Patents

Literature

53results about How to "Expand line spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

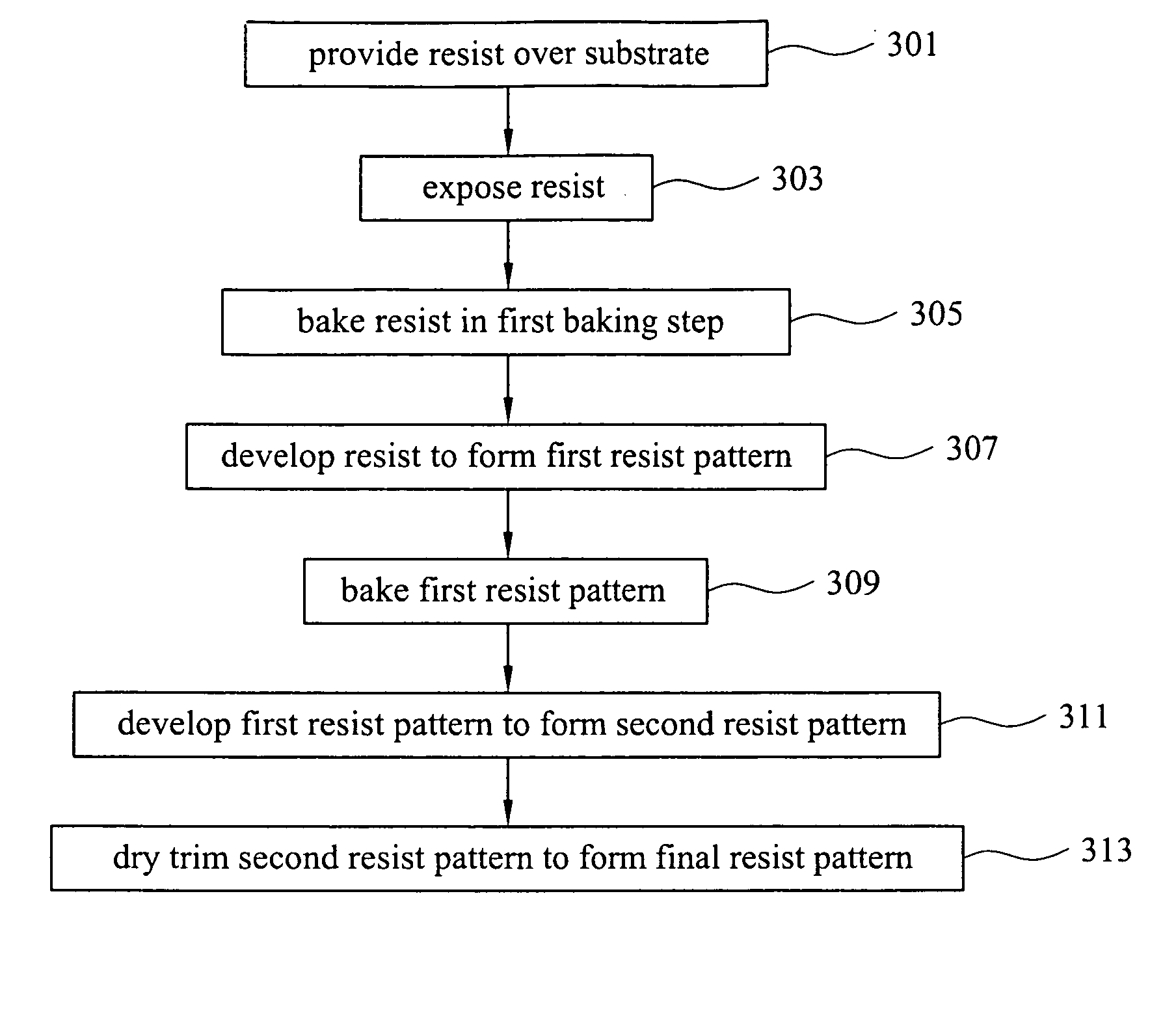

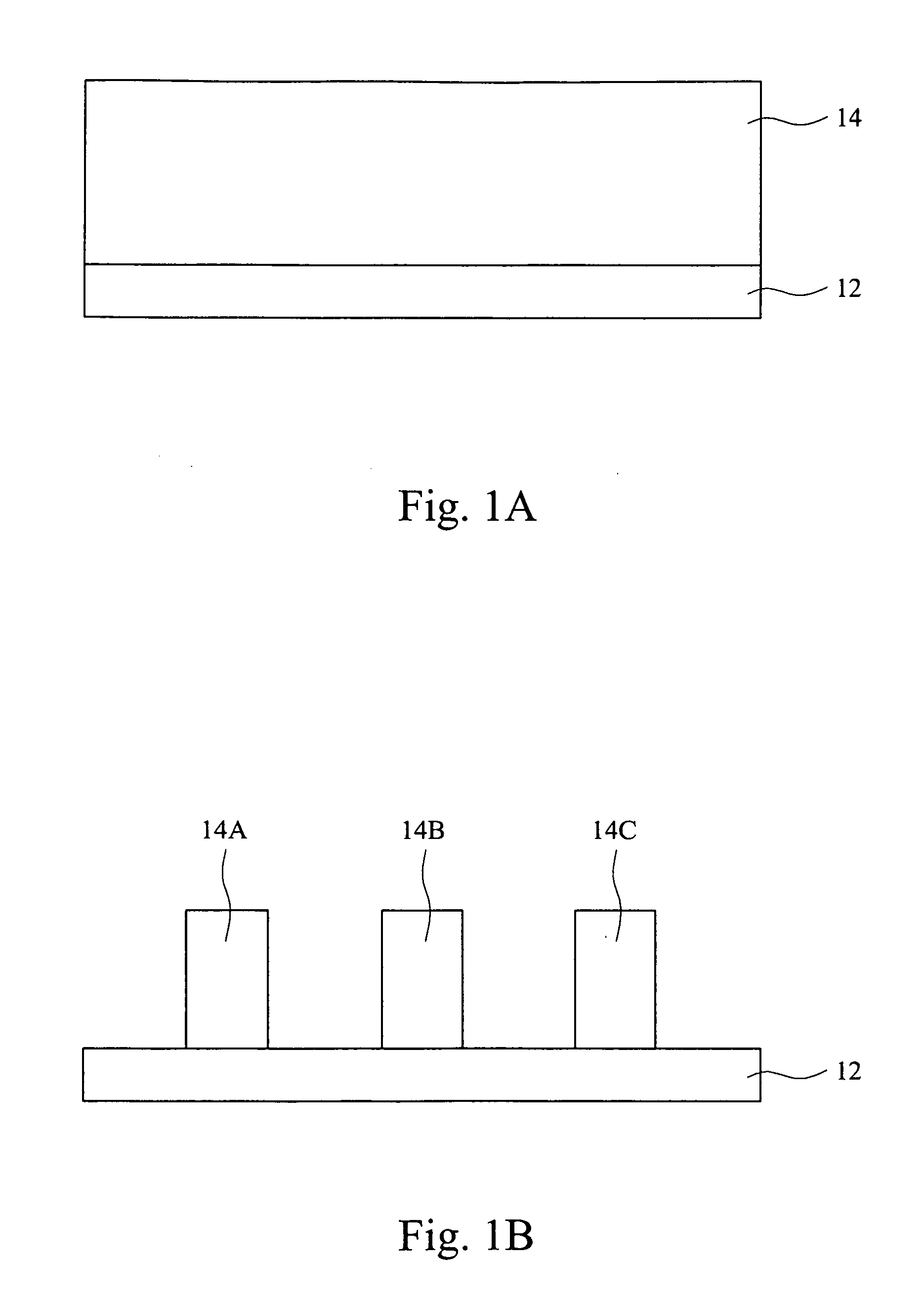

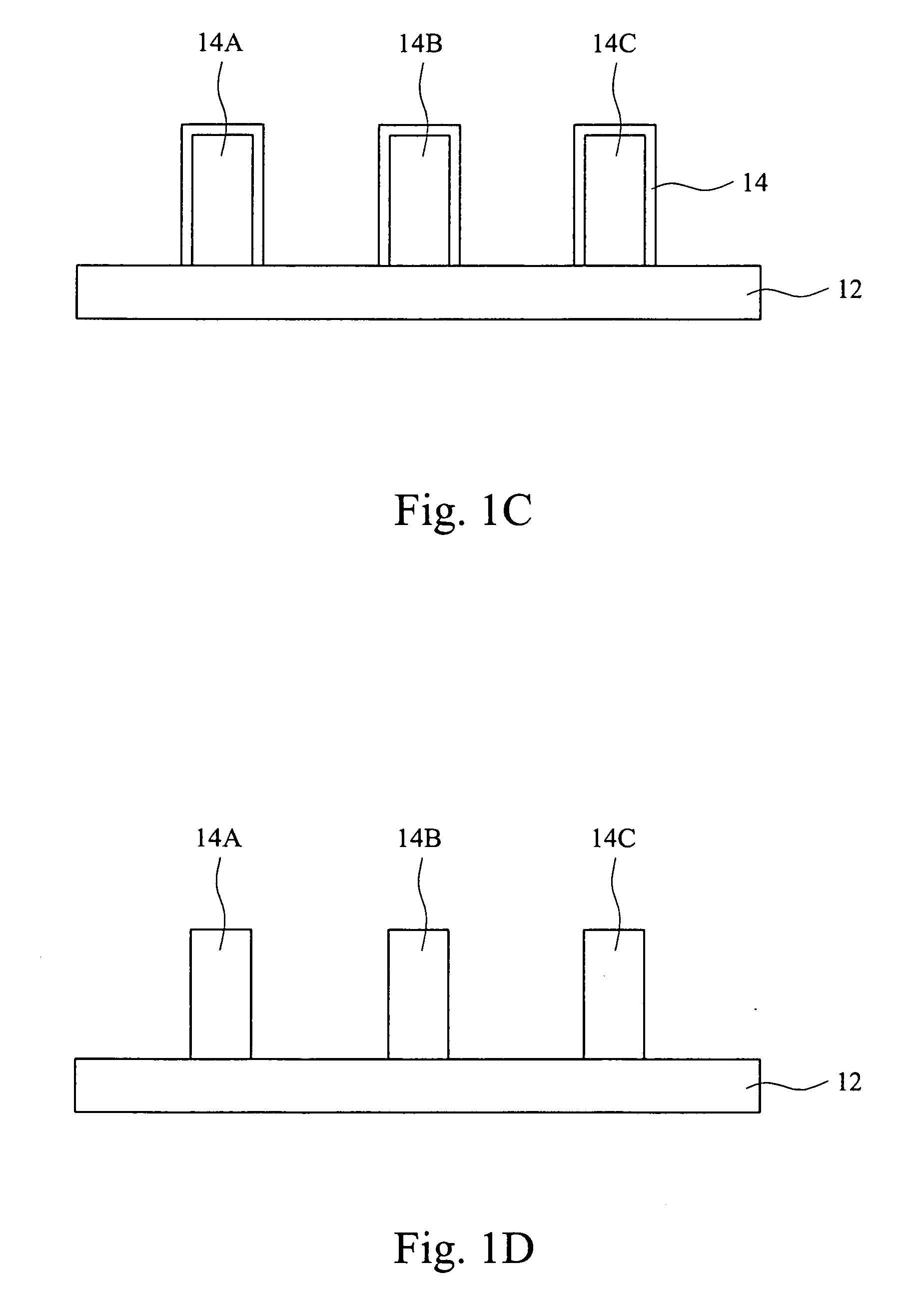

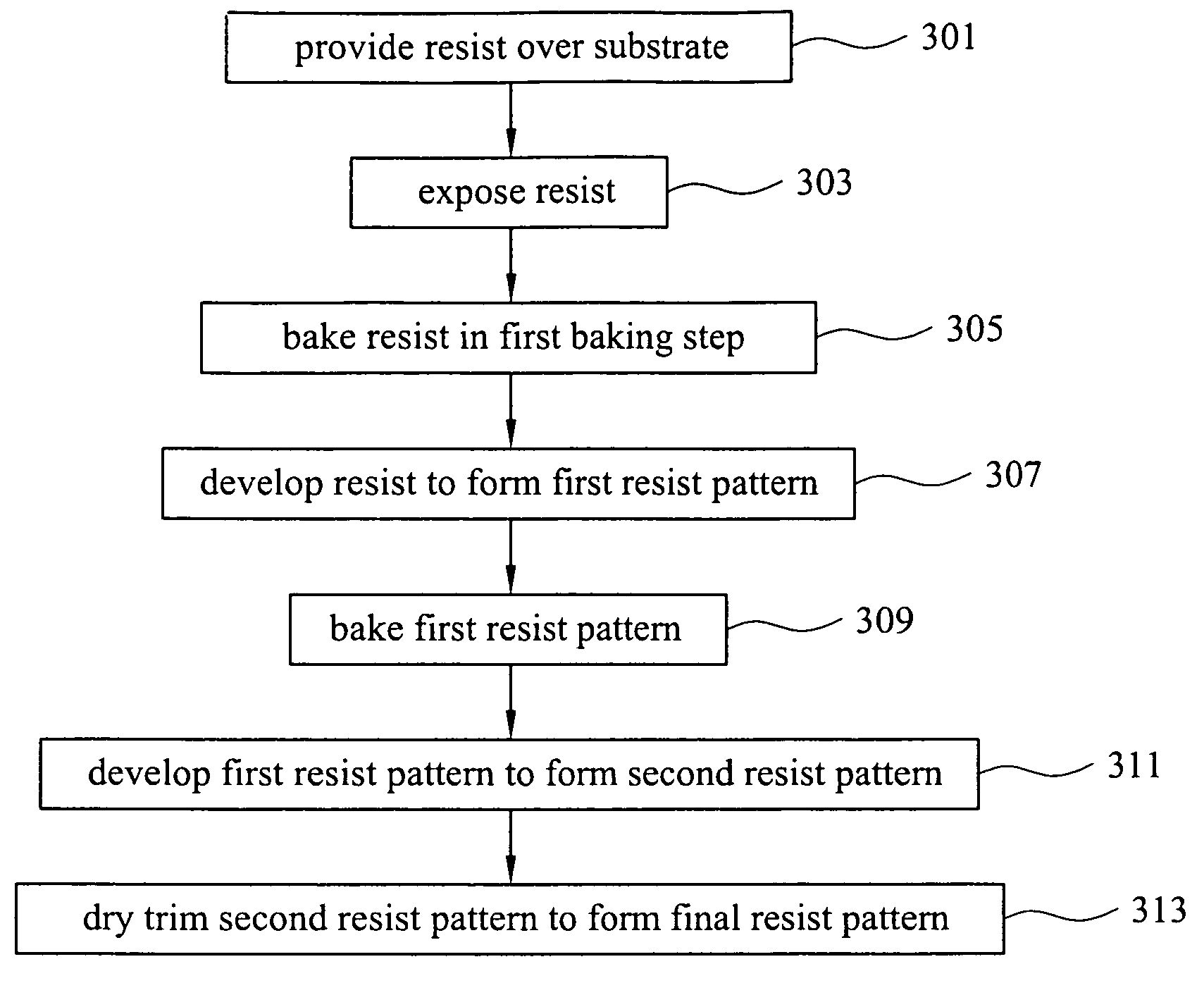

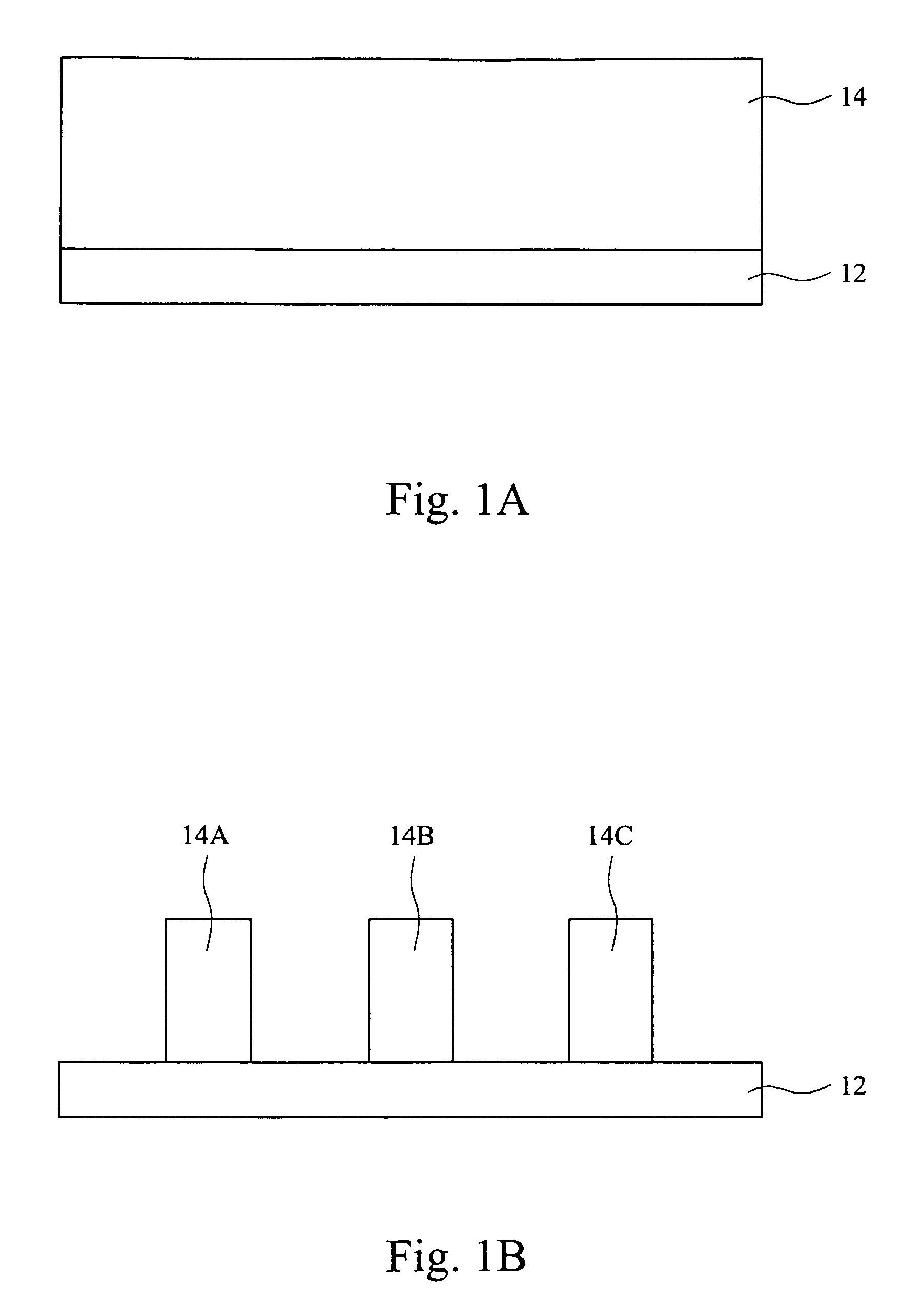

Method for forming a finely patterned resist

InactiveUS20060154185A1Critical dimension be reduceImprove spacingPhotosensitive material processingOriginals for photomechanical treatmentResistPhotoresist

A method for reducing a critical dimension of a photoresist pattern while improving a line spacing between distal end portions of pattern lines wherein the method includes providing a substrate including an overlying resist; exposing the resist to an activating light source; baking the resist in a first baking process followed by developing the resist in a first development process to form a first resist pattern; then baking the first resist pattern in a second baking process followed by developing the first resist pattern in a second development process to form a second resist pattern having reduced dimensions; and, then dry trimming the second resist pattern to form a final resist pattern with reduced dimensions compared to the second resist pattern.

