Patents

Literature

122results about How to "Adapt to processing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

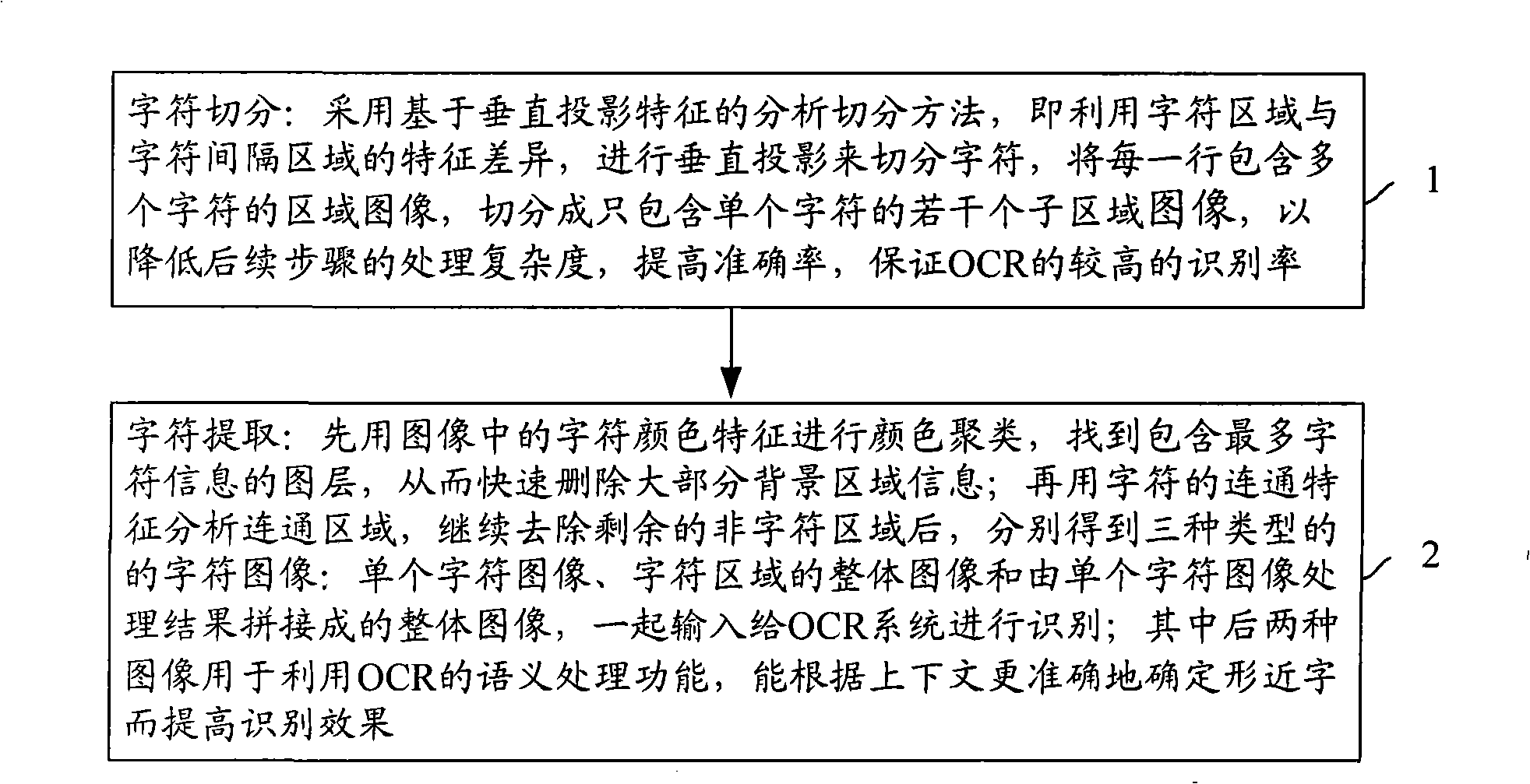

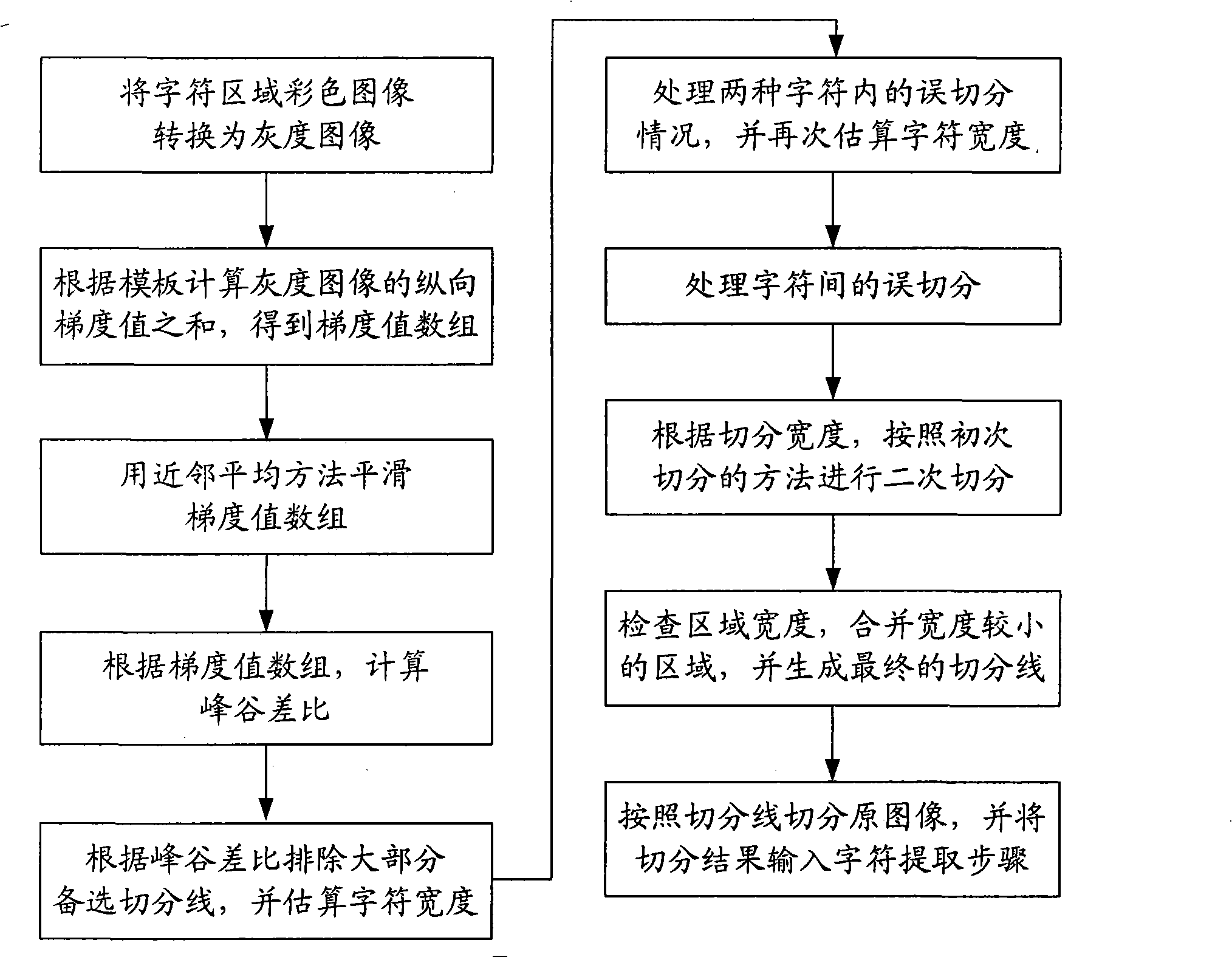

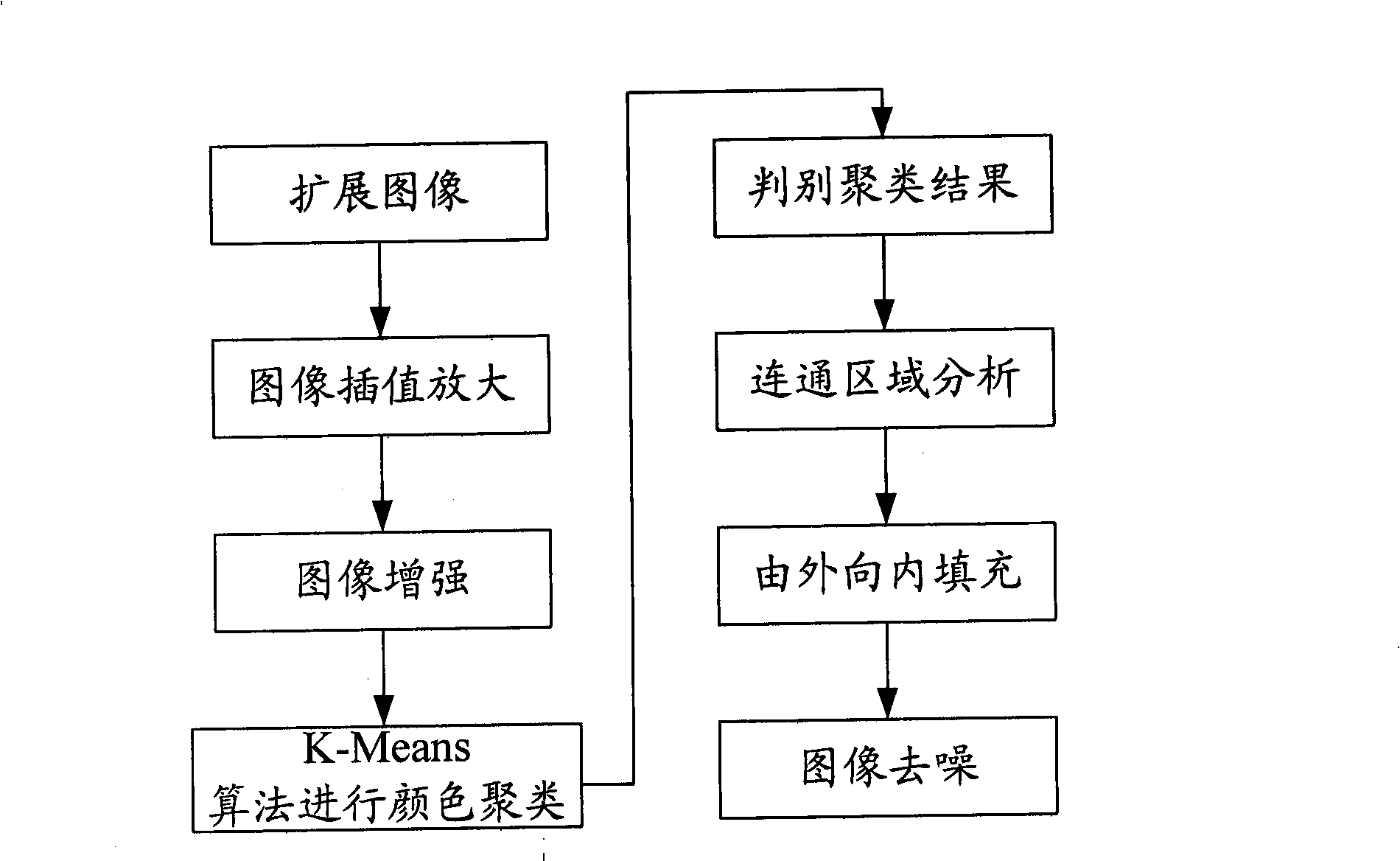

Character extracting method in digital video based on character segmentation and color cluster

InactiveCN101515325AImprove recognition rateReduce processing complexityCharacter and pattern recognitionVertical projectionDigital video

The invention relates to a character extracting method in a digital video based on character segmentation and color cluster, which comprises the following steps: (1) character segmentation: utilizing the characteristic differences of a character area and a character interval area to carry out vertical projection to segment images in the character area, namely, segmenting each row of area image containing a plurality of characters into a plurality of subarea images only containing a single character so as to reduce the post operating and treating difficulties and improve the identifying accuracy rate of OCR; and (2) character extraction: firstly, using the character color characteristic in the image to cluster colors, finding out an image layer containing maximum character information as a target image layer, and deleting the background area; and then, using the communicating characteristics of the characters to analyze a communicating area of the target image layer, and removing non-character areas to obtain such three results as single character images, an integral image of the character area and an integral image spliced by the single character images respectively, wherein all the three results are input to an OCR system to be identified, and the latter two results use the semantic processing function of the OCR and can accurately determine the characters with similar forms according to the context to improve the identifying effect.

