Prestressed full-anchor squeezed anchoring device and method thereof

An anchoring device and prestressing technology, which is applied in the direction of earthwork drilling, bolt installation, mining equipment, etc., can solve the problems of stress concentration, increased eccentricity of bolts, poor stability, etc. The effect of internal anchoring force and avoiding stress weakness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the implementation examples in the accompanying drawings:

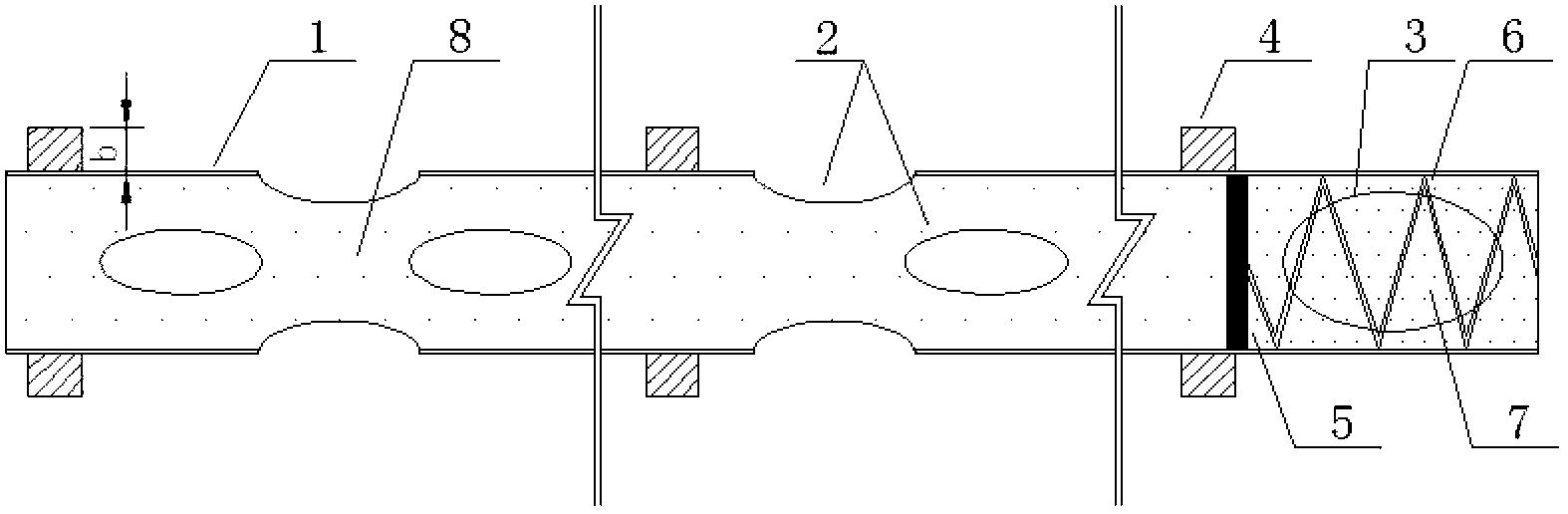

[0020] Such as figure 1 As shown, the prestressed full-anchor extrusion anchoring device of the present invention is mainly composed of a casing 1, a grouting annular plug 4, a piston 5; There are a plurality of through-holes 12 distributed in a cross shape on the pipe wall of the casing 1, and a plurality of slurry-separating annular plugs 4 are set at intervals on the casing 1, and there are 3 in the accompanying drawing, and the number is determined according to the length of the casing. One at each end, one or two in the middle; the thickness b of the slurry-separating annular plug 4 is 6-8 mm. The front part of the casing 1 is symmetrically opened with a through hole 2 3 slightly larger than the through hole 1 2, and the through hole 1 2 and the through hole 2 3 are in the shape of an oval hole, a circular hole or a strip-shaped hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com