Potato seeder

A seeder and potato technology, applied in the field of agricultural machinery, can solve the problems of long seed lifting distance, large jitter of the seeding device, uneven seeding spacing, etc., and achieve the effects of low production cost, reduced labor intensity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

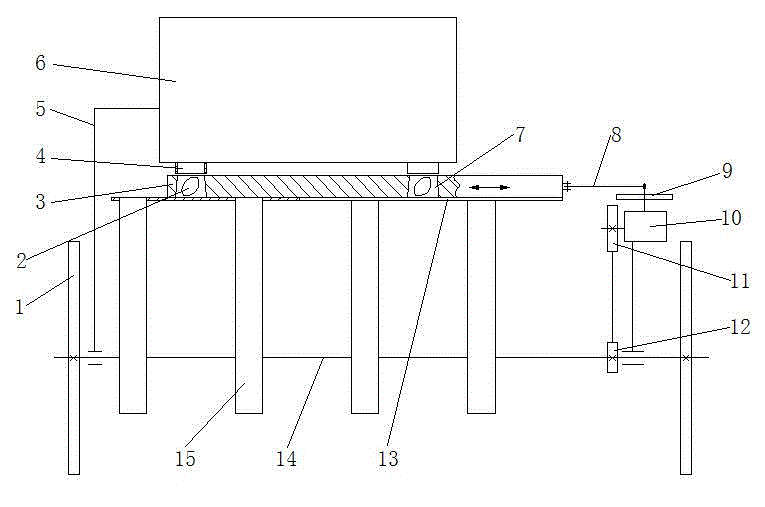

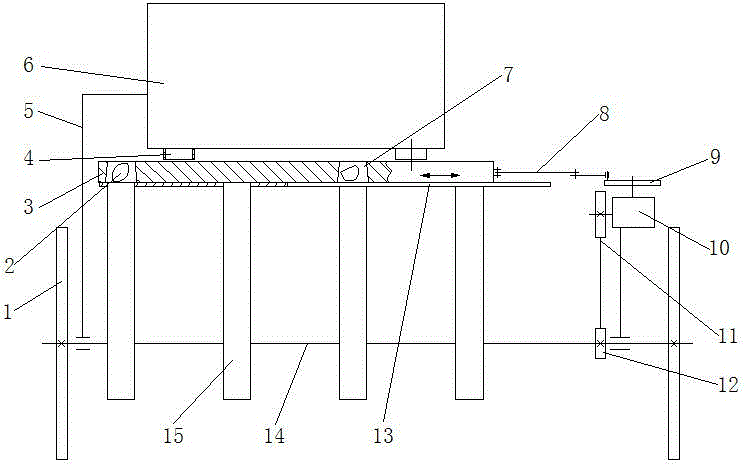

[0020] Such as figure 1 , 2 , 4, 5, and 6 show that a kind of box 6 is installed on the frame 5, and a seed drop pipe 4 is installed on the lower end face. The road wheel 1 is fixedly installed at the end, and the main sprocket wheel 12 is installed on the road wheel fixed shaft.

[0021] A reduction box 10 is installed on the right side of the frame. In order to change the horizontal rotation into a vertical rotation, the reduction box adopts a bevel gear reducer or a worm gear reducer, and a sprocket 11 is installed on the input shaft in the reducer. The main sprocket and The sprockets are connected by a chain. An eccentric wheel 9 is installed on the output shaft in the reducer, the left end of the connecting rod 8 is hinged with the seed plate 3, and the right end of the connecting rod is hinged with the eccentric wheel, and the seed hole 7 is arranged on the seed plate.

[0022] On the frame of the seed pipe lower end, a fixed plate 13 is installed, and the seed pipe 1...

Embodiment 2

[0027] On the basis of Embodiment 1, the device is installed on a tractor, and the reduction box 10 is driven to rotate through the tractor's power output end and transmission chain, thereby realizing the cycle of taking seeds and sowing. That is to remove the fixed shaft of the road wheel, the main sprocket, and the road wheel, directly install the driving sprocket at the power output end of the tractor, and drive the eccentric wheel to rotate through the chain and the sprocket installed on the input shaft of the reduction box to realize the above-mentioned seed picking, Sowing cycle process.

Embodiment 3

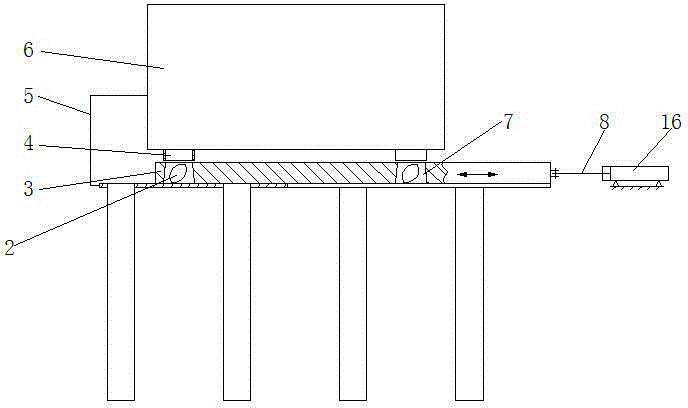

[0029] On the basis of embodiment 1 or 2, change the device that drives the seed-taking plate to move left and right into oil cylinder or cylinder 16, utilize the high-pressure oil on the tractor or the piston rod in the gas cylinder to promote oil cylinder or cylinder to move left and right. In order to realize the above-mentioned working process of left and right movement, an electromagnetic control valve is installed on the pipeline connecting the tractor with the oil cylinder or the two inlets of the cylinder. The electromagnetic control valve is connected with the electrical control device, and the left and right movement speed of the piston rod is controlled by the electrical control device. Realize the left and right movement of the seed picking plate, and complete the cycle process of seed picking and sowing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com