Paddy rice broad-width direct seeding and simultaneous seeding fertilizing method

A rice seed, wide-width technology, applied in nitrogen fertilizers, fertilization devices, urea compound fertilizers, etc., can solve the problems of large differences in individual plant growth, high use and maintenance costs, and impact on individual growth quality, saving labor and time. The effect of improving ventilation rate and improving ventilation and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

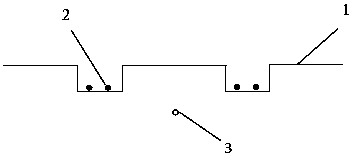

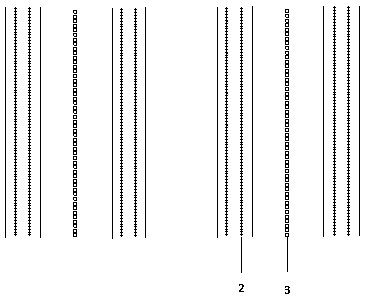

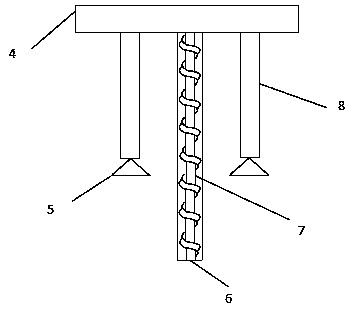

[0035]This embodiment relates to a method of live-seeding rice in wide strips and simultaneously sowing seeds and fertilizers, such as figure 1 , 2 , 3, and 4, the specific implementation steps are as follows:

[0036] In the production area where machinery is easy to cultivate, after the last stubble crop is harvested, it is sown with a special direct seeding rice seed fertilizer simulcast machine, and the rice seeds 2 and the special controlled release fertilizer for direct direct rice are applied at the same time.

[0037] Selection of improved varieties: Select excellent hybrid rice seeds with strong tillering ability and high yield that are suitable for local climate and cultivation conditions, arrange the sowing time reasonably, soak the rice seeds in advance for 2 hours until the breasts are exposed, and wait for sowing.

[0038] Soil preparation: After harvesting the last stubble crops, use a deep tiller to plow the land and then harrow it or use a rotary tiller to le...

Embodiment 2

[0044] This embodiment relates to a method of live-seeding rice in wide strips and simultaneously sowing seeds and fertilizers, such as figure 1 , 2 , 3, and 4, the specific implementation steps are as follows:

[0045] In the production area where machinery is easy to cultivate, after the last stubble crop is harvested, it is sown with a special direct seeding rice seed fertilizer simulcast machine, and the rice seeds 2 and the special controlled release fertilizer for direct direct rice are applied at the same time.

[0046] Selection of improved varieties: Select excellent japonica rice seeds with strong tillering ability and high yield that are suitable for local climate and cultivation conditions, arrange the sowing time reasonably, soak the rice seeds in advance for 2 hours until the breasts are exposed, and wait for sowing.

[0047] Soil preparation: After harvesting the last stubble crops, use a deep tiller to plow the land and then harrow it or use a rotary tiller to...

Embodiment 3

[0053] This embodiment relates to a method of live-seeding rice in wide strips and simultaneously sowing seeds and fertilizers, such as figure 1 , 2 , 3, and 4, the specific implementation steps are as follows:

[0054] In the production area where machinery is easy to cultivate, after the last stubble crop is harvested, it is sown with a special direct seeding rice seed fertilizer simulcast machine, and the rice seeds 2 and the special controlled release fertilizer for direct direct rice are applied at the same time.

[0055] Selection of improved varieties: Select excellent glutinous rice seeds with strong tillering ability and high yield that are suitable for local climate and cultivation conditions, arrange the sowing time reasonably, soak the rice seeds in advance for 2 hours until the breasts are exposed, and wait for sowing.

[0056] Soil preparation: After harvesting the last stubble crops, use a deep tiller to plow the land and then harrow it or use a rotary tiller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com