Owner:BEIJING UNIV OF POSTS & TELECOMM

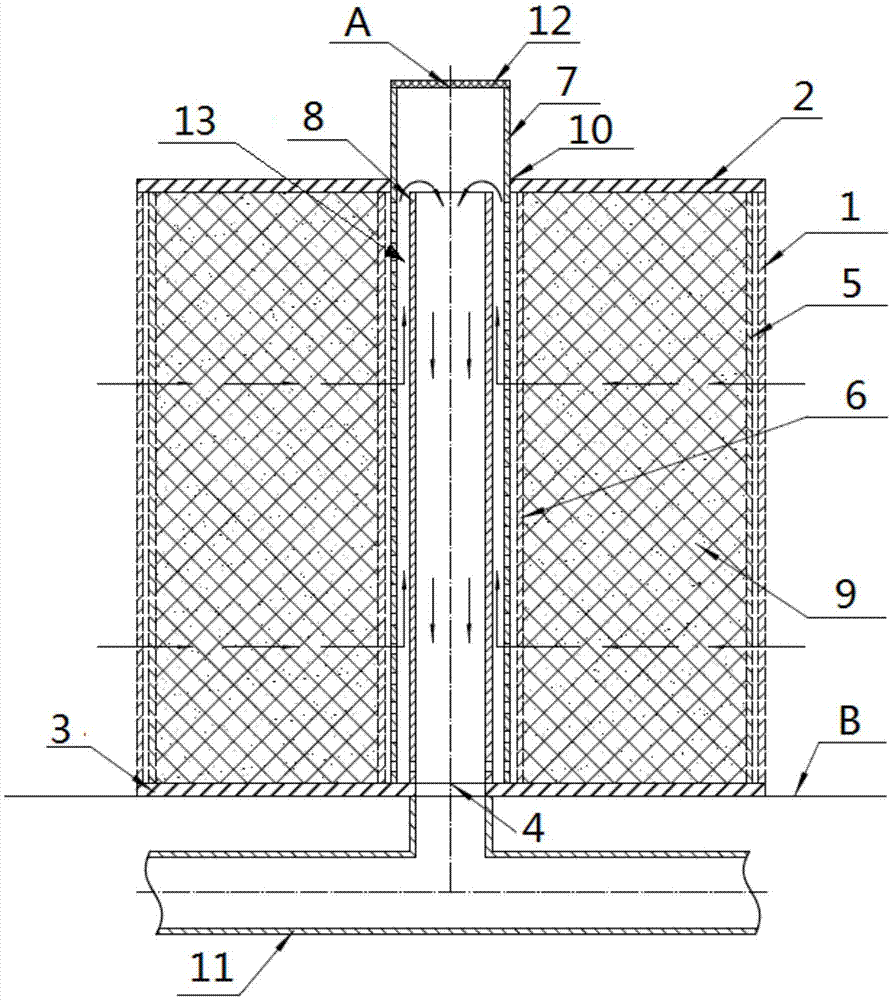

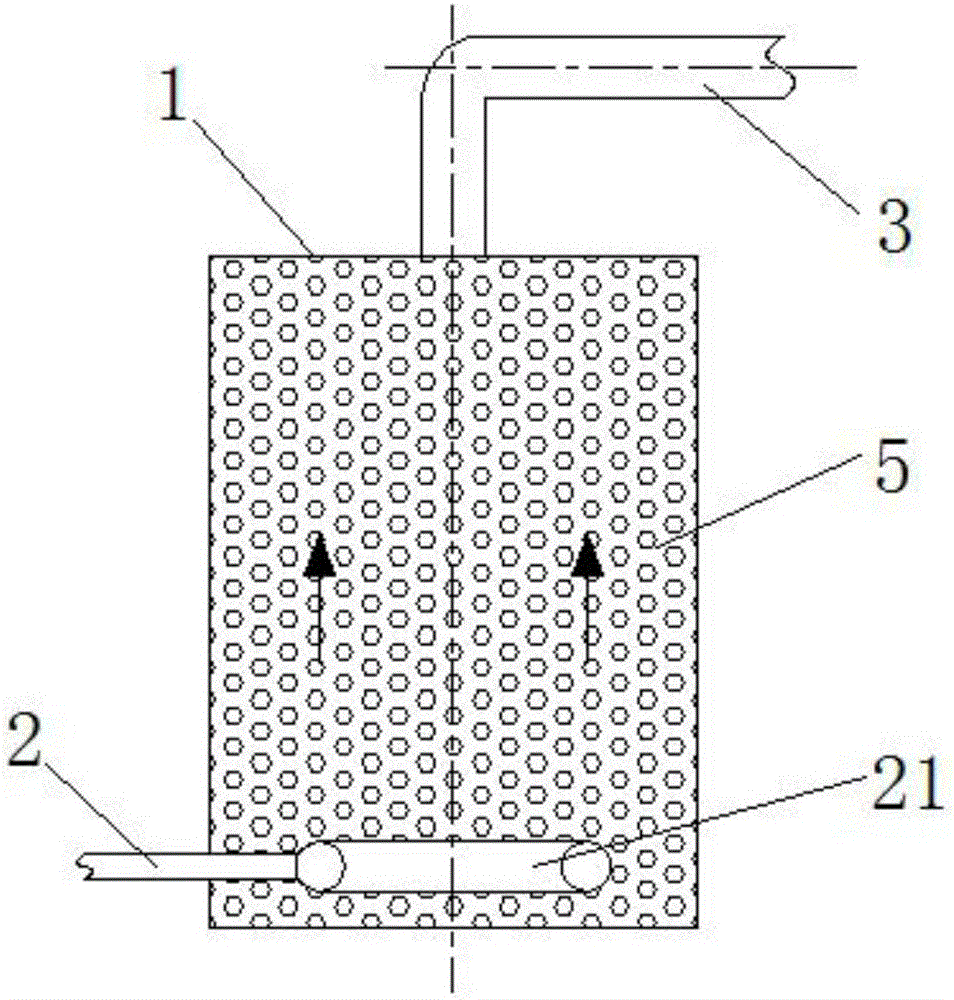

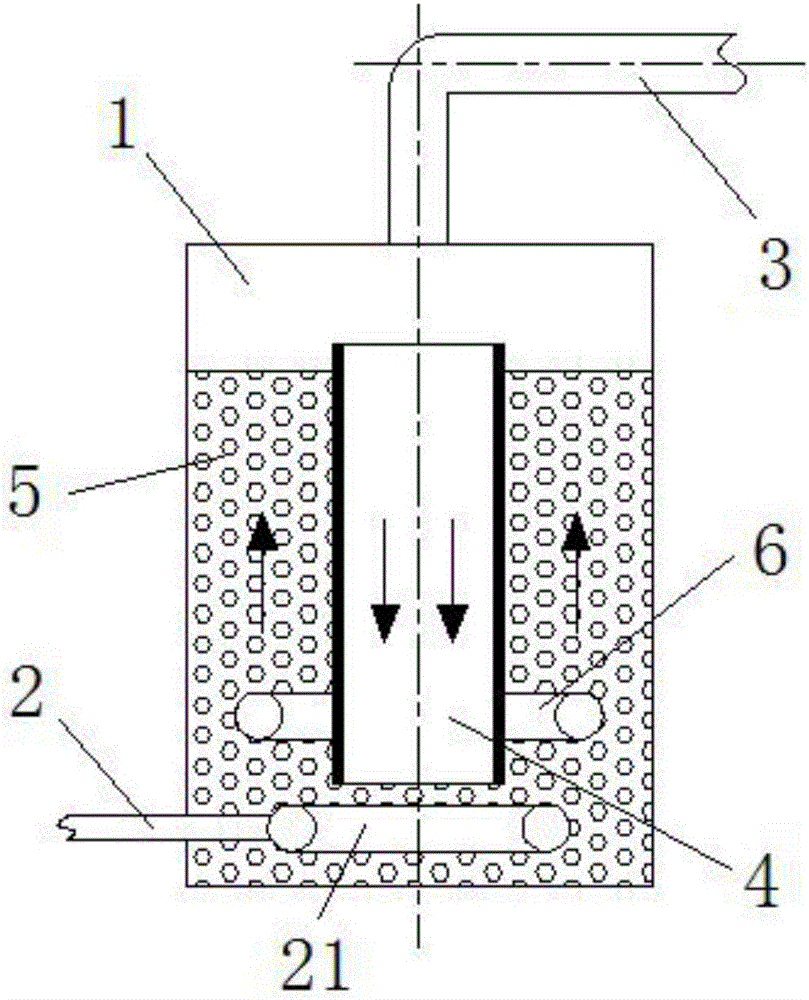

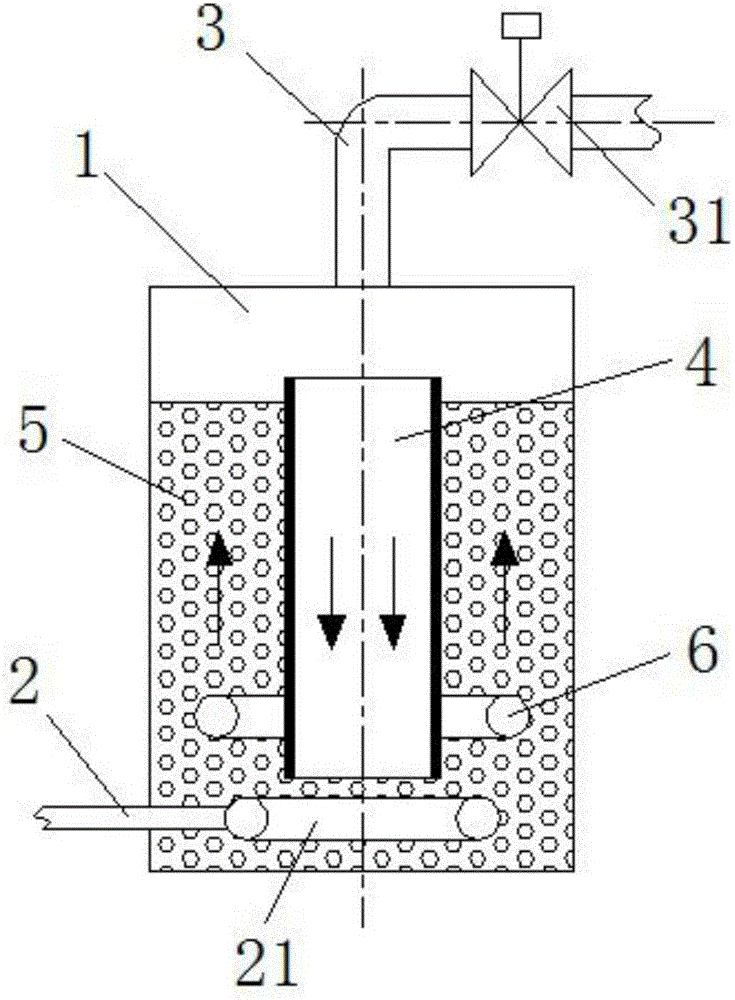

Efficient rainwater filter

ActiveCN105435495AGuaranteed utilizationGuaranteed processing efficiencyMembrane filtersLoose filtering material filtersFilter mediaEngineering

The invention discloses an efficient rainwater filter and belongs to the technical field of rainwater treatment devices. The efficient rainwater filter comprises a filter communicated with a drain pipe, a collecting pipe with a water hole is coaxially arranged in the filter, and a central cylinder is coaxially arranged in the collecting pipe. The central cylinder is provided with an overflow hole, the bottom end of the central cylinder is communicated with the drain pipe, and a rainwater retention channel is formed between the collecting pipe and the central cylinder. Rainwater accumulated in the rainwater retention channel is discharged through the overflow hole in the central cylinder. The efficient rainwater filter is simple in structure and convenient to manufacture and use; in the whole filtering process, not only is full contact between the rainwater and a filtering medium guaranteed, but also pollutants in the rainwater can be effectively removed, and the filtering medium utilization rate and the treatment efficiency of the filter are also guaranteed.

Owner:WUHAN MEIHUA YUSHUI ENVIRONMENT CO LTD

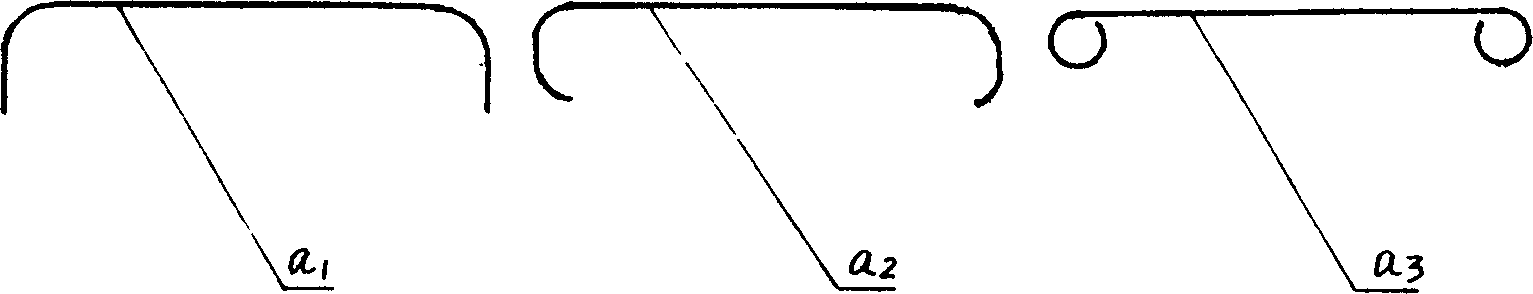

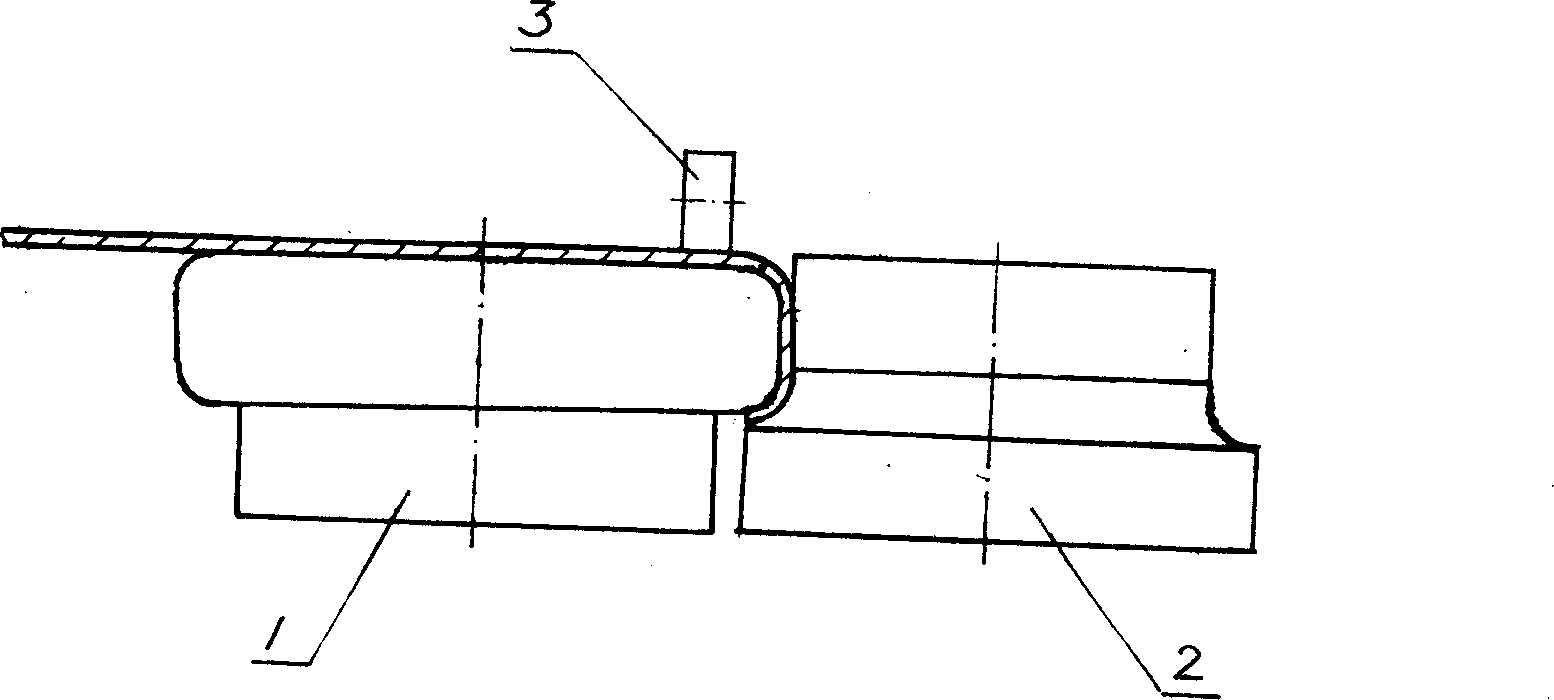

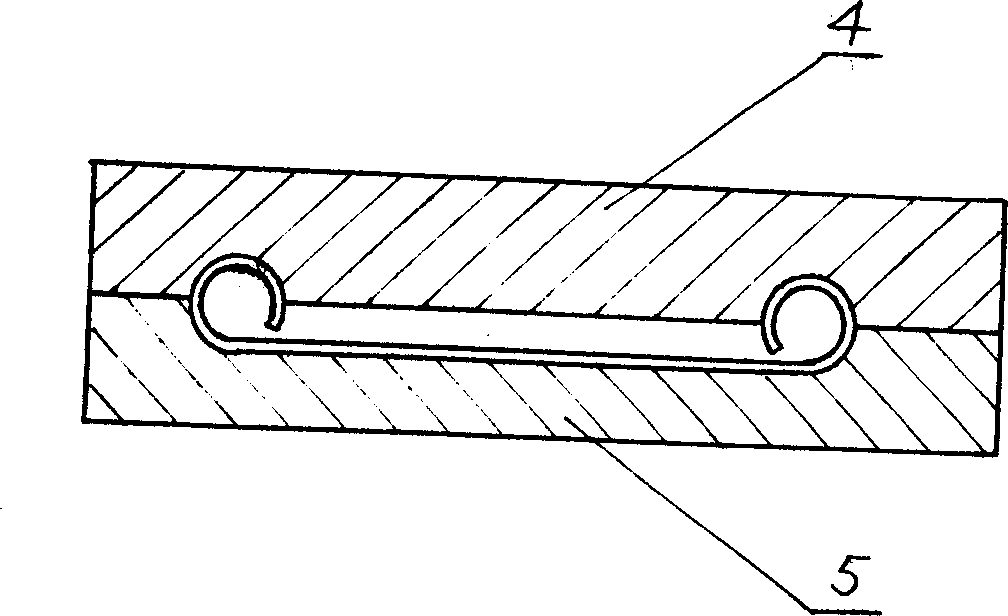

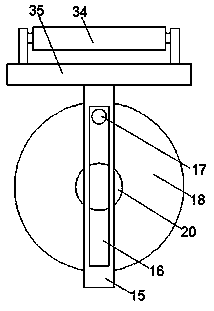

I-Wheel curling formation process

The I-wheel curling formation process includes three steps of bending, rolling and shaping to form right-angled, arced or tubular hems in the edges of circular steel plate. The rolling step is completed with special rolling mold with transmission mechanism , the rolling mold includes inner driving wheel and radially feeding inner driven wheel, and the vertical pressure and the horizontal pressure of the workpiece applied on the driving wheel are provided by the hydraulic oil cylinder. Compared with available welding and extruding formation process, the technological process of the present invention has significant progress.

Owner:卢惠林

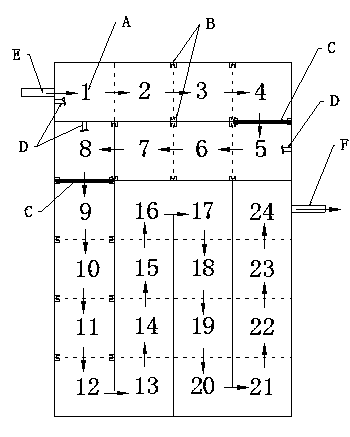

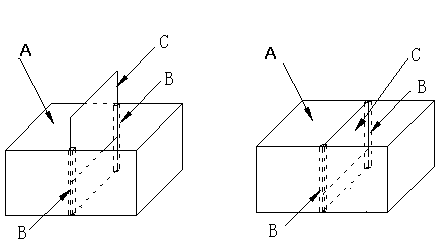

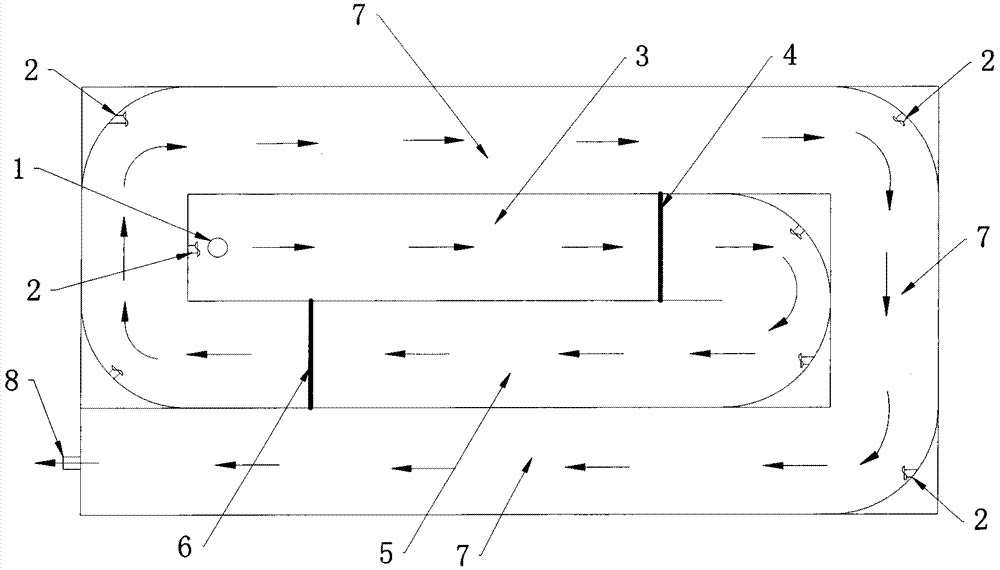

Sub-grid adjustable anaerobic-anoxic-aerobic biochemical reactor

InactiveCN103408143AReasonable designCompact structureTreatment with aerobic and anaerobic processesBiochemical engineeringWater quality

The invention discloses a sub-grid adjustable anaerobic-anoxic-aerobic biochemical reactor which is in the form of a covered way and comprises 24 sub-grid tanks (A), wherein the 24 sub-grid tanks (A) are divided into an anaerobic segment, an anoxic segment and an aerobic segment; a trough (B) is formed between every two sub-grid tanks from the first sub-grid tank (A) to the twelfth sub-grid tank (A); division plates (C) are inserted into the troughs (B) to realize the segmentation of the anaerobic segment, the anoxic segment and the aerobic segment; a water passing orifice is formed in the lower part of each trough (B); and an aerator is arranged at the lower part of each sub-grid tank (A) of the reactor. The biochemical reactor is reasonable in design and compact in structure, the relative residence time of the anaerobic segment, the anoxic segment and the aerobic segment can be flexibly adjusted according to the water quality condition of waste water to be treated, and when different waste water is treated or the water quality of the waste water to be treated is changed, the anaerobic segment, the anoxic segment and the aerobic segment can perform efficient biochemical treatment, so that the reactor can obtain an overall stable and efficient treatment effect and has good environmental and economic benefits.

Owner:YANCHENG INST OF TECH

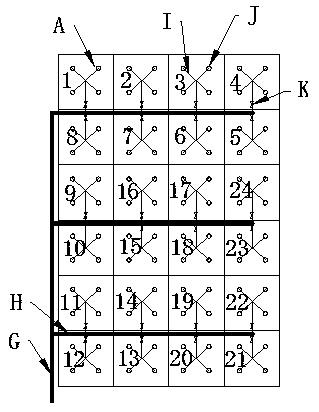

Bamboo fiber yarns and production method thereof

InactiveCN101967710AReduce tensionDecreased elastic strengthFibre mixingYarnEnvironmental resistanceYarn

The invention discloses bamboo fiber yarns and a production method thereof. The bamboo fiber yarns are prepared by spinning the following blended raw materials in part by weight: more than 5 and less than or equal to 95 parts of bamboo fibers (preferably 20 to 40 parts) and 60 to 80 parts of natural fibers (such as cotton) or environmentally-friendly differential fibers. The production method comprises the following steps of: blending slivers made of the bamboo fibers and the natural fibers (such as the cotton) or the environmentally-friendly differential fibers again; and drawing, roving, spinning and spooling for 2 to 3 times to prepare various blended bamboo fiber yarns with low bamboo fiber content, which have naturally antibacterial, bacteriostatic, anti-ultraviolet, hygroscopic, air-permeable characteristics and the like. A plurality of superfine grooves on the surfaces of the bamboo fibers contributes to the improvement on moisture absorption, so that the yarns have the function of dehumidifying. The production method has the advantages of uniqueness, effectiveness, easily controllable manufacturing process, basically no need of equipment replacement, low manufacturing cost and high production efficiency.