Owner:TAIWAN SEMICON MFG CO LTD

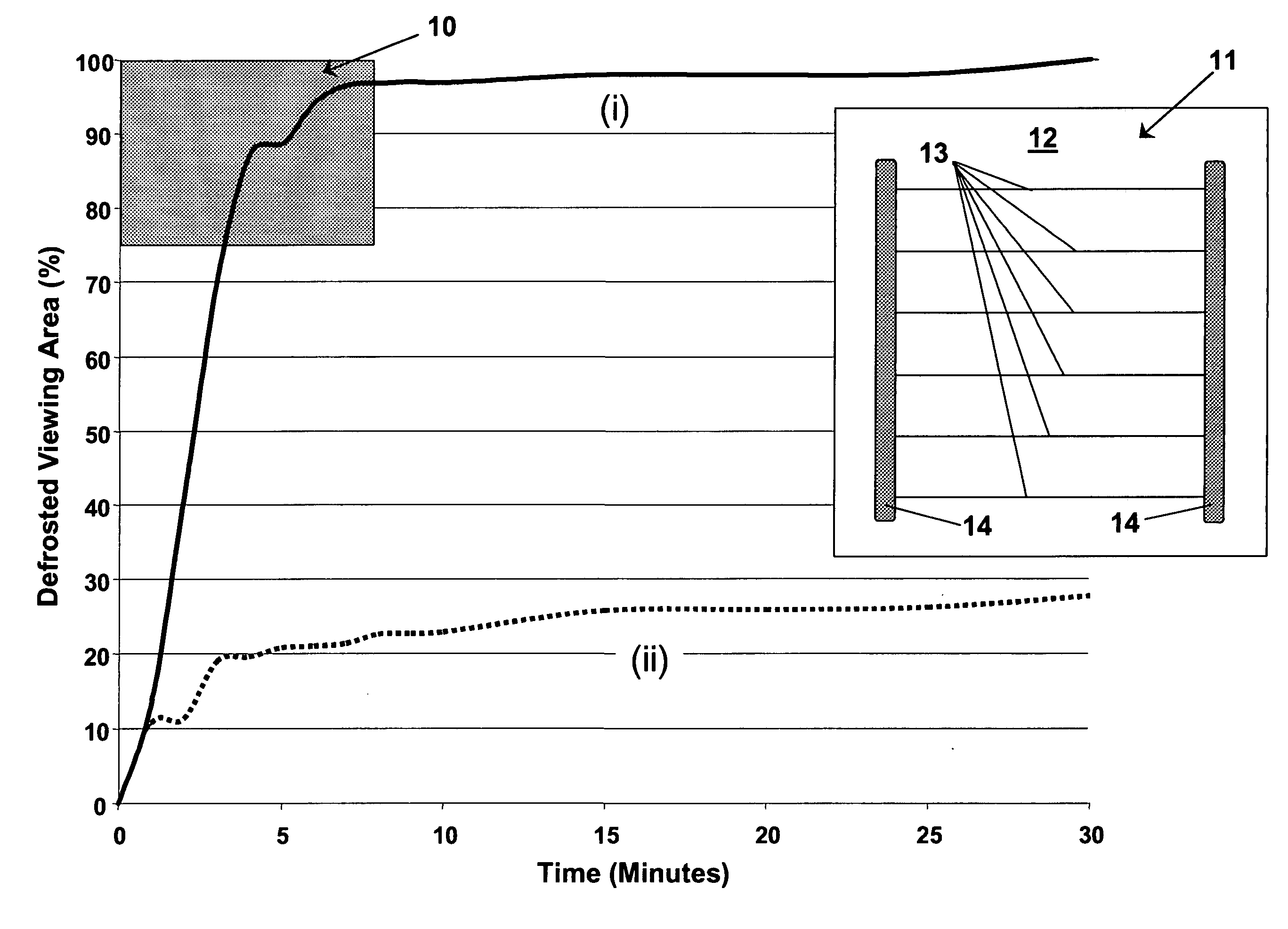

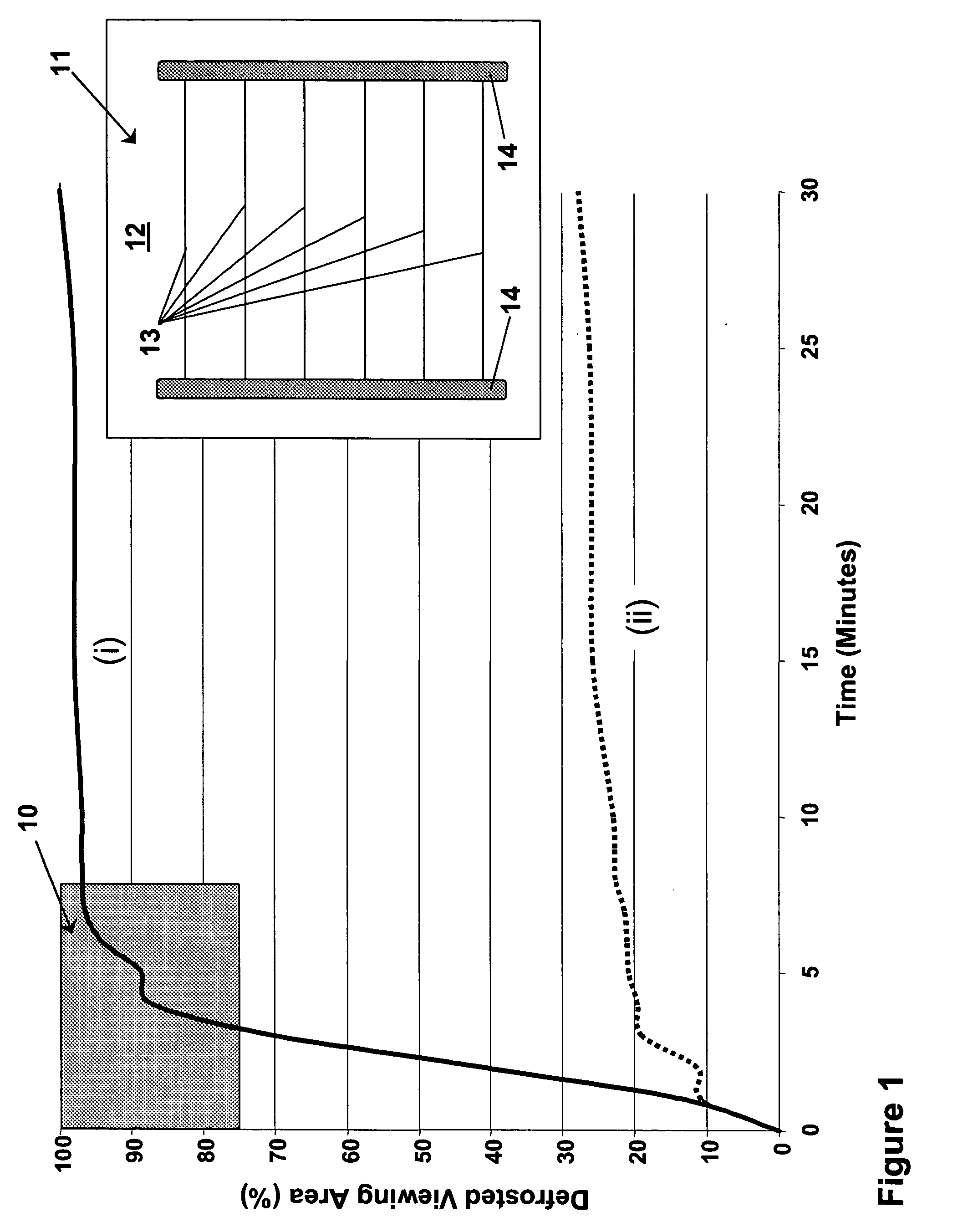

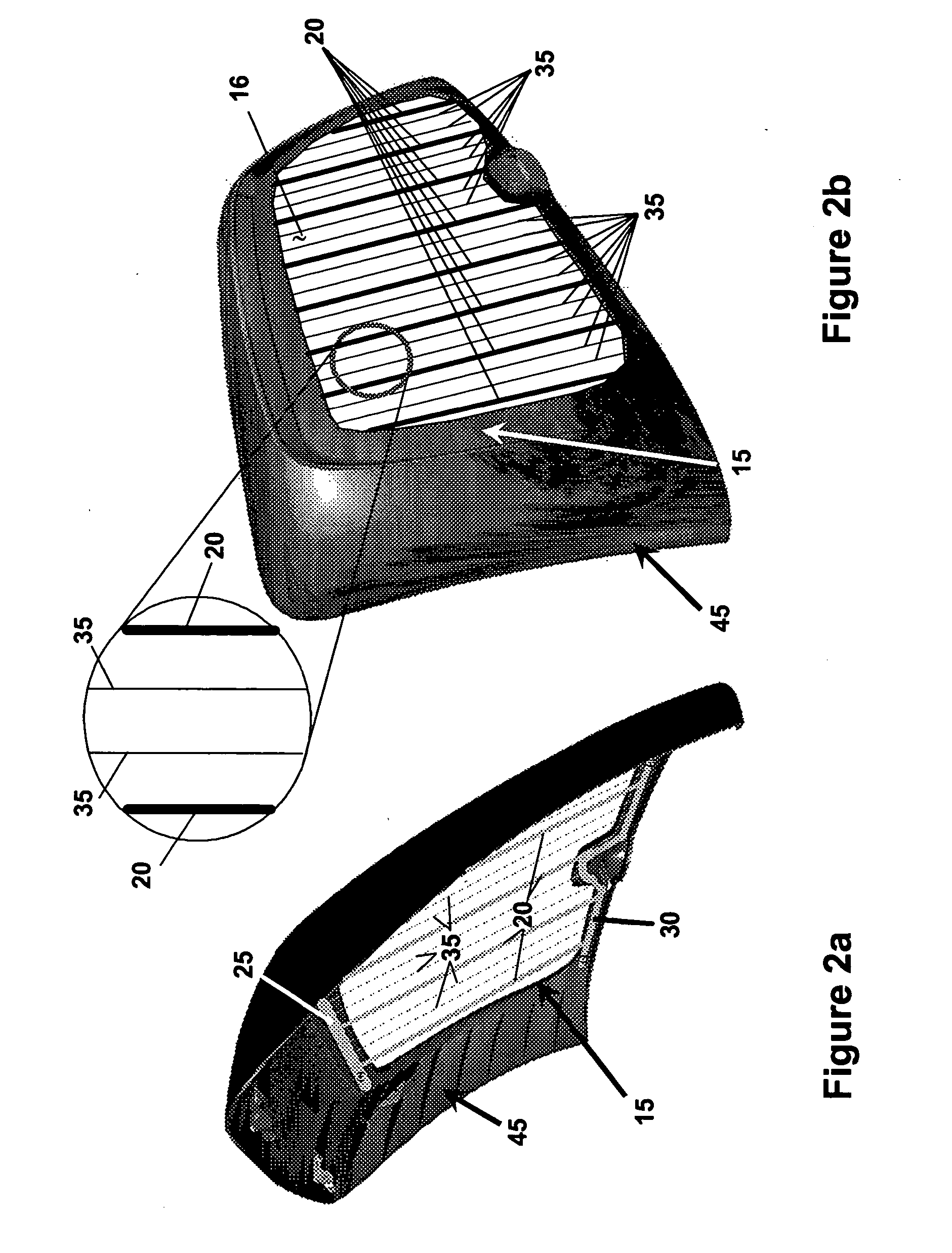

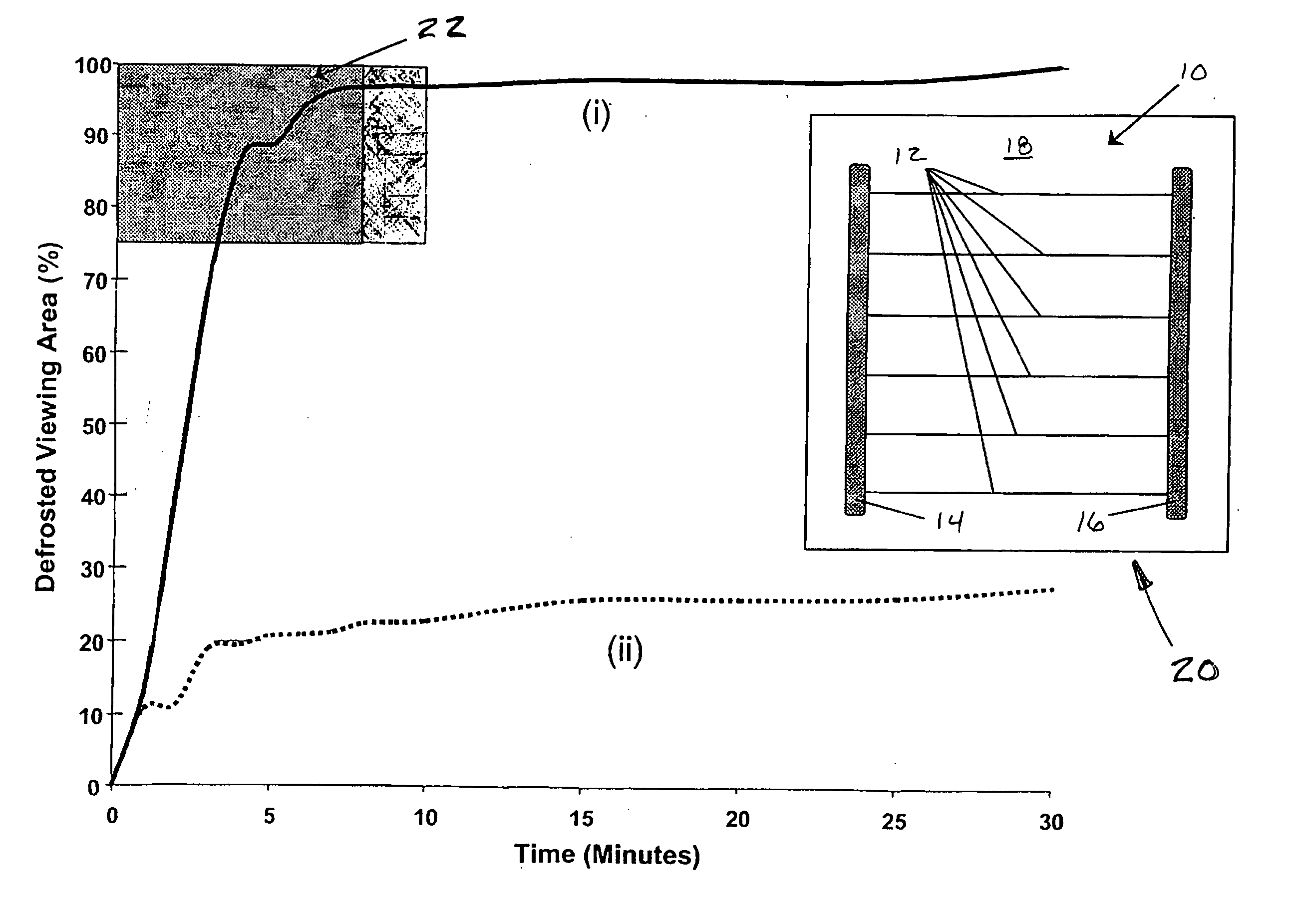

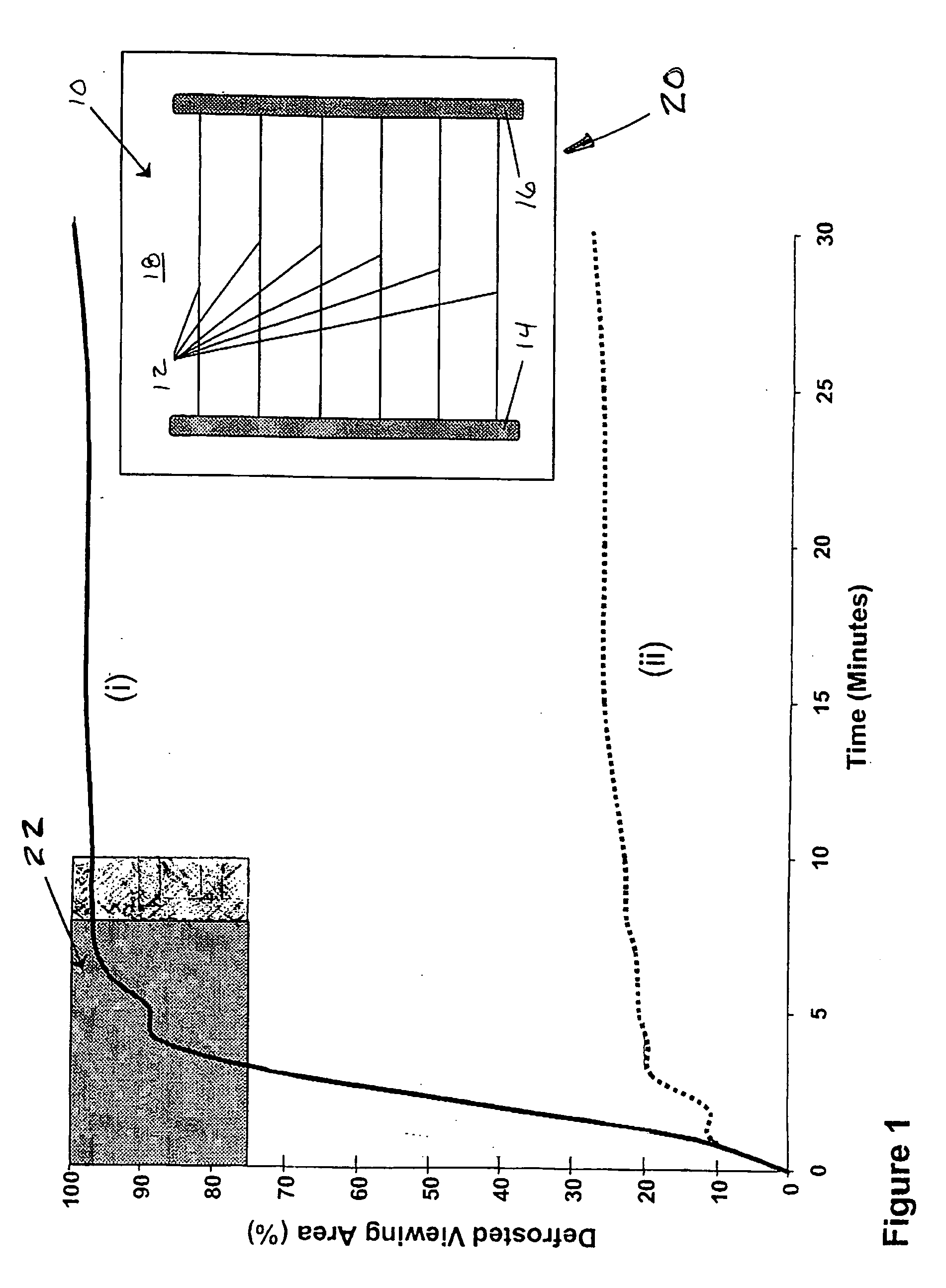

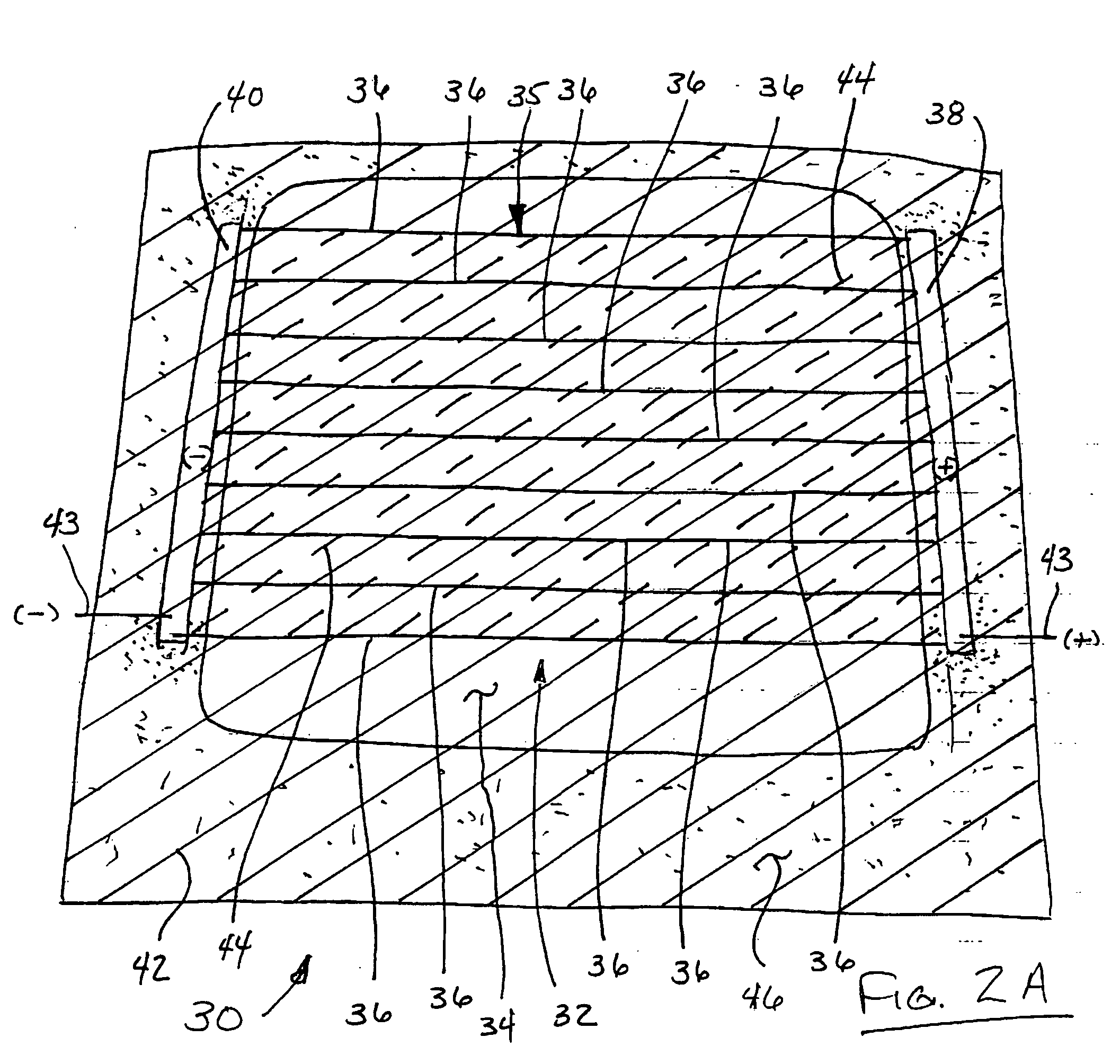

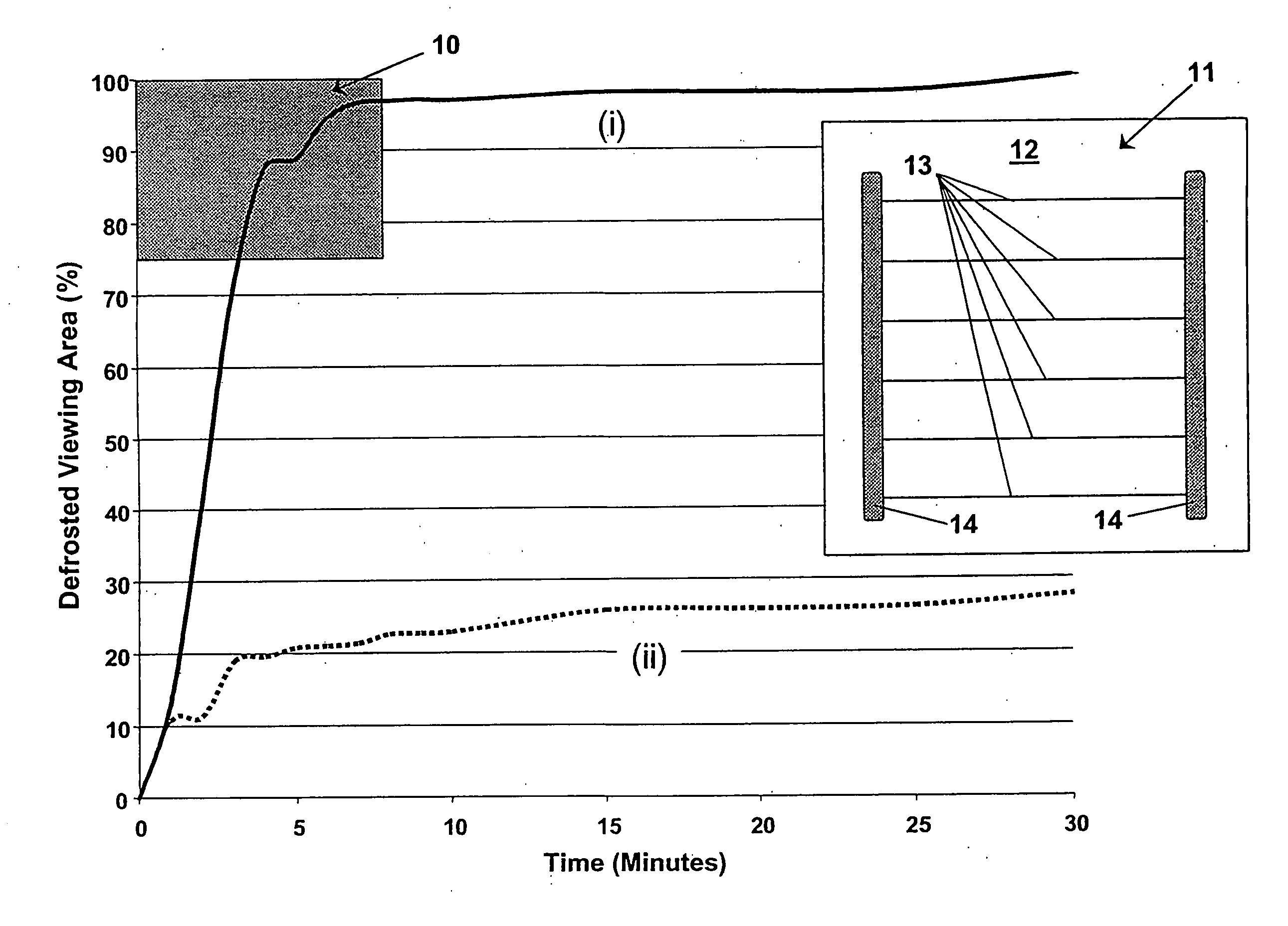

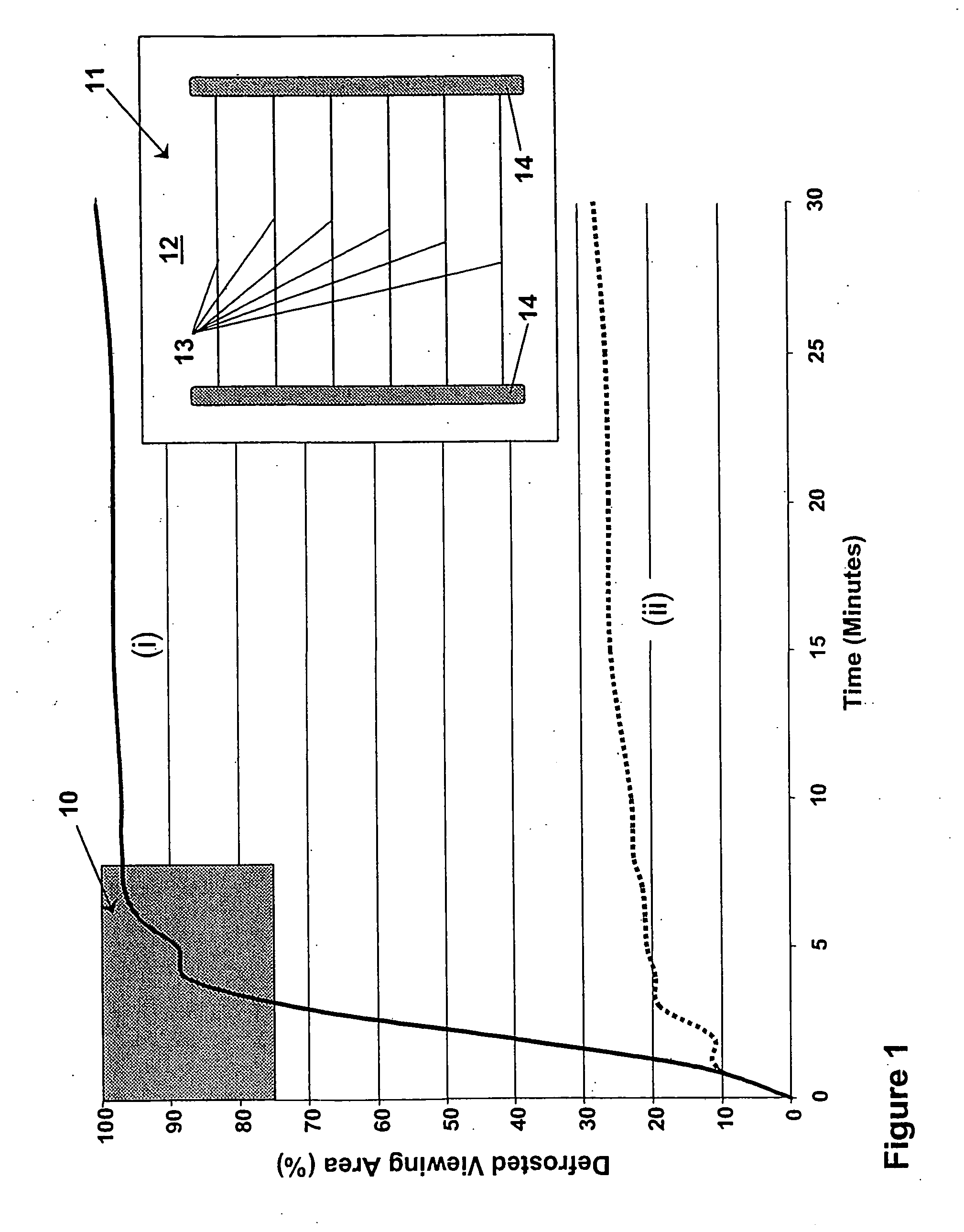

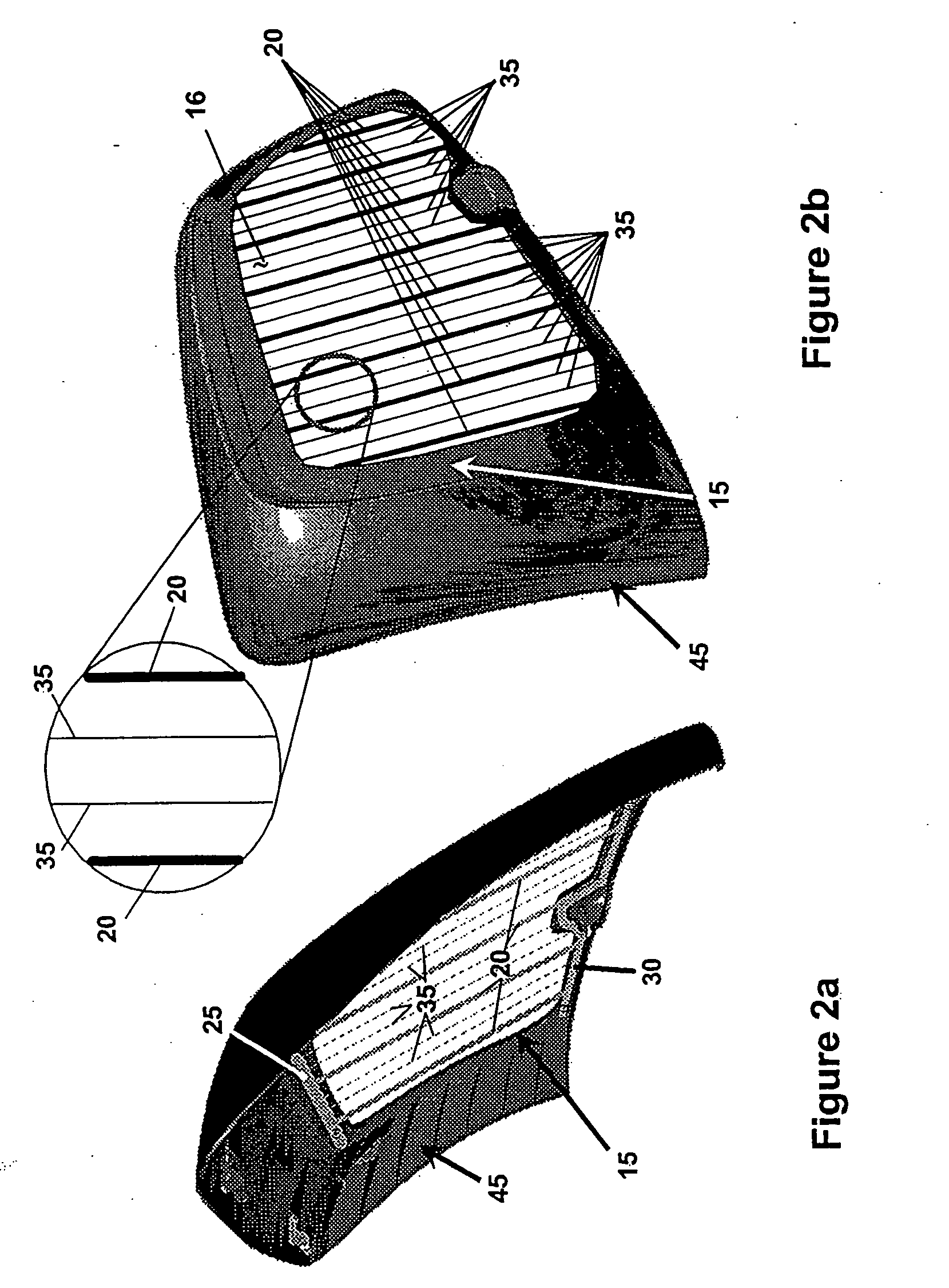

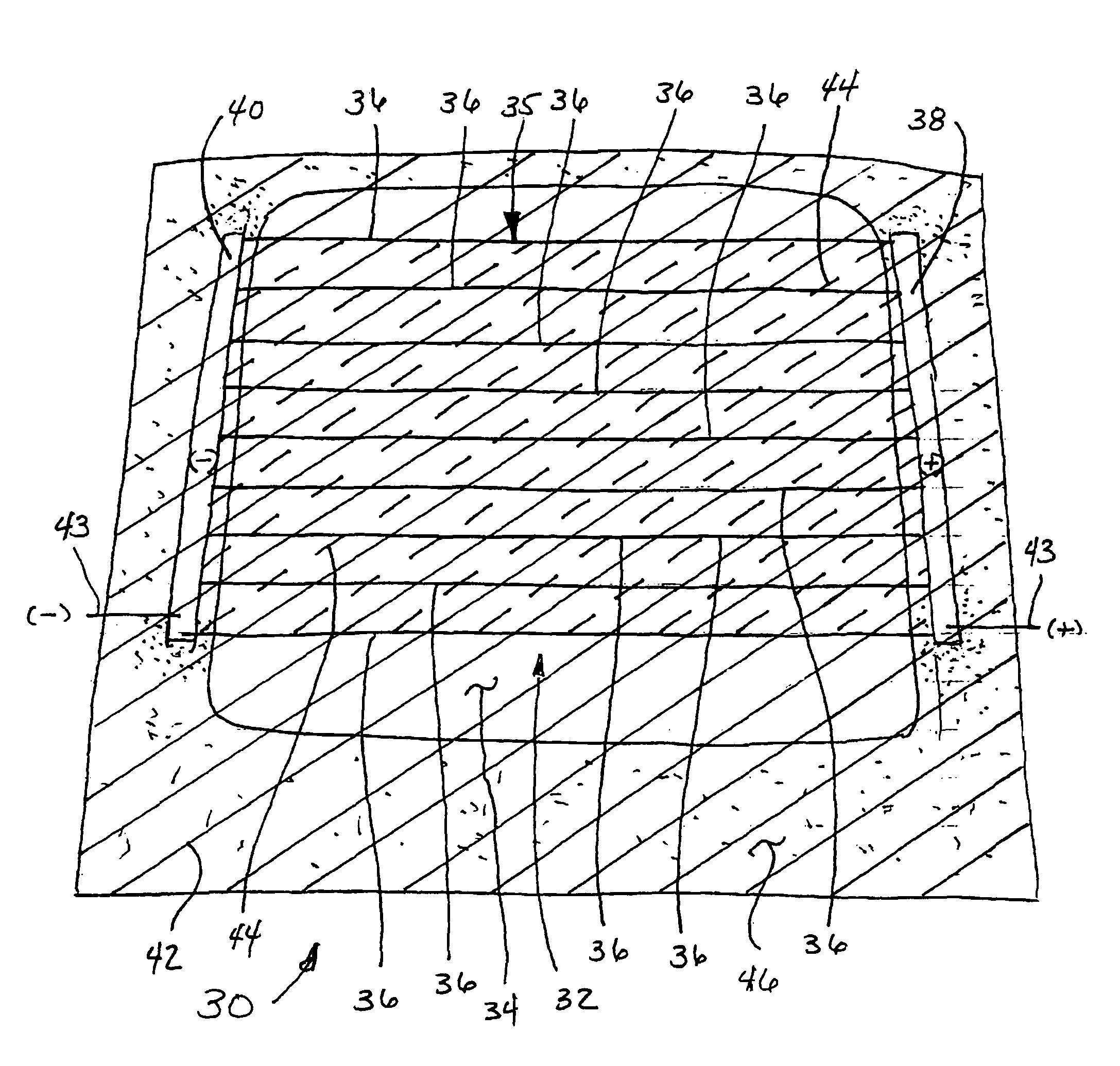

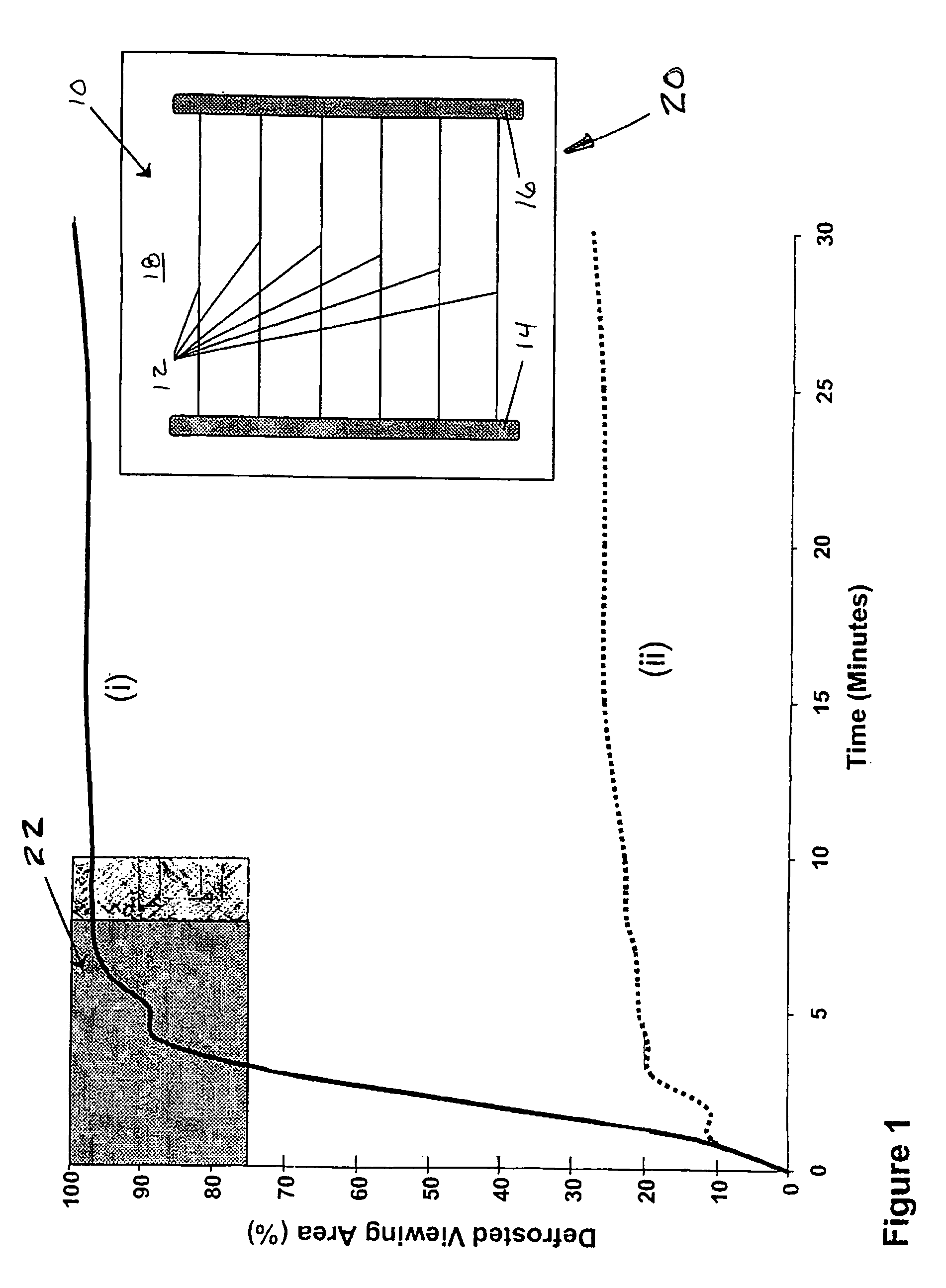

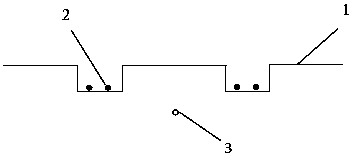

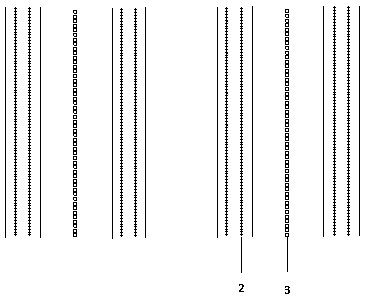

High performance defrosters for transparent panels

InactiveUS20050252908A1Expand line spacingSpacingHeater elementsTransparent/reflecting heating arrangementsBusbarEngineering

The present invention provides a window assembly having a transparent panel and a conductive heater grid formed integrally with the transparent panel. The conductive heater grid has a first group of grid lines and a second group of grid lines, with opposing ends of each group being connected to first and second busbars. Grid lines of the second group are spaced between adjacent grid lines of the first group, with the width of the grid lines themselves in the second group being less than the width of the grid lines in the first group.

Owner:EXATEC LLC

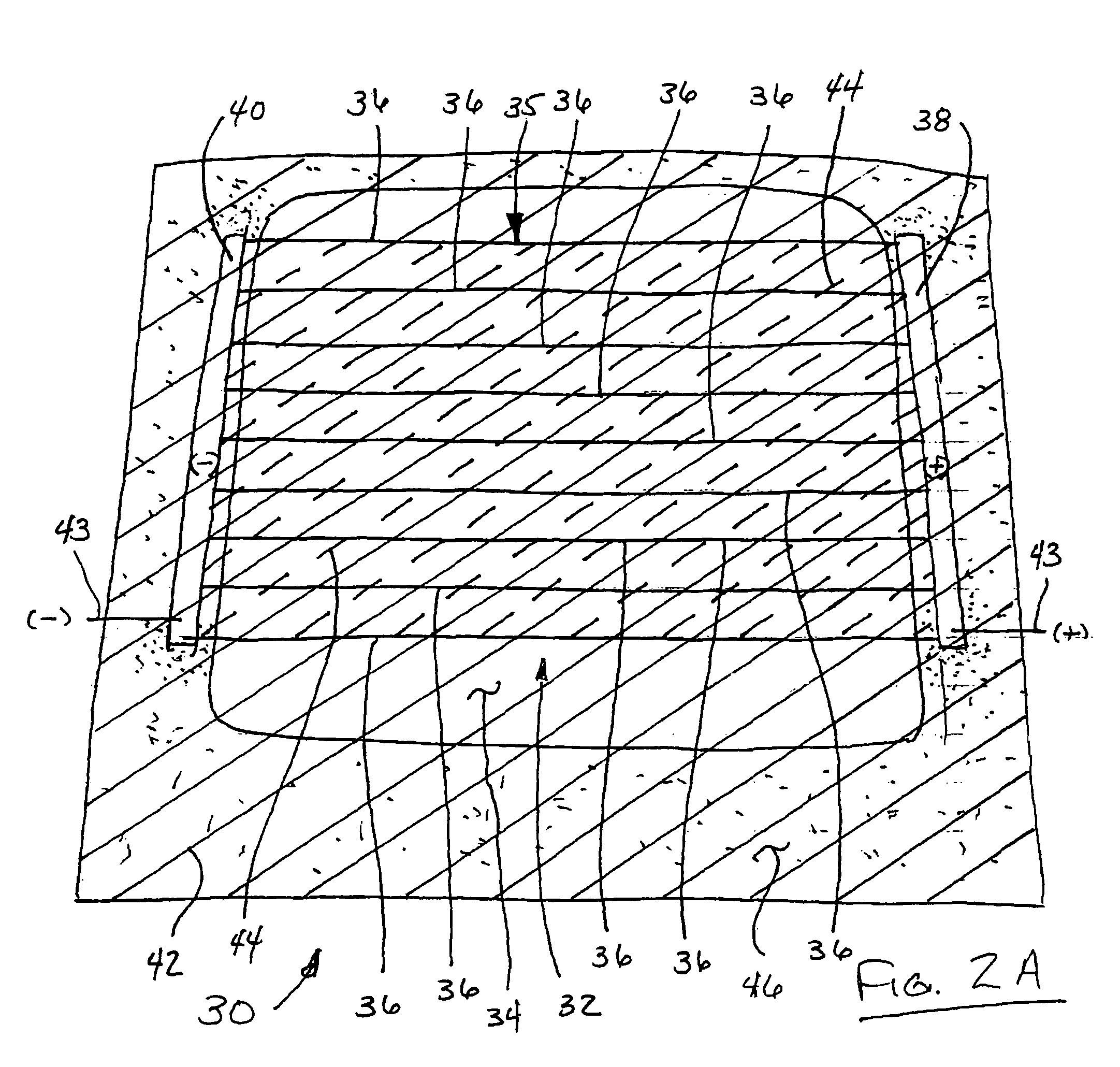

Window defroster assembly having transparent conductive layer

InactiveUS20060096967A1Expand line spacingLarge spacingTransparent/reflecting heating arrangementsPower to electric heating circuitsEngineeringElectrically conductive

A window defroster assembly having a transparent panel and a defroster. The defroster includes a conductive layer applied over the panel and an electrically conductive heater grid formed integrally with the transparent panel. The heater grid includes a series of grid lines and at least a portion of the conductive layer is located between adjacent ones of the grid lines.

Owner:EXATEC LLC

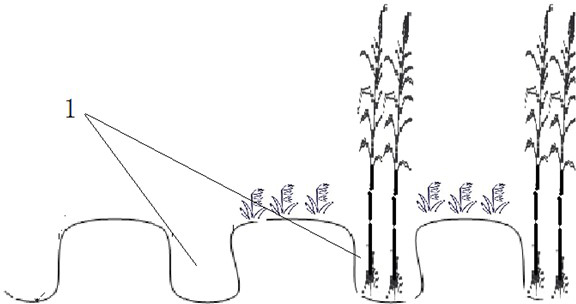

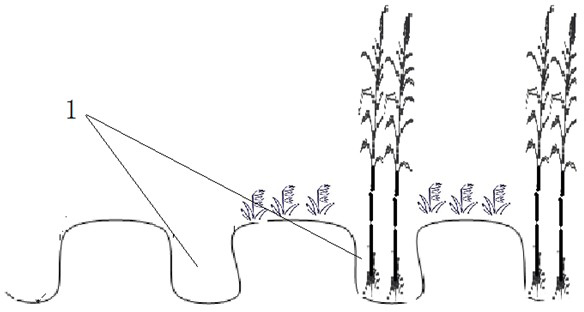

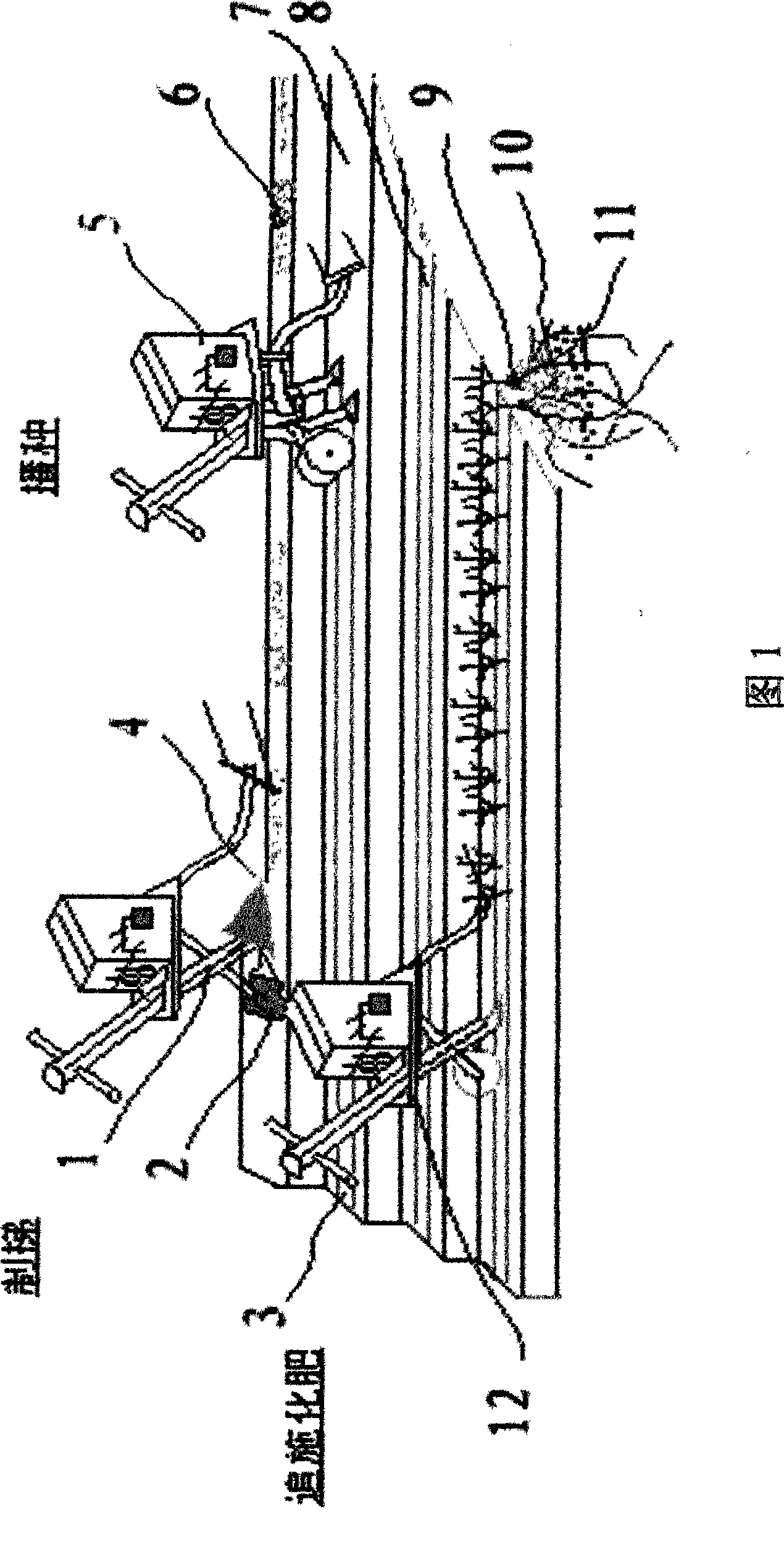

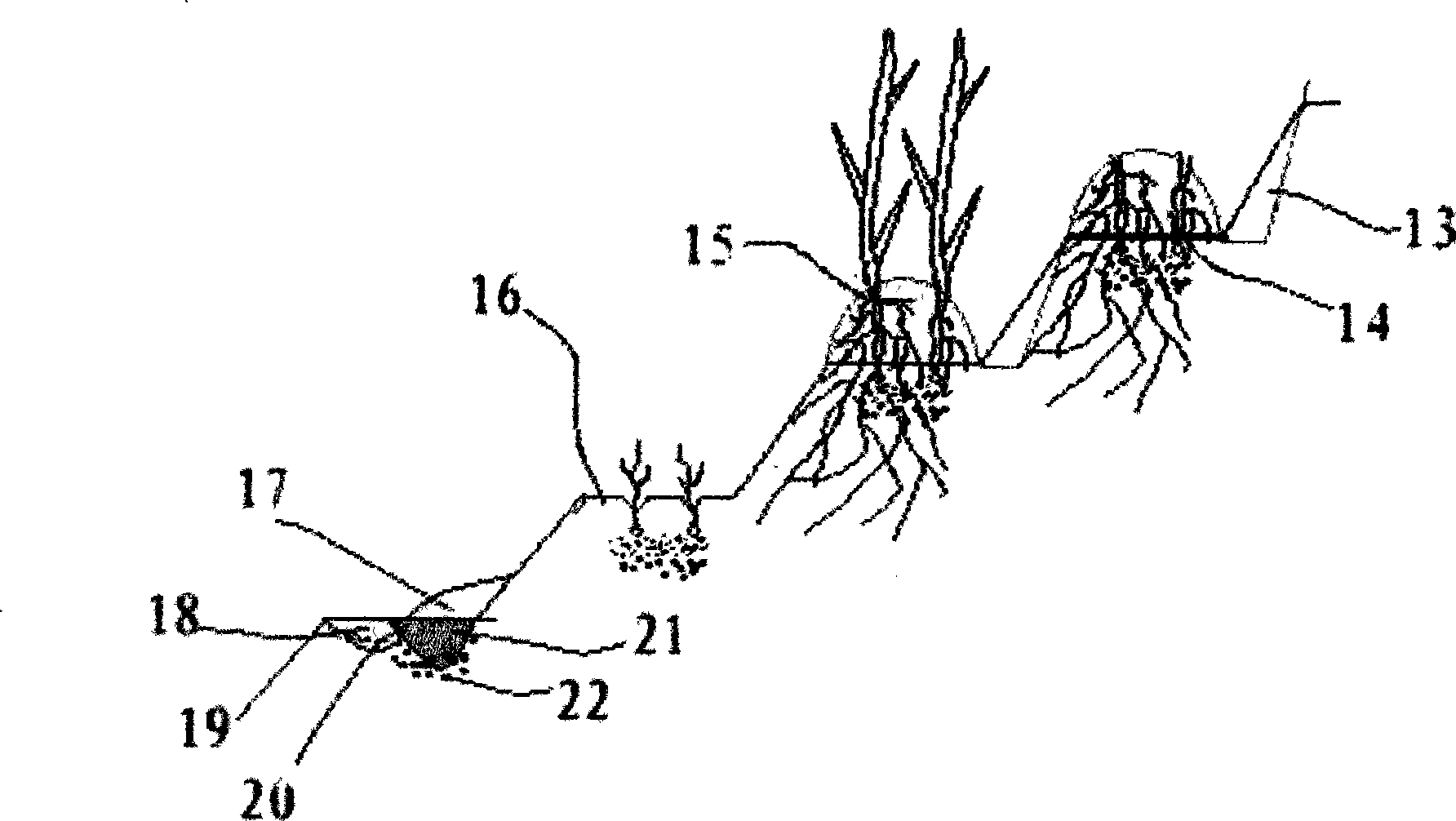

Wide box and wide belt culture method for sugarcane

InactiveCN102687636AExpand line spacingSmall footprintClimate change adaptationHorticultureCeratovacuna lanigeraDisease

The invention discloses a wide box and wide belt culture method for sugarcane. Sugarcane planting furrows with the space greater than 2m are dug, the sugarcane is planted in double rows in the sugarcane planting furrows, and soil filling and covering is carried out; a season of soybean, peanut or pepper is interplanted between the sugarcane planting furrows. The sugarcane planting line distance is increased, in addition, a season of short stem crops such as the soybean, the peanut or the pepper is interplanted between the lines, through adopting such a mode, the occupied area of the sugarcane is reduced, the ventilation and light transmission conditions are improved, diseases such as leaf spot diseases and dry top rot diseases generated under the high-temperature high-humidity and concealed conditions cannot easily occur, the generating rate of pests of ceratovacuna lanigera zehntner, mealybug and the like is smaller than that of the conventional single-crop sugarcane, more than 50 percent of pesticide and disease and pest prevention and treatment cost is reduced; in addition, the short stem crops are interplanted, the farm work operation is favorably carried out, and the field management efficiency is improved; and in addition, the short stem crops such as the peanut, the soybean and the like with nitrogen fixation capability are interplanted, partial nitrogen fertilizers can be provided for the sugarcane, and meanwhile, the consumption of chemical fertilizers is reduced.

