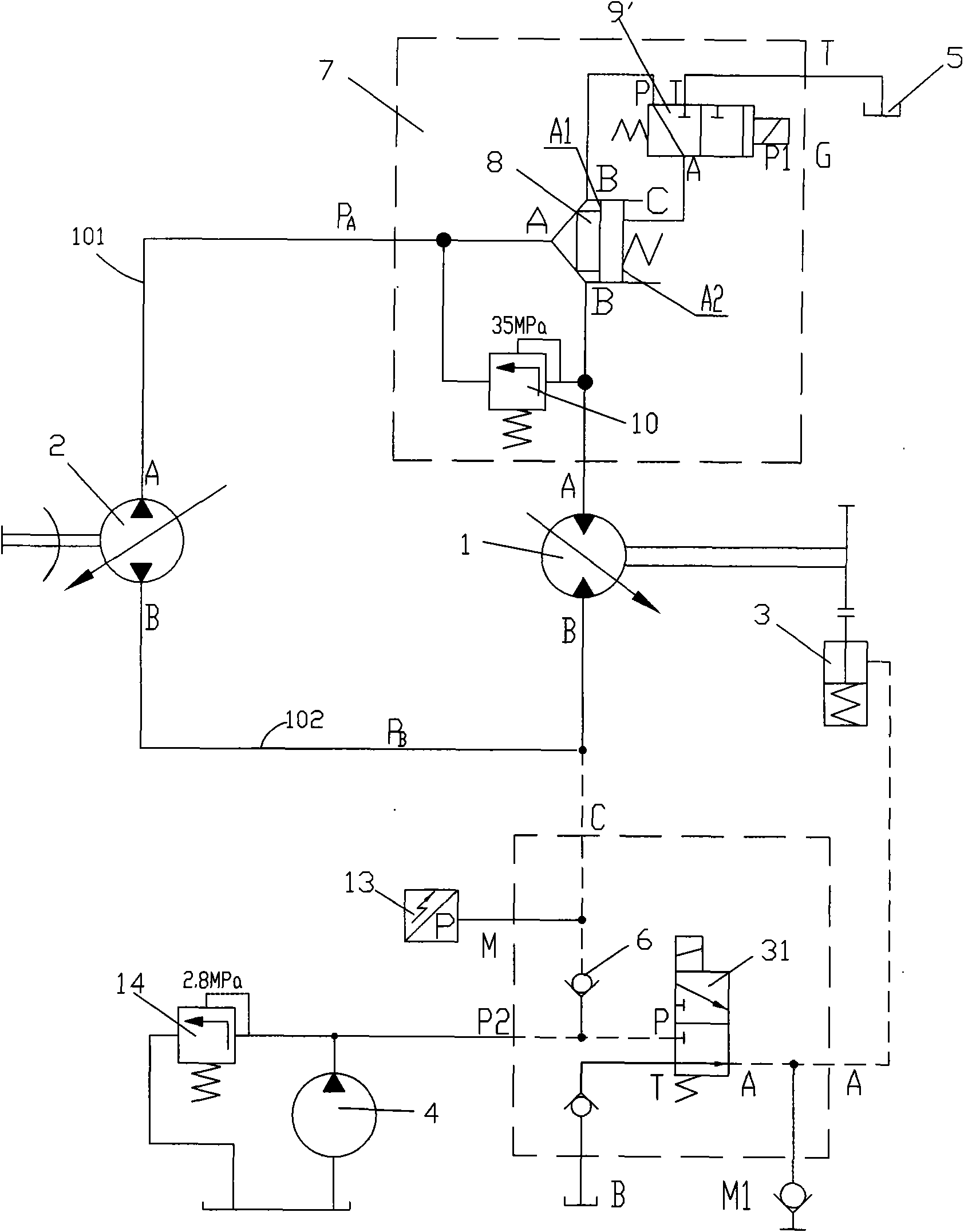

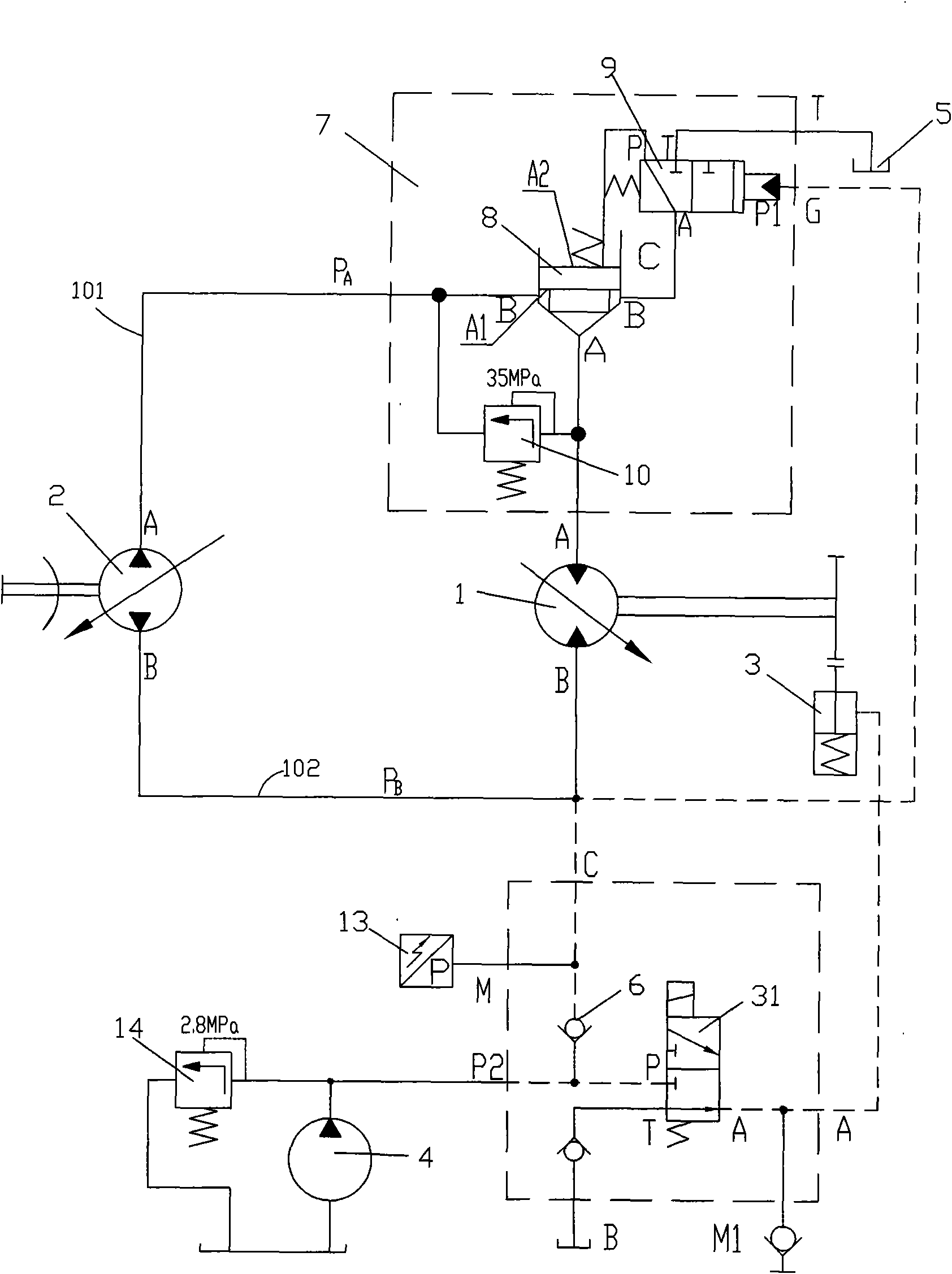

[0025] see figure 1 , the closed hydraulic system of the winch motor with the anti-pipeline bursting device of the present invention, which includes the winch motor 1 and its ascending oil passage 101, descending oil passage 102, and the closed hydraulic system arranged in series in the above-mentioned oil passage of the winch motor 1 type pump 2; connected to the brake 3 of the hoist motor 1 and its corresponding brake solenoid valve 31; respectively connected to the oil circuit of the hoist motor 1, the oil supply circuit of the brake solenoid valve 31, the oil supply pump 4, and the oil return tank 5 And the oil return circuit; a pipeline burst prevention device 7, the pipeline burst prevention device 7 includes a two-way cartridge valve 8, a reversing valve---hydraulic control reversing valve 9; the two-way cartridge valve 8 is set In the oil circuit between the hoist motor 1 and the closed pump 2, the two ports B and A of the two-way cartridge valve 8 correspond to the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com