Tea seed cake filler device

A technology of filling machine and tea meal, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc. It can solve the problems of consuming a lot of manpower and material resources, increasing the moisture content of tea meal, and increasing the processing cost of enterprises, so as to reduce labor intensity, The effect of improving work efficiency and simple structure

Inactive Publication Date: 2011-06-15

HUBEI HOIL WOODY OIL

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the processing method of tea oil production enterprises is to directly discharge the tea meal into the warehouse for stacking. This method has three defects: first, due to the high temperature of the tea meal just discharged from the leaching process (usually temperature of 90°C), it is easy to absorb moisture when stacked in the open air, causing the moisture content in the tea dregs to rise, and it is easy to mold and deteriorate; second, at present, the tea dregs stacked in the warehouse are usually bagged manually, which requires a lot of manpower Material resources increase the processing cost of the enterprise; third, the tea meal is easy to agglomerate after being piled up in large quantities, which brings certain difficulties to the later processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

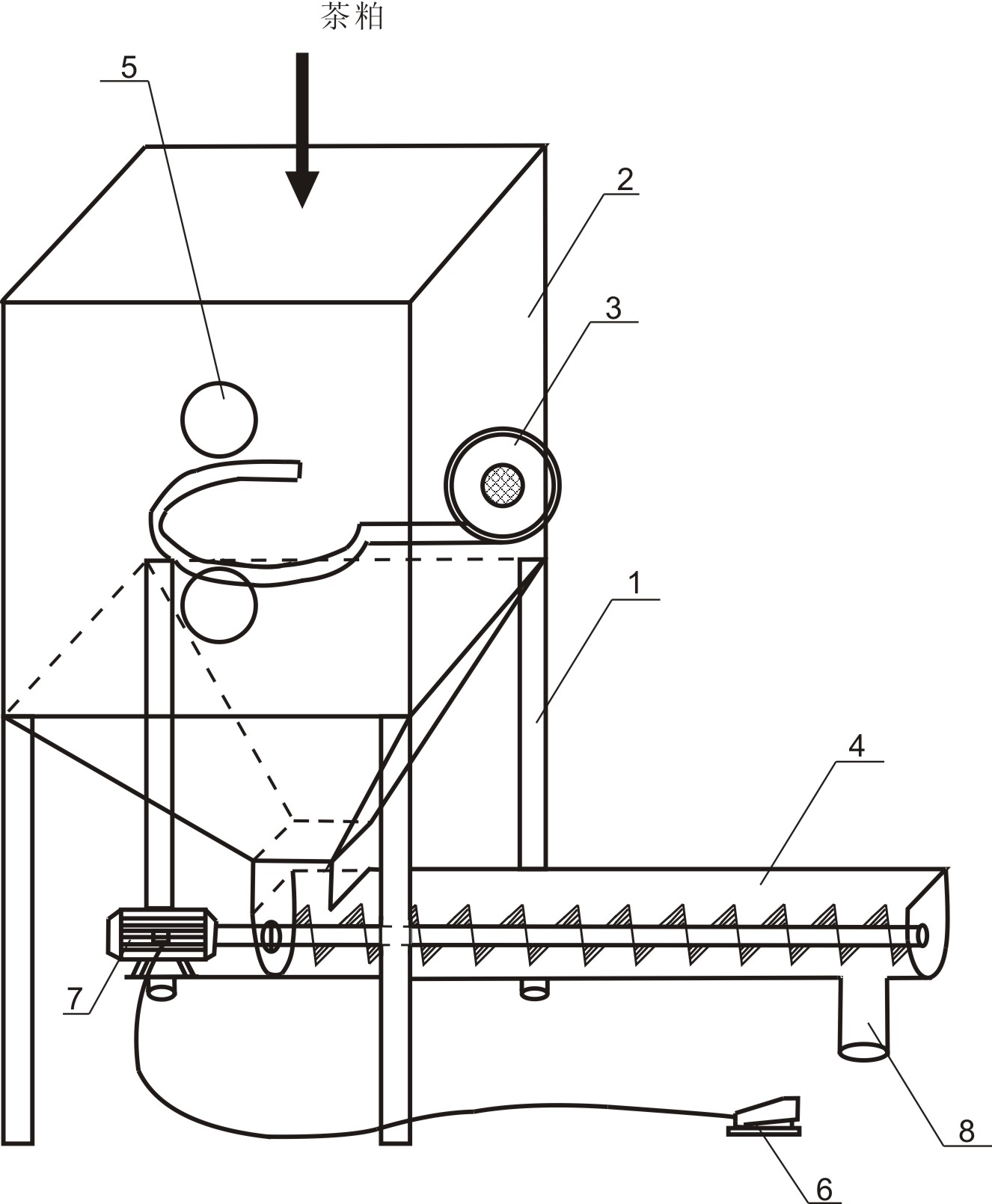

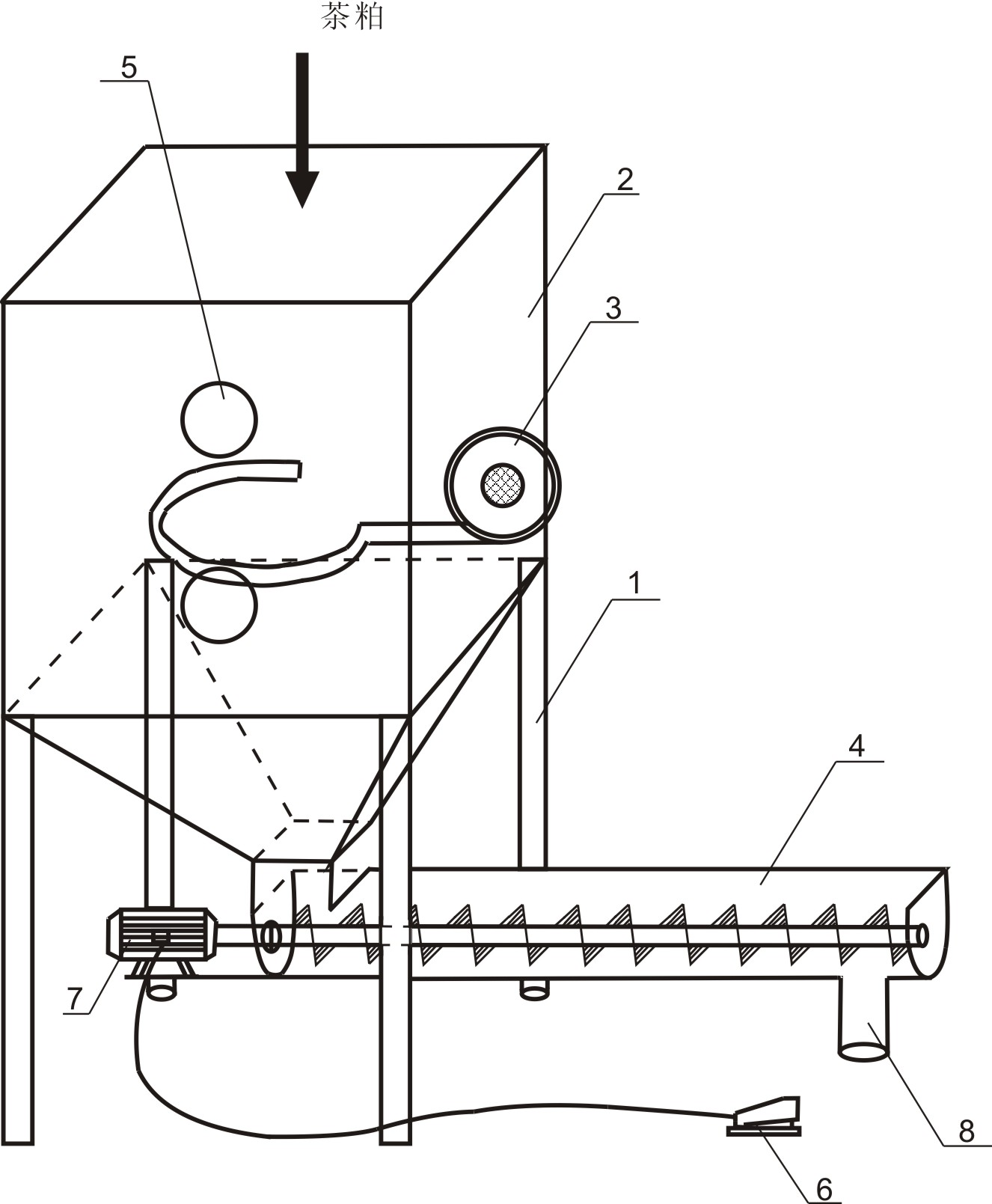

The invention discloses a tea seed cake filler device, which comprises a seed cake storage tank, wherein the seed cake storage tank is arranged on a bracket and has an upper opening; the lower part of the seed cake storage tank forms a cone; an air duct of a fan is communicated with the seed cake storage tank; the lower end of the seed cake storage tank is communicated with a material inlet of a screw conveyor; the fan