Superhydrophobic coating, superhydrophobic coating and preparation method of the superhydrophobic coating

A technology of super-hydrophobic coating and hydrophobic nano-technology, applied in the direction of coating, etc., can solve the problems of insufficient stability of super-hydrophobic surface, unfavorable industrial production, insufficient tolerance, etc., achieve good reusability and service life, and not easy to aging and failure , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

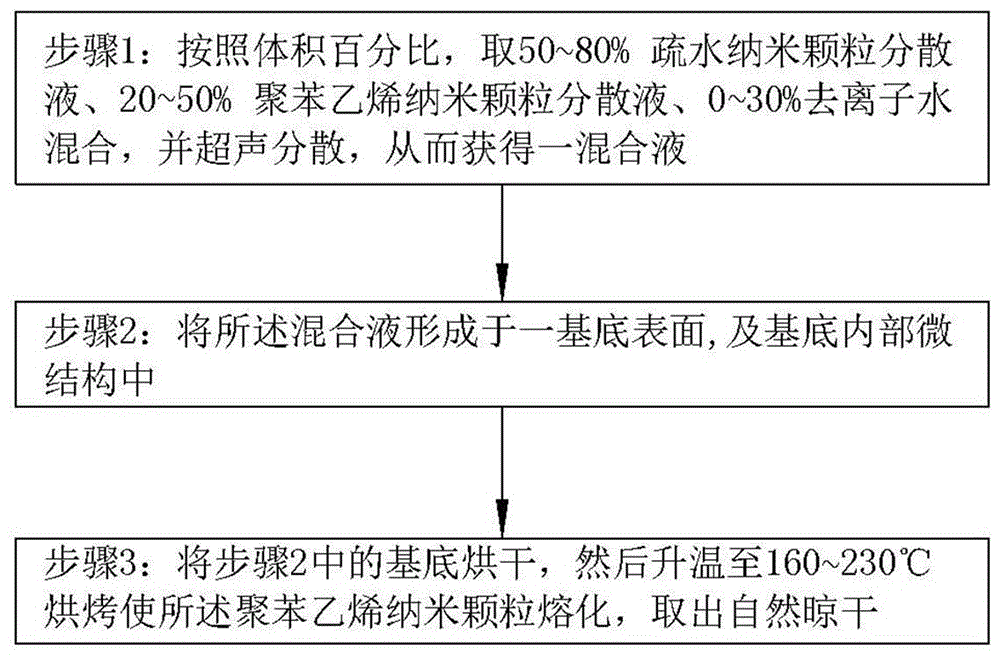

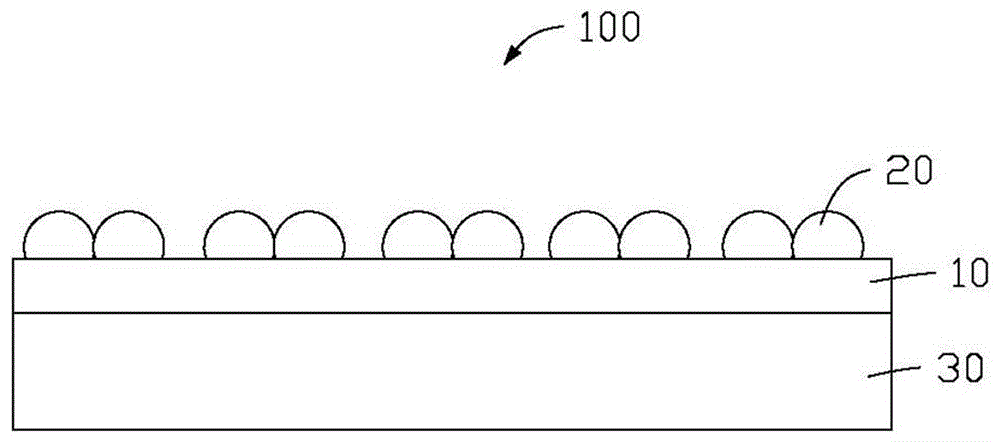

[0019] Please refer to figure 1 , the embodiment of the present invention provides a kind of preparation method of superhydrophobic coating, it comprises the following steps:

[0020] Step 1: According to the ratio of parts by volume, take 50-80 parts of hydrophobic nanoparticle dispersion with a mass fraction of 2% to 15%, 20-50 parts of polystyrene nanoparticle dispersion with a mass fraction of 1% to 10%, 0~30 parts of solvents are mixed and ultrasonically dispersed to obtain a mixed solution;

[0021] Step 2: forming the mixed solution on the surface of a substrate and in the microstructure inside the substrate;

[0022] Step 3: Dry the substrate in step 2, then heat up to 160-230°C and bake to melt the polystyrene nanoparticles, take it out and dry it naturally.

[0023] In step (1), the hydrophobic nanoparticle dispersion can be obtained by dispersing the hydrophobic nanoparticles in a solvent, or by suspension polymerization, emulsion polymerization and other polymeri...

Embodiment 1

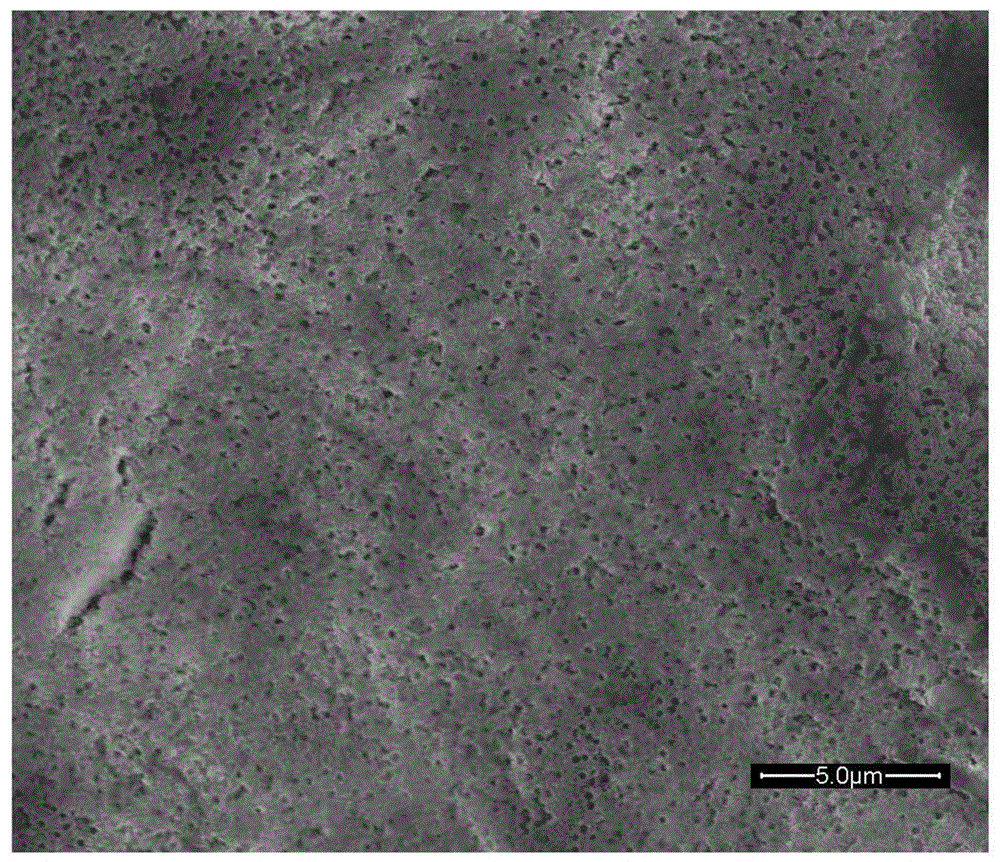

[0036] Take 60 parts (parts by volume) of polytetrafluoroethylene dispersion with a mass fraction of 6%, 20 parts of polystyrene dispersion with a mass fraction of 2.5%, and 20 parts of water, and then ultrasonically disperse to obtain a mixed solution, wherein, The particle size of the polytetrafluoroethylene is about 220nm, and the particle size of the polystyrene is about 200nm; use a high-density cotton cloth (average pore size less than 200 microns) as the substrate, and immerse it in the mixed solution to deposit 20 minutes; take out the high-density cotton cloth immersed in the mixed solution, put it in a drying oven at 70°C for 30 minutes, and finally raise the temperature to 220°C for 20 minutes, take it out and dry it naturally to obtain a superhydrophobic cotton cloth. After testing, the contact angle of the superhydrophobic cotton cloth to water is greater than 150°. In addition, the contact angle of the super-hydrophobic cotton cloth to oil (n-hexane, n-hexadecane...

Embodiment 2

[0038] This embodiment is basically the same as the above-mentioned embodiment 1, except that a polyester or polypropylene non-woven fabric is used as the base and immersed in the mixed solution, wherein the average pore size of the non-woven fabric is less than 200 microns. Thereby superhydrophobic polyester or polypropylene non-woven fabrics are obtained. After testing, the contact angle of the hydrophobic polyester or polypropylene nonwoven fabric to water is greater than 150°. At the same time, the hydrophobic polyester or polypropylene non-woven fabric has a contact angle of 0° to oil (n-hexane, n-hexadecane, chloroform, gasoline, silicone oil, etc.), so it can also be used for oil-water separation. The hydrophobic polyester or polypropylene non-woven fabric has a separation efficiency of more than 99% for mixtures of oil (n-hexane, n-hexadecane, chloroform, gasoline, silicone oil, etc.) and water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com