Integrated circuit layout structure and manufacturing method thereof

A technology of integrated circuit and layout structure, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve problems such as copper metal residues, achieve the effects of improving yield, avoiding hot spots, and increasing line spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

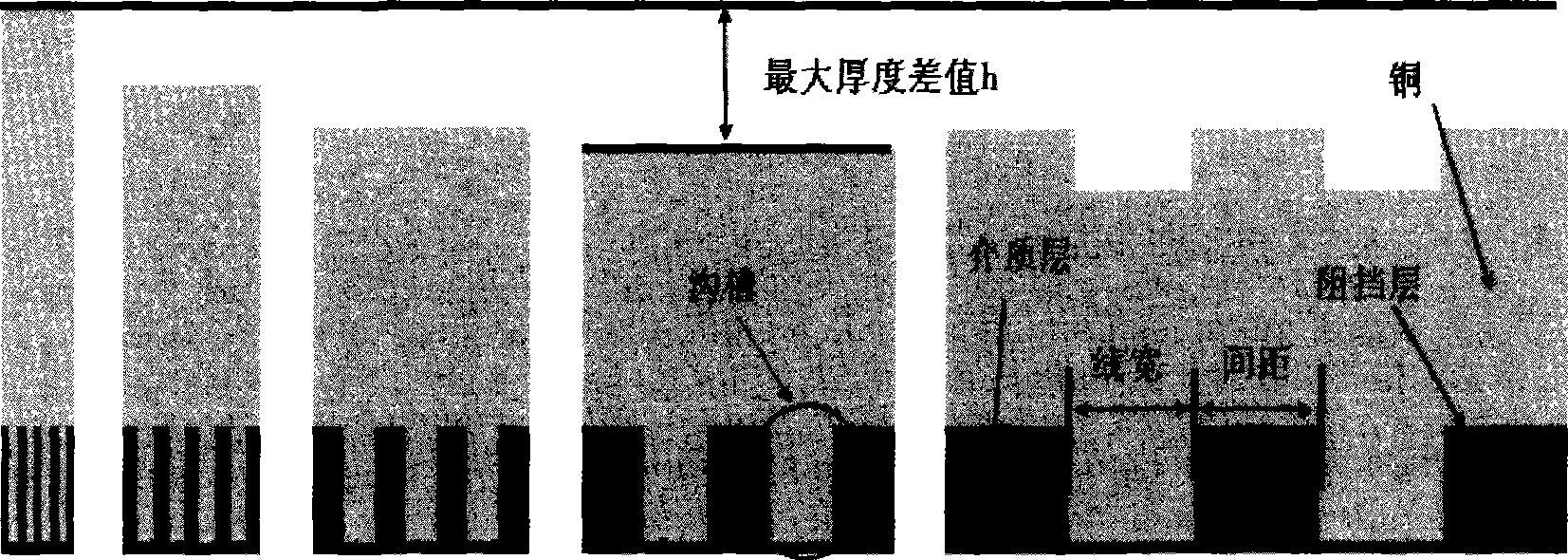

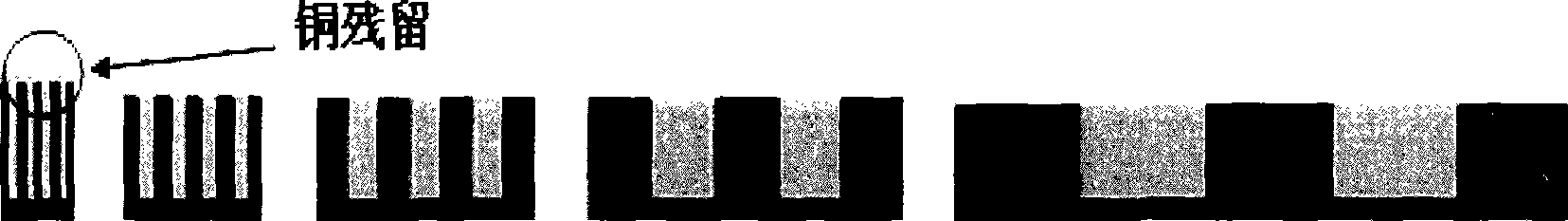

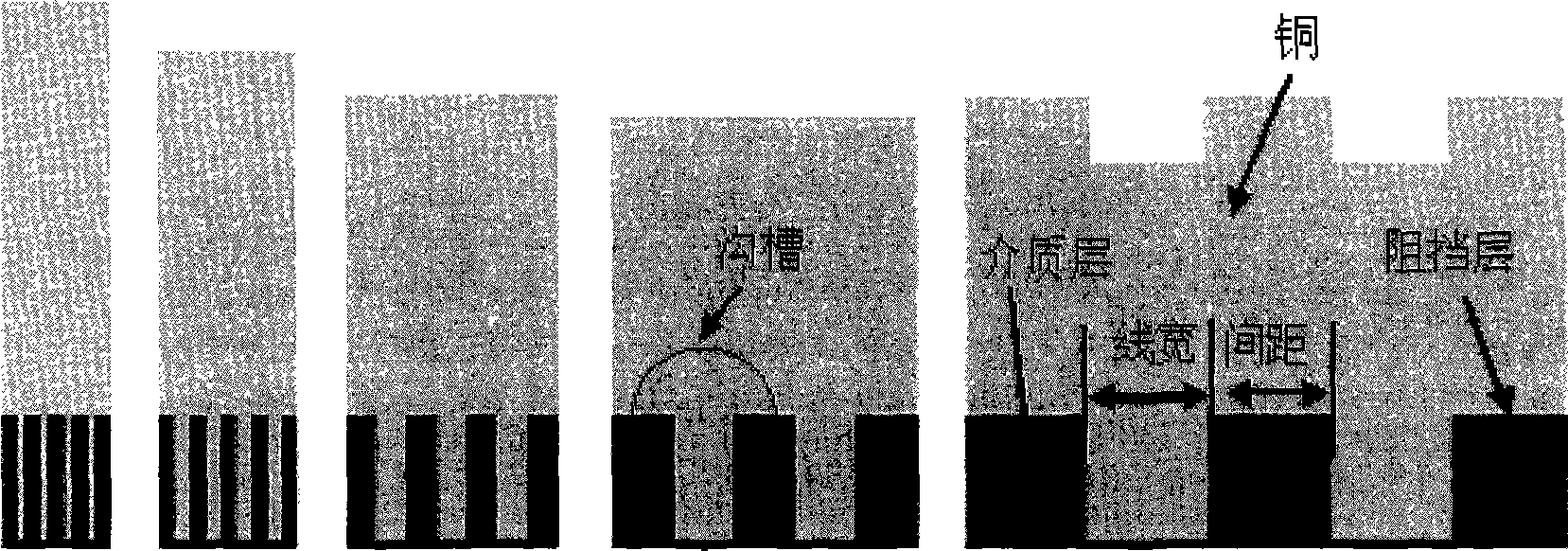

[0017] see image 3 , the present invention is a layout structure of an integrated circuit, the width of the copper wire in the thin line area is less than 0.2 microns, the line spacing in the thin line area is twice the width of the copper wire, and the area of the copper wire is 30% of the total area of the layout, This structure reduces the copper growth thickness in the thin line area, and the copper growth of different structures is relatively uniform, which reduces the surface fluctuation before the CMP process, reduces the burden of the CMP process, improves the chemical mechanical polishing ability, and will obtain the optimal planarization effect.

[0018] A manufacturing method of an integrated circuit layout, under the condition that the total area of the layout is allowed, during the layout and wiri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com