High-frequency electric coalescence type high-efficiency oil-gas-water three-phase separator

A three-phase separator, oil-gas-water technology, used in the dehydration treatment of aged oil and crude oil containing high polymer and demulsifier, and the field of high water-cut crude oil, which can solve the problem of low equipment utilization rate, large equipment area, and dehydration process flow. Complex problems, to achieve the effect of compact equipment, overcoming the inverted electric field, and high dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

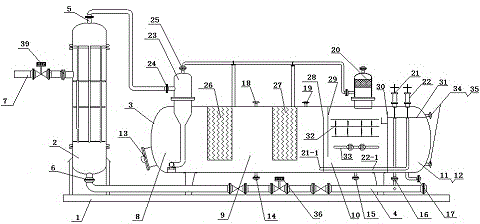

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] The invention is a high-frequency electric coalescence type high-efficiency oil-gas-water three-phase separator. The tank body needs to be treated with anticorrosion and heat preservation, and the internal components are made of stainless steel. Depending on the processing capacity, 3 to 10 cyclone tubes with a diameter of 50-100mm are arranged inside the cyclone.

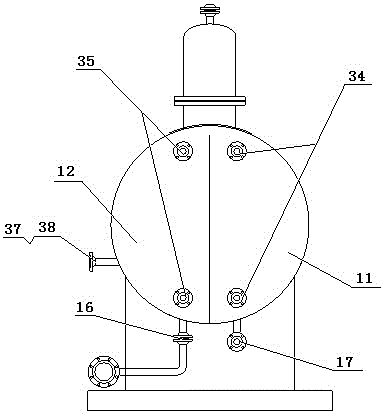

[0022] Such as Figure 1 to Figure 2 As shown, the high-frequency electric coalescence high-efficiency oil-gas-water three-phase separator includes a base (1), a cyclone (2), a horizontal tank (3), and a sewage system (4).

[0023] Both the cyclone (2) and the horizontal tank (3) are placed on the base (1); the cyclone (2) is placed on the inlet side of the horizontal tank (3) for pre-separation of oil and water, A large amount of free water present in the crude oil is separated to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com