Owner:SUBTROPICAL CROPS INST OF GUIZHOU PROVINCE

High-yield cultivation method for peanuts

InactiveCN102057829AExtended growing seasonReduce lossesHorticulture methodsFertilizer mixturesChemical controlArachis hypogaea

The invention discloses a high-yield cultivation method for peanuts, comprising the steps of fertilizer applying, seed drying, seed sowing, leaf fertilizer spraying and chemical control. In the invention, the steps are adopted to cultivate the peanuts so as to make soil nutrients comprehensive and rich and sowing density increased, fully meet the demands of the peanuts on nutrients due to additional fertilizer supplement by human labor and timely chemical control, and generate fertilizer response to the greatest extent, thereby the yield and the quality of the peanuts are greatly improved, and more than 600 kilograms of the peanuts per mu can be yielded.

Owner:山东鲁花农业科技推广有限公司

High performance defrosters for transparent panels

InactiveUS20060196865A1Expand line spacingSpacingHeater elementsTransparent/reflecting heating arrangementsBusbarEngineering

The present invention provides a window assembly having a transparent panel and a conductive heater grid formed integrally with the transparent panel. The conductive heater grid has a first group of grid lines and a second group of grid lines, with opposing ends of each group being connected to first and second busbars. Grid lines of the second group are spaced between adjacent grid lines of the first group, with the height of the grid lines themselves in the second group being less than the height of the grid lines in the first group.

Owner:EXATEC LLC

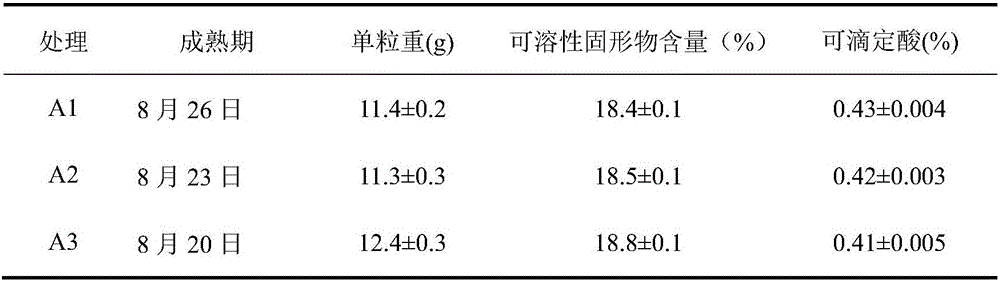

Kyoho grape labor-saving cultivation method achieving production and sightseeing and picking

InactiveCN106069564AIn line with growth habitsHigh differentiation rateCultivating equipmentsHorticulture methodsVitis viniferaPest control

The invention discloses a Kyoho grape labor-saving cultivation method achieving production and sightseeing and picking. The method comprises various measures such as garden plot selection, canopy frame building, medium cultivation, ridging, field planting, water management, psi-shaped pruning, denuclearization treatment, soil management, anti-bird mesh covering, leaf picking, bagging and disease and pest control. According to the Kyoho grape labor-saving cultivation method achieving production and sightseeing and picking, a psi-shaped pruning mode is adopted to shape grapes, the method conforms to growth habits of the Kyoho grapes, a tree body reaches a balance of reproductive growth and vegetative growth, the flower bud differentiation rate, the fruit setting rate, the fruit sugar degree and the fruit yield are obviously increased, and the quality is obvious improved; mechanical picking can be conducted, the method is suitable for sightseeing and picking, and the method can be popularized in a large area in industrial production of the grapes.

Owner:句容市万山红遍应时鲜果专业合作联社

Window defroster assembly having transparent conductive layer

InactiveUS8653419B2Expand line spacingLarge spacingHeater elementsTransparent/reflecting heating arrangementsEngineeringElectrically conductive

A window defroster assembly having a transparent panel and a defroster. The defroster includes a conductive layer applied over the panel and an electrically conductive heater grid formed integrally with the transparent panel. The heater grid includes a series of grid lines and at least a portion of the conductive layer is located between adjacent ones of the grid lines.