Owner:FUJIAN KARTEX TEXTILE

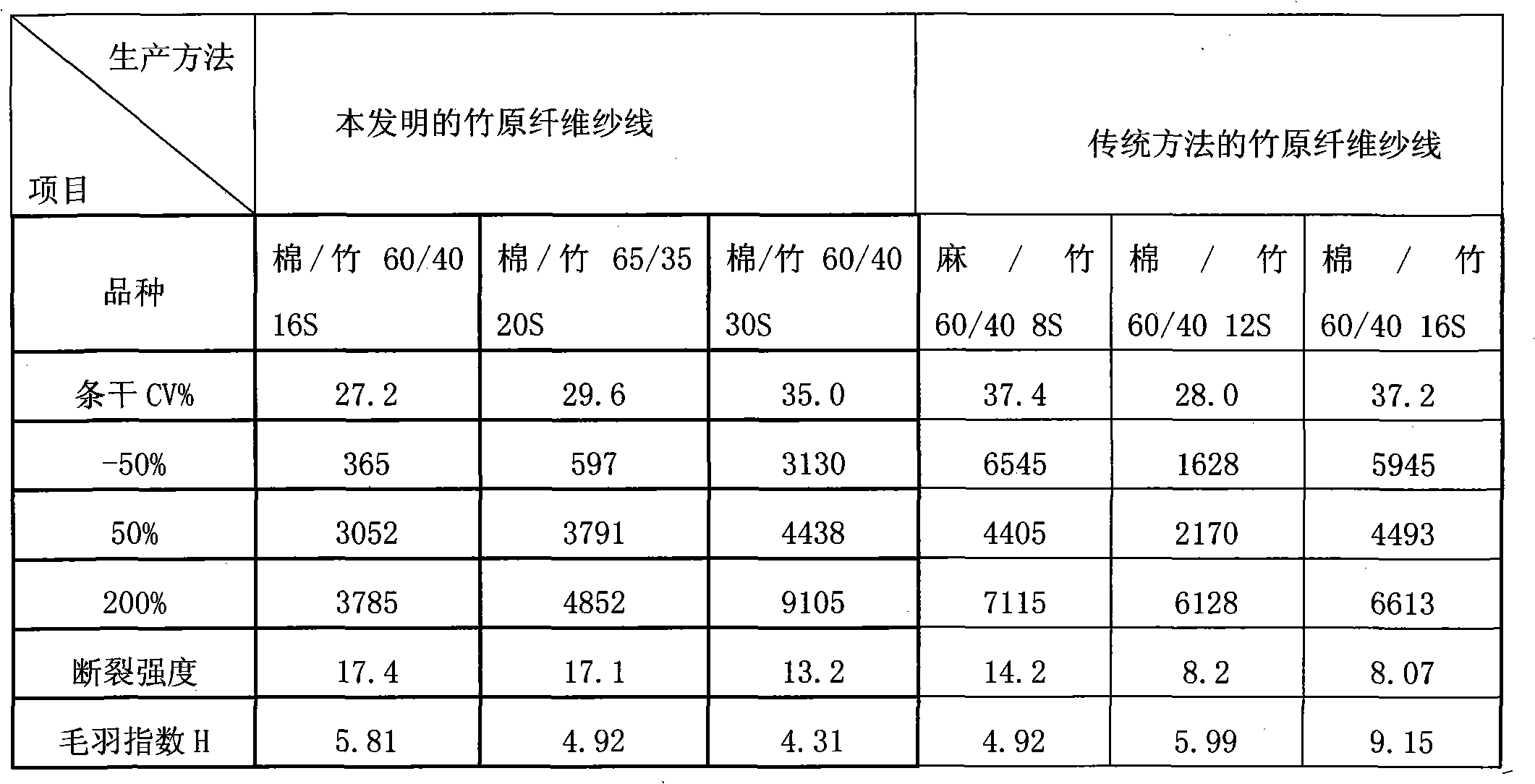

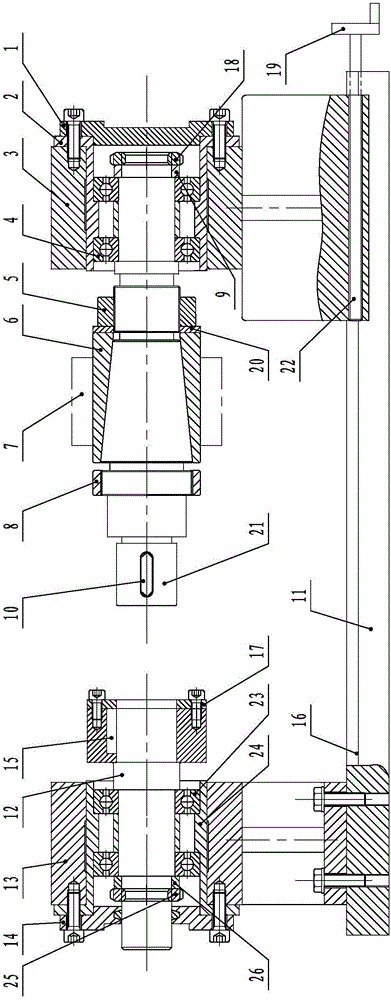

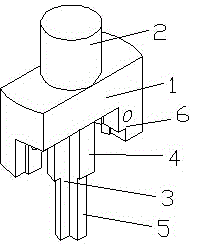

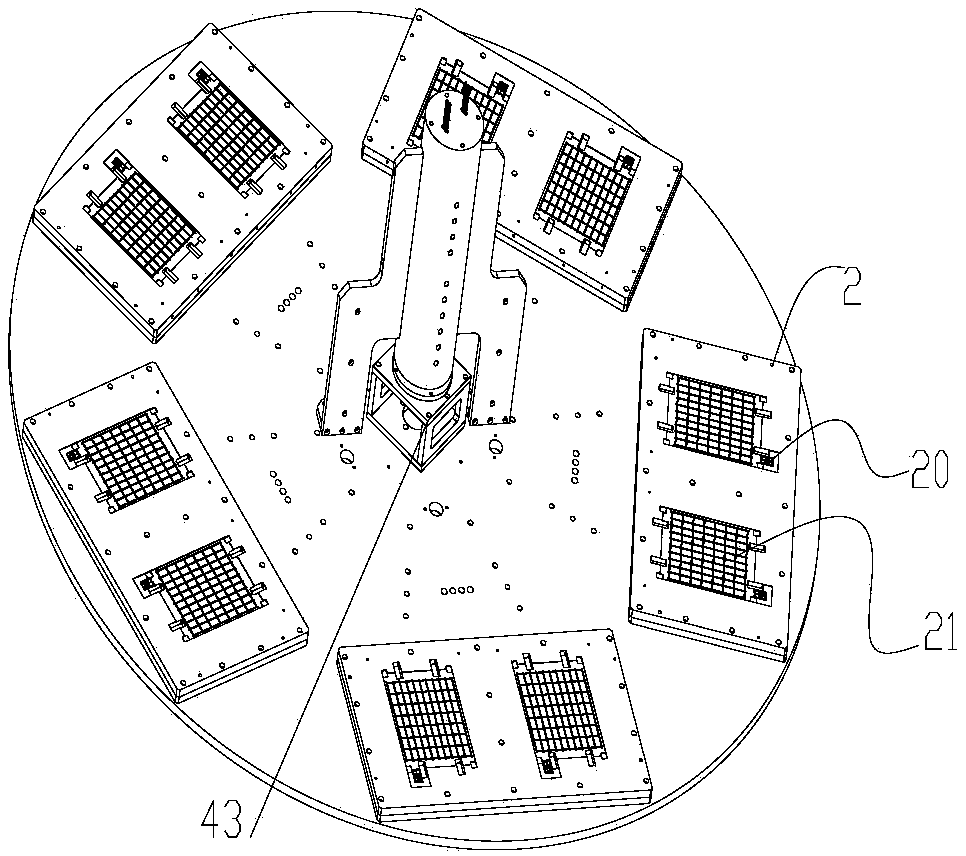

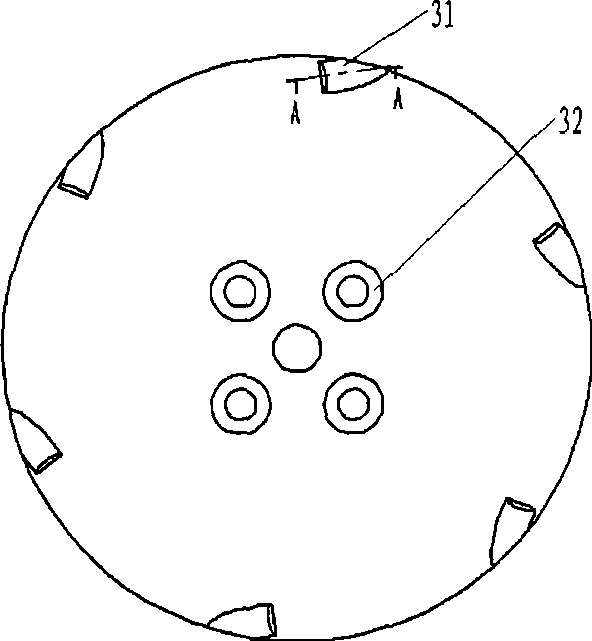

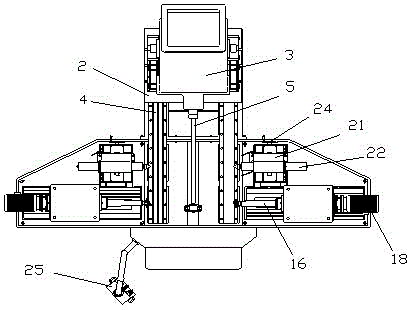

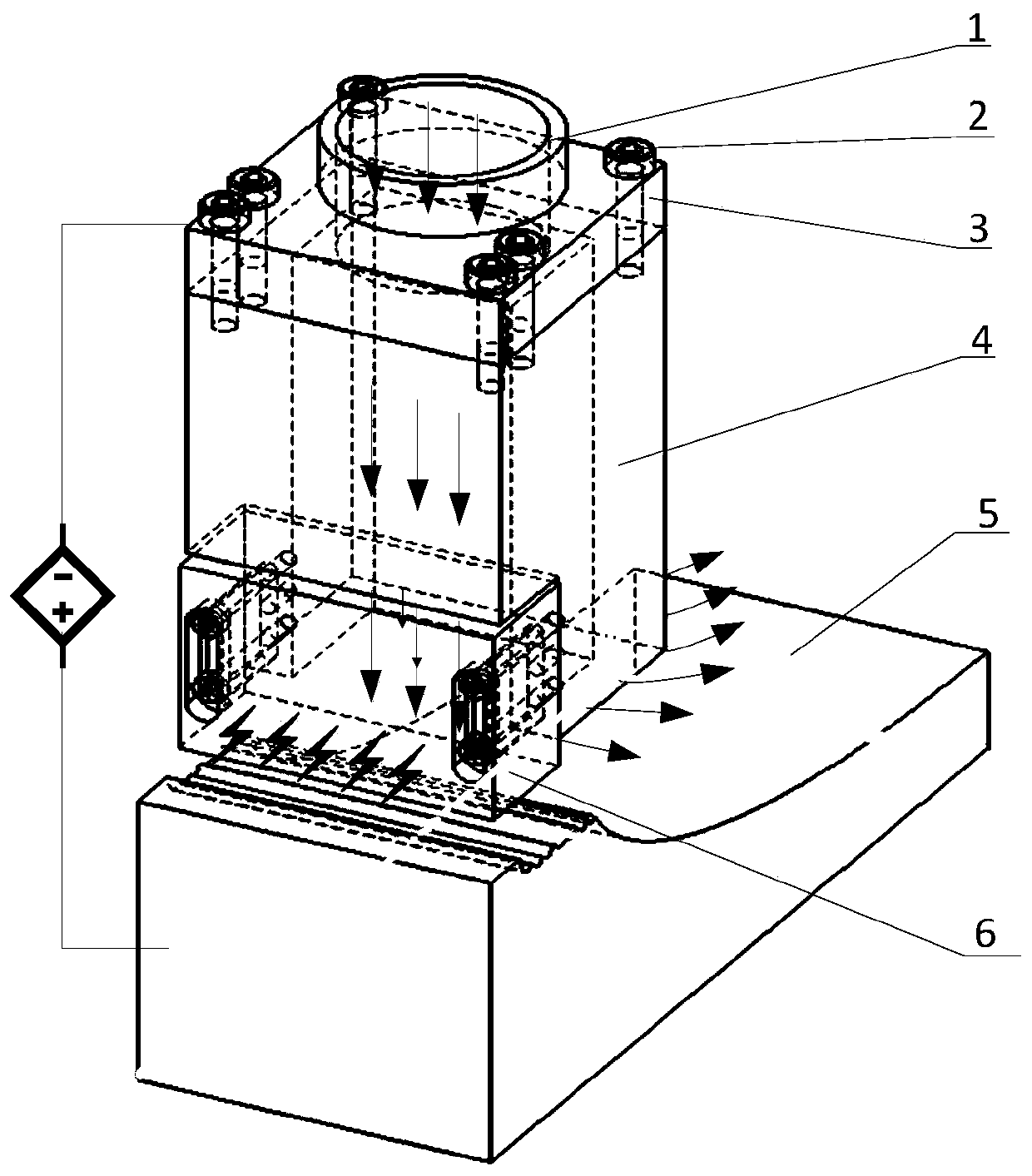

Integral impeller multi-channel electrolytic machining device

InactiveCN106342003BImprove processing efficiencyShorten the manufacturing cycleElectrochemical machining apparatusImpellerElectrolysis

A multi-channel electrolytic machining device for an integral impeller belongs to the technical field of electrolytic machining. It includes a machine tool body, a power supply system, and an electrolyte system. The machine tool has a Z-axis. It is characterized in that: (1), the device also has a machine tool that is installed on the Z-axis of the machine tool and can be fed in the Z-direction of the Z-axis of the machine tool, and the disk surface is vertical. The cathode clamping disc on the Z axis of the machine tool; (2), a plurality of cathodes are installed on the above-mentioned cathode clamping disc through an adjustment device for adjusting the distance between the cathodes and the center distance between the cathode and the impeller, and can be moved along with the clamping disc Z-direction feed; (3), the device is also provided with a device to make the above-mentioned multiple cathodes rotate around their own rotation axis at the same time. The device has the characteristics of low cost, high efficiency and strong versatility.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

