Heat collection device for recycling waste heat in calcium carbide cooling process

A technology of cooling process and waste heat recovery, which is applied in the field of waste heat recovery devices, can solve the problems of environmental heat pollution and waste of heat energy, and achieve the effects of ensuring health and safety, reducing production costs, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

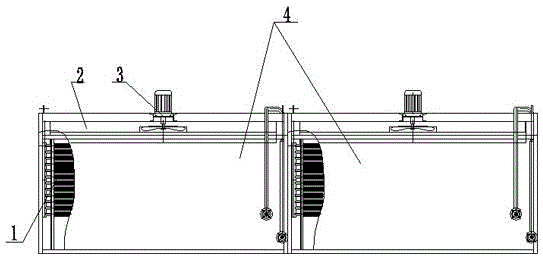

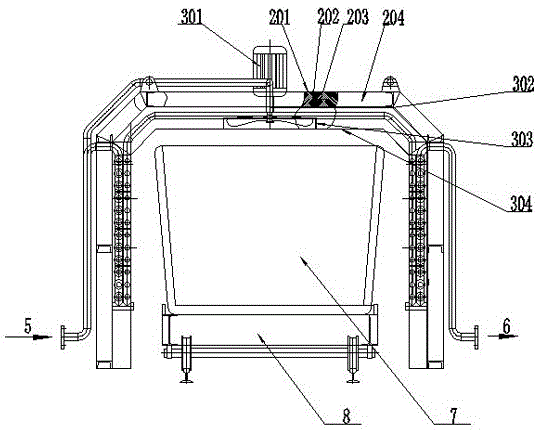

[0018] Figure 1-Figure 5 As shown, the specific implementation is as follows:

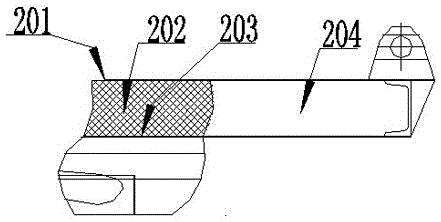

[0019] A heat collecting device for recovering waste heat in the calcium carbide cooling process, including a heat collecting module 4, the heat collecting module includes a main frame 2, a heat exchange tube bundle assembly 1 and a circulating fan assembly 3, and the circulating fan assembly 3 is installed on the top of the main frame 2, The main frame 2 is fixed on the installation surface and its cross section is an inverted U-shaped structure. The cavity surrounded by the main frame 2 constitutes a passage for the transport vehicle 8 to pass through, that is, the main frame 2 is just covered on the track of the transport vehicle 8 to form a supply channel. The channel through which the transport vehicle 8 passes, and the calcium carbide pot 7 installed on the transport vehicle 8 is located in the channel. The heat exchange tube bundle assembly 1 includes two composite heat exchange assemblies,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com