Owner:EXATEC LLC

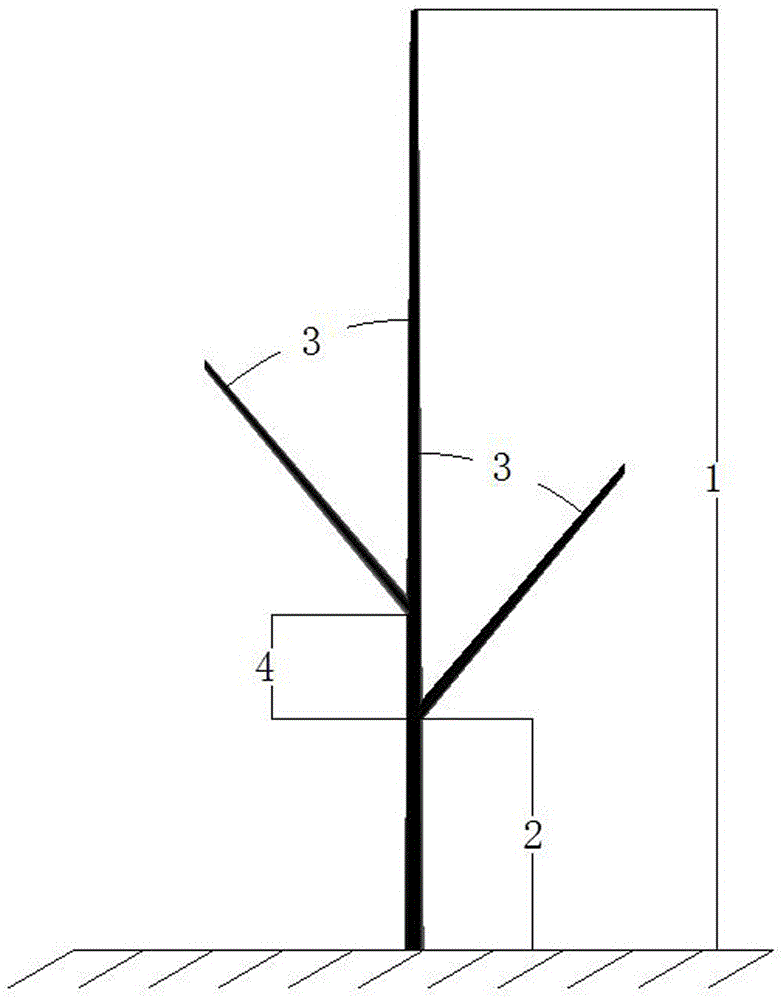

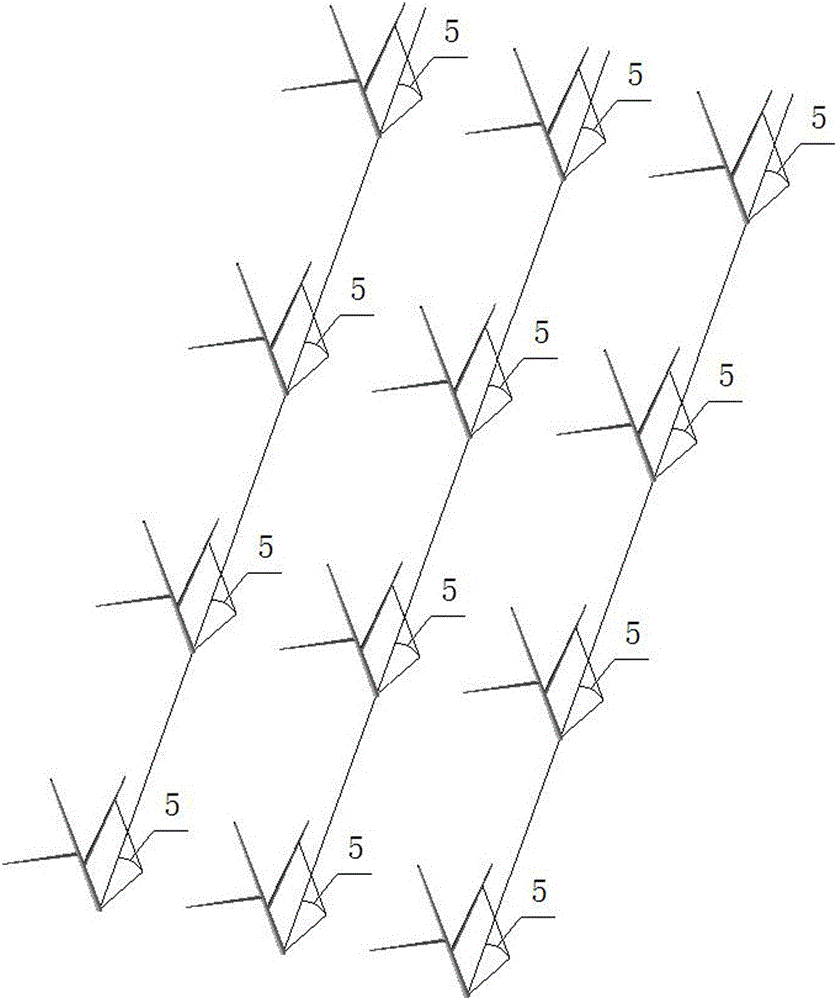

Inverted-umbrella-shaped cultivation technology for peach trees

InactiveCN105746290AExpand line spacingReduce pests and diseasesCultivating equipmentsHorticulture methodsTruckThinning

The invention discloses an inverted-umbrella-shaped cultivation technology for peach trees.The technology comprises the steps of defining the plantation density; conducting shaping and trimming in a quantitive mode, wherein the central trunk of a tree is robust, erect, free of principal branches or lateral branches, two adjusting branch sets grow out of the basal part of the central trunk, small bearing branch sets directly grow out of the remaining parts of the central truck, the small bearing branch sets are distributed at an interval of 10-15 cm and uniformly arranged upward in the helical form, the tree height is 2.5-3 m, the crown diameter is 1.5-2 m, the trunk height is 50-70 cm, the growing points of the two adjusting branch sets are vertically staggered with the spacing being 10-15 cm and are distributed at the angle of 180 degrees, the included angle between the growing points of the two adjusting branch sets and the line direction of a plantation line is 30 degrees, meanwhile the included angle between the growing points of the two adjusting branch sets and the central trunk is 40 degrees, attention is paid to control the thickness of branches on the central trunk so that the thickness cannot exceed 1 / 3 or above of the thickness of the central trunk, and thinning is conducted when necessary.By means of the inverted-umbrella-shaped cultivation technology for the peach trees, early fruiting and a high and stable yield are promoted, the full productive age of the peach trees is prolonged, the commodity rate and high quality fruit rate of fruits are raised, meanwhile, work efficiency is improved, and labor intensity is lowered.

Owner:INST OF GARDENING ANHUI ACADEMY OF AGRI SCI

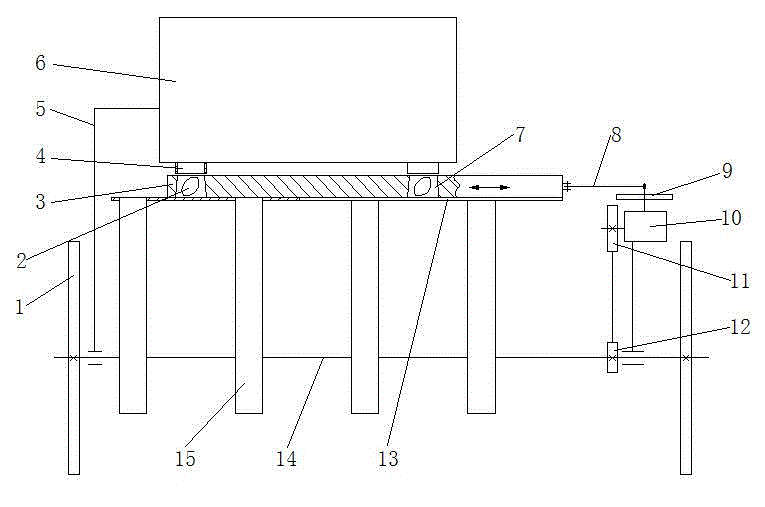

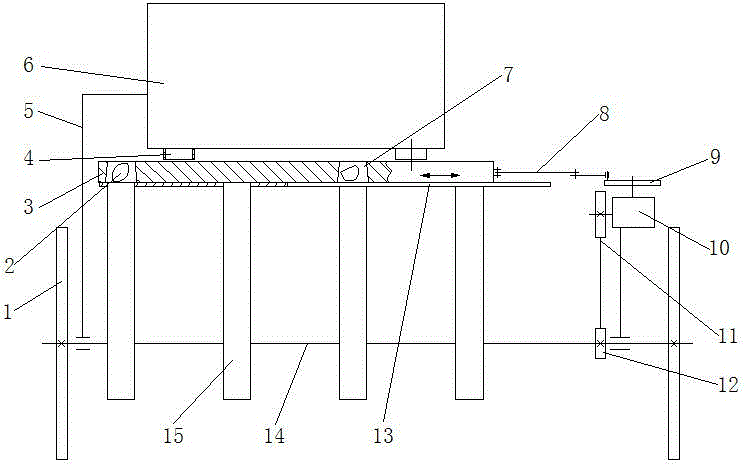

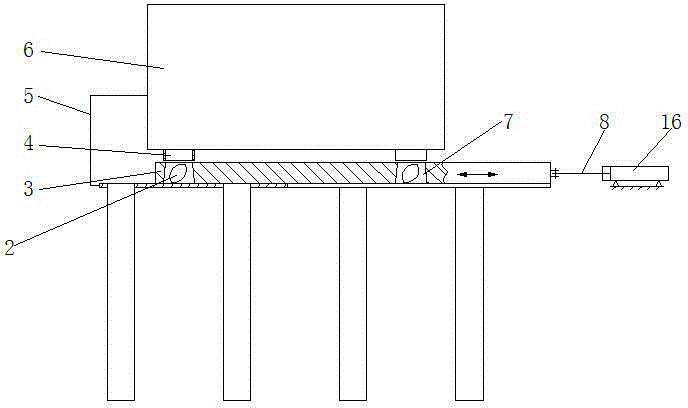

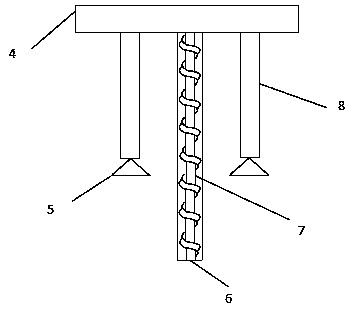

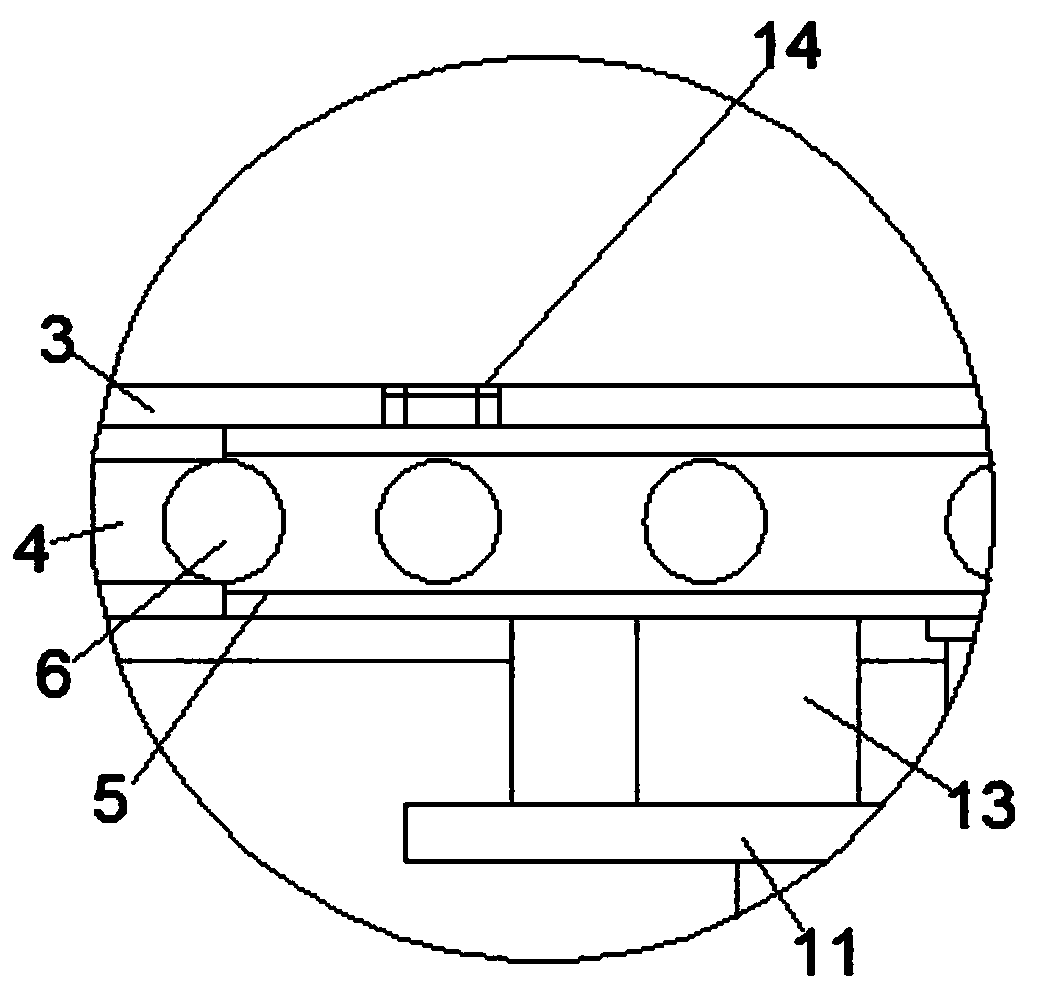

Potato seeder

The invention relates to agricultural machinery, particularly to a potato seeder. The device comprises a frame and a seed box mounted on the frame, and is characterized in that a seed falling pipe is mounted on the lower end face of the seed box, wherein a fixed plate is mounted on the frame at the lower end of the seed falling pipe; another seed falling pipe is mounted on the fixed plate; a seed fetching plate is mounted between the seed falling pipe and the fixed plate; seed fetching holes are formed in the seed fetching plate; a power device capable of driving the seed fetching plate to move left and right is mounted at one end of the seed fetching plate. According to the technical scheme disclosed by the invention, the potato seeder is novel in structure, convenient to fetch seeds, simple in structure, and low in production cost; the left and right reciprocating motion speed of the seed fetching plate can be changed conveniently, so as to adjust the row spacing.

Owner:YINCHUAN LIZHIXIN INTPROP ADVISORY SERVICES

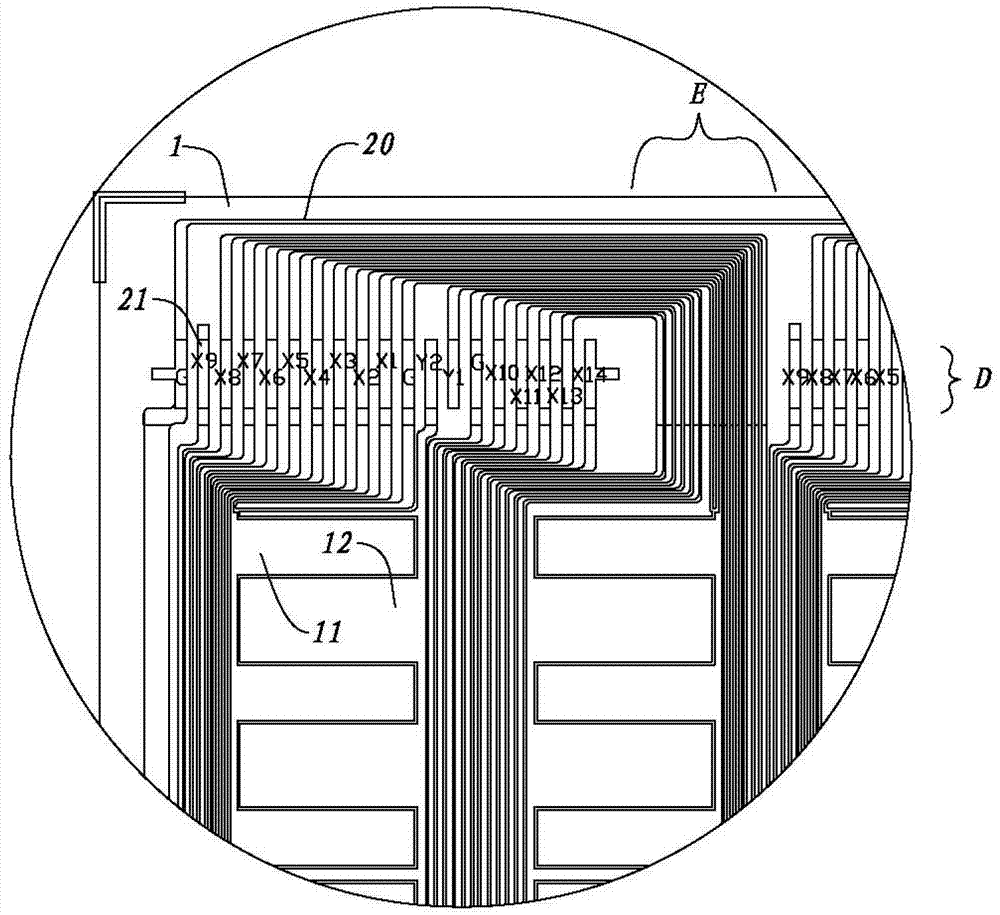

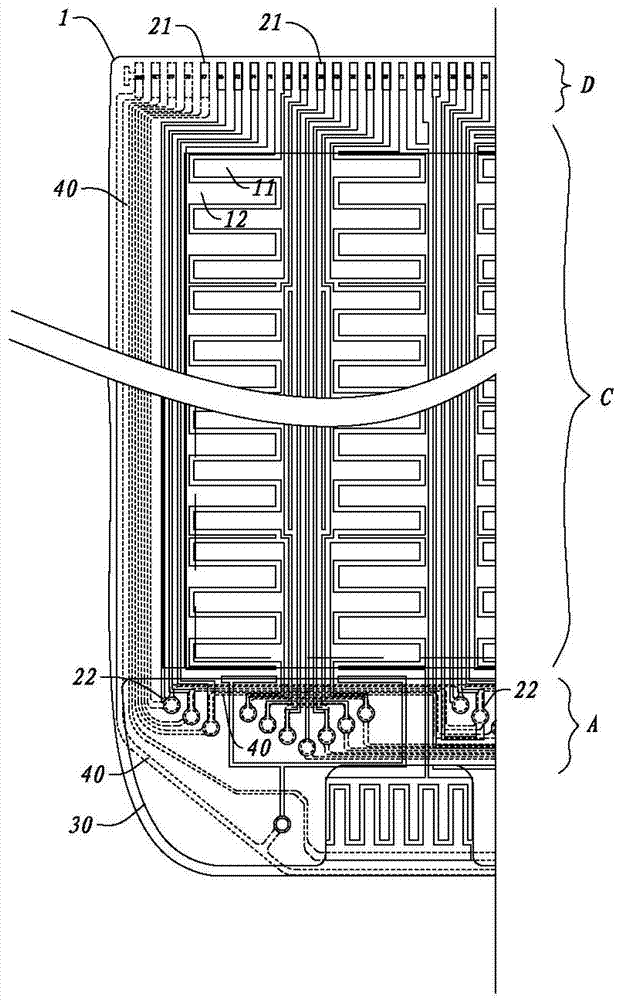

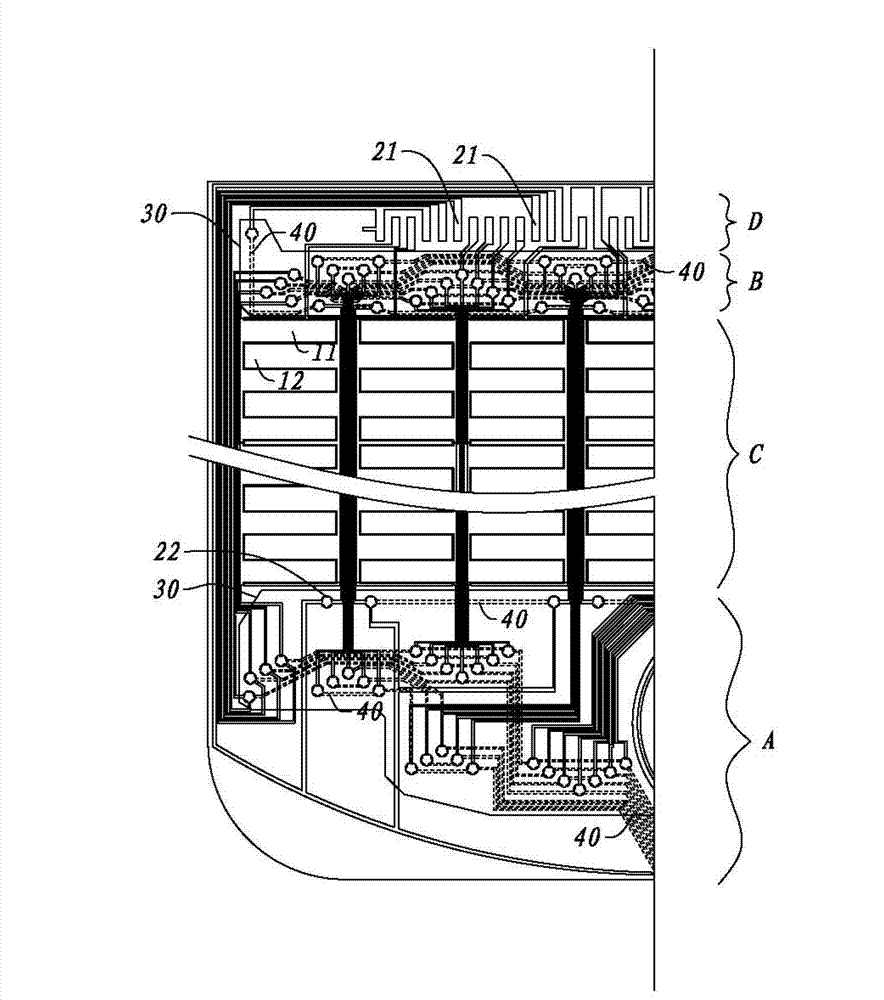

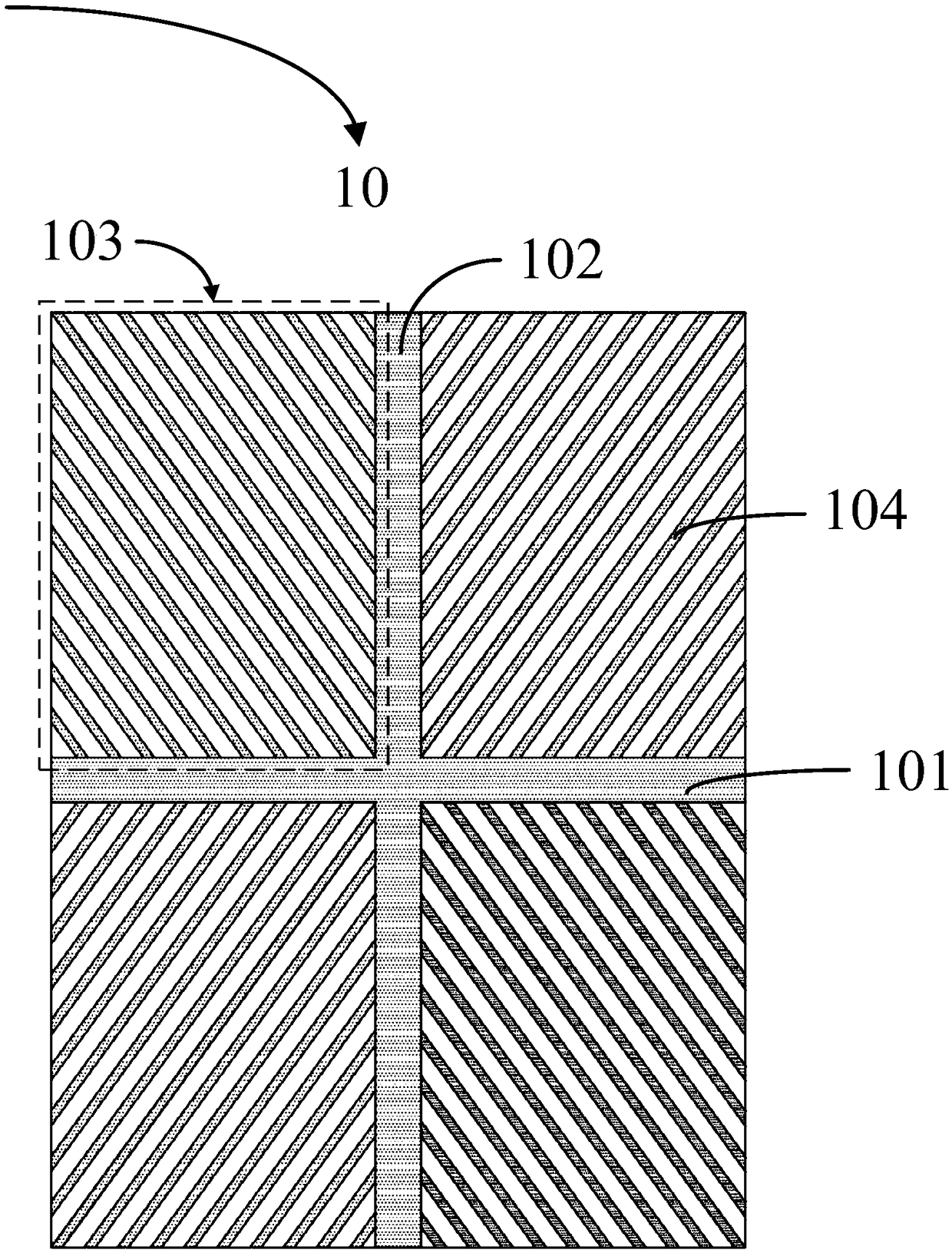

Bridging and wire-leading sensor of monolayer multi-point touch screen and forming process thereof

InactiveCN103116427AIncrease widthExpand line spacingInput/output processes for data processingLine sensorIndium tin oxide

The invention discloses a bridging and wire-leading sensor of a monolayer multi-point touch screen and a forming process thereof. The forming process is characterized by comprising the following steps: firstly, providing an insulating and transparent substrate, and etching one surface of the substrate into an induction electrode and an indium tin oxide (ITO) leading wire which extends out, wherein contacting points and bridging points for bridging connection are arranged at the tail end of the leading wire, then, keeping on forming a transparent insulating layer on the surface of the substrate, wherein the insulating layer covers all bridging points in the plane and presetting through holes at positions of the bridging points, and at last, forming a bridging layer on the substrate, the insulating layer of which is processed, wherein the bridging layer is positioned on the surface of the insulating layer or comprises the surface of the substrate, the bridging layer is communicated with the bridging points through the through holes, and the bridging and wire-leading sensor is got. Due to the fact that bridging wires exist, the contacting points of the monolayer multi-point touch screen are distributed evenly, the phenomena that the contacting points are blocked and crossed by the leading wire are avoided, the widths of the contacting points and wire distance are enlarged, binding difficulty between the contacting points and flexible printed circuit (FPC) is reduced, and yield is increased.

