Solarization recrystallization salt-manufacturing technology

A technology of recrystallization and craftsmanship, applied in the field of solar salt production, can solve the problems of unnatural crystal form, many impurities, poor color, etc., and achieve the effect of reducing the time of brine making, good quality and clear brine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

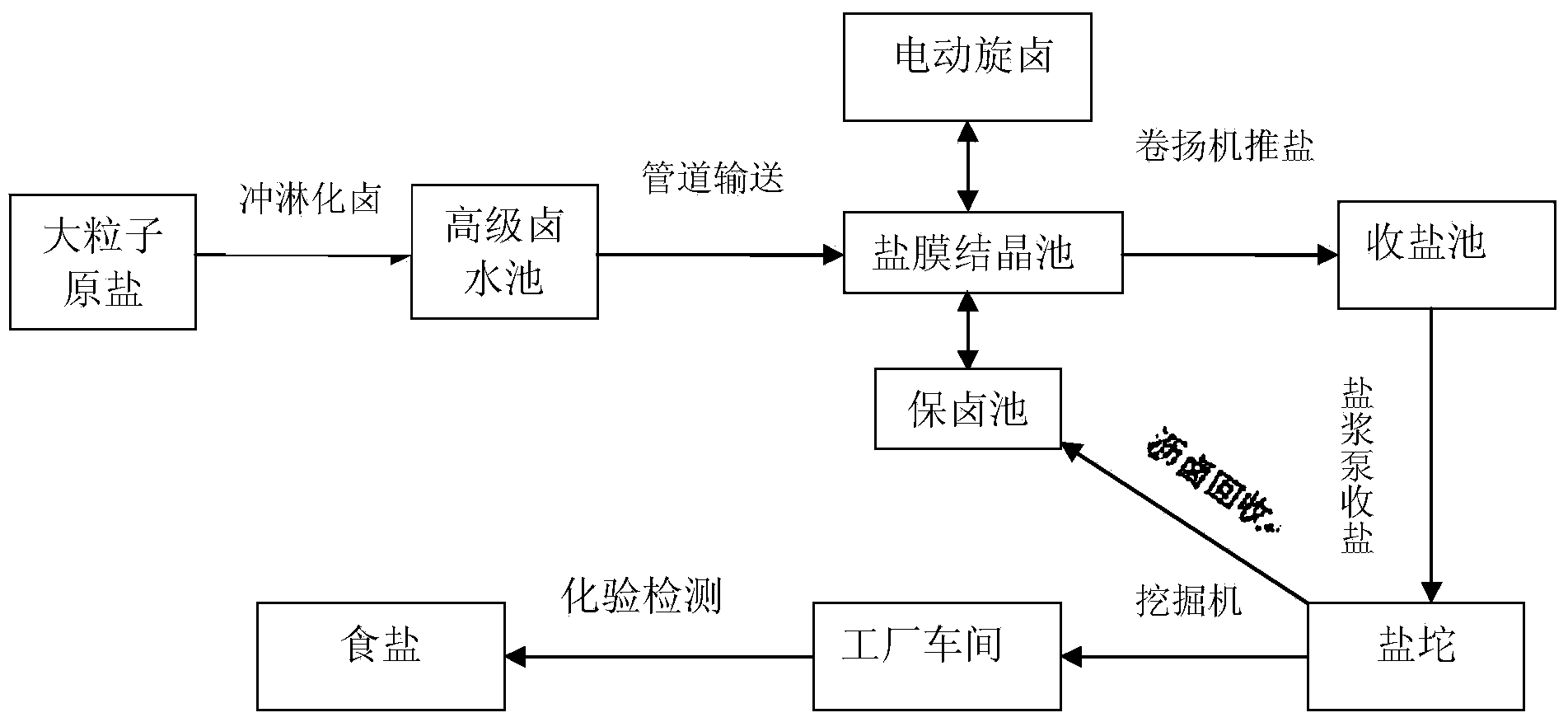

Image

Examples

Embodiment 1

[0024] The solar recrystallization salt production process comprises the following steps:

[0025] ①Centralized brine production: The large-grained raw salt with a particle size of 5mm is concentrated and piled up, and washed with seawater, unsaturated brine or desalinated concentrated water. After the large-grained raw salt is dissolved, the saturated high-grade salt with a concentration of 21°Bé is directly obtained. brine;

[0026] ②Transportation of brine: After clarification, the saturated high-grade brine obtained from the concentrated brine in step ① is directly sent to each crystallization beach pool through the PVC pipeline;

[0027] ③Mechanical blowing: the salt collection area of the crystallization tank after brine change is divided into six areas, and the thickness of 0.2m and the size of 1600m are laid at the bottom of each crystallization tank 2 At the same time, a punching point is set in the center of each area, and a mechanical punching machine is used to ...

Embodiment 2

[0034] The solar recrystallization salt production process comprises the following steps:

[0035] ①Centralized brine production: use unsaturated brine to rinse large grains of raw salt with a particle size of 7mm, and concentrate the brine to obtain high-grade brine with a concentration of 24°Bé;

[0036] ②Conveying brine: After clarification, the high-grade brine obtained from the concentrated brine in step ① is directly sent to each crystallization beach pool through the pvc pipeline;

[0037] ③Mechanical blowing: the salt collection area of the crystallization tank after brine change is divided into six areas, and the thickness of 0.3mm is laid on the bottom of the crystallization tank, and the size is 1800m 2 At the same time, a punching point is set in the center of each area, and a mechanical punching machine is used to regularly and quantitatively stir the crystallized beach brine to grind the salt, and each beat is about 40 minutes.

[0038] ④ Crystallization and b...

Embodiment 3

[0044] The solar recrystallization salt production process comprises the following steps:

[0045] ①Centralized brine production: use large-grain raw salt with a particle size of 10mm to rinse with concentrated water after seawater desalination, and concentrate the brine to obtain high-grade brine with a concentration of 27°Bé;

[0046] ②Conveying brine: After clarification, the high-grade brine obtained from the concentrated brine in step ① is directly sent to each crystallization beach pool through the pvc pipeline;

[0047] ③Mechanical blowing: the salt collection area of the crystallization tank after the brine change is divided into six areas, and the thickness of 0.25mm is laid on the bottom of the crystallization tank, and the size is 2000m 2 At the same time, a punching point is set in the center of each area, and a mechanical punching machine is used to regularly and quantitatively stir the crystallized beach brine to grind and spin the salt, about 50 minutes each t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com