is an intermediate pressure fan; two observation windows are formed on the seed cake storage tank, and are vertically arranged on the front surface of the seed cake storage tank; a switch of a motor of the screw conveyor is a foot switch; and an electronic weigher is arranged below a material outlet of the screw conveyor. The tea seed cake filler device provided by the invention can cool tea seed cakes discharged by a leaching process and automatically bag the cooled tea seed cakes, overcomes the shortcomings of conventional manual bagging, reduces the labor intensity of workers, reduces labor forces and ensures the quality of the tea seed cakes.

Description

Tea meal filling machine device technical field The invention relates to a filling machine device, in particular to a tea dregs filling machine device for bagging tea dregs. Background technique The purpose of tea oil oil extraction process is to reduce the residual oil rate of oil cake, improve the oil yield of oil crops, save production costs, and the cake after extraction becomes tea meal. At present, the processing method of tea oil production enterprises is to directly discharge the tea meal into the warehouse for stacking. This method has three defects: first, due to the high temperature of the tea meal just discharged from the leaching process (usually temperature of 90°C), it is easy to absorb moisture when stacked in the open air, causing the moisture content in the tea dregs to rise, and it is easy to mold and deteriorate; second, at present, the tea dregs stacked in the warehouse are usually bagged manually, which requires a lot of manpower Material resources i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65B63/08B65B1/12B65B1/32B65B57/00

Inventor 李国宝李军鹏裴黎

Owner HUBEI HOIL WOODY OIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com