Owner:来宾市永典木业有限公司

Efficient planting mode of grapes

The invention discloses an efficient planting method of table grapes. The method includes the following steps: preferentially selecting the grape varieties of red globe, summer black, superior seedless and crimson grape which are popularized in a large area, planting sparsely with high ridges, mounting a single width connecting shed used for rain shelter cultivation, mounting a solar water heater as well as drop irrigation and sprinkling irrigation facilities and arranging grape bonsais. The method provided by the invention systematically summarizes and improves the technical contents of substrate cultivation, root zone restriction cultivation, rain shelter cultivation, grape growth and development, and water and fertilizer demands, and solves the key technical problems existing in the industrial development of grapes in a targeted manner; the method fully utilizes the self attributes of the grapes, adopts diversified operation, and improves the comprehensive benefits of the vineyard.

Owner:大理白族自治州农业科学推广研究院药用植物及农业新技术研究所

No-tillage no-hole farming method for directly seeding broad bean in rice stubble

InactiveCN102090260ASave labor to fight for the seasonFavorable stable and high yieldHorticultureFertilizerHorticulture

The invention discloses a no-tillage no-hole farming method for directly seeding broad bean in rice stubble, comprising the following steps: (A) earthing up broad bean ridges: lofting, ditching and earthing up the ridges on a rice stubble soil-compaction field, wherein the width of each ridge surface is 100cm, and the width of each ridge ditch is 40cm; (B) directly seeding broad beans: sowing two rows of broad beans on each ridge along with a rib strip, wherein the inter plant distance is 30cm, the row space is 60cm, the inter plant distance between the ridges is 80cm, 3170 holes are dug per acre, two broad beans are planted in each hole, and 6340 broad beans are planted per acre; (C) carrying out base fertilizer furrow application: carrying out fertilizer furrow application along with the inner sides of ribs; (D) deep digging furrows: ploughing ditch soil below an opposite ridge by a farmer standing on the ridge surfaces, deep ploughing the furrows to be 20cm below a field surface, and evenly putting upturned soils on the ridge surface; and (E) carrying out field management. The no-tillage no-hole farming method has the advantages that all types of field can be ploughed under any weather, no-tillage no-hole rice stubble row planting can be carried out, the row space is enlarged, the inter plant distance is reduced, double-row strip seeds are performed with reasonable close planting, soil is heaped in zanjon for logging and preserving soil moisture, manual striving seasons are saved, and the method is favourable for the high and stable yield of the broad beans.

Owner:狄正兴

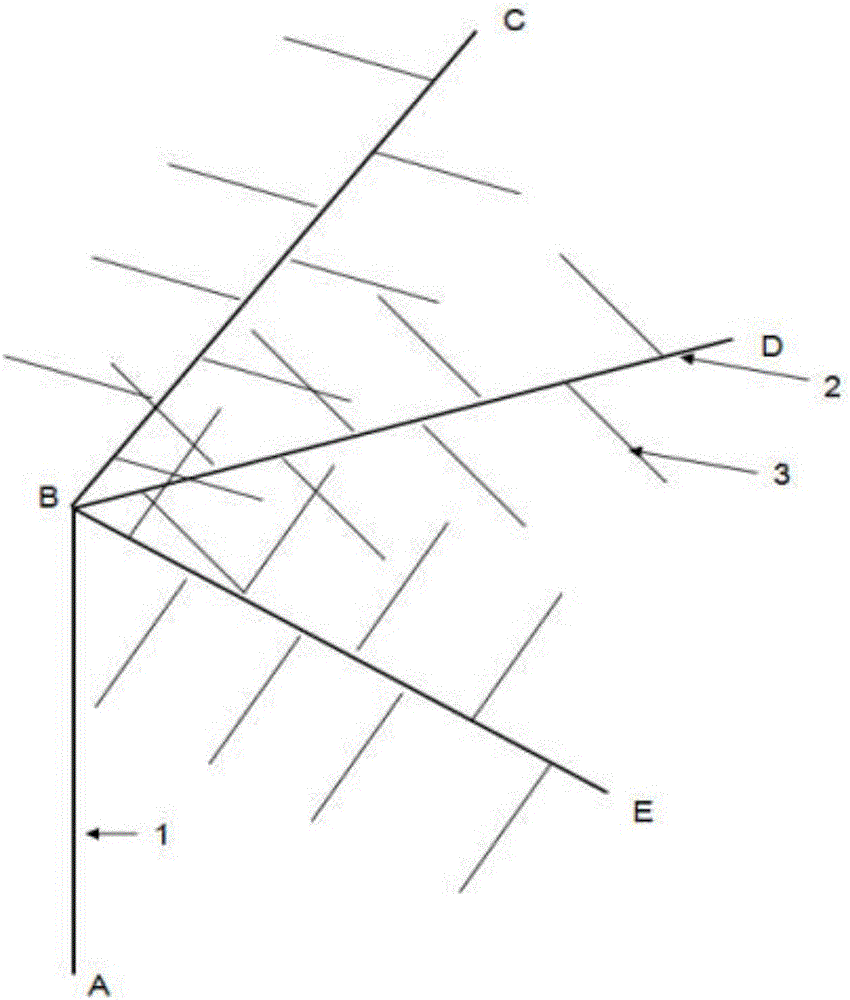

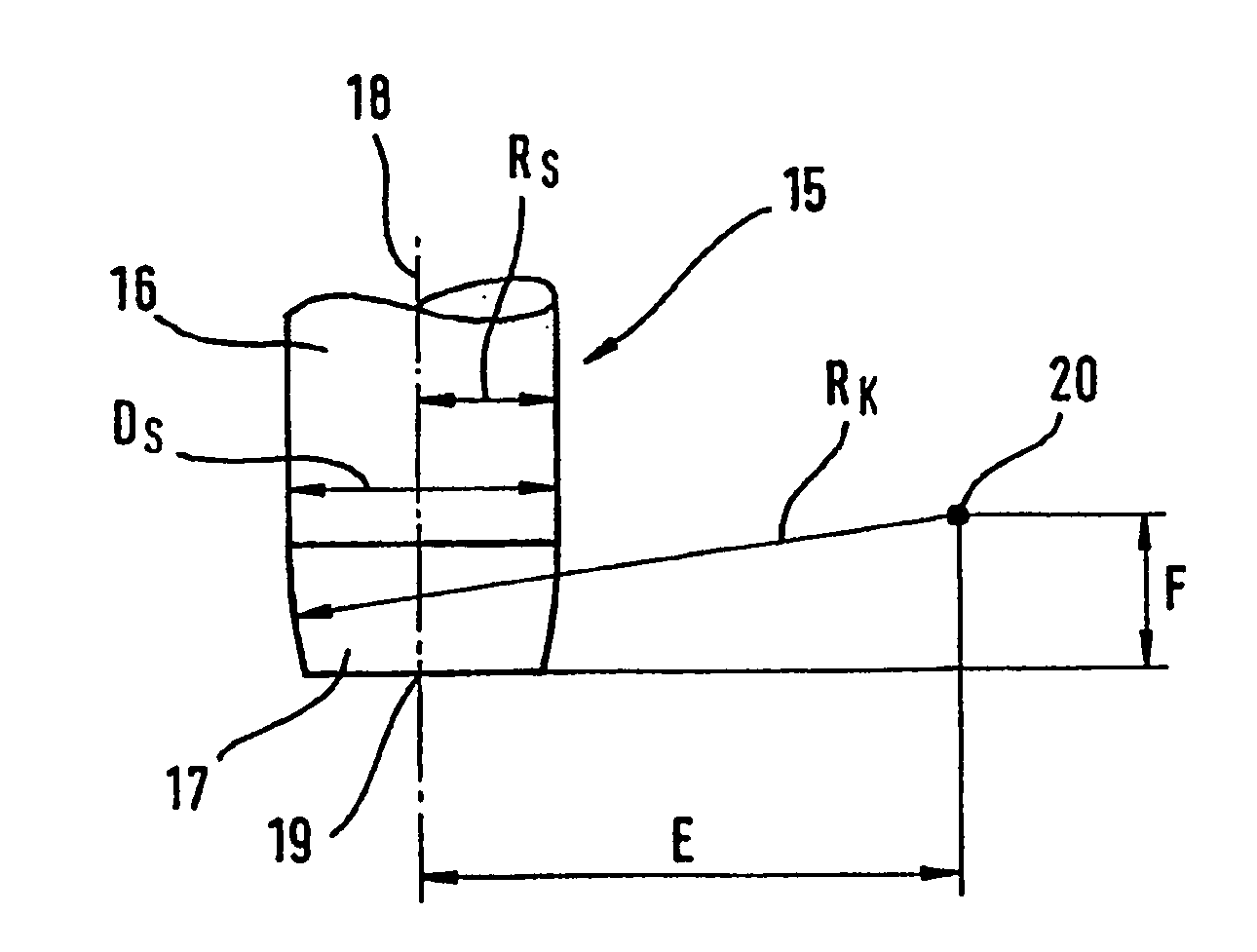

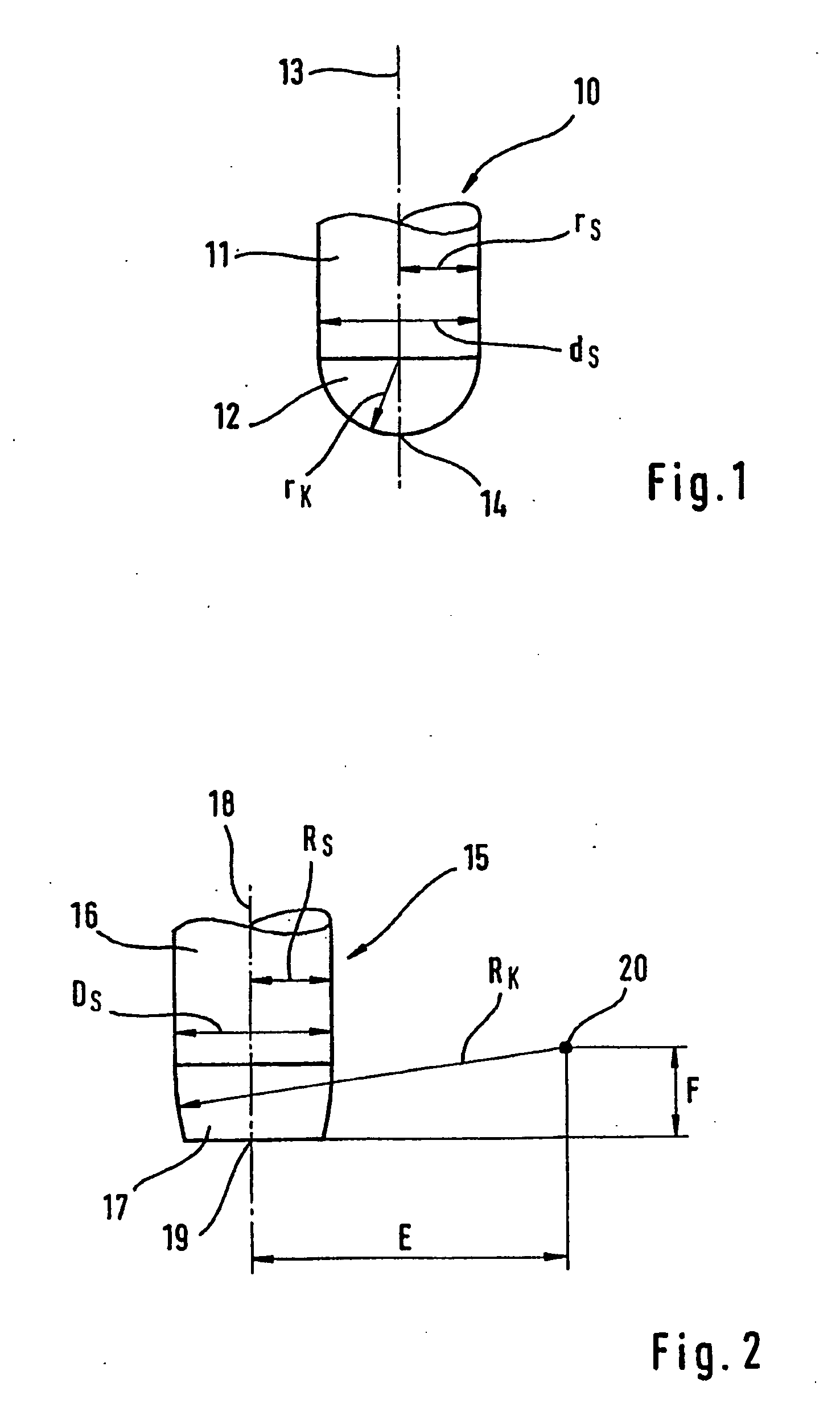

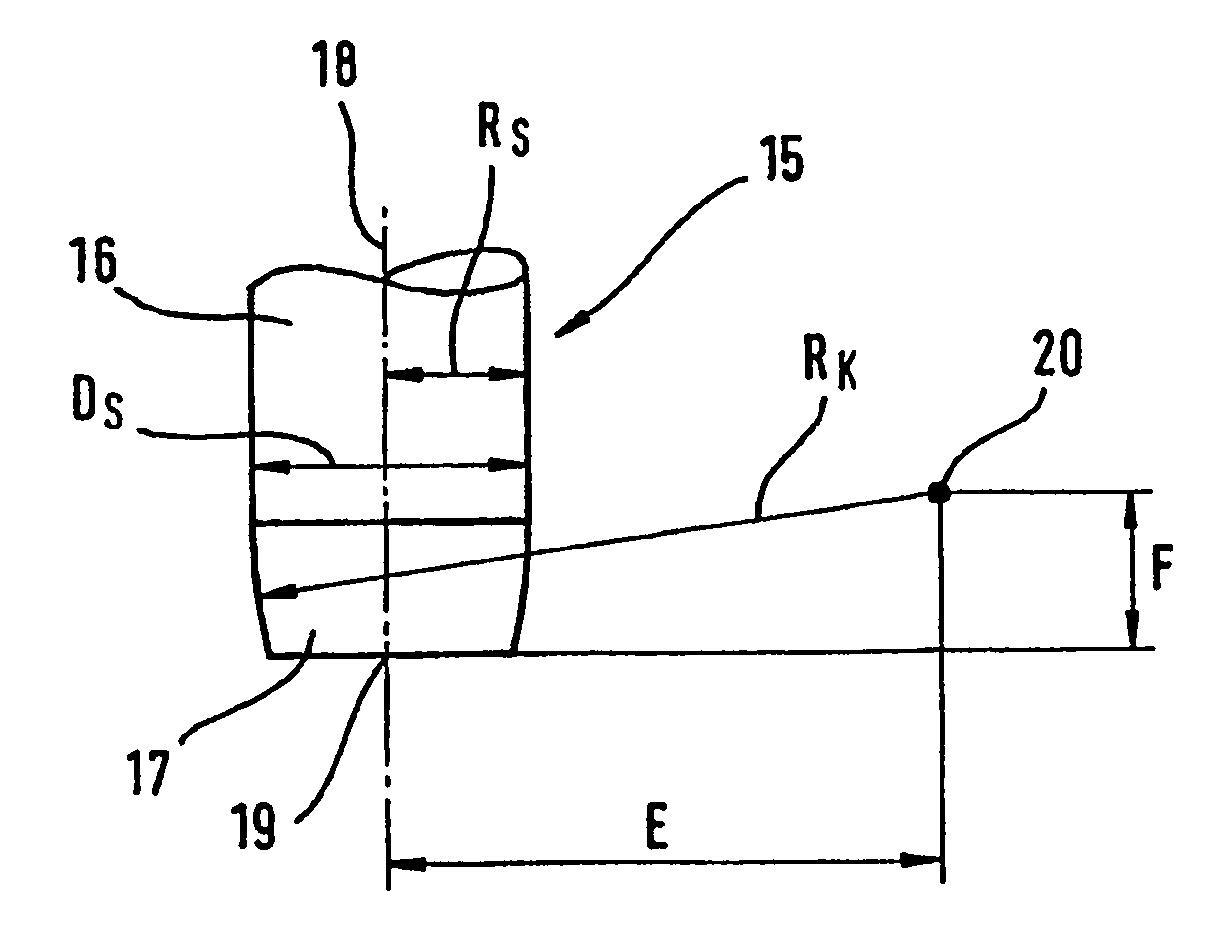

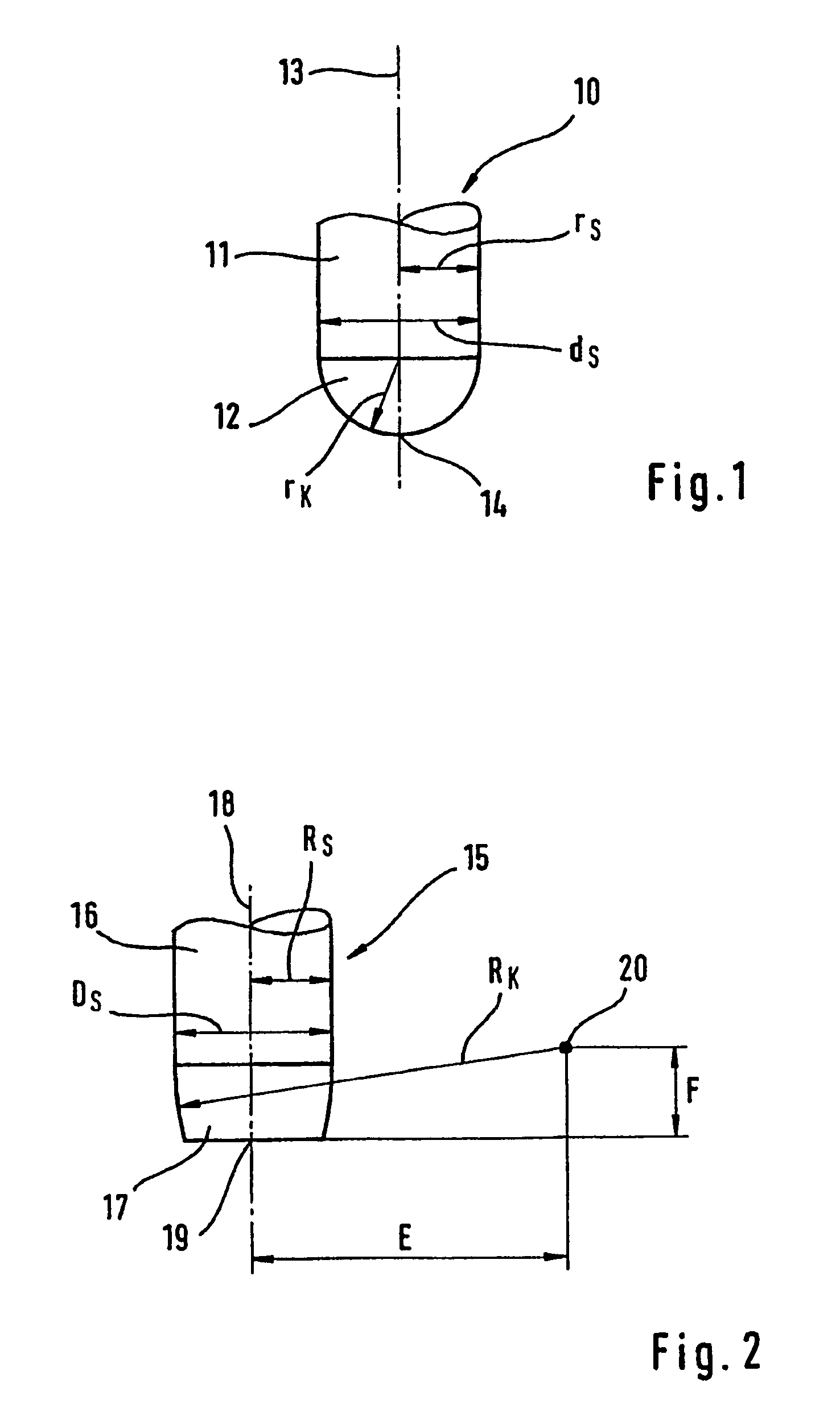

Method For Cutting Freeform Surfaces, Cutting Tool And Use Of The Cutting Tool

ActiveUS20080050184A1Low residual line formationExpand line spacingLathesProgramme controlEngineeringHead parts

In a method for cutting freeform surfaces, a workpiece is cut by a cutting tool such that a desired freeform surface may be achieved, the cutting tool for cutting purposes being moved along at least one defined cutting path relative to the workpiece. A cutting tool is used, the tool head of which has a greater radius than a tool shank of the cutting tool.

