A method for producing ultrapure ammonia

A technology of ultra-pure ammonia water and ultra-pure water, which is applied in the preparation/separation of ammonia, etc. It can solve the problems of huge investment in absorption and desorption equipment, potential safety hazards, high energy consumption and danger of distillation high-temperature operation, and achieve compact equipment structure , no discharge of three wastes, and the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

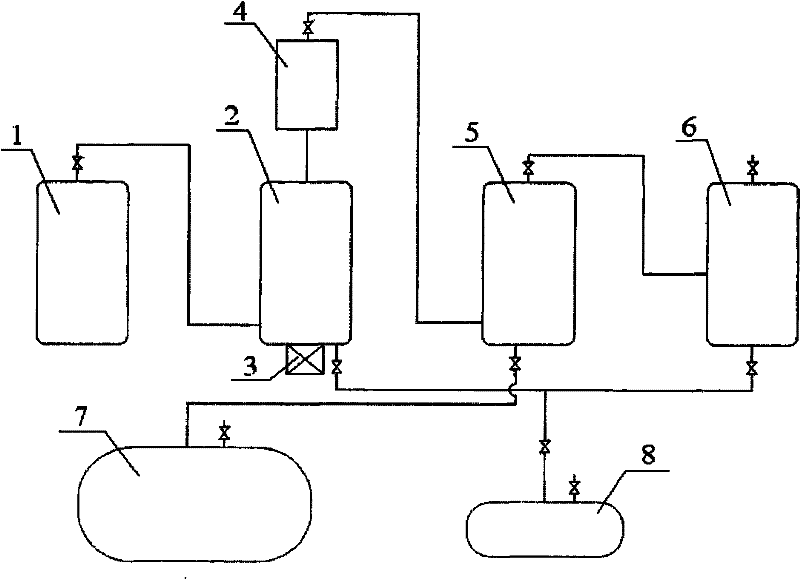

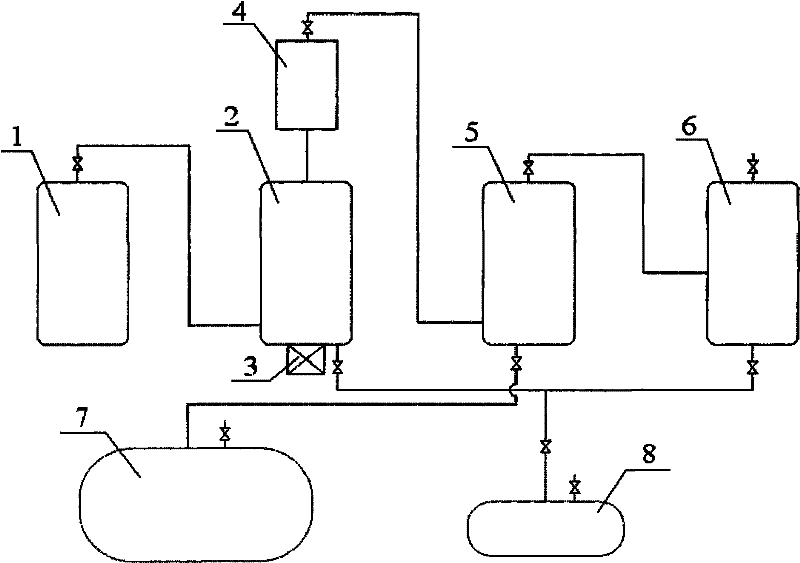

[0020] A method for producing ultrapure ammonia, its flow process is as follows figure 1 As shown, the method includes the following steps:

[0021] The ammonia gas volatilized in the liquid ammonia container 1 is input into the ultrasonic purification tower 2, the temperature of the ultrasonic purification tower is controlled to be ≥0°C, the pressure is controlled to be ≥0.08Mpa, and the targeted pretreatment agent persulfuric acid is added to the ultrasonic purification tower 2 Ammonium and ammonium persulfate are added in an amount of 0.01% of the weight of the ammonia gas passing through the ultrasonic purification tower, and are used to complex volatile impurities in the ammonia gas that have an impact on the quality of the end product. A large number of fine ammonia water particles are produced in the ultrasonic purification tower 2 through the ultrasonic atomizer 3, the particle size distribution of the ammonia water particles is basically 0.1 to 30 μm, and the weight r...

Embodiment 2

[0023] A method for producing ultrapure ammonia, the method comprises the following steps:

[0024] The ammonia gas volatilized in the liquid ammonia container is input into the ultrasonic purification tower, the temperature of the ultrasonic purification tower is controlled at 20°C, and the pressure is controlled at 0.3Mpa, and the targeted pretreatment agent hydrogen peroxide, hydrogen peroxide is added to the ultrasonic purification tower The addition amount is 0.1% of the weight of the ammonia gas passing through the ultrasonic purification tower, and is used to complex the volatile impurities in the ammonia gas that have an impact on the quality of the end product. A large number of fine ammonia water particles are produced in the ultrasonic purification tower through an ultrasonic nebulizer, and the particle size distribution of the ammonia water particles is basically 0.1-30 μm. The huge surface area of the particles absorbs more impurities contained in the ammonia ga...

Embodiment 3

[0026] A method for producing ultrapure ammonia, the method comprises the following steps:

[0027] The ammonia gas volatilized in the liquid ammonia container is input into the ultrasonic purification tower. The temperature of the ultrasonic purification tower is controlled to be ≤50°C and the pressure is controlled to be ≤0.8Mpa. The targeted pretreatment agent phosphoric acid is added to the ultrasonic purification tower. The amount of phosphoric acid added It is 1% of the weight of the ammonia gas passing through the ultrasonic purification tower, and is used to complex the volatile impurities in the ammonia gas that have an impact on the quality of the end product. A large number of fine ammonia water particles are produced in the ultrasonic purification tower through an ultrasonic atomizer. The particle size distribution of the ammonia water particles is basically 0.1-30 μm. The weight ratio of the ammonia water particle production to the ammonia gas passing through the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com