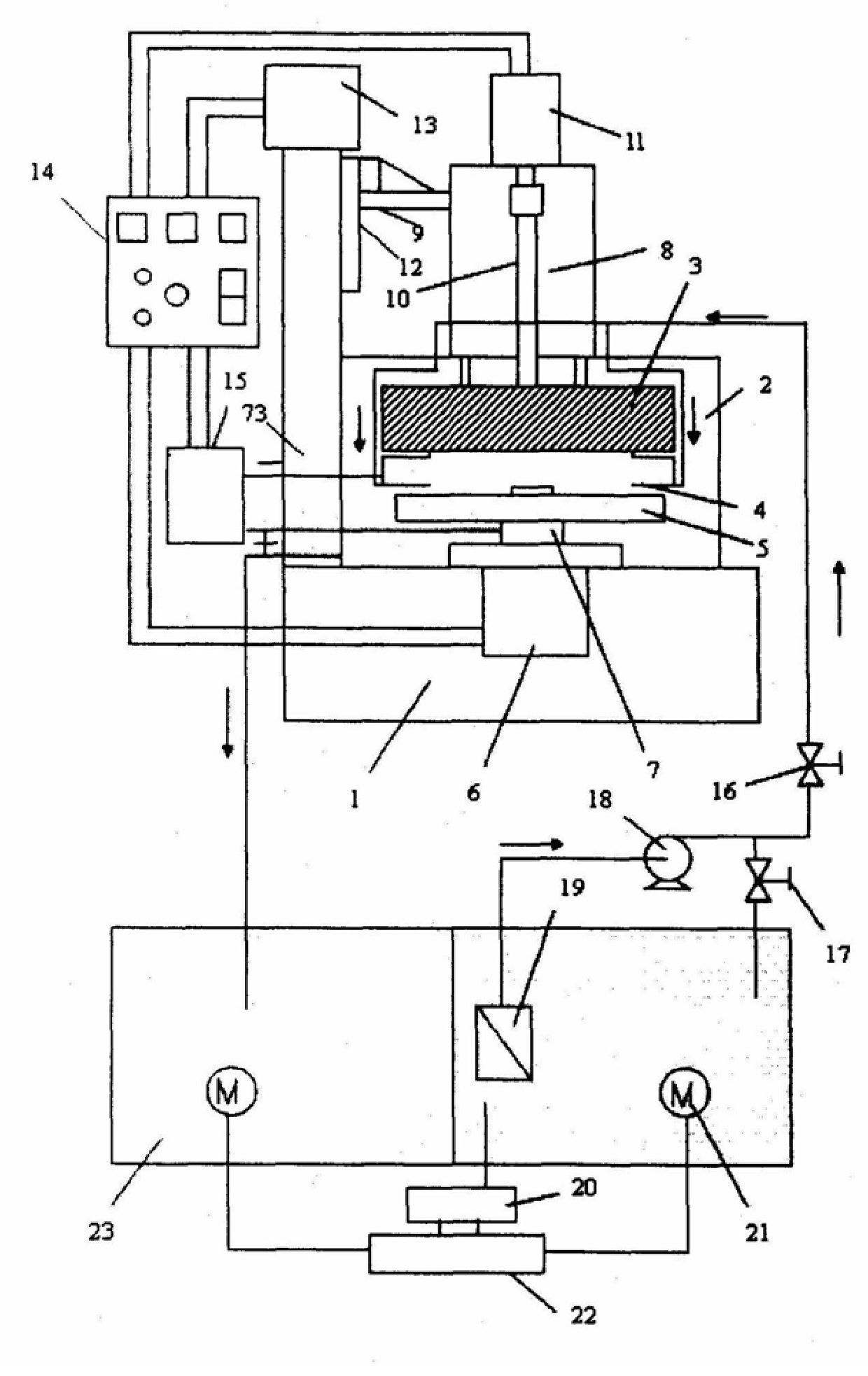

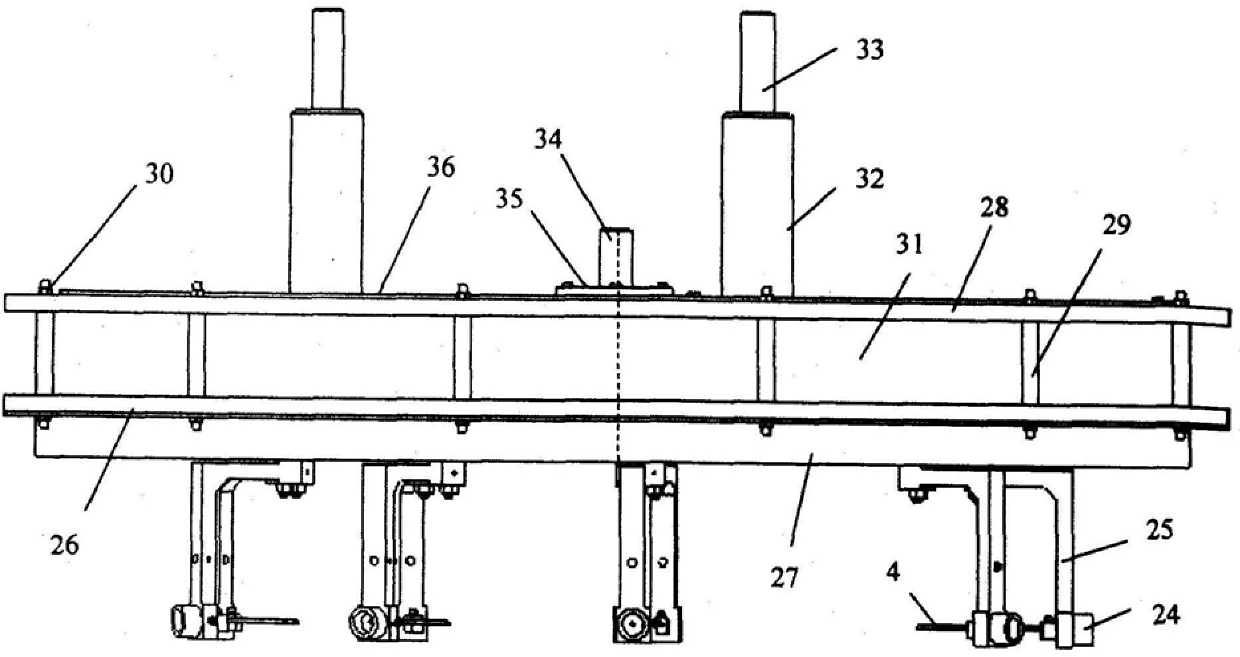

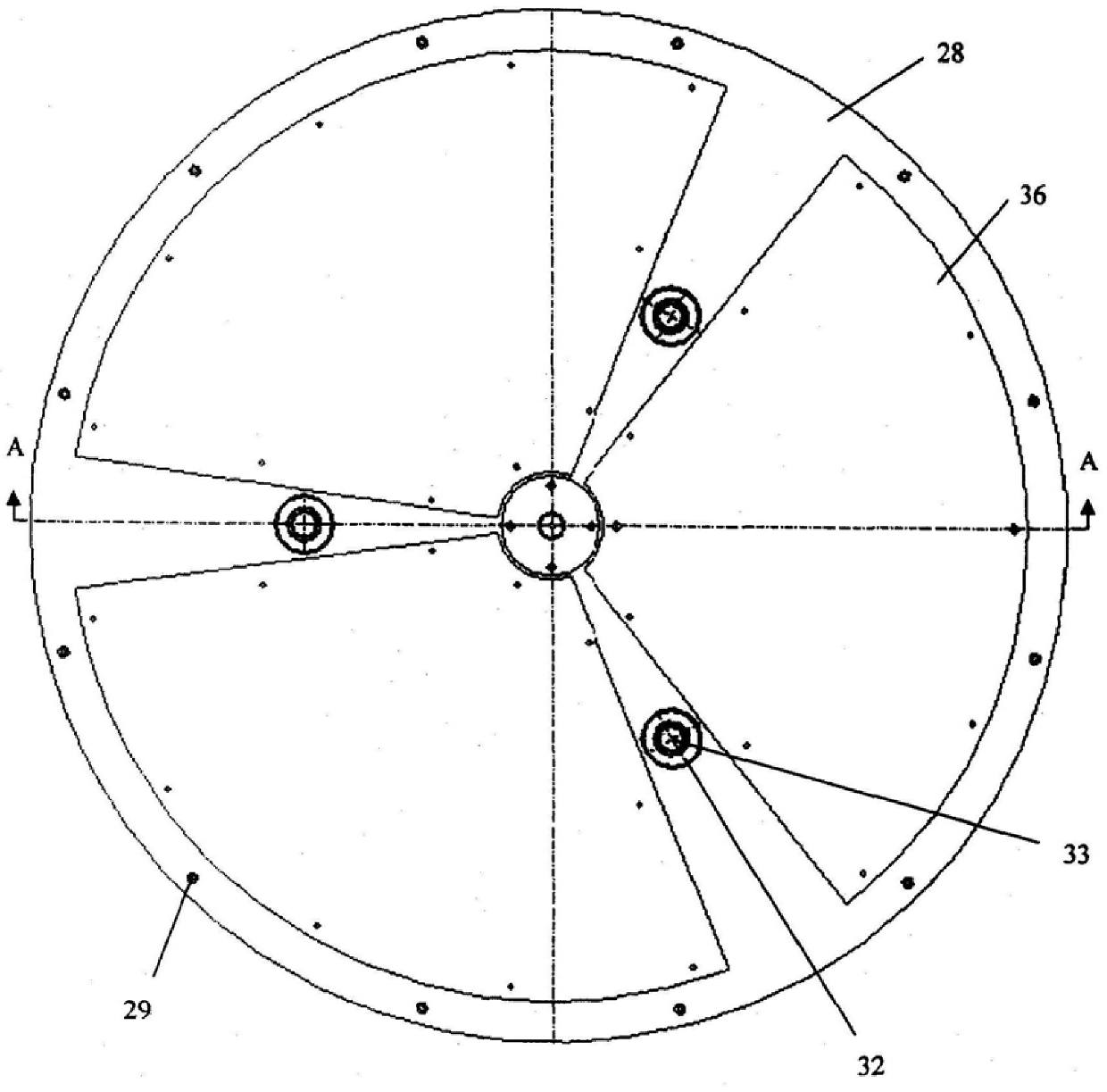

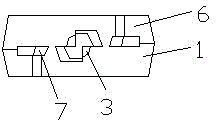

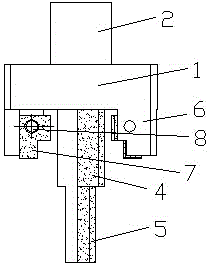

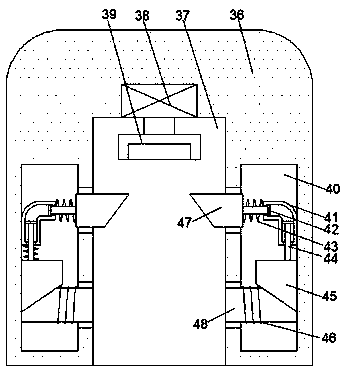

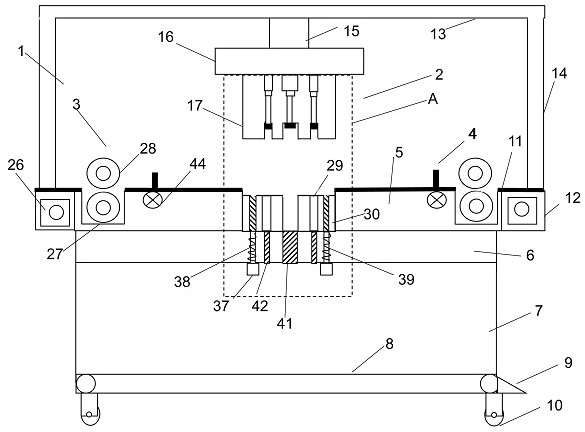

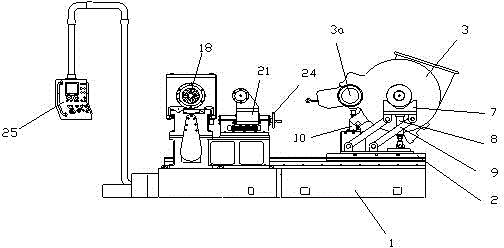

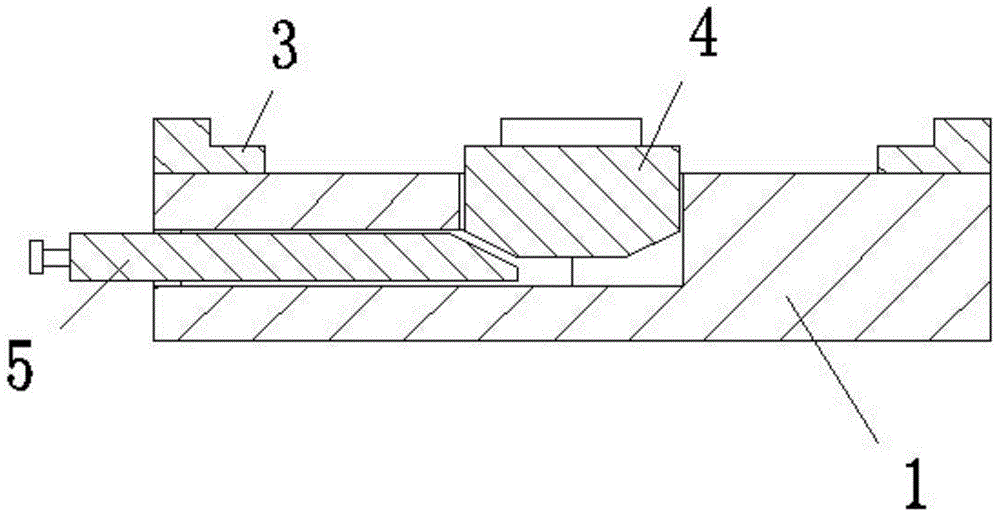

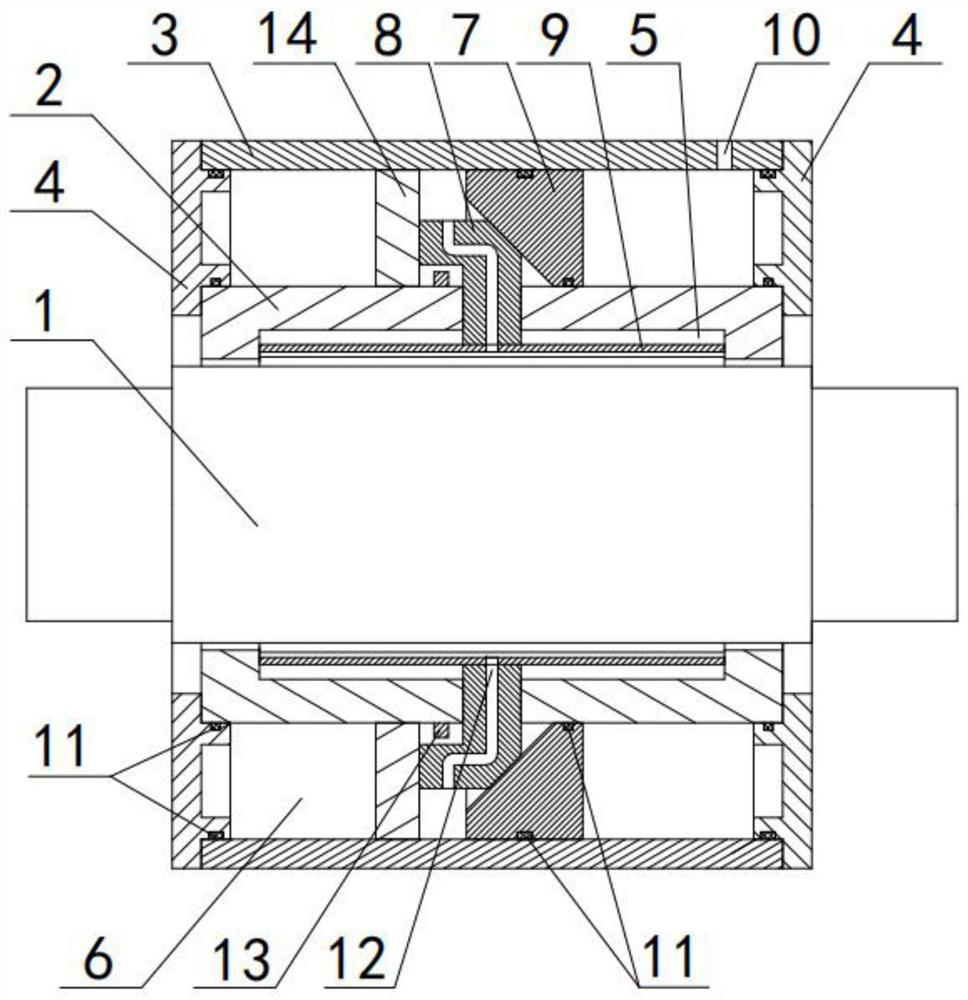

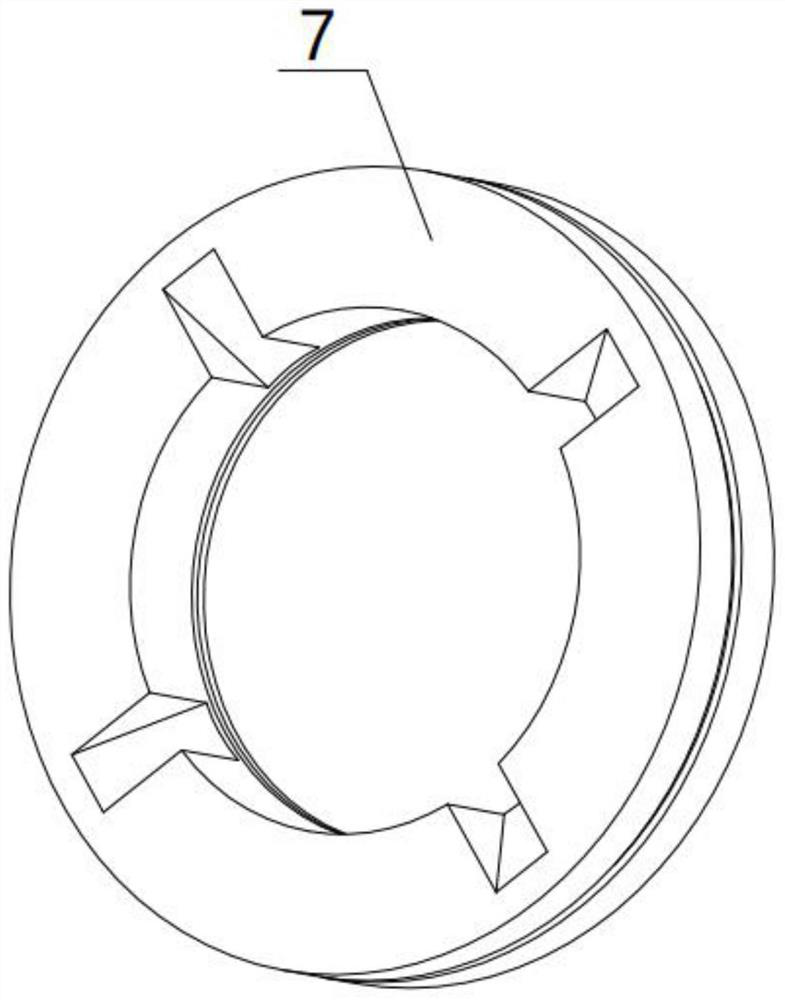

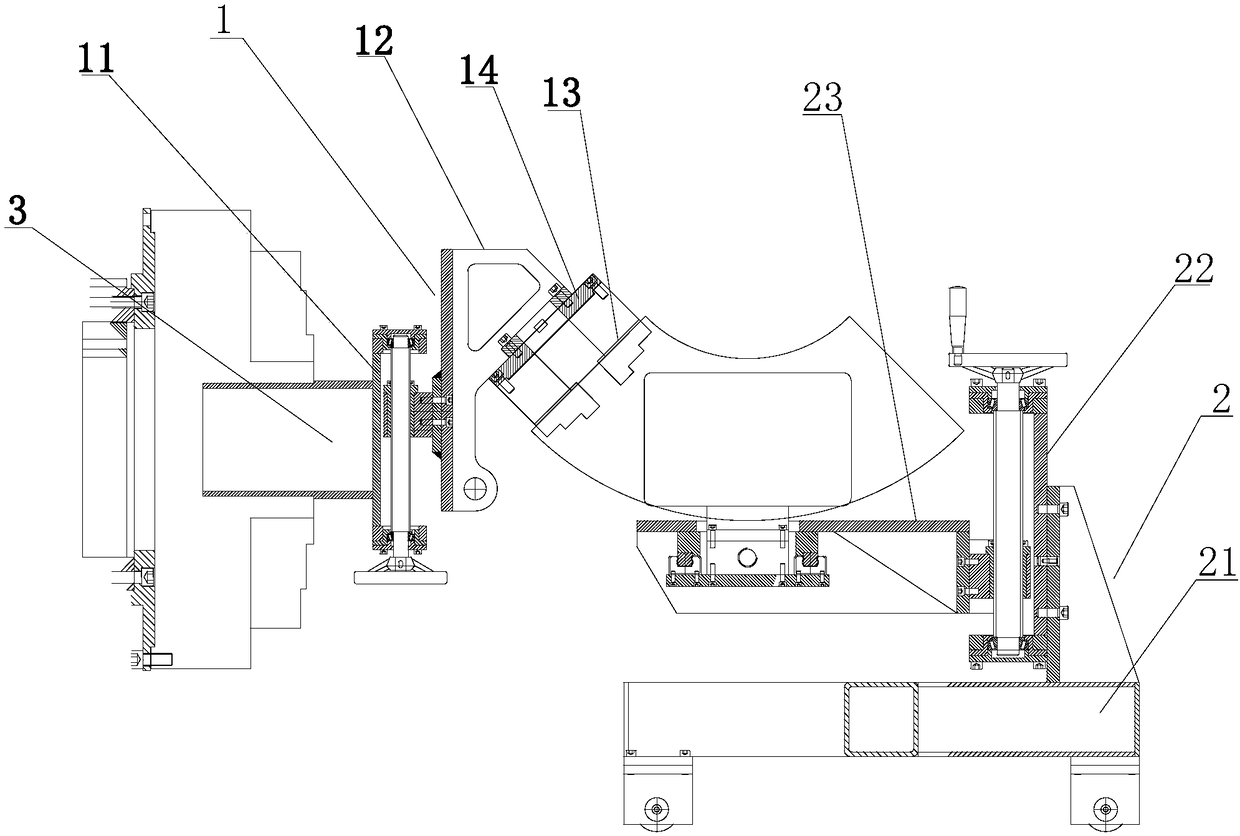

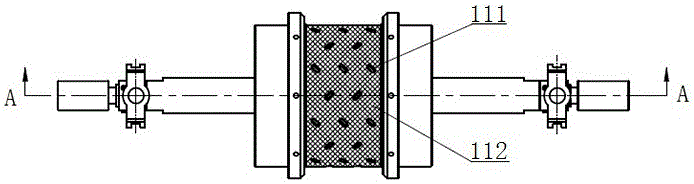

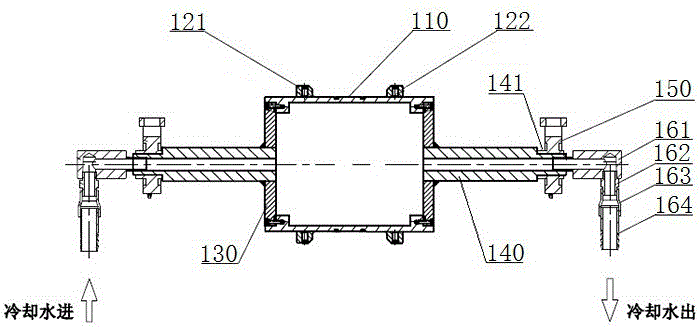

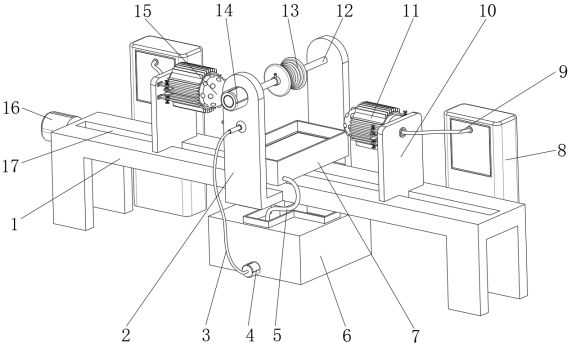

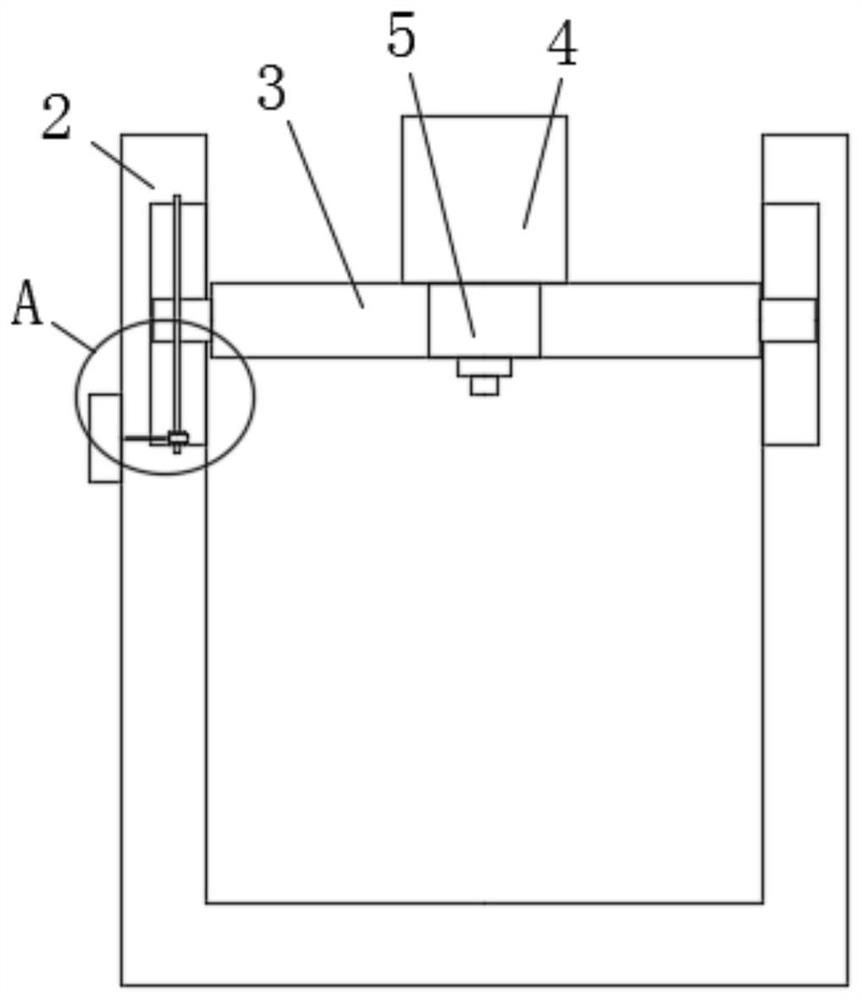

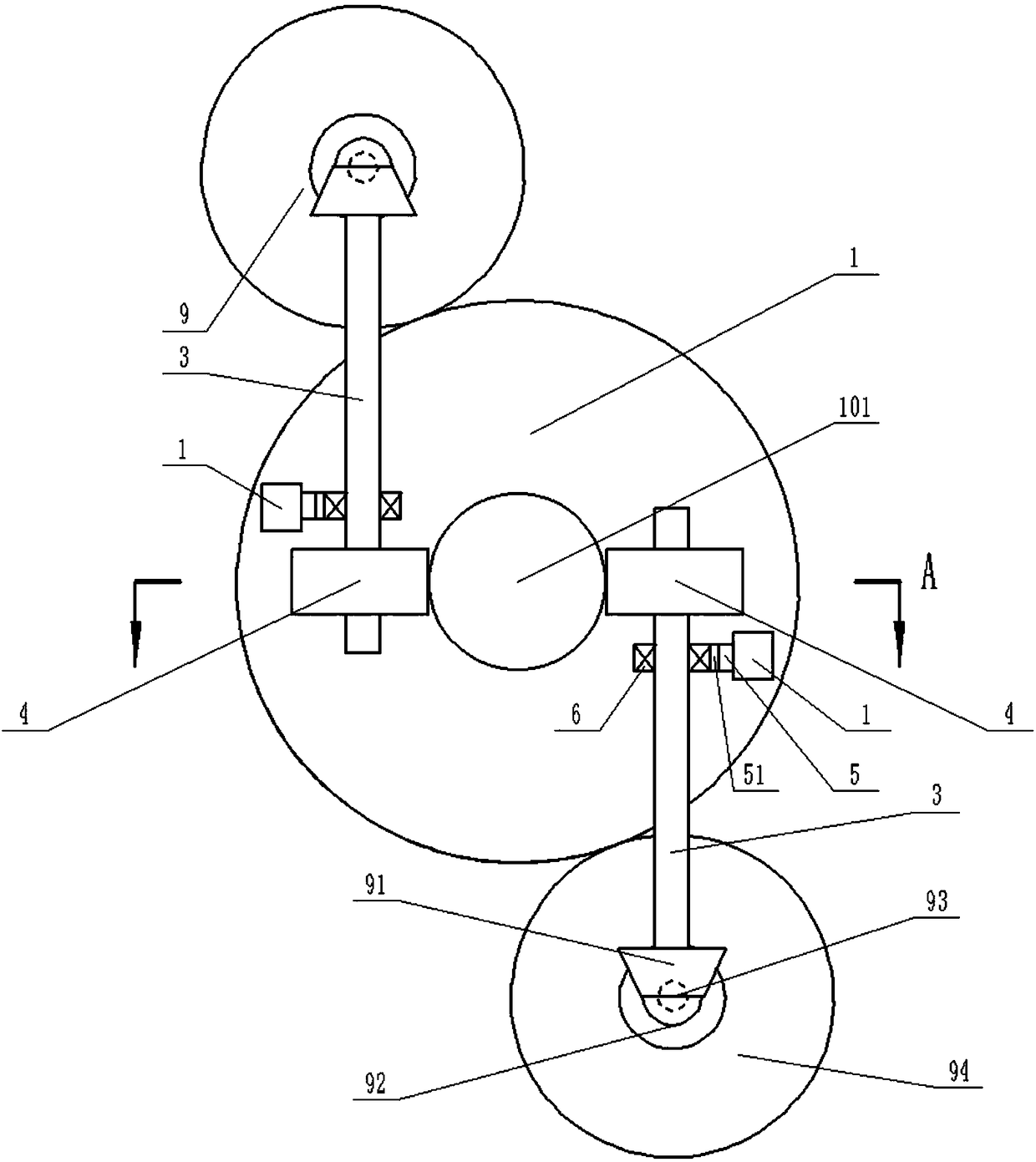

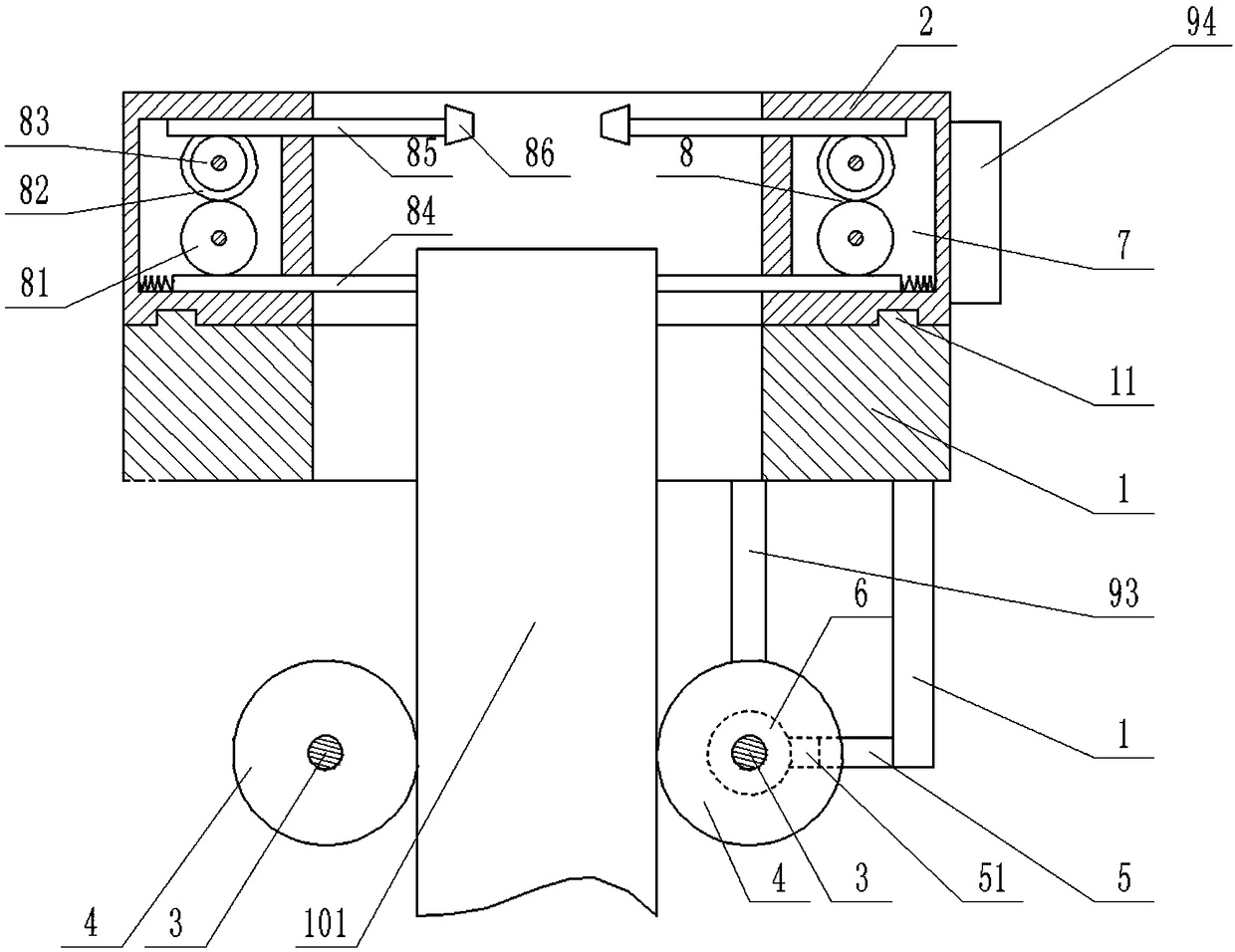

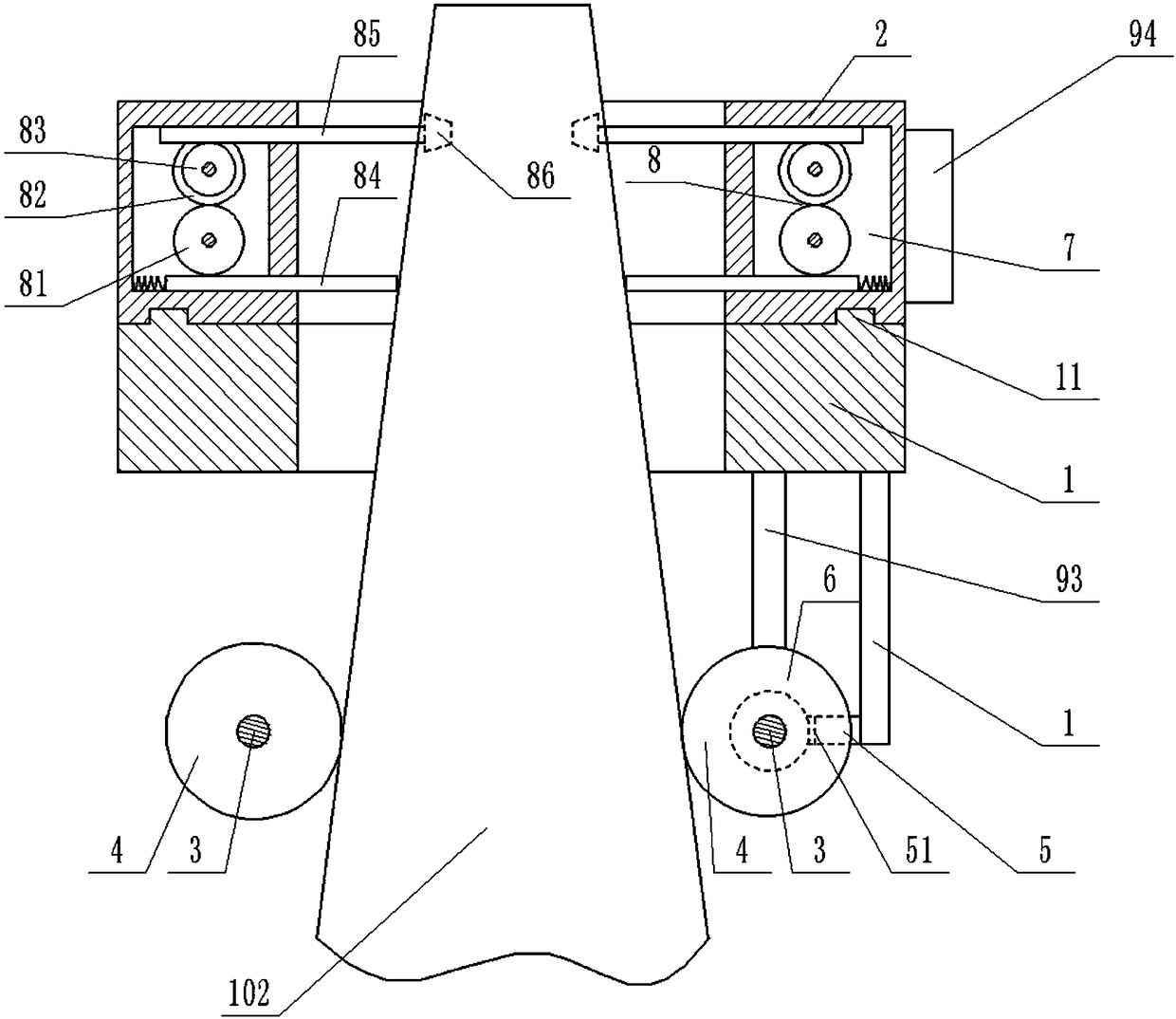

Loading device for prestress circumferential abrasive belt grinding annular part

InactiveCN106112754AAdapt to processing needsImprove fatigue lifeBelt grinding machinesGrinding work supportsFixed bearingEngineering

The invention discloses a loading device for a prestress circumferential abrasive belt grinding annular part. A sliding bearing seat is arranged on a bottom plate. A clamp body is installed on the sliding bearing seat. The middle of the clamp body is provided with a left-big right-small taper shaft which is sleeved with an expansion sleeve matched with the taper shaft. An unloading nut is arranged on the left side of the expansion sleeve. A loading nut is arranged on the right side of the expansion sleeve. A fixed shaft is arranged on the left side of the clamp body and rotationally installed on a fixed bearing seat. The bottom of the fixed bearing seat is supported by the left end of the bottom plate fixedly. The left end of the clamp body can be put in a matching hole in the right end of the fixed shaft in a sleeved mode, and thus the fixed shaft and the clamp body are connected together fixedly. The loading device is simple in structure, easy to