Synthetic method of novel liquid crystal material 3-butoxy-N,N-dimethylpropanamide

A technology of dimethylpropionamide and dimethylacrylamide, which is applied in the field of material synthesis, can solve the problems of long synthesis route, high cost, low yield and the like, and achieves low environmental impact, strong operability and simple source of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples.

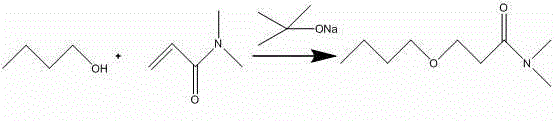

[0017] Reaction equation of the present invention is as follows:

[0018]

[0019] The synthetic steps of the present invention at least include:

[0020] Step 1: Condensation reaction:

[0021] In a 50-liter circulating heating jacketed reactor, add 10 kg of n-butanol, under stirring, add 0.5 kg of catalytic amount of sodium tert-butoxide, and heat to 80°C. Slowly add 11.1 kg of N,N-dimethylacrylamide dropwise, the temperature is controlled at 78°C-82°C, and the dropwise addition time is about 5-8 hours. After the dropwise addition, keep the temperature at 80°C for 12-15 hours. Treatment: 1) Central control, when the raw material is less than 3%, stop heating. 2) Cool down and proceed to the next step.

[0022] Step 2: Refining:

[0023] Distillation: Under the high vacuum of the mechanical vacuum pump, the product is extracted from 21 kg of crude product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com