Owner:MTU AERO ENGINES GMBH

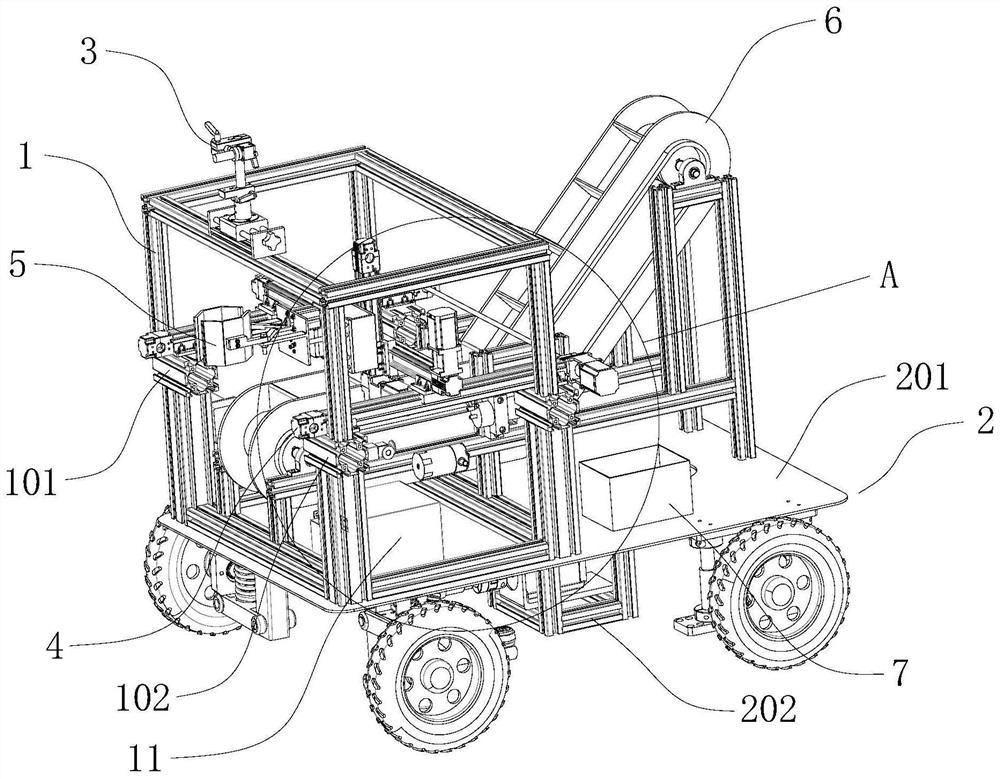

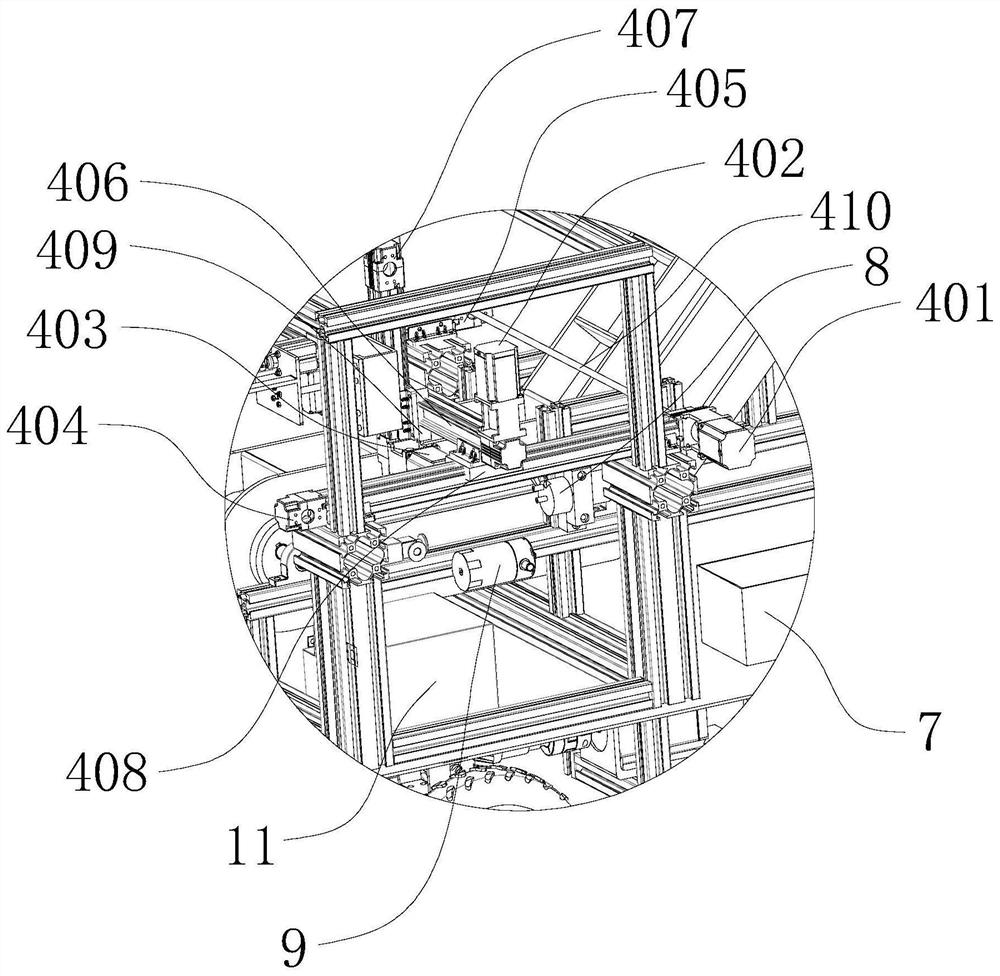

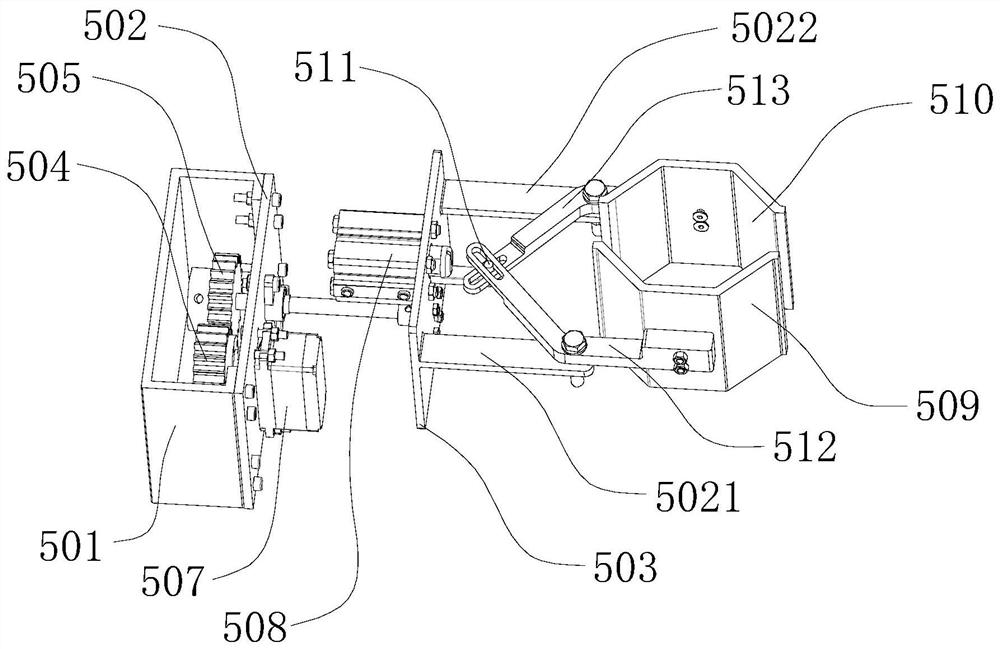

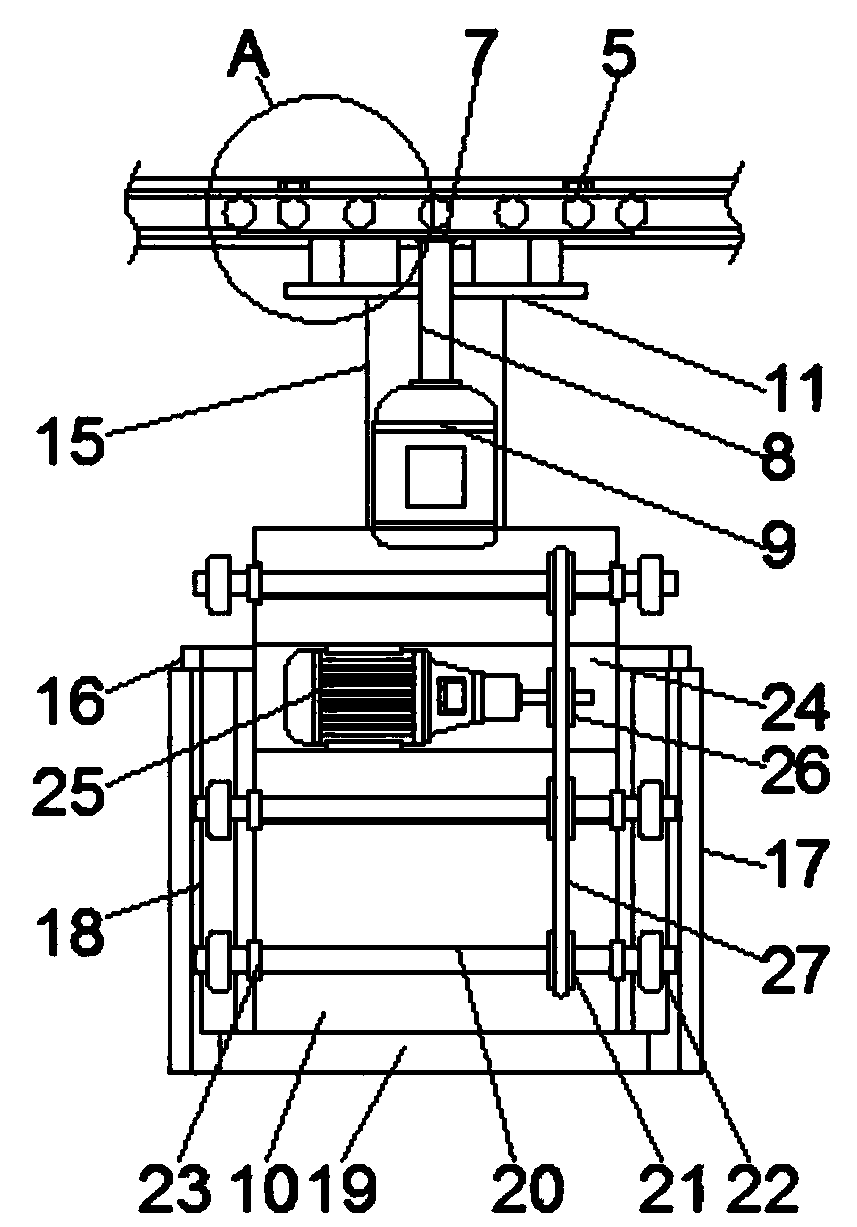

Pineapple picking machine based on machine vision and picking method

ActiveCN111802066AAdaptableExtended service lifeTelevision system detailsHarvestersControl engineeringAgricultural engineering

The invention discloses a pineapple picking machine based on machine vision and a picking method. The pineapple picking machine comprises a rack, a chassis, a machine vision mechanism, a movement mechanism, a pneumatic mechanism, a picking mechanism, a transportation mechanism and a control box, wherein the rack and the control box are arranged above the chassis; the machine vision mechanism, themovement mechanism and the transportation mechanism are arranged on the rack; the chassis, the machine vision mechanism, the movement mechanism, the pneumatic mechanism and the transportation mechanism are connected with the control box respectively; the picking mechanism is arranged on the movement mechanism and is connected with the pneumatic mechanism; the movement mechanism is used for controlling the picking mechanism to move; the pneumatic mechanism is used for controlling the picking mechanism to clamp or release pineapples; and the transportation mechanism is used for transporting thepineapples picked by the picking mechanism. Aiming at a planting manner of the pineapples and economic values of the pineapples except fruits, the pineapple picking machine disclosed by the inventionis used for efficiently picking the pineapples through accurate positioning and a picking mechanical arm, and meanwhile, the integrity of plants is also effectively protected.

Owner:SOUTH CHINA AGRI UNIV

Method for forming a finely patterned resist

InactiveUS7419771B2Critical dimension reductionExpand line spacingSemiconductor/solid-state device manufacturingPhotosensitive material processingResistEngineering

A method for reducing a critical dimension of a photoresist pattern while improving a line spacing between distal end portions of pattern lines wherein the method includes providing a substrate including an overlying resist; exposing the resist to an activating light source; baking the resist in a first baking process followed by developing the resist in a first development process to form a first resist pattern; then baking the first resist pattern in a second baking process followed by developing the first resist pattern in a second development process to form a second resist pattern having reduced dimensions; and, then dry trimming the second resist pattern to form a final resist pattern with reduced dimensions compared to the second resist pattern.

Owner:TAIWAN SEMICON MFG CO LTD

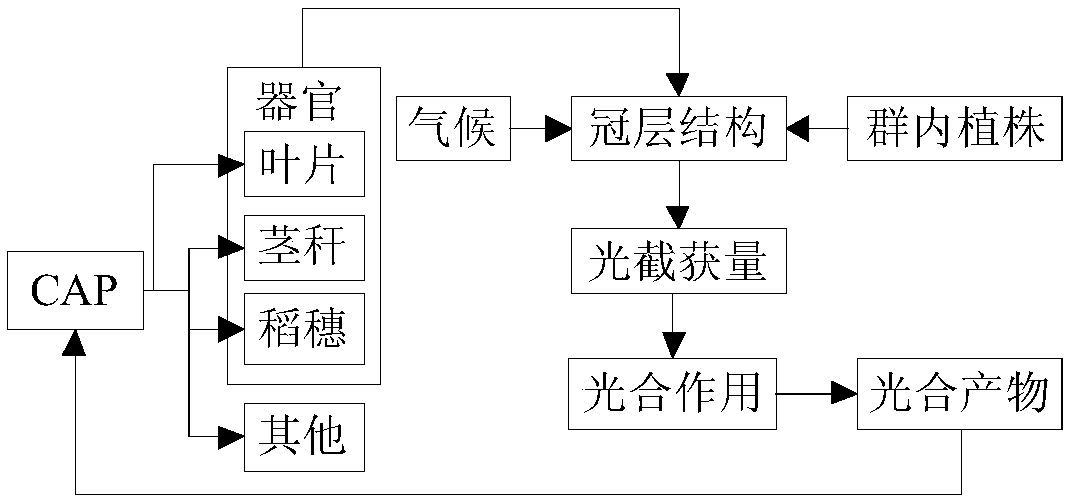

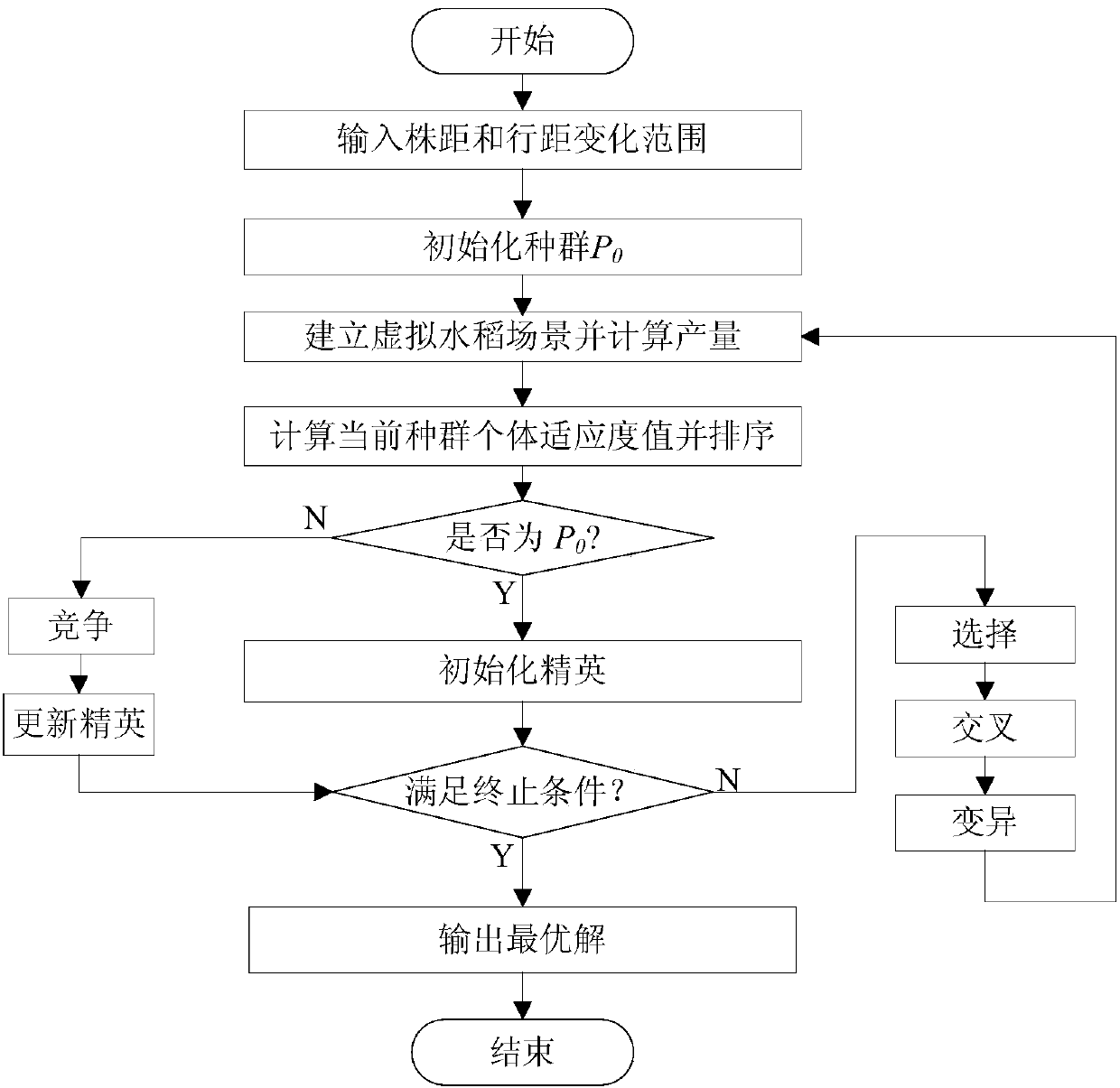

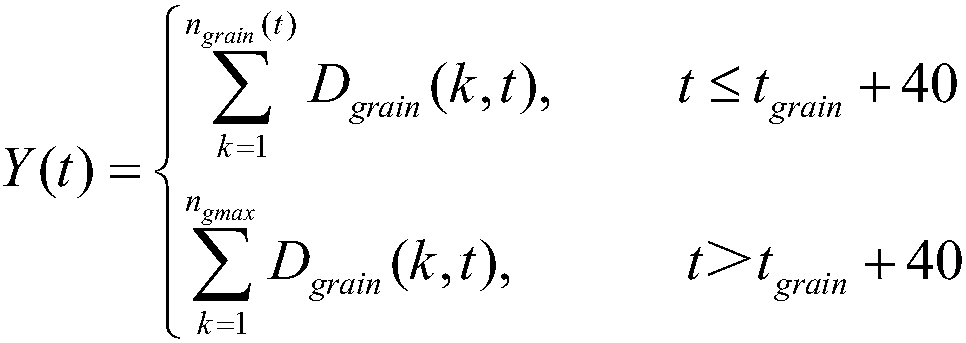

Virtual model-based paddy rice plant distance optimization method

InactiveCN107871039ATime consuming to solveCalculating Light Intercept AmountDesign optimisation/simulationSpecial data processing applicationsRice plantField tests

The invention discloses a virtual model-based paddy rice plant distance optimization method. The method comprises the following steps that 1) based on an existing functional structure model of singlepaddy rice, a light radiation model is built according to a nested radiosity algorithm and a reverse Monte Carlo ray tracing algorithm by utilizing a GroIMP platform, a transmission process of light rays, shielded by different mediums, in a scene is simulated, and an illumination interception quantity of a canopy of a single plant in a colony is calculated, thereby building a paddy rice colony growth model with a certain physiological function; and 2) a genetic algorithm-based plant distance optimization method comprises the following steps of (2.1) performing genetic coding; (2.2) performingpopulation initialization; and (2.3) performing genetic operation to obtain relatively high-yield plant distance and line spacing suitable for paddy rice. The optimum or suboptimum of the plant distance is achieved on the premise of taking the yield as an optimization standard; and the problem of long time of a field test is solved.

Owner:ZHEJIANG UNIV OF TECH

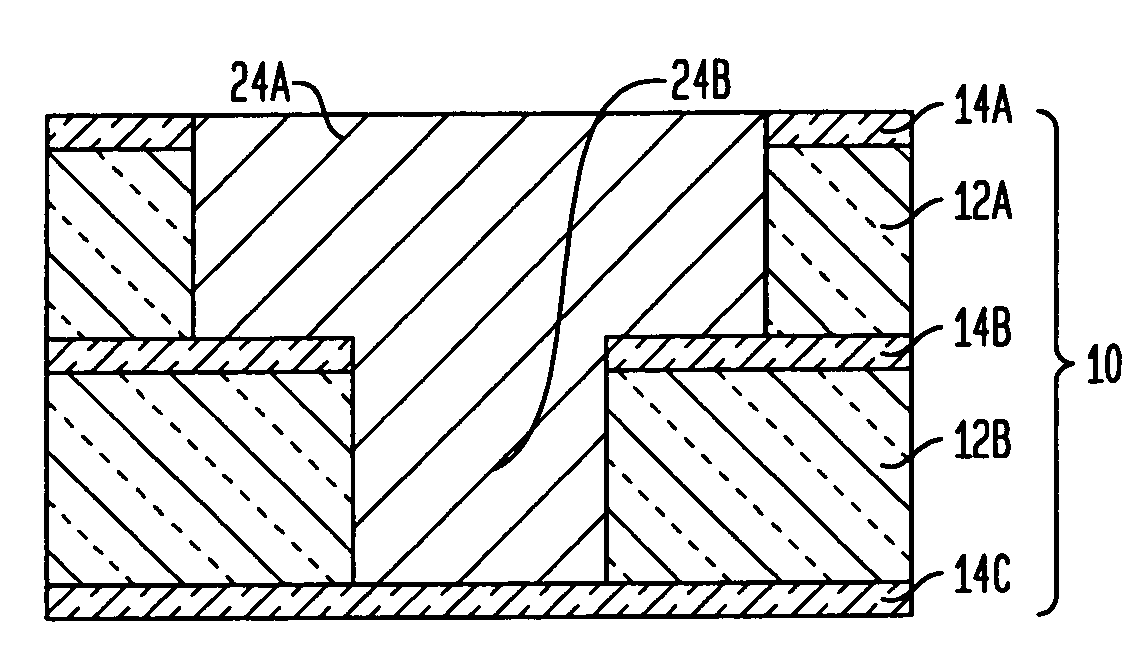

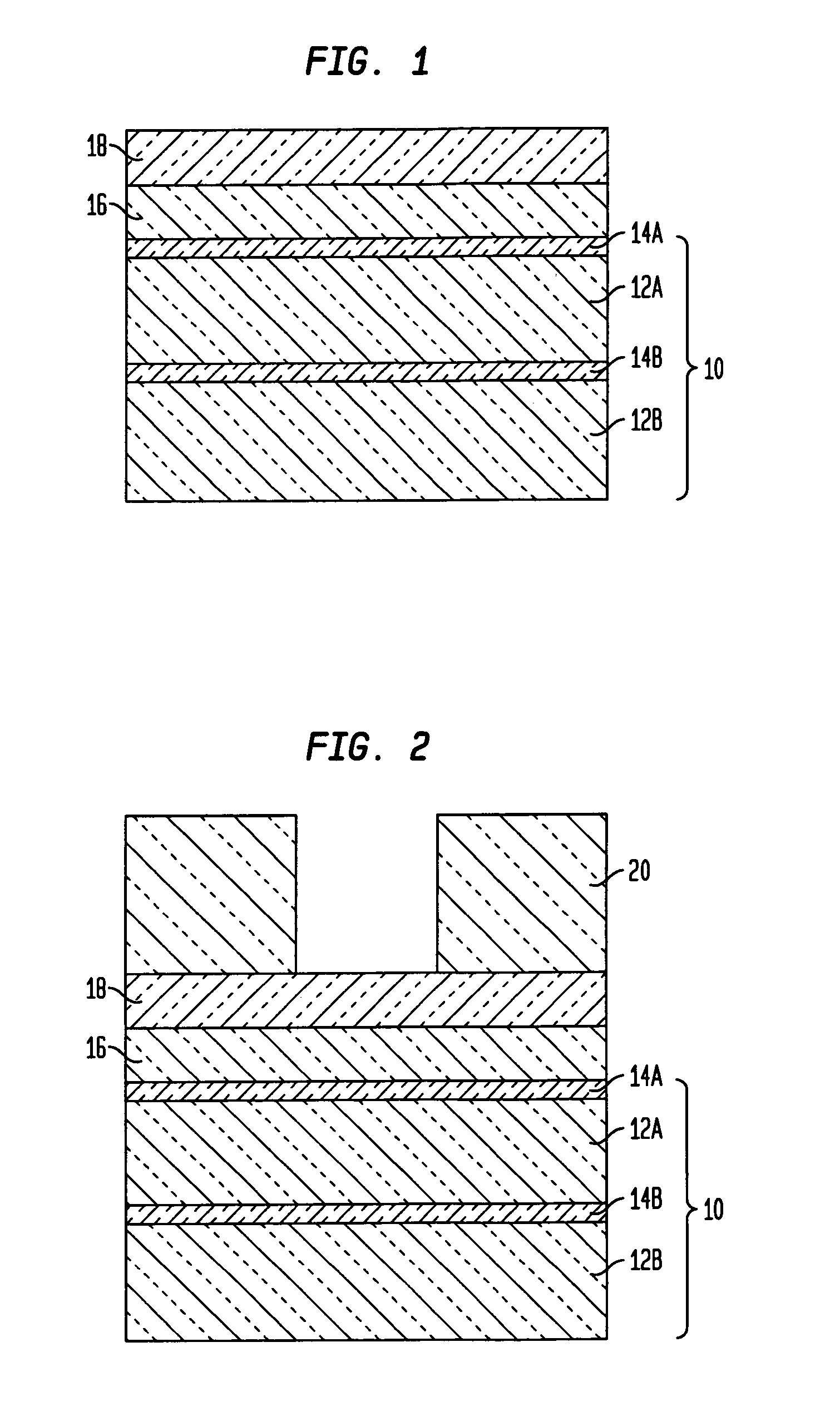

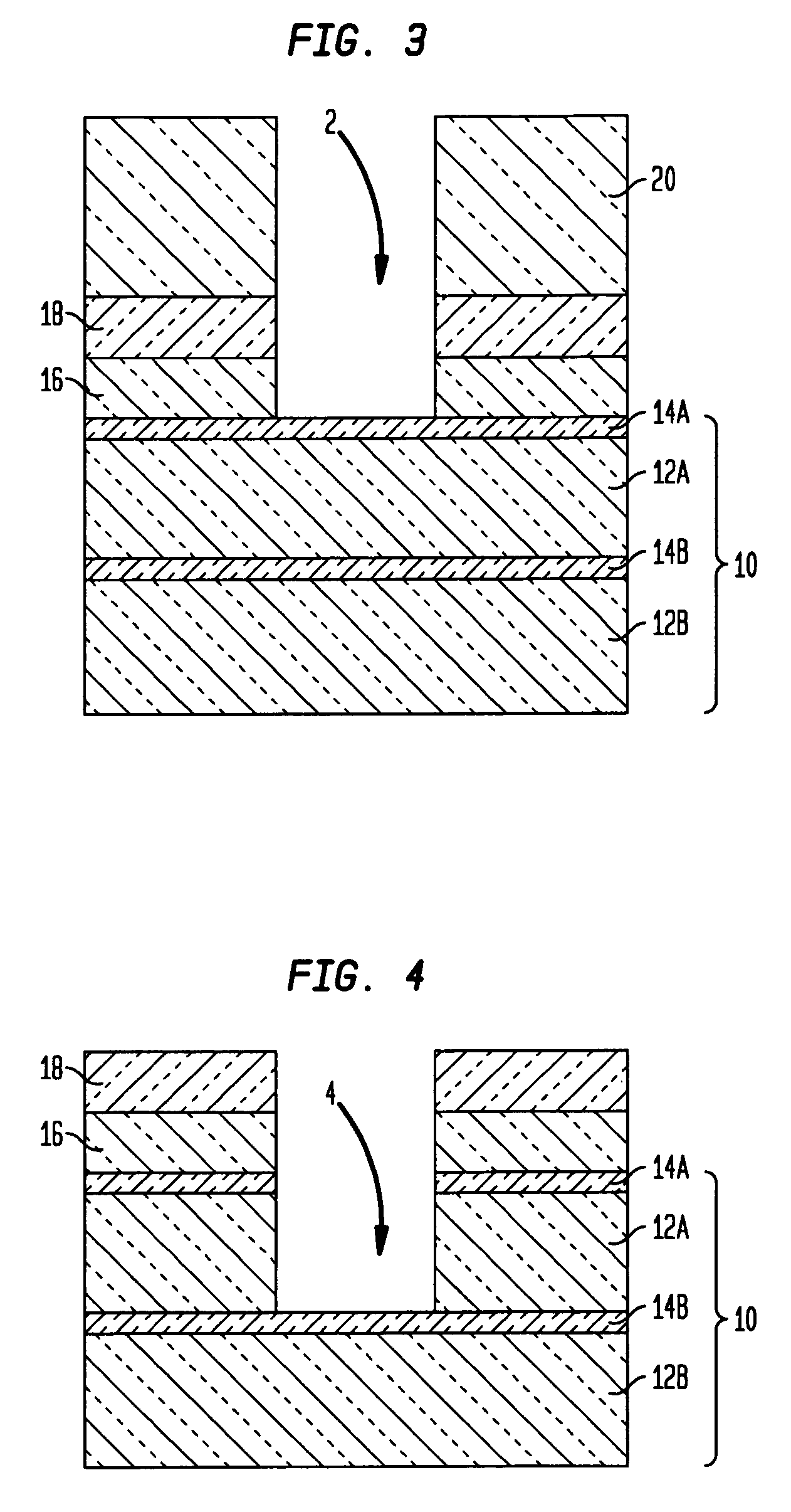

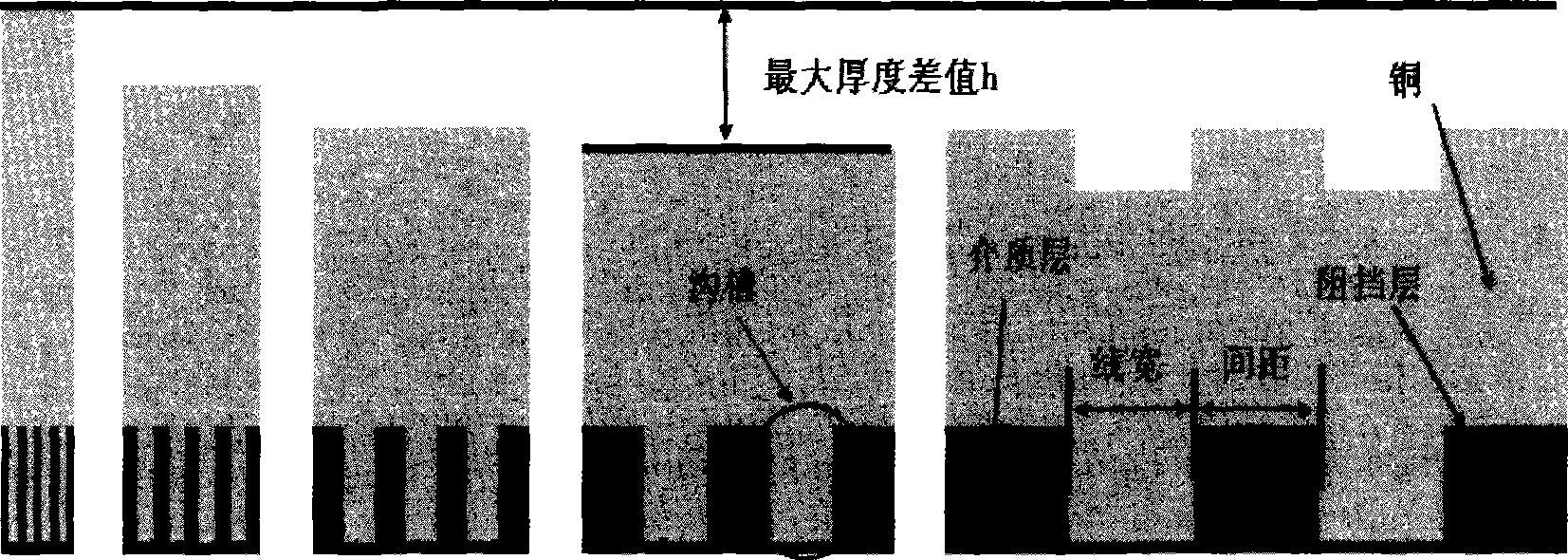

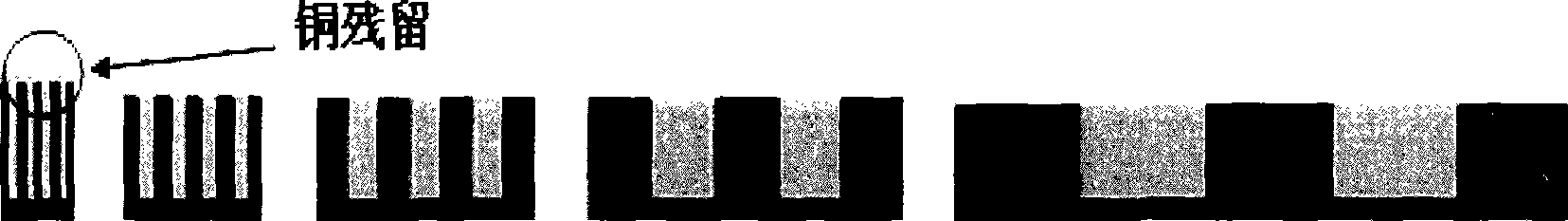

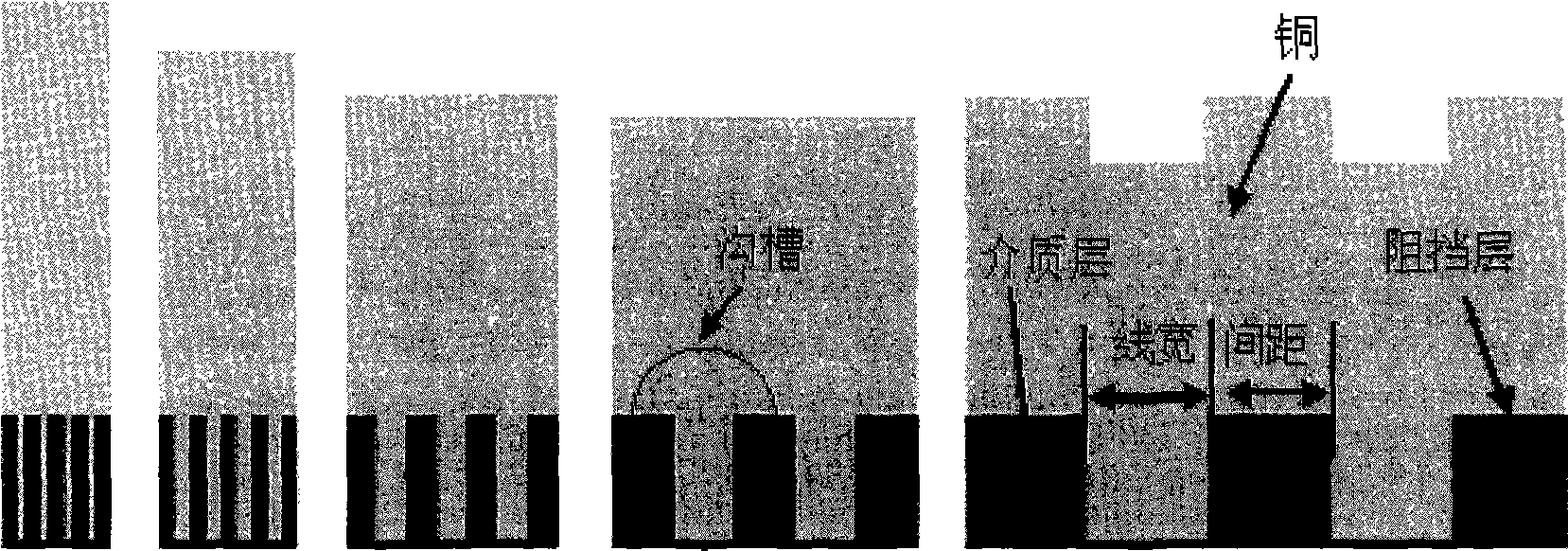

Structures and methods for low-k or ultra low-k interlayer dielectric pattern transfer

InactiveUS7695897B2Expand line spacingIncreasing the thicknessElectric discharge tubesDecorative surface effectsDielectricResist

The present invention relates to improved methods and structures for forming interconnect patterns in low-k or ultra low-k (i.e., having a dielectric constant ranging from about 1.5 to about 3.5) interlevel dielectric (ILD) materials. Specifically, reduced lithographic critical dimensions (CDs) (i.e., in comparison with target CDs) are initially used for forming a patterned resist layer with an increased thickness, which in turn allows use of a simple hard mask stack comprising a lower nitride mask layer and an upper oxide mask layer for subsequent pattern transfer. The hard mask stack is next patterned by a first reactive ion etching (RIE) process using an oxygen-containing chemistry to form hard mask openings with restored CDs that are substantially the same as the target CDs. The ILD materials are then patterned by a second RIE process using a nitrogen-containing chemistry to form the interconnect pattern with the target CDs.

Owner:GLOBALFOUNDRIES INC

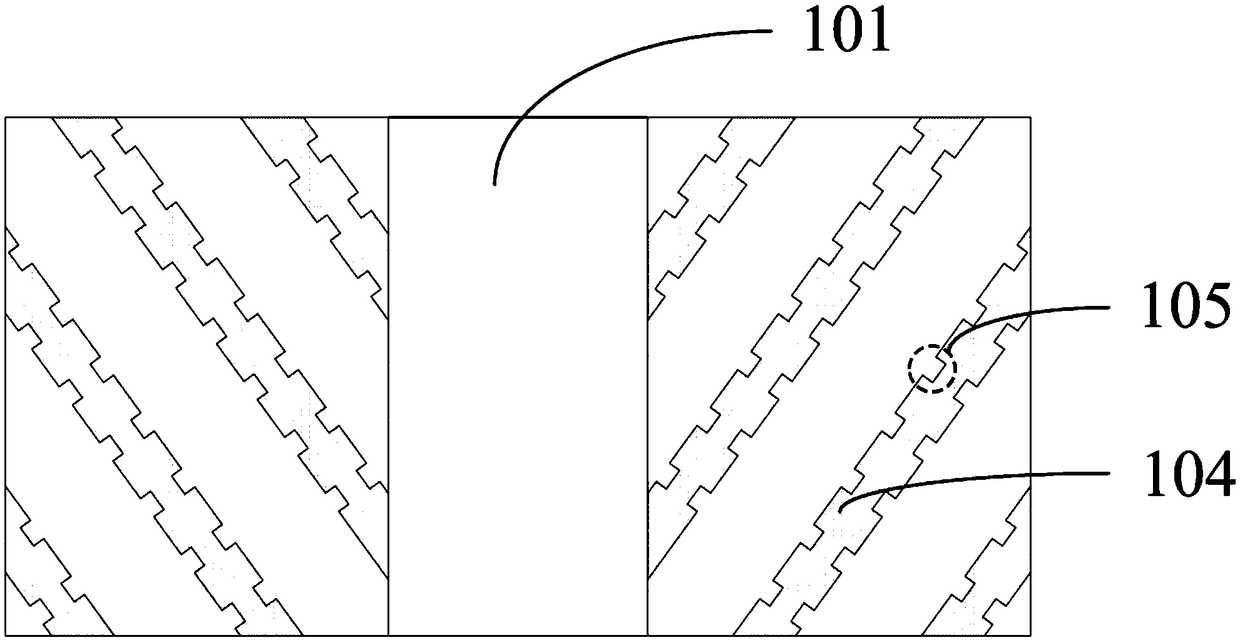

Pixel electrode and array substrate

InactiveCN109375434AReduce line widthExpand line spacingNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a pixel electrode and an array substrate. The pixel electrode comprises a first main electrode and a second main electrode which is vertically intersected with the first main electrode; the first main electrode and the second main electrode divide the pixel electrode into a plurality of liquid crystal alignment areas, a plurality of branch electrodes are arranged in each liquid crystal alignment area, and a preset included angle is formed between each branch electrode and the first main electrode or the second main electrode, wherein each branch electrode is provided with a hollowed-out part. According to the pixel electrode, the hollowed-out parts are arranged on the branch electrodes of the pixel electrode, so that the wire width of the branch electrodes is reduced, and the wire distance between every two adjacent branch electrodes is increased in order to improve the liquid crystal efficiency in a liquid crystal displayer and lower the energy consumption of the displayer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Paddy rice broad-width direct seeding and simultaneous seeding fertilizing method

PendingCN108307740ASimplify seeding and fertilizationImprove planting efficiencyAgriculture gas emission reductionFertiliser and seeding apparatusCoated ureaPhotosynthesis

The invention provides a paddy rice broad-width direct seeding and simultaneous seeding fertilizing method. According to the paddy rice broad-width direct seeding and simultaneous seeding fertilizingmethod, paddy rice seeds with husk broken white part exposure and a controlled-release fertilizer are subjected to seeding and fertilizing using a special direct seeding paddy rice simultaneous seeding fertilizing machine so as to obtain seed rows and fertilizer rows, wherein the seed rows and the fertilizer rows are strip shaped parallel lines, the row distance of the seed rows is controlled to be 18 to 32cm, the seeding width is controlled to be 5 to 15cm, the fertilizer rows are arranged between each pair of adjacent seed rows, and one fertilizer row is shared by two seed rows; in seeding of paddy rice seeds, concave seeding strips with a width of 5 to 15cm and a depth of 2 to 4cm are formed on wet soil surface via pressing, and the paddy rice seeds are placed at the bottoms of the concave seeding strips with a distance ranging from 2 to 4cm from the soil surface to the seeds. The paddy rice broad-width direct seeding and simultaneous seeding fertilizing method is capable of realizing simultaneous seeding and fertilizing, so that plantation efficiency is increased; paddy rice row distance and seeding width are increased appropriately, so that ventilation light transmittance is improved, photosynthesis is promoted, excellent plant growth states are achieved, and colony quality is high; resin-coated urea is adopted to supply 30 to 90% nitrogen, so that seed and seedling burn caused by high fertilizing amount is avoided; the fertilizing depth is controlled to be high, so that nitrogen phosphor potassium utilization rate is increased, and direct seedling paddy rice lodging resistance is improved.

Owner:MAOSHI AGRI TECH CO LTD

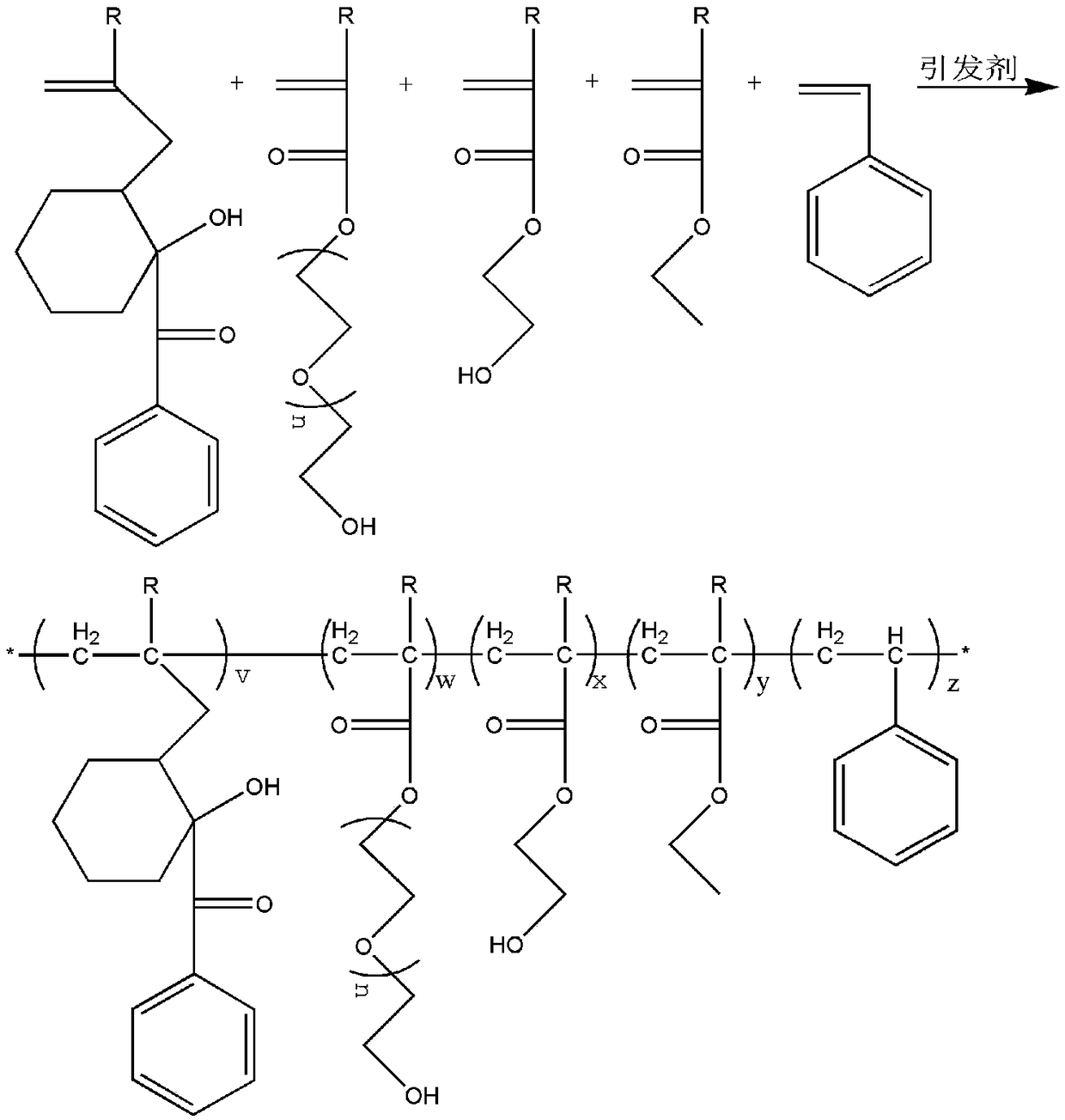

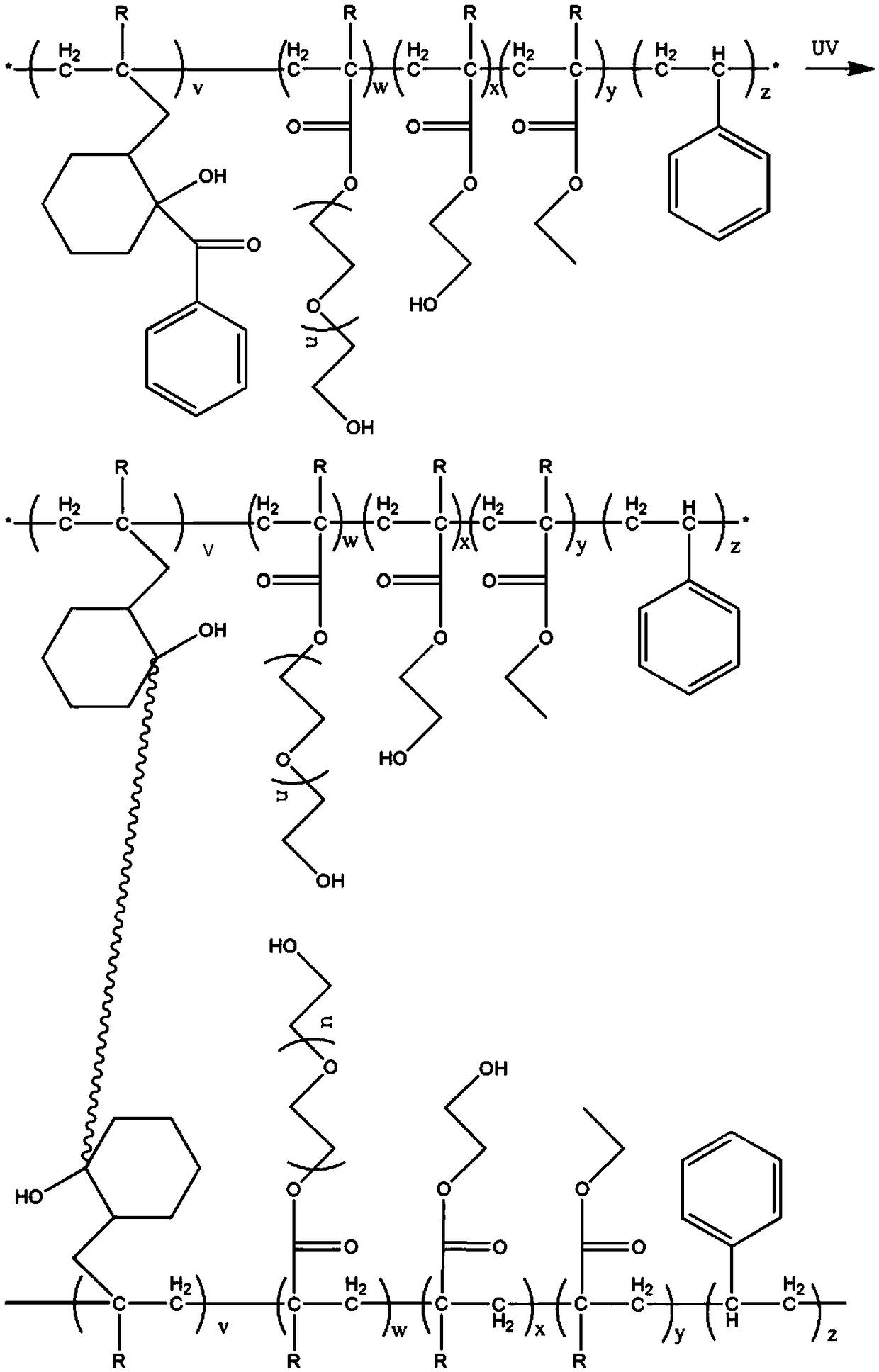

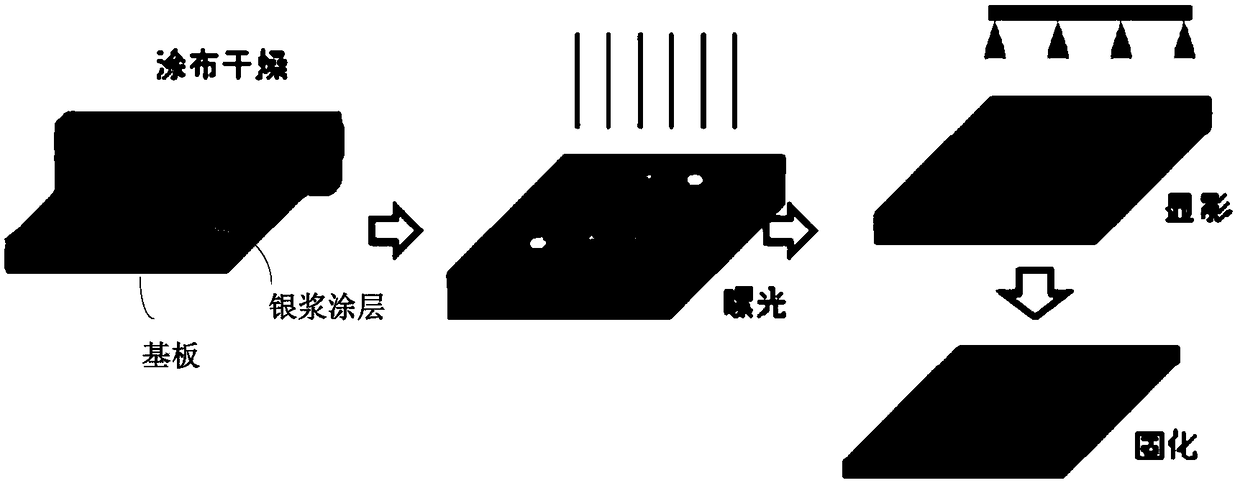

Photosensitive resin composition, yellow light slurry and preparation method thereof

ActiveCN109143780AHigh polar affinityImprove performancePhotosensitive materials for photomechanical apparatusHydrophilic monomerPolymer science

The invention provides a photosensitive resin composition, comprising a macromolecular polymer composed of a plurality of monomer units, wherein the monomers forming the monomer units in the macromolecular polymer comprise a photopolymerization initiator, a hydrophilic monomer and a hydrophobic monomer, wherein the monomers are all compounds containing an olefinic double bond; and the yellow lightslurry prepared by using the photosensitive resin composition provided by the invention can be well matched with noble metal powder, is not easy to be delaminated and precipitated, can be self-initiated and self-crosslinking solidified, and can be used for preparing a substrate circuit with excellent conductivity, high resolution and good adhesion. In addition, the invention also provides a preparation method of a photosensitive resin composition, yellow light slurry and a preparation method thereof.

Owner:乾宇微纳技术(深圳)有限公司

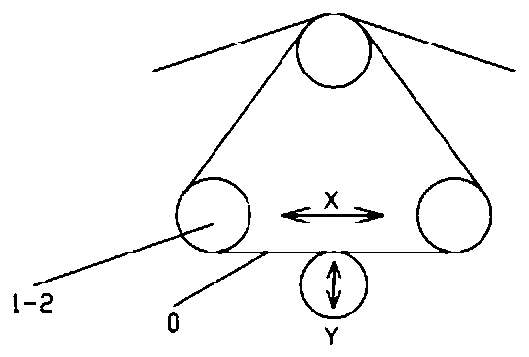

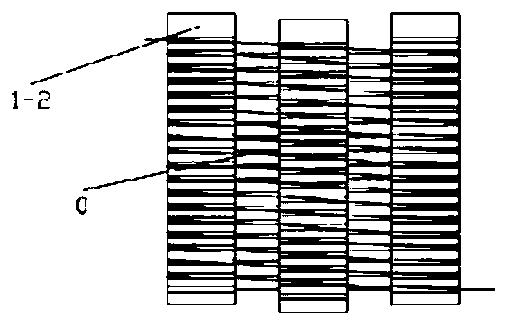

Cutting method of multi-wire cutting machine and multi-wire cutting machine

PendingCN110076669AShorten the processing cycleAdapt to processing needsGrinding drivesWorking accessoriesLinear motionWire cutting

The invention discloses a cutting method of a multi-wire cutting machine and the multi-wire cutting machine. The method comprises the following steps that a circle of steel wire is wound around a roller; or a plurality of circles of steel wires are wound around the roller, and the distance between every two adjacent circles of steel wires is larger than or equal to twice of the minimum distance between the two adjacent line grooves of the roller and is smaller than or equal to the distance between the line grooves at the two ends of the roller; and when the cutting is carried out, the cuttingmaterial is taken out of the steel wire after last cutting is done and before the next cutting is carried out, and then the cutting material is moved a certain distance along the length direction of the roller, and the distance is equal to the thickness of the slice. The multi-wire cutting machine comprises a cutting part and a feeding part, the cutting part comprises an X-direction reciprocatinglinear motion mechanism, the feeding part comprises a material plate, a Y-direction reciprocating linear motion mechanism and a Z-direction reciprocating linear motion mechanism, the X direction, theY direction and the Z direction are perpendicular to each other. According to the cutting method of the multi-wire cutting machine and the multi-wire cutting machine, the cutting slices with any thickness can be cut by using the roller with the same groove distance, and the requirement of small-batch multi-variety processing is met.

Owner:玉田县昌通电子有限公司

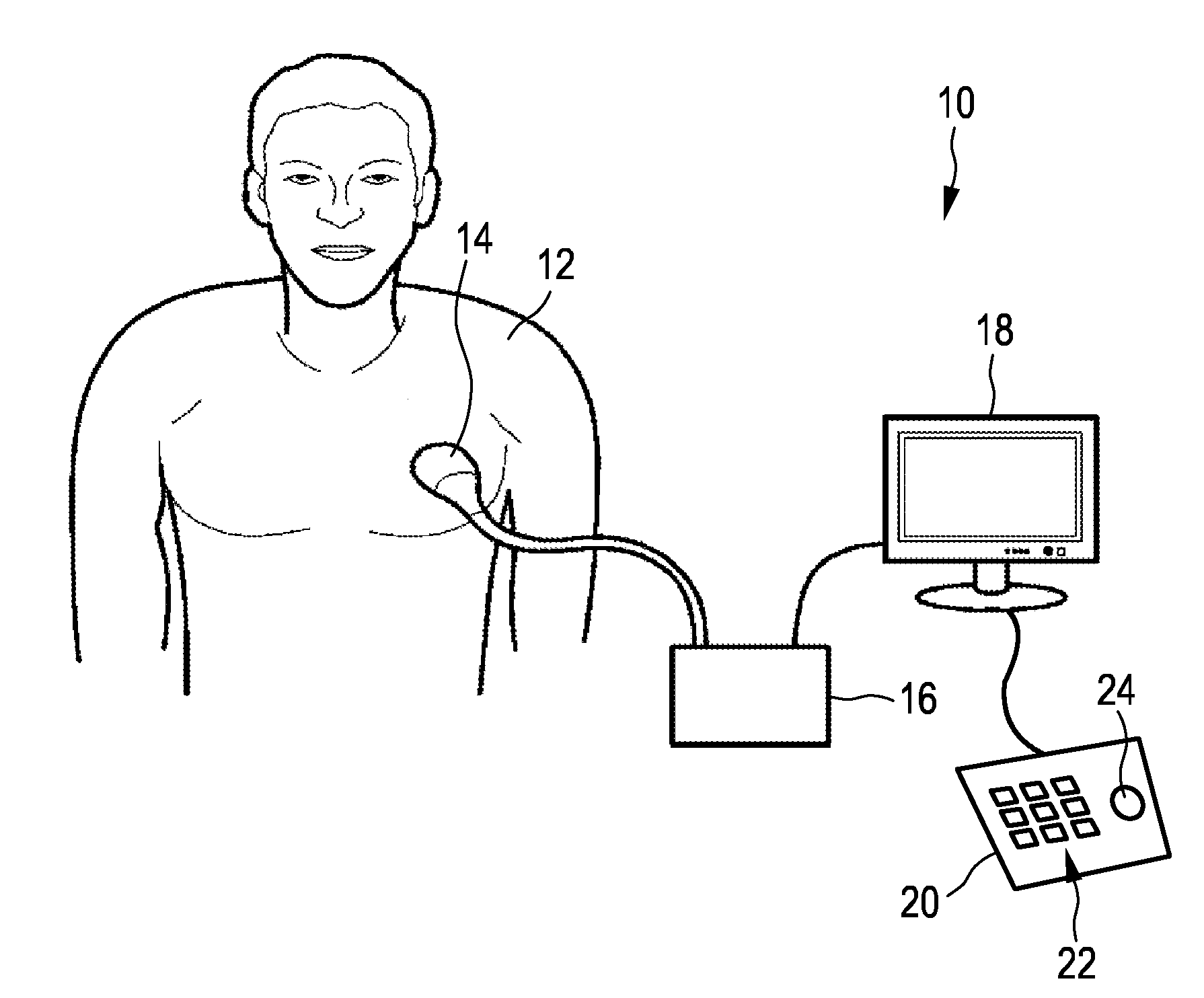

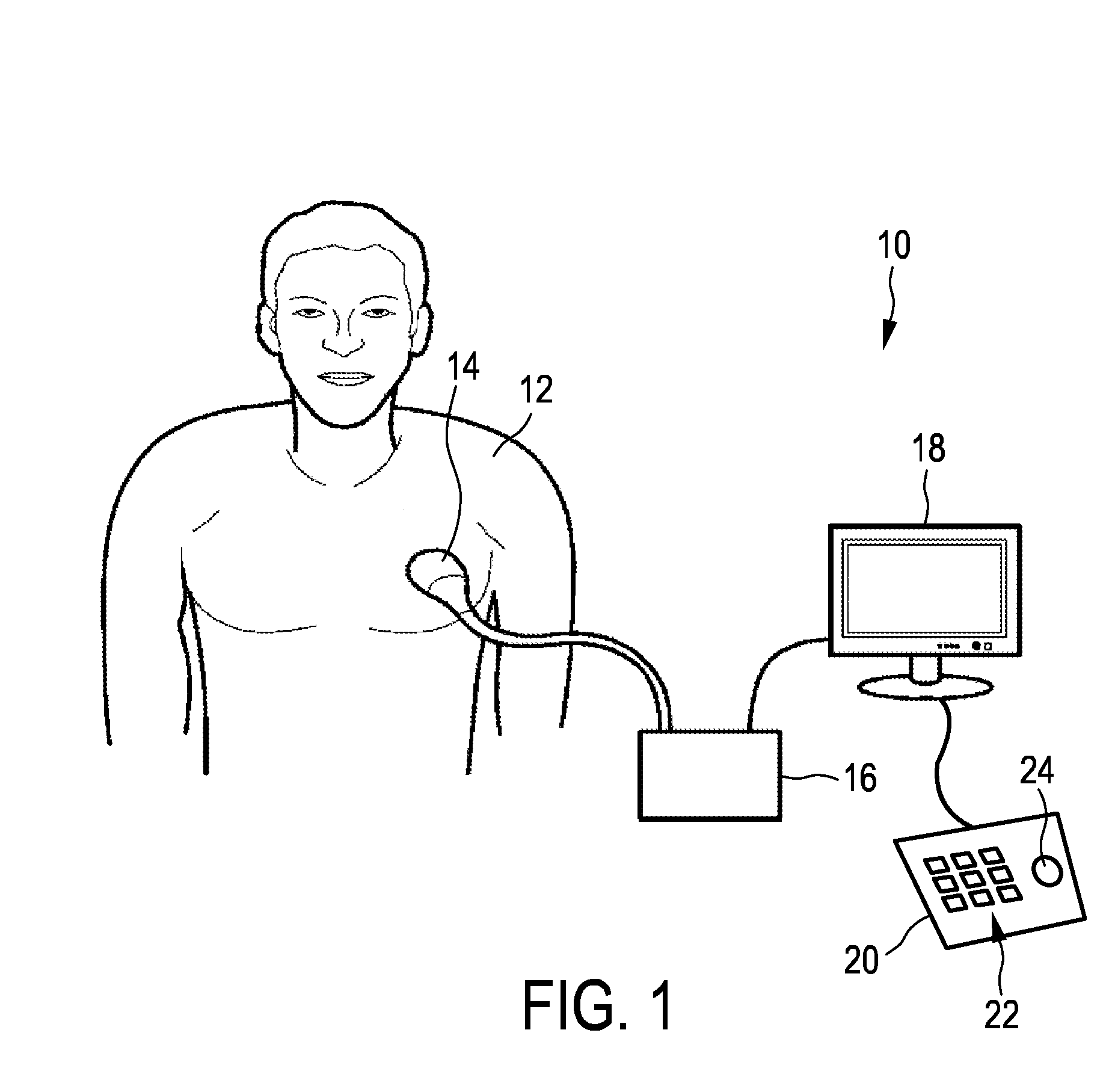

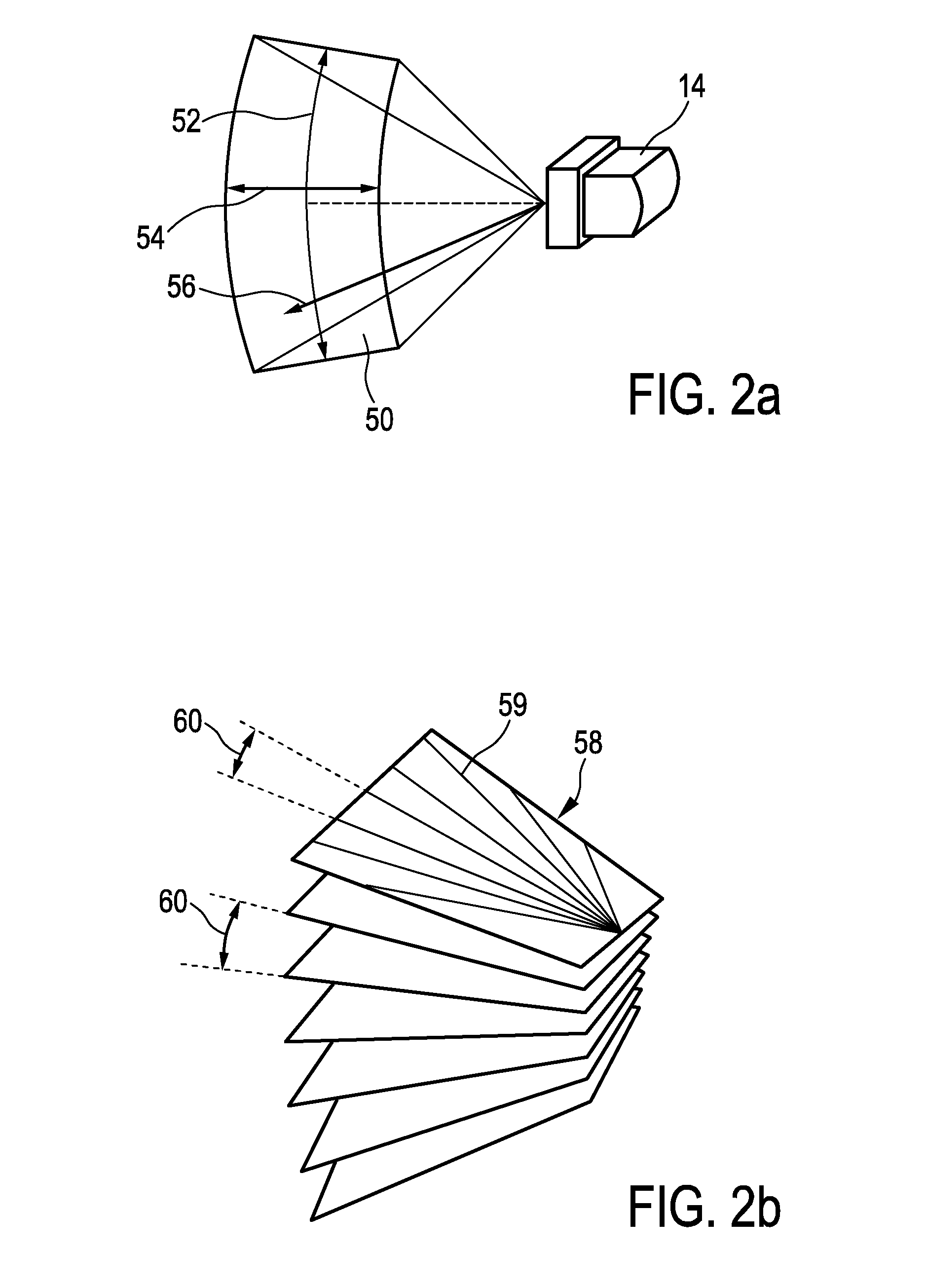

Large volume three-dimensional ultrsaound imaging

InactiveUS20140330125A1Low bandwidthIncrease spacingOrgan movement/changes detectionInfrasonic diagnosticsBandpass filteringUltrasound imaging

The present invention relates to a method for providing a three-dimensional ultrasound image of a volume (50) and an ultrasound imaging system (10). In particular, the current invention applies to live three-dimensional imaging. To improve three-dimensional dimensional ultrasound imaging of a large volume, it is contemplated to adjust the central receive frequency (70) of a bandpass filter (35) of a signal processor (34) as a function of a spacing (60) of scanning lines (59) of a transducer array (26).

Owner:KONINKLJIJKE PHILIPS NV

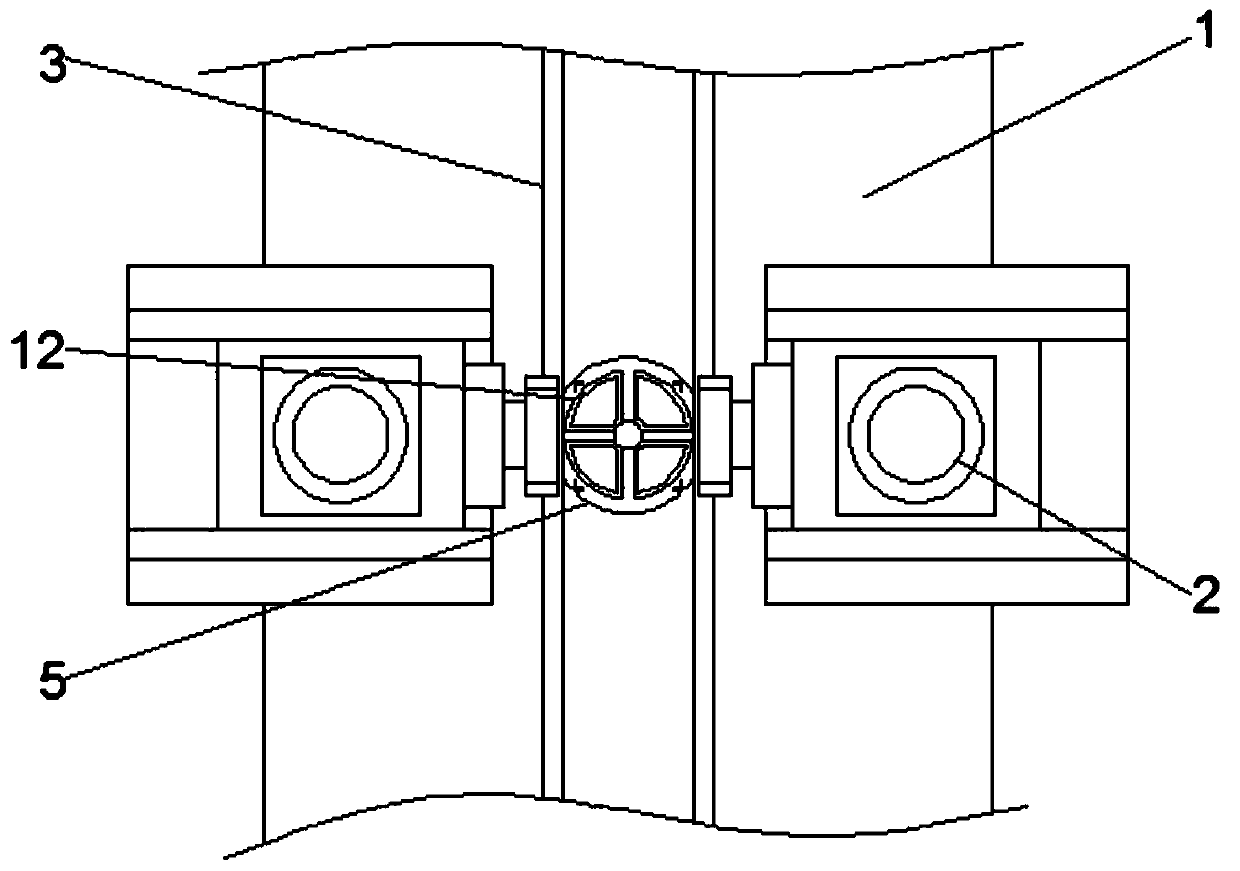

Multi-axis ultrasonic metal welder

PendingCN111375883ATo achieve the purpose of all-round weldingExpand line spacingNon-electric welding apparatusElectric machineryEngineering

The invention relates to the technical field of ultrasonic metal welders, and discloses a multi-axis ultrasonic metal welder. The multi-axis ultrasonic metal welder comprises a workbench, wherein thefront surface of the workbench is fixedly equipped with two machine bodies. According to the multi-axis ultrasonic metal welder disclosed by the invention, a VC sheet is firstly placed between fixed bases, a second drive motor is then started to drive a first rotary disc, and a roller is driven to generate relative friction with a second slide slot for pushing an outer frame to move upwards, so that a connecting plate jacks a mounting disc and a placing table to pass through a through hole for being in contact with the VC sheet; the VC sheet applies the placing table which continuously rises and is in contact with welding heads of the machine bodies at the two sides for welding; the placing table is returned for re-arranging the VC sheet between the fixed bases, and a first drive motor isstarted to drive a tray to rotate; the placing table rotates along with the tray under assistance of the connecting plate and a rotary disc ring; and after the tray stops, the second drive motor is re-started for jacking the VC sheet to be in contact with the machine bodies for welding, so that once all-around welding purpose is achieved.

Owner:江苏明利嘉科技有限公司

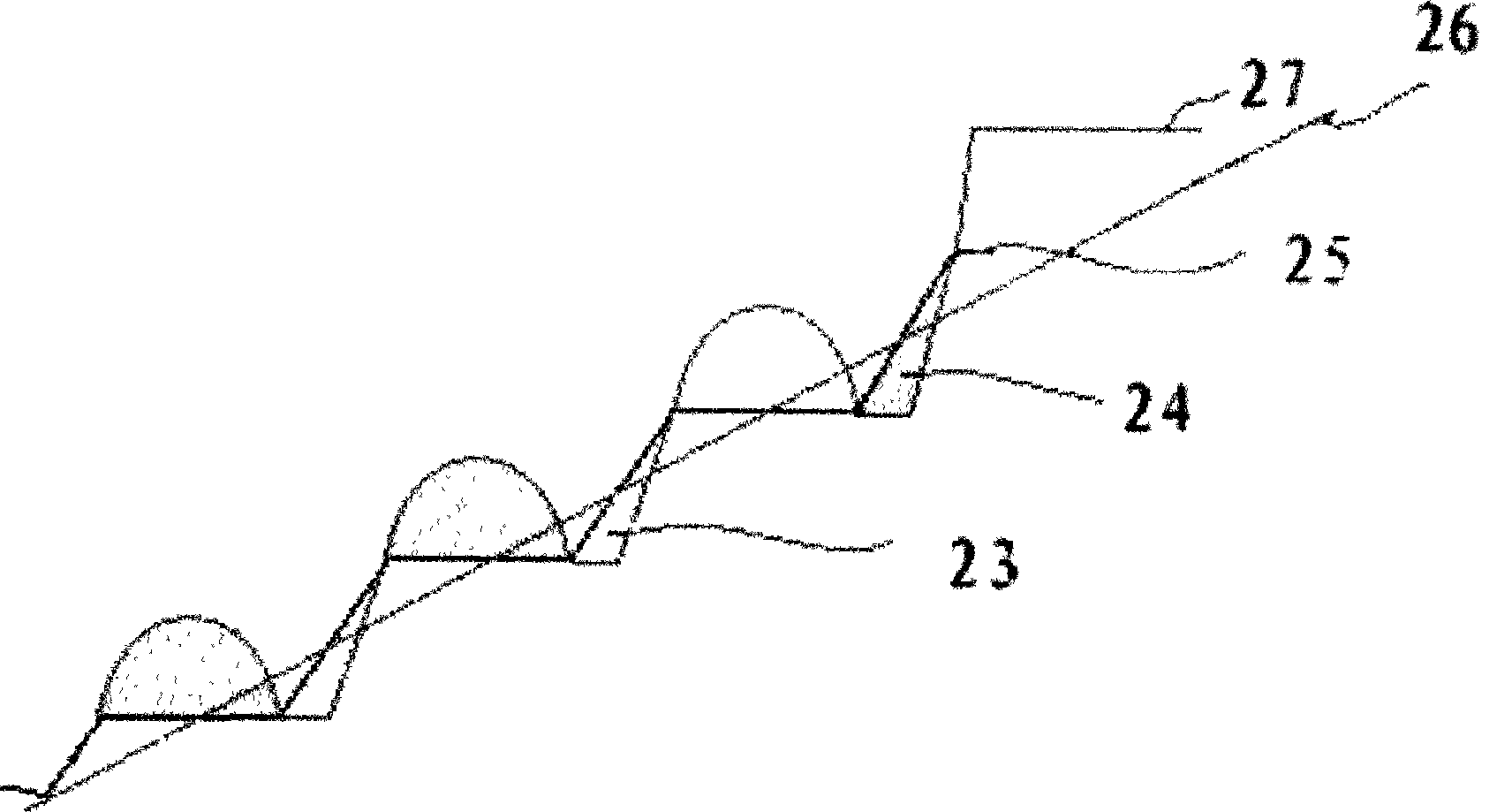

Slope planting technique

InactiveCN101361442AWide applicabilityImprove technical qualityFertilising methodsAgriculture gas emission reductionFertilizerSite management

The invention relates to an agricultural cultivation technique, in particular to a sloping field cultivation technique which implements the cultivation with manpower, animal power or mechanical power. The technique is characterized in that: (1) the active layer of the sloping field, with the manpower or animal power cultivation way, is stacked and made into horizontal strip ladders, and the strip ladder number, the strip ladder height, the row spacing number and the planting distance number of each Chinese acre field are arranged; (2) during the strip ladder making process, the chemical fertilizer is buried deeply, the farm manure is buried moderately, and the seed is sowed shallowly; (3) the seeding can be carried out at best time according to characteristics of the variety, under the tool work implementation, the variety of the seeding sowed on the horizontal ladders achieves good soil moisture content, the sowed seeds have consistent depth, earth backing and earth pressure, and the seeding quantity achieves the best number; and (4) the field management is carried out according to the growth need of the crops on the basis of the growth time of the crops. The technique can replace and change the backward traditional cultivation technique, solve the problem of soil erosion brought by the agricultural cultivation, and realize the mountainous region scientific farming with less cultivation but more grain production.

Owner:薛怀清

Zero-tillage and free-pit- cultivation method for rice stubble-transplanted horsebeans

The invention discloses a zero-tillage and free-pit-cultivation method for rice stubble-transplanted horsebeans. The method comprises the following steps: (A) the growing of horsebean seedlings; (B) the making of horsebean border checks: a rice stubble field is set out and ditched to make border checks, the width of each border check surface is 100cm, and the width of each border ditch is 40cm; (C) the row replacement of base fertilizer: the row replacement of the fertilizer is carried out along the inner sides of soil ridges; (D) the transplantation of horsebeans: two rows of horsebeans are transplanted along the inner sides of the soil ridges of each border check, the spacing in the rows is 15cm, the spacing between rows is 60cm, the interval spacing between rows is 80cm, and the field has 6340 plants per mu; (E) the deep ploughing of the border ditches: the border ditches are deeply ploughed 20cm below the surface of the field, and the upturned soil is evenly placed on the surfaces of the border checks; and (F) field management. The cultivation method can be carried out in dry and muddy fields in sunny, cloudy and rainy days, zero-tillage, pit-free stubble transplantation can be carried out, the spacing between rows is enlarged, the spacing in the rows is reduced, close planting and double-row plantation are carried out reasonably, the deep ditches and the heaped soil can prevent flooding and preserve soil moisture, the transplantation of the seedlings can gain the season, and the yield is high and stable because of early plantation on late stubbles.

Owner:狄正兴

Method for cutting freeform surfaces, cutting tool and use of the cutting tool

ActiveUS8096215B2Low formationExpand line spacingLathesProgramme controlEngineeringMechanical engineering

In a method for cutting freeform surfaces, a workpiece is cut by a cutting tool such that a desired freeform surface may be achieved, the cutting tool for cutting purposes being moved along at least one defined cutting path relative to the workpiece. A cutting tool is used, the tool head of which has a greater radius than a tool shank of the cutting tool.

Owner:MTU AERO ENGINES GMBH

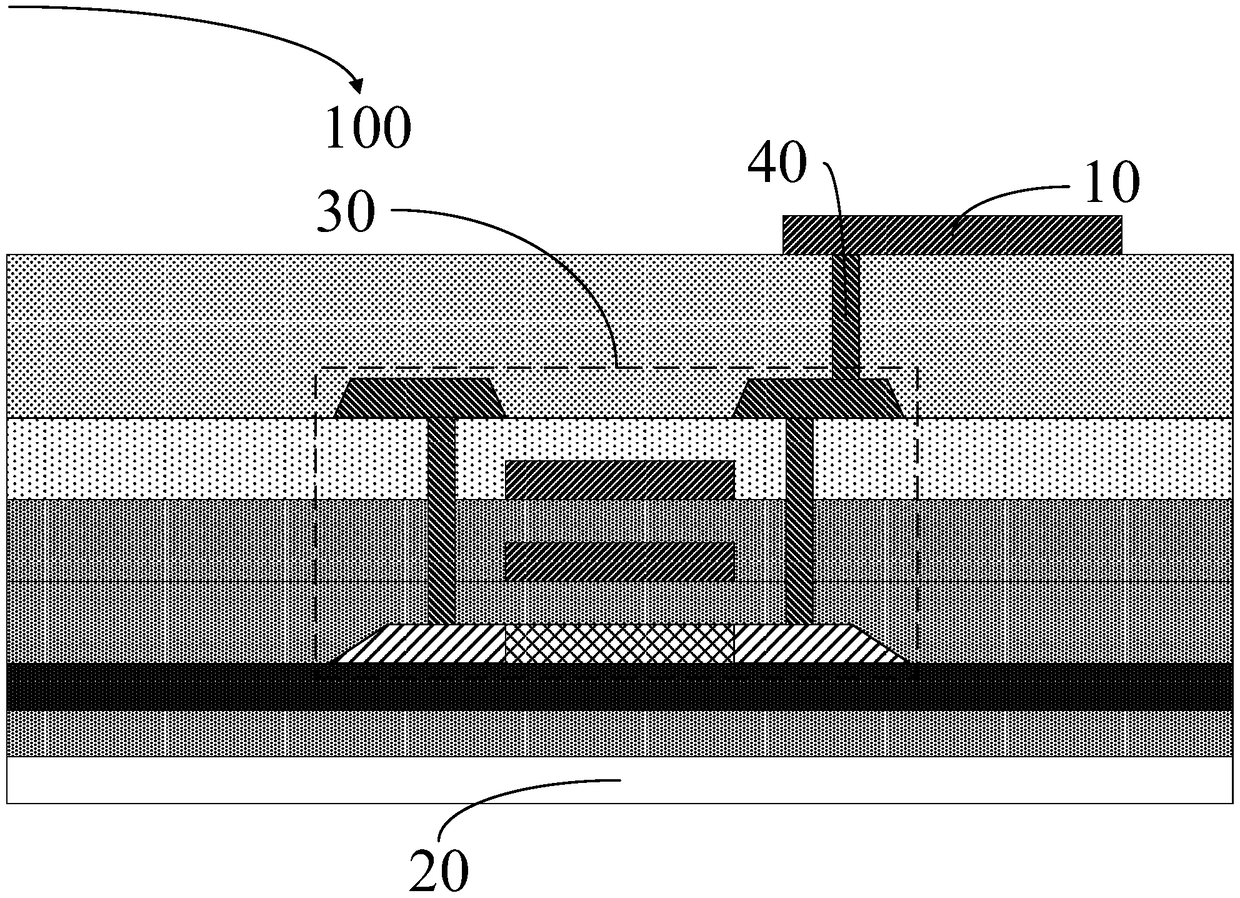

Integrated circuit layout structure and manufacturing method thereof

InactiveCN101447473AUniform growthReduce the burden onSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuit layoutEngineering

The invention relates to an integrated circuit layout structure and a manufacturing method thereof belonging to the technical field of the manufacturing process of an integrated circuit and the layout design. In order to solve the problem in the prior art that after chemical mechanical polishing, copper metal in a thin line area of the integrated circuit layout is left, the invention provides the integrated circuit layout structure and the manufacturing method thereof. By increasing the line space in the thin line area, the growth thickness of the copper in the thin line area is lowered, and copper with different structures grows evenly, thus reducing the load of chemical mechanical polishing, improving planarization capacity, avoiding heat spots in the thin line area and improving yield of products.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for hybrid seed production, flowering period coordination and field seedling preservation for millet

InactiveCN110583394AIncrease hybridization rateImprove seed productionCereal cultivationPlant genotype modificationProduction rateHybrid seed

The invention discloses a method for hybrid seed production, flowering period coordination and field seedling preservation for millet. Seedlings are cultured according to different staggered periods and different proportions of male and female parents and at suitable time in the hybrid millet seed production field, and during field planting, the seedlings are cultured at suitable time according toactual production demands. According to the method, by transplanting cultured millet seedlings, the hybrid seed production and flowering period coordination for the millet are achieved, a suitable seedling reservation density is adopted for millet planting, and the problems are solved that the flowering periods of produced hybrid millet seeds are not coordinated, the hybridization rate and the seed production rate are low, seedling emergence is difficult through direct seeding of traditional millet seeds in the field, lacking seedlings and seedlingless ridges are frequently caused, the per unit area yield of the millet in the field is seriously affected, varieties with a long growth period are planted, or the accumulated temperature of millet for multiple cropping is insufficient after preceding crops are harvested, and the planting enthusiasm of farmers is not high.

Owner:定襄县农业技术推广中心

Planting method for chromium-rich corn

InactiveCN106416689AImprove planting efficiencyGood for ventilationBiocideBio-organic fraction processingFertilizerGermination

The invention relates to the technical field of planting and discloses a planting method for chromium-rich corn. The method comprises the steps of preparing soil and fertilizing, selecting seeds, sowing corn, managing water and fertilizer and preventing and controlling diseases and pests. According to the planting method for chromium-rich corn provided by the invention, sufficient base fertilizer is applied to the soil; the fertilizer ratio is proper; the soil is covered with a soil film and is fermented; the harmful diseases and pests are killed; the germination rate of the corn is 99-100%; the seeds are subjected to bud forcing treatment; the germination period is reduced by 2-3 days; the separate planting based on density is performed; the row spacing of the close planting set is small; the row spacing between the close planting set and the close planting set is larger; the ventilation is benefited; the land utilization is saved; the corn yield is increased to 846kg / mu; the thousand seed weight of the corn is 347g; the water and fertilizer management is performed in stages; the traditional Chinese medicine insecticide is periodically applied; water and fertilizer are saved; the disease and pest ratio is 4%; 16.3% of the planting cost is saved; the compound fertilizer is rich in chromium element; the chromium content in the corn is increased to 54.87ng / 100g; the corn grade is promoted; the nutrition and healthcare function of the corn are enhanced.

Owner:任彦永

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com