achieve, capable of achieving loading and unloading easily, flexible to operate and wide in application range. Through pretightening of the loading nut, applying of different-magnitude prestress can be controlled actively in a certain range, unloading of circumferential prestress of a workpiece is achieved through the unloading nut, and the distribution state of surface residual stress can be controlled actively to achieve the effect that the fatigue life of the workpiece is improved.

Owner:CHONGQING UNIV +1

One-step molding knife for metal workpiece

InactiveCN104475831AImprove efficiencyEasy to useTransportation and packagingTrepanning drillsReamerEngineering

The invention discloses a one-step molding knife for a metal workpiece. A drilling reamer is detachably mounted at the center position of the lower surface of a main knife holder through a locking screw and consists of drilling reamer bodies which are integrally formed and are used for processing different apertures, wherein the drilling reamer body for processing a thick aperture is positioned between the main knife holder and the drilling reamer body for processing a thin aperture; two sides of the lower surface of the main knife holder downwards extend to form additional knife holders; cutting blades are detachably mounted on the additional knife holders through locking screws; cutting edges of the cutting blades consist of two vertical cutting edges which are integrally formed and are used for cutting different diameters. The one-step molding knife for the metal workpiece can be used for processing a steplike hole and an outer surface step of a workpiece according to a requirement or only selectively processing the steplike hole of the workpiece or only processing the outer surface step of the workpiece; furthermore, the one-step molding knife can process the steplike hole or the step or both the steplike hole and the step by one step, so that the efficiency is greatly improved.

Owner:CHONGQING HUAQING AUTOMOBILE PARTS

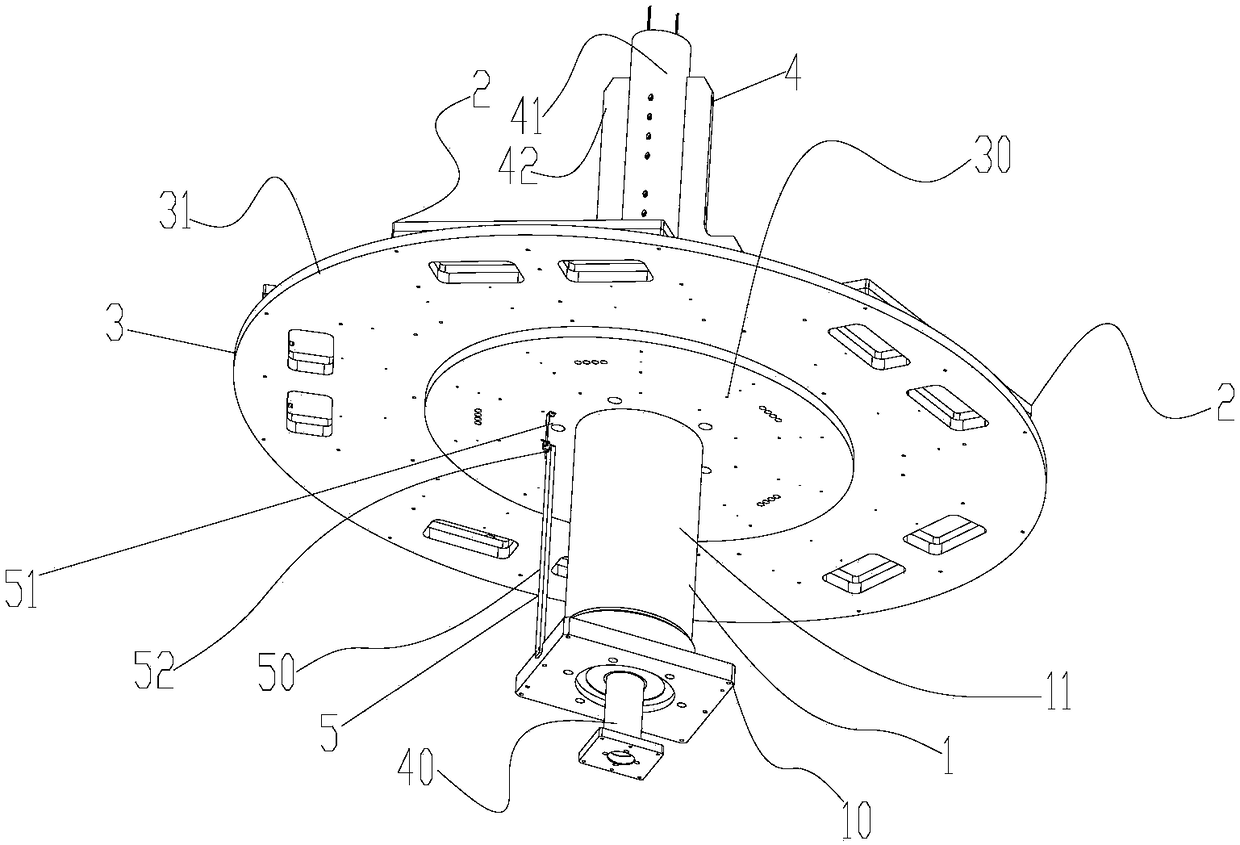

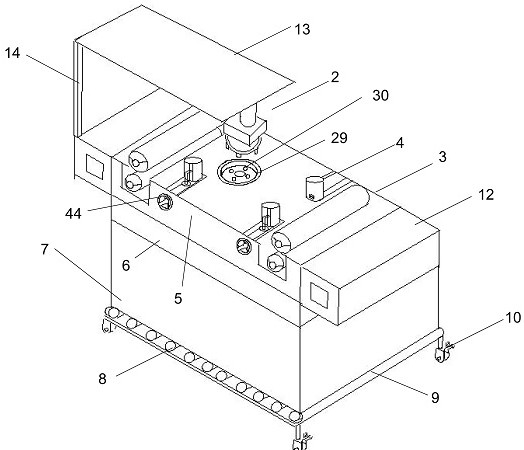

Multi-station rotary disc mechanism

The invention belongs to the technical field of material conveying rotary discs of backlight modules, and provides a multi-station rotary disc mechanism used for conveying backlight modules. The multi-station rotary disc mechanism comprises a DD motor assembly, a rotary disc mechanism body and a plurality of carrier jigs. The multi-station rotary disc mechanism drives the rotary disc mechanism body to rotate through the DD motor assembly, accordingly, the multiple carrier jigs loaded with the multiple backlight modules correspondingly are driven to sequentially circularly rotate and convey thebacklight modules between a plurality of preset stations, and the multiple backlight modules are subjected to corresponding treatment between the multiple preset stations in sequence; and a DD motorkeeps sufficient torque during low-speed rotating, moreover, smooth rotating of a rotary disc is ensured, the conveying efficiency of the rotary disc is improved, and the corresponding treatment requirements of the multiple stations are met. Meanwhile, the multiple carrier jags of the multi-station rotary disc mechanism and a plurality of jig installation positions on the upper disc face of a jigrotary disc are detachably fixed, thus, all the carrier jigs can be disassembled and assembled to load the backlight modules with different specifications and sizes, and the compatibility and practicality of the multi-station rotary disc mechanism are improved.

Owner:SHENZHEN BOEEN AUTOMTION EQUIP CO LTD

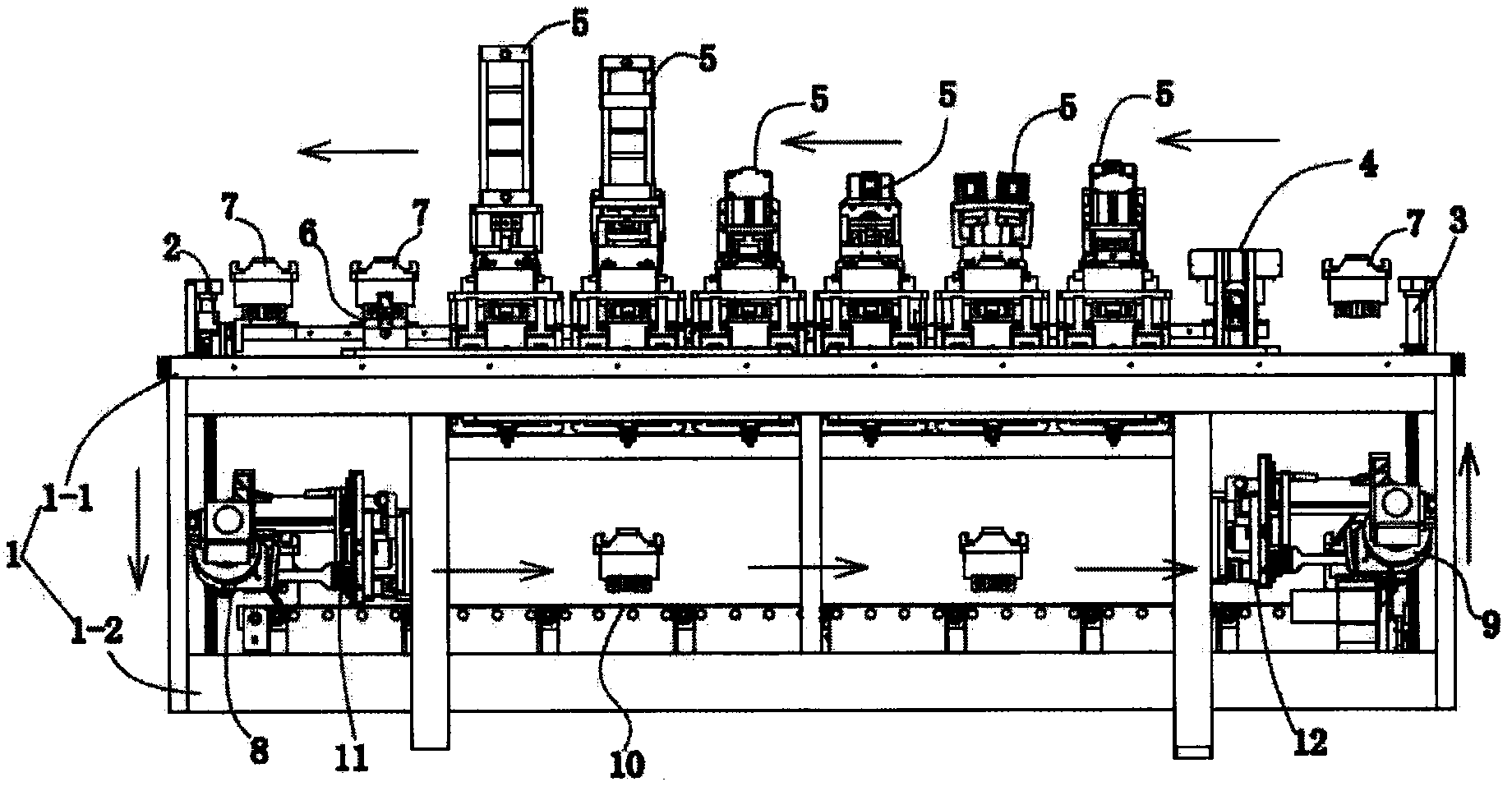

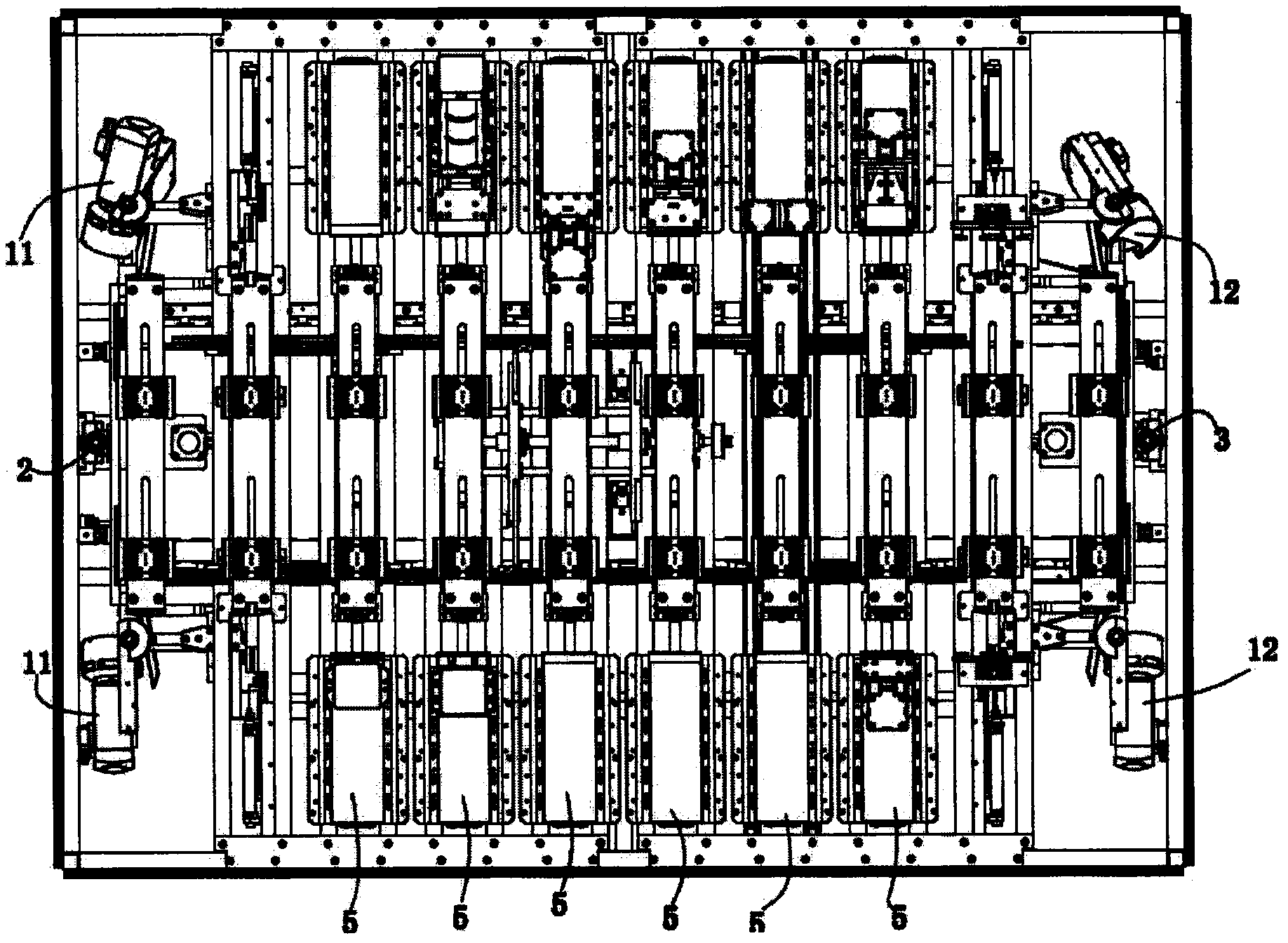

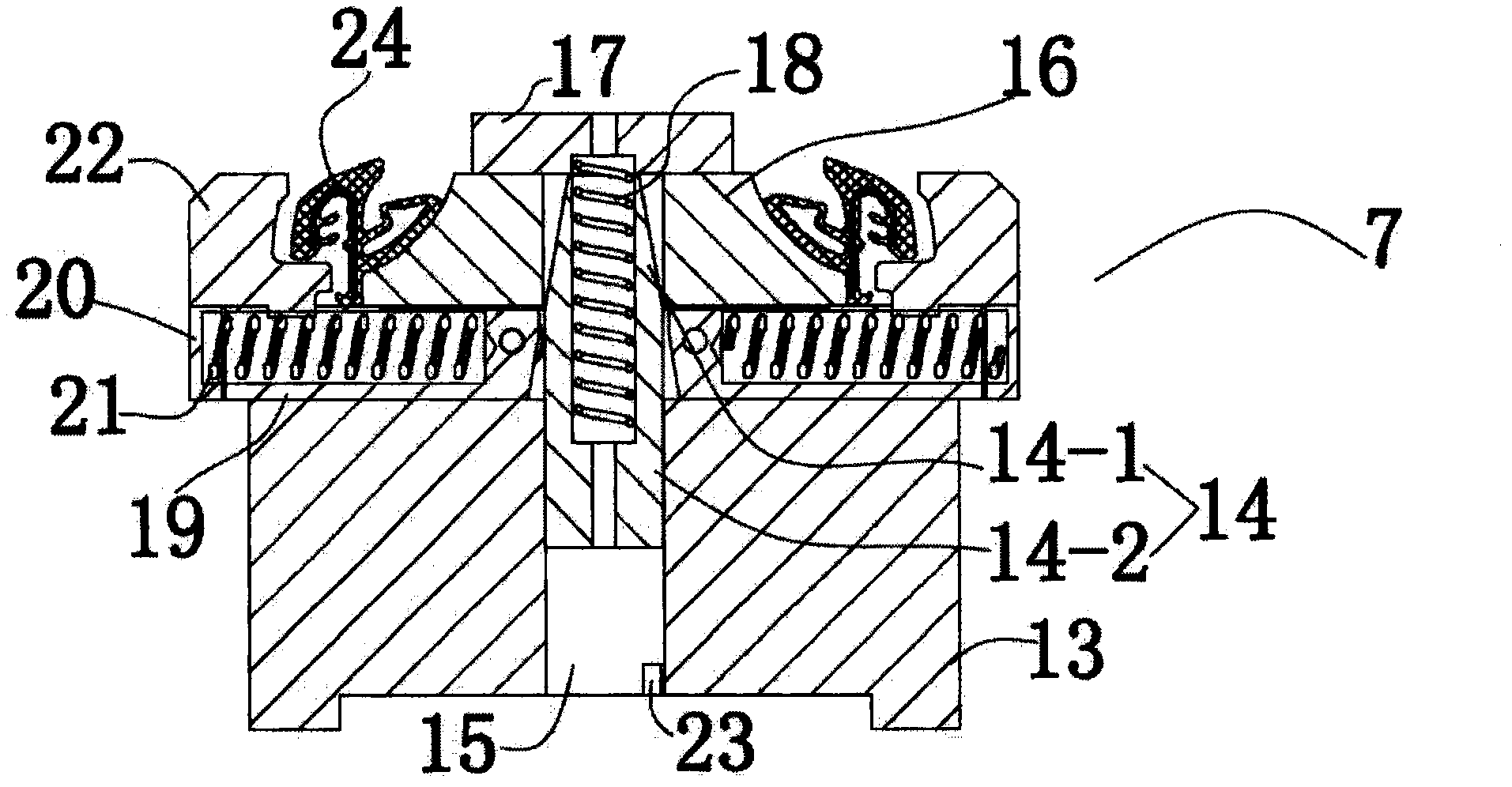

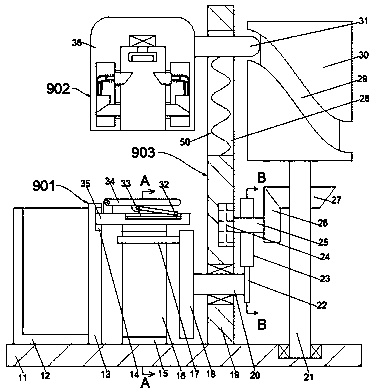

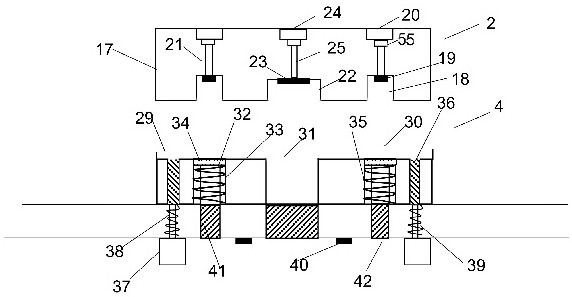

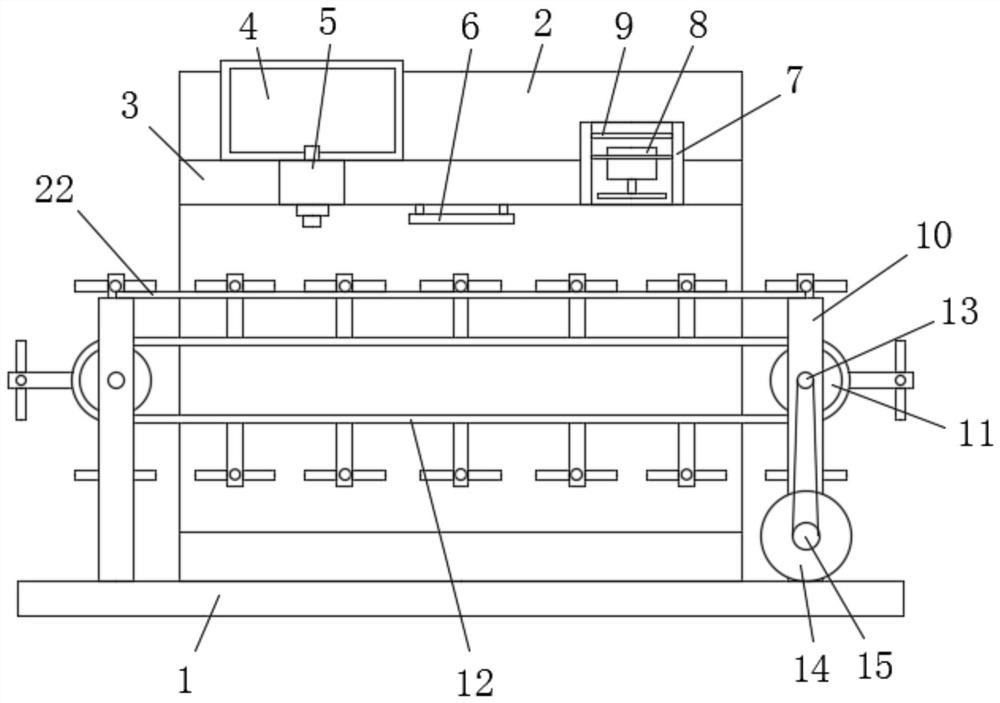

Automatic punching device of vehicle door outer pressing bar

ActiveCN104308895AImprove work efficiencyGood repeatabilityMetal working apparatusPunchingRepeatability

Disclosed is an automatic punching device of a vehicle door outer pressing bar. The automatic punching device of the vehicle door outer pressing bar comprises a rack, the rack comprises an upper layer rack and a lower layer rack, a descending station is arranged at one end of the upper layer rack, an ascending station is disposed at the other end of the upper layer rack, a material pick-and-place station, a plurality of punch dies and at least one or more reserved station are sequentially disposed between the ascending station and the descending station, the automatic punching device further comprises a clamping device and a claming driving mechanism, a descending mechanism and a descending driving mechanism are mounted on the lower layer rack located below the descending station, an ascending mechanism and an ascending driving mechanism are disposed on the lower layer rack located below the ascending station, a conveying belt and a conveying belt driving mechanism are disposed between the descending mechanism and the ascending mechanism, one end of the conveying belt, which is close to the descending mechanism, is provided with a first saw cutting mechanism, and one end of the conveying belt, which is close to the ascending mechanism, is provided with a second saw cutting mechanism. The automatic punching device of the vehicle door outer pressing bar has the advantages that the operation is convenient, the repeatability of the produced outer pressing bar is good, the machining accuracy and the machining efficiency are high, and the costs are low.

Owner:建新赵氏科技股份有限公司

Electric quantity load detection device after waste storage battery recovery

InactiveCN111323707AAchieve sievingContact stabilityElectrical testingSortingElectrode ContactMechanical engineering

The invention discloses an electric quantity load detection device after waste storage battery recovery. A base is included. A positioning plate is arranged on an upper side of the base; a transposition device is arranged on a left side of the positioning plate; and the transposition device comprises a translation frame which is in sliding connection with an end surface of the upper side of the base. In the invention, through lifting and plugging, a detection electrode is in contact with or disconnected from the electrode of the storage battery; through a bidirectional clamping mode, during electric quantity detection, contact is ensured to be stable and a determination result is not affected; and in addition, the determination result further controls an inclination angle of a bearing plate where the storage batteries are placed so that the storage batteries with the residual electric quantity and the storage batteries without the residual electric quantity are screened, manual intervention can be abandoned in a whole process, and the device is more convenient, efficient and suitable for batch processing requirements.

Owner:建德希傅电子科技有限公司

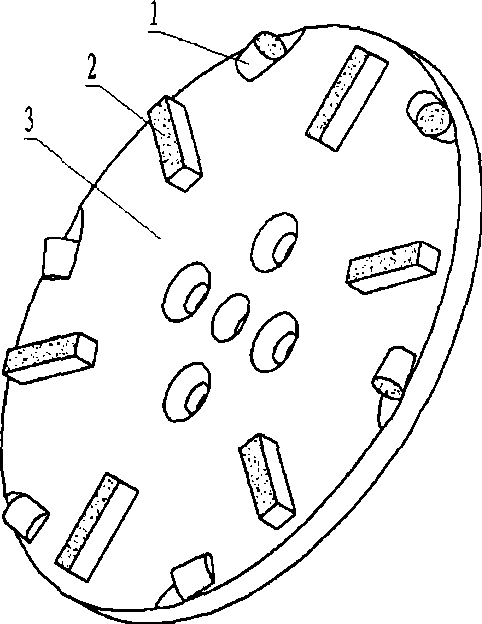

Superhard material cutting tool and preparation method thereof

ActiveCN101502926AGuaranteed smoothnessExclude smoothlySoldering apparatusOther manufacturing equipments/toolsSuperhard materialTool bit

The invention relates to a superhard material cutting tool and a preparation method thereof, which belongs to the technical field of superhard material. The superhard material cutting tool comprises a steel matrix and a cutting tool bit. The cutting tool bit consists of a polycrystalline diamond compact (1) and a diamond tool bit (2); 1 to 12 inclined cylindrical tanks used for welding the diamond compact are distributed on the outer circle surface of the steel matrix, and the center line of the inclined cylindrical tank forms a cutting angle with the cutting face; the diamond tool bit is welded on the surface of the steel matrix. The polycrystalline diamond compact is combined by PCD and cemented carbide matrix and is sintered from the mixture of diamond and the metal powder after being compacted; the structure thereof is in the shape of cylinder, ladder or squareness; the fringe area of the clad compact is the cutting blade. The superhard material cutting tool solves the materials hard to be processed in the cutting field, and ensures the surface of the machined part free of burr, nick, spray and chatter mark; the cutting and grinding combination not only improves the cutting speed, but also ensures the cutting quality.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

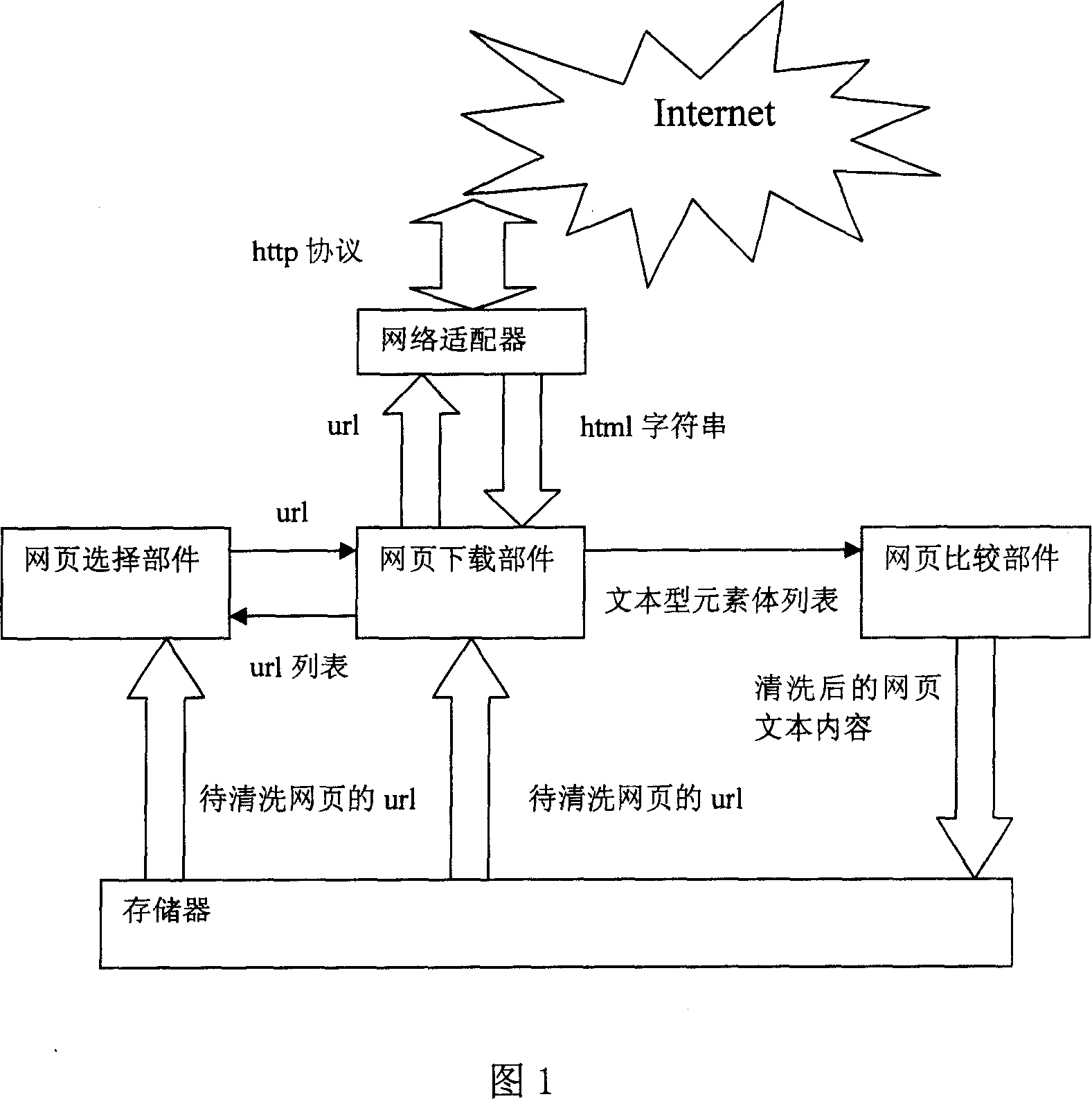

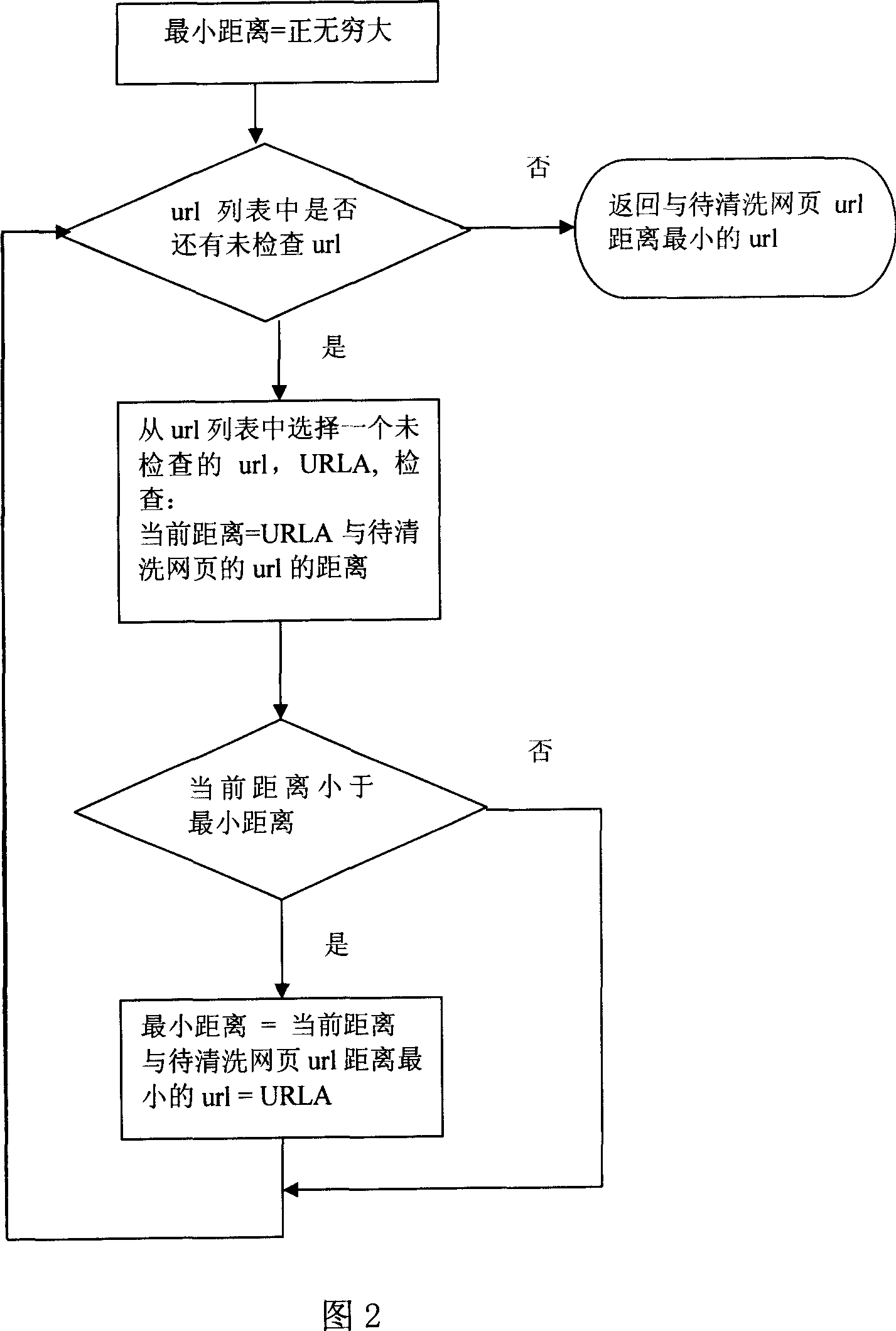

Web page cleaning method based on web page content

InactiveCN1920815AAdapt to processing needsImprove general performanceSpecial data processing applicationsWeb contentHyperlink

The invention relates to a website clearing method based on the website content, wherein it avoids assumption the html label of website, but arranges the invent point on the test of website, as the element without label; the invention comprises that downloading needed website from internet, decomposing the website into url list as super linkage in html, and the test element list; finding the website with similar website structure of needed website; based on two appointed websites, if one text element appears in two websites, deleting the test element in needed website, to obtain cleared text content. The invention has the advantages that: it is irrelevant with website structure, to support the treatment on variable self-defined websites.

Owner:上海态格信息技术有限公司

Machining tool for metal sealing gasket

ActiveCN114054591ASolve the waste of manpowerRealize the punching operationShaping toolsPerforating toolsMachine toolMachining

The invention discloses a machining tool for a metal sealing gasket. The machining tool comprises a stamping cavity, a die cavity, a bearing box and a workbench and further comprises a stamping mechanism, a feeding mechanism and a clamping mechanism, wherein the stamping cavity is formed in the workbench and composed of a top plate and four brackets located on the workbench, the stamping mechanism is located on the top plate, the bottom surface of the workbench is connected with the die cavity, control boxes are arranged on the left side and the right side of the die cavity, a die groove is formed in the die cavity, the upper portion of the die groove is not covered by the workbench, the feeding mechanism and the clamping mechanism are further arranged on the workbench and in the die cavity, the bearing box is arranged below the die cavity, the bearing box communicates with a waste box, a conveying belt is arranged in the waste box, a discharging port is formed in the joint of the conveying belt and the waste box, and universal wheels are connected to the bottom surface of the waste box. According to the invention, automatic feeding of metal plates, stamping machining of sealing gaskets and automatic ejection and taking can be achieved, waste materials are automatically discharged, manpower is saved, and the machining efficiency is improved.

Owner:烟台长鑫密封产品有限公司

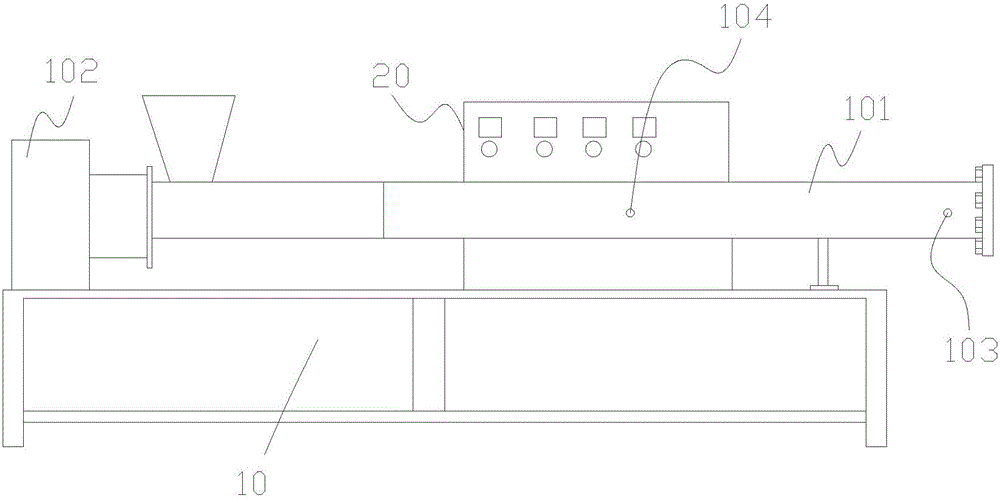

Energy-saving environment-friendly extrusion device for intelligently controlling recycled plastic based on PLC

ActiveCN105922540AAdapt to the needs of different product processingAdapt to processing needsHeating timeDirect observation

An energy-saving environment-friendly extrusion device for intelligently controlling recycled plastic based on a PLC comprises an extrusion part and the PLC; the extrusion part mainly comprises an extrusion material barrel and a transmission mechanism in transmission connection with the extrusion material barrel; a heating screw is arranged in the extrusion material barrel, a heating wire is arranged in the heating screw, the extrusion material barrel is divided into seven heating segments, the seven heating segment are independent of one another, and each heating segment comprises an electromagnetic heating oil arranged on the extrusion material barrel in a sleeving manner; a cooling cavity is formed in the middle of the extrusion material barrel and is connected with a cooling system; the heating wire is connected with the PLC, and the heating temperature and the heating time of the heating wire are controlled through logic programming; PLC data are transmitted to an office computer through the internet, the data can be directly observed through the computer, and therefore production is guided, and mechanical monitoring failures are maintained; and the aim of intelligently controlling extrusion of the recycled plastic is achieved, manpower, material resources and financial resources are saved, and the device meets the sustainable development requirement.

Owner:沧州智方药用包装材料科技有限公司

Workpiece clamping device of special boring machine for axle hole of machine body

InactiveCN104439393AAdapt to processing needsExpand the scope of processingPositioning apparatusMetal-working holdersEngineeringStructural engineering

The invention discloses a workpiece clamping device of a special boring machine for an axle hole of a machine body. The device comprises a machine body and hydraulic jack mechanisms which are arranged on two sides of a machine body processing region for clamping and fixing a to-be-processed workpiece, wherein each hydraulic jack mechanism comprises a jack sliding guide rail, a jack seat which is arranged on the jack guide rail, a jack driving mechanism for driving the jack seat to slide along the jack sliding guide rail and a hydraulic jack which is arranged on the jack seat and can extent. The hydraulic jack provided by the invention can be used for adjusting the distance from the center line of the jack to the center line of a main shaft of a boring cutter by transverse movement, so that the device is suitable for processing requests of different machine bodies, and the processing range of the machine body is expanded; meanwhile, a high-precision raster displacement sensor is additionally arranged for measuring the transverse moving distance of the jack, so that the distance from the center line of the jack to the center line of the main shaft of the boring cutter is accurately controlled.

Owner:CHONGQING HONGYI MACHINERY

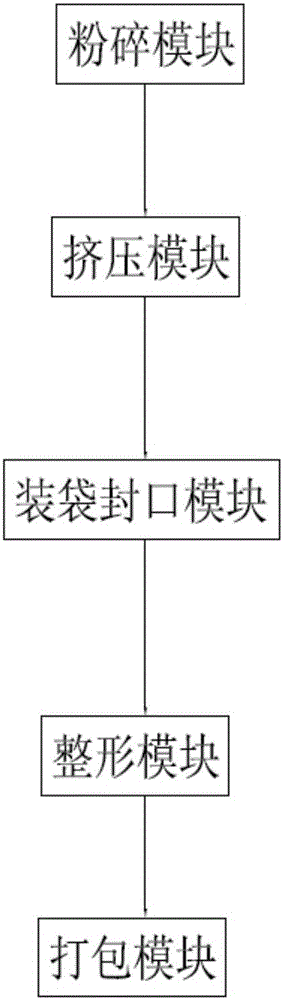

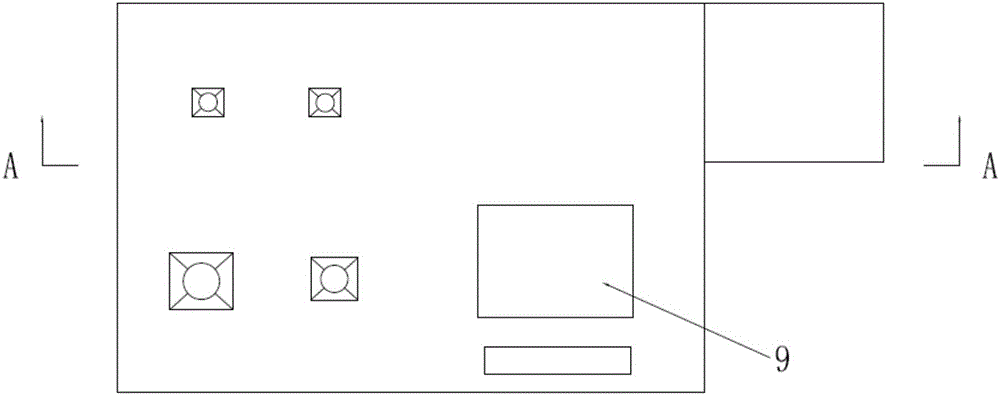

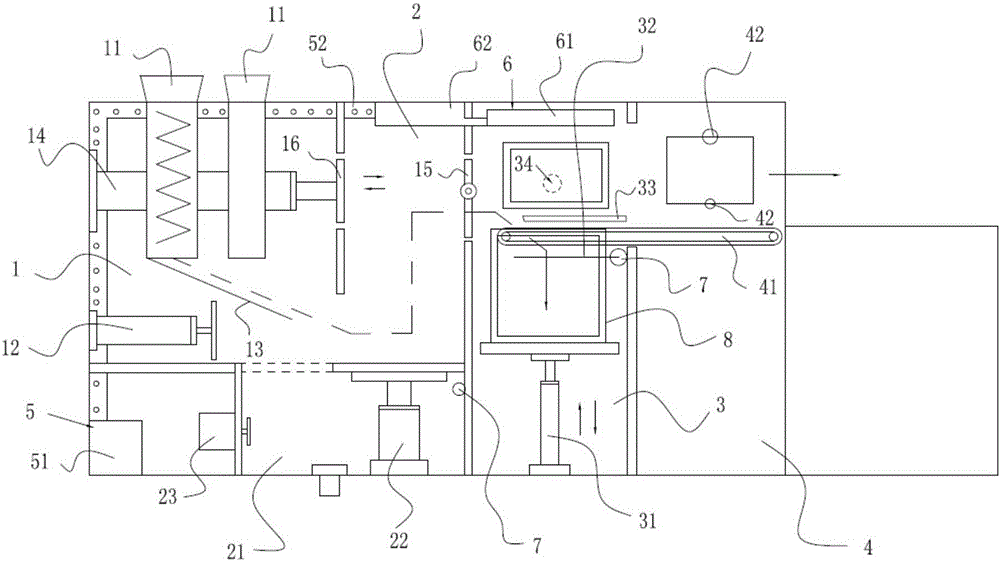

Automatic treatment system and equipment for food waste

ActiveCN105728437AHigh degree of automationImprove processing efficiencyTransportation and packagingSolid waste disposalDecompositionSewage

The invention discloses an automatic treatment system for food waste. The automatic treatment system for food waste comprises a smashing module, an extruding module, a bagging and sealing module and a shaping module. Oil and water contamination of food can be smashed, extruded, bagged, shaped and packed at a time. The invention further discloses automatic treatment equipment for food waste. The automatic treatment equipment for food waste can automatically smash, extrude, bag, shape and pack the oil and water contamination and conduct decomposition and purification treatment on the oil and water contamination, operation is simple, the treatment efficiency is high, the treatment time is short, and the equipment is safe, reliable, environmentally friendly and free of pollution.

Owner:宁波恒特汽车零部件有限公司

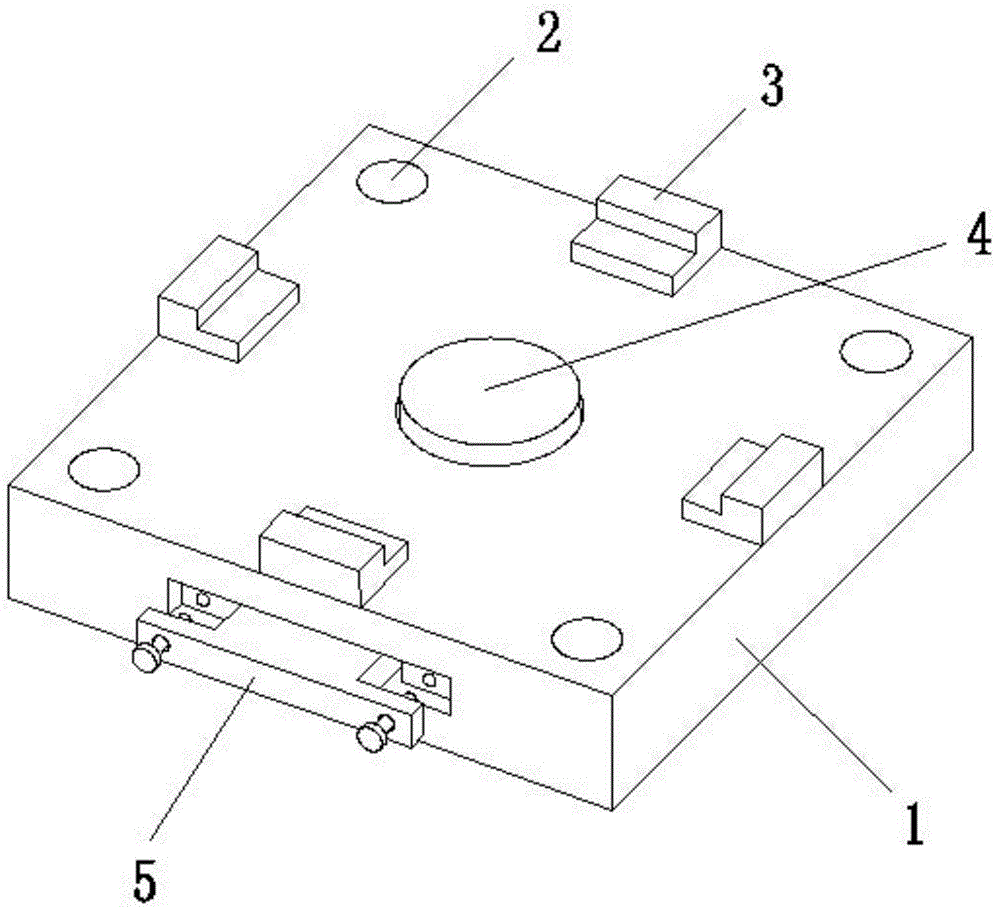

Carrying table-adjustable fixture

InactiveCN104400485AAdapt to processing needsWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention discloses a carrying table-adjustable fixture. The carrying table-adjustable fixture comprises a fixture body, wherein the fixture body is provided with a positioning hole, a positioning block, a carrying table and an adjusting rod; the positioning block is arranged on the side part of the fixture body; the section of the positioning block is L-shaped; the vertical face of the inner side face of the positioning block is a clamping surface, and the horizontal face of the inner side face of the positioning block is a carrying surface; a carrying table groove is formed in the middle part of the fixture body; the carrying table is movably arranged in the carrying table groove; an adjusting groove which is communicated with the carrying table groove is further formed in the fixture body; the adjusting rod is movably arranged in the adjusting groove; the front end of the adjusting rod and the lower side of the carrying table are provided with slopes which are matched with each other; a fixing component is arranged at the back end of the adjusting rod. According to the carrying table-adjustable fixture in the scheme, the carrying table can be retracted or ejected through matching of the carrying table and the adjusting rod, so that a workpiece is only carried by the carrying surface of the positioning block, or the workpiece is carried by the carrying surface of the positioning block and the carrying table in a matching way in order to meet the machining requirements of different workpieces.

Owner:SUZHOU MINGYUAN STAMPING PARTS FACTORY

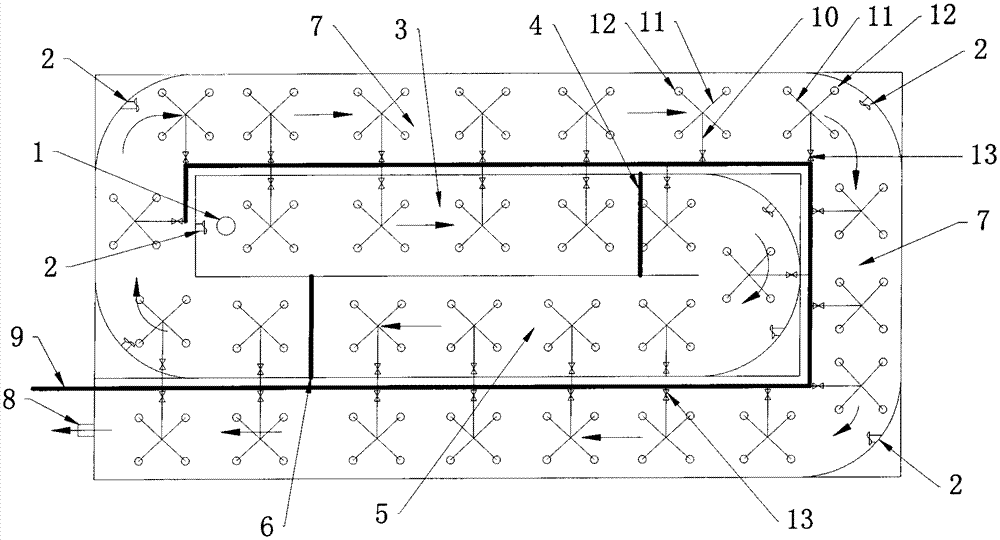

Rotary adjustable anaerobic-anoxic-aerobic biochemical reactor

InactiveCN103755024AReasonable designCompact structureTreatment with aerobic and anaerobic processesBiochemical engineeringWater quality

The invention discloses a rotary adjustable anaerobic-anoxic-aerobic biochemical reactor. The rotary adjustable anaerobic-anoxic-aerobic biochemical reactor is in the form of a rotary channel, and are divided into 4 continuous water channels with equal width and height including an anaerobic segment, an anoxic segment, and an aerobic segment; volume distribution adjustment of the anaerobic segment, the anoxic segment, and the aerobic segment can be realized by moving movable separating plates; the lower parts of the movable separating plates are provided with water passing orifices; and the lower part of each channel of the rotary adjustable anaerobic-anoxic-aerobic biochemical reactor is provided with a controllable aerating apparatus. The rotary adjustable anaerobic-anoxic-aerobic biochemical reactor is reasonable in design and compact in structure; the channels are designed to be flexible, and adjustment is convenient and practicable; investment and operation cost is low; the relative hydraulic retention time of the anaerobic segment, the anoxic segment and the aerobic segment can be flexibly adjusted according to the water quality conditions of waste water to be treated; and when different waste water is treated or the water quality of the waste water to be treated is changed, overall stable and efficient treatment effects of the rotary adjustable anaerobic-anoxic-aerobic biochemical reactor can be maintained, and excellent environmental benefits and economic benefits are obtained.

Owner:YANCHENG INST OF TECH

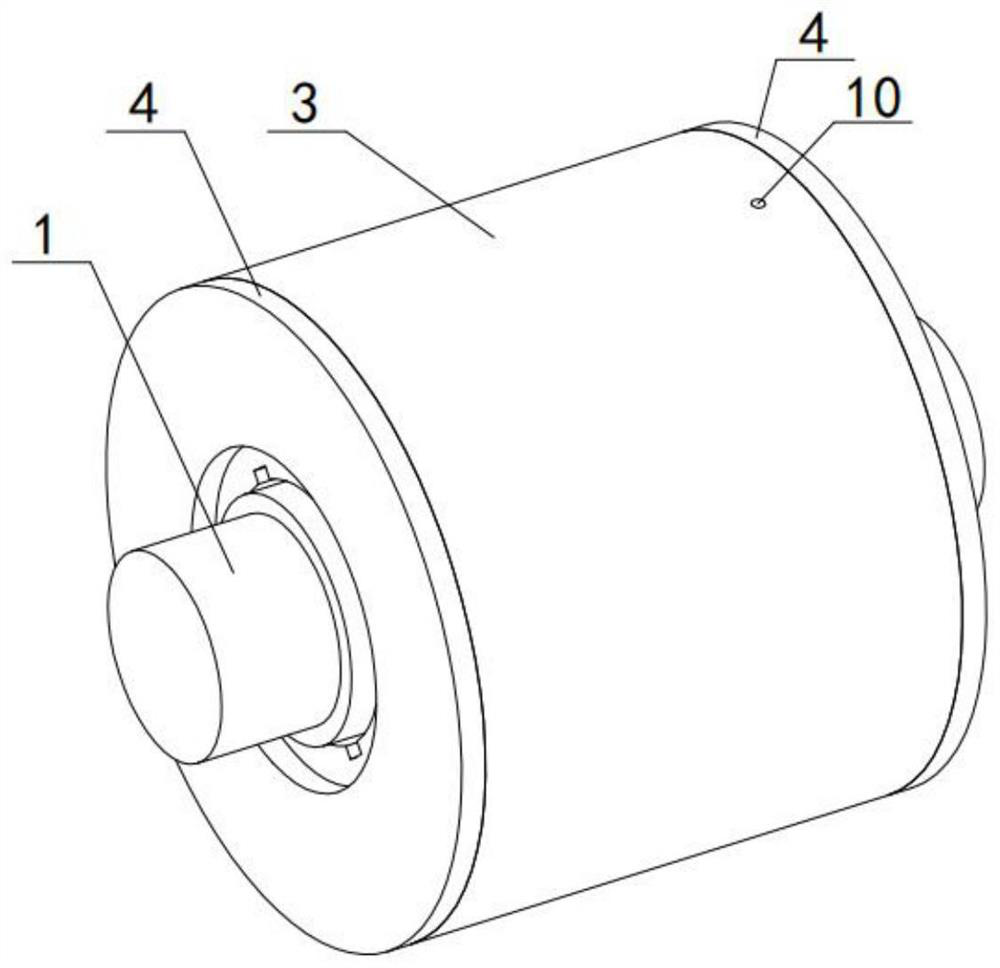

Hydrodynamic journal bearing

PendingCN113833764AAvoid affecting processingImprove the smoothness of movementLiquid cushion bearingsHydrostatic bearingsReciprocating motionProcessing accuracy

The invention discloses a hydrodynamic journal bearing which comprises a main shaft, a shaft sleeve, a bearing outer shell and two sealing end covers. A plurality of oil cavities are evenly distributed in the inner wall of the shaft sleeve, the main shaft is arranged in the middle of the shaft sleeve in a penetrating mode, the bearing outer shell is arranged on the outer side of the shaft sleeve in a sleeving mode, a working cavity is formed between the bearing outer shell and the shaft sleeve, a driving disc is arranged in the working cavity, a plurality of driving blocks are arranged on one side of the driving disc in a sliding mode, and an adjusting plate is arranged at the end, penetrating through a preformed hole in the shaft sleeve, of each driving block. According to the hydrodynamic journal bearing provided by the invention, the pressure of compressed air injected into air holes is adjusted. The driving disc can be controlled to reciprocate in the horizontal direction, so that all the driving blocks are driven to synchronously contract inwards or expand outwards in the direction perpendicular to the main shaft, the adjusting plate is driven to reciprocate, a gap between each oil cavity and the main shaft is changed, the thickness of an oil film is adjusted, the machining requirements of different products are met, the machining precision is improved, and the service life is prolonged.

Owner:JIANGSU JITRI JINGKAI HIGH VALUE MFG CO LTD

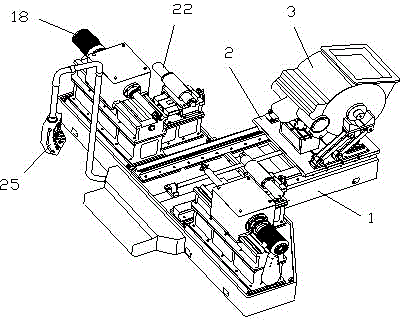

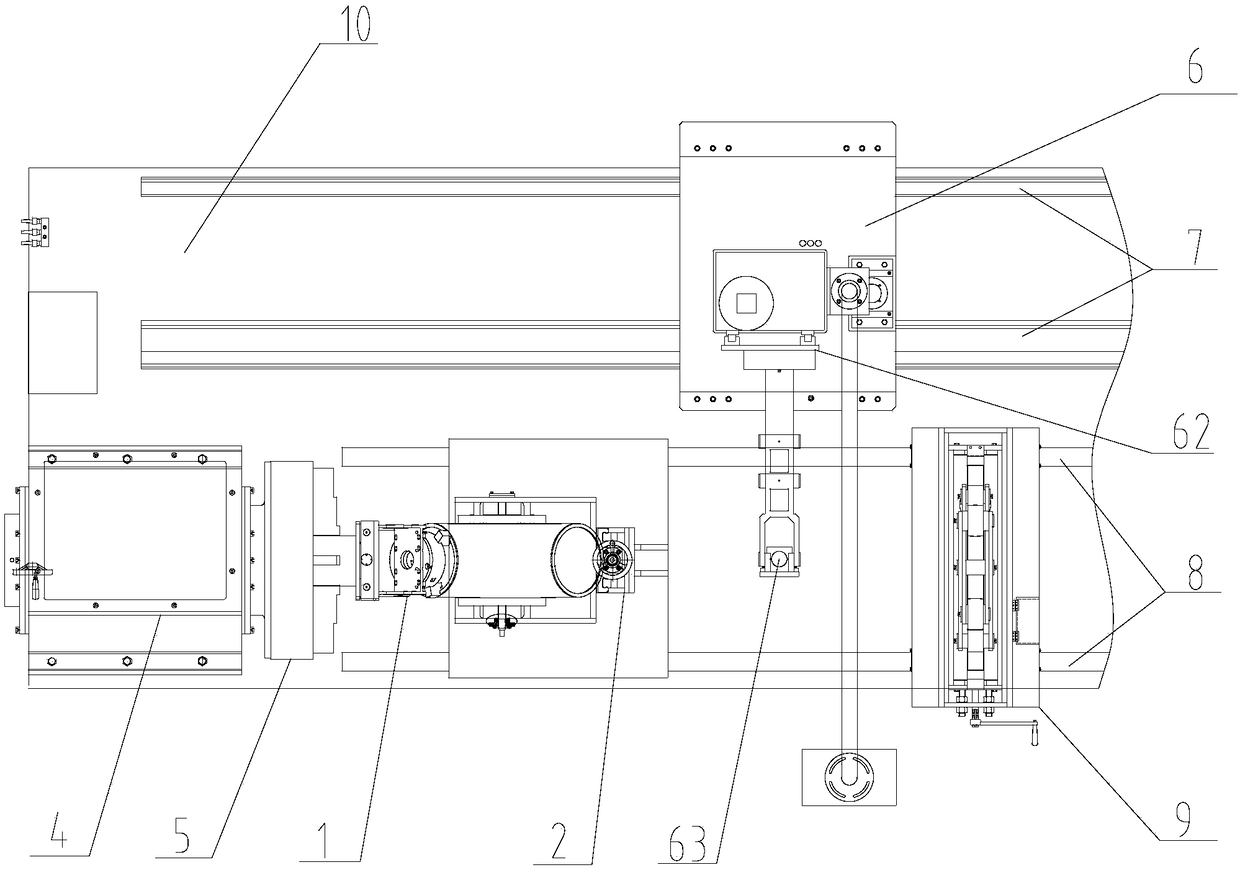

