One-pot method for preparing stable superhydrophobic antibacterial fabrics

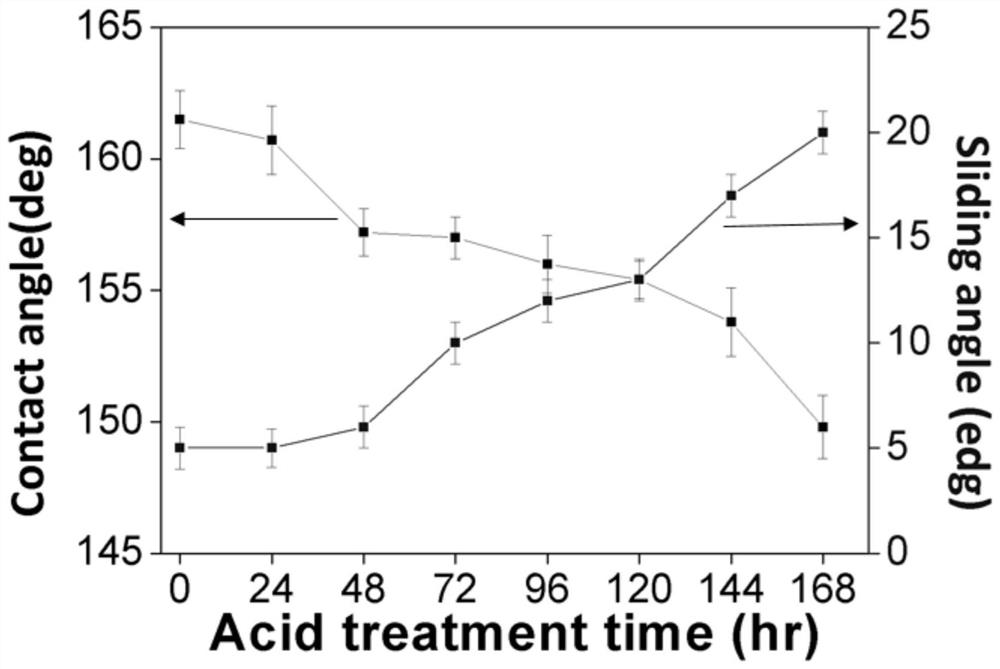

A kind of antibacterial fabric and super-hydrophobic technology, which is applied in the direction of resistance to media-borne diseases, textiles and papermaking, and liquid-repellent fibers. It can solve the problems of poor durability of fabrics, cumbersome polymerization process of dopamine, and long polymerization time. Effects of superhydrophobicity, shortened polymerization time, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The one-pot method for preparing stable superhydrophobic antibacterial fabric includes the following steps:

[0029] (1) Dopamine hydrochloride and silver nitrate are added in 50mL of dehydrated alcohol, so that the mass concentration of dopamine hydrochloride in dehydrated alcohol is 6mg / mL, and the mass concentration of silver nitrate in dehydrated alcohol is 4.8mg / mL, after sonicating for 1 min and mixing, adjust the pH to 8.5 with 1M, pH=8 Tris-HCl buffer solution, then add 100 μL of hexadecyltrimethoxysilane, ultrasonically treat for 5 min and mix well to obtain the treatment solution;

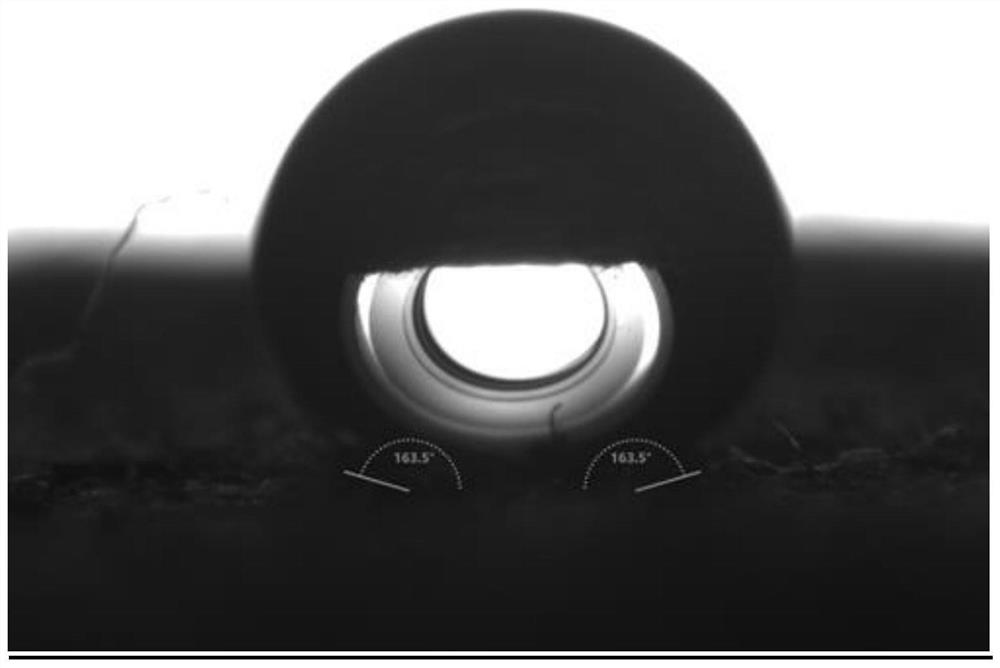

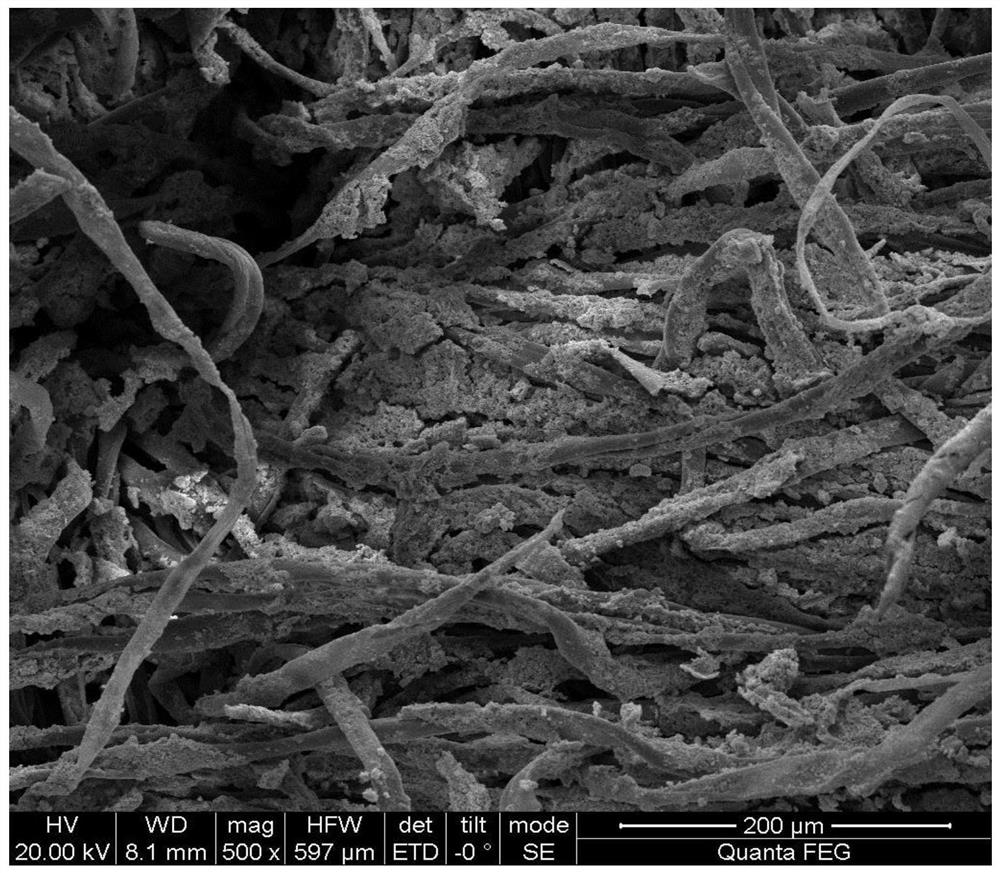

[0030] (2) Wash the fabric with deionized water and ethanol respectively, and then place it in an oven at 60 ° C to dry; soak the cleaned and dried fabric in the above-mentioned treatment solution, ultrasonically treat it for 5min, and take out the treatment solution after the above-mentioned treatment solution. The fabric was dried in an oven at 100 °C; then the stable superhydro...

Embodiment 2

[0058] The one-pot method for preparing stable superhydrophobic antibacterial fabric includes the following steps:

[0059] (1) Dopamine hydrochloride and silver nitrate are added in 50mL of dehydrated alcohol, so that the mass concentration of dopamine hydrochloride in dehydrated ethanol is 6mg / mL, and the mass concentration of silver nitrate in dehydrated ethanol is 4.2mg / mL, after sonicating for 1 min and mixing, adjust the pH to 8.3 with 1M, pH=8 Tris-HCl buffer solution, then add 100 μL hexadecyltrimethoxysilane, ultrasonically treat for 5 min and mix well to obtain the treatment solution;

[0060] (2) Wash the fabric with deionized water and ethanol respectively, and then place it in an oven at 75 ° C for drying; soak the cleaned and dried fabric in the above-mentioned treatment solution, ultrasonically treat it for 5min, and take out the treatment solution after the above-mentioned treatment solution. The fabric was dried in an oven at 80 °C; then the stable superhydro...

Embodiment 3

[0063] The one-pot method for preparing stable superhydrophobic antibacterial fabric includes the following steps:

[0064] (1) Dopamine hydrochloride and silver nitrate are added in 50mL of dehydrated alcohol, so that the mass concentration of dopamine hydrochloride in dehydrated ethanol is 6mg / mL, and the mass concentration of silver nitrate in dehydrated ethanol is 4.2mg After sonicating for 1 min and mixing, adjust the pH to 9 with 1M, pH=8 Tris-HCl buffer solution, then add 100 μL hexadecyltrimethoxysilane, sonicate for 5 min and mix to obtain the treatment solution;

[0065] (2) Wash the fabric with deionized water and ethanol respectively, and then place it in an oven at 90 ° C for drying; soak the cleaned and dried fabric in the above-mentioned treatment solution, ultrasonically treat it for 5 min, and take out the treated solution. The fabric was dried in an oven at 90 °C; then the stable superhydrophobic antibacterial fabric was obtained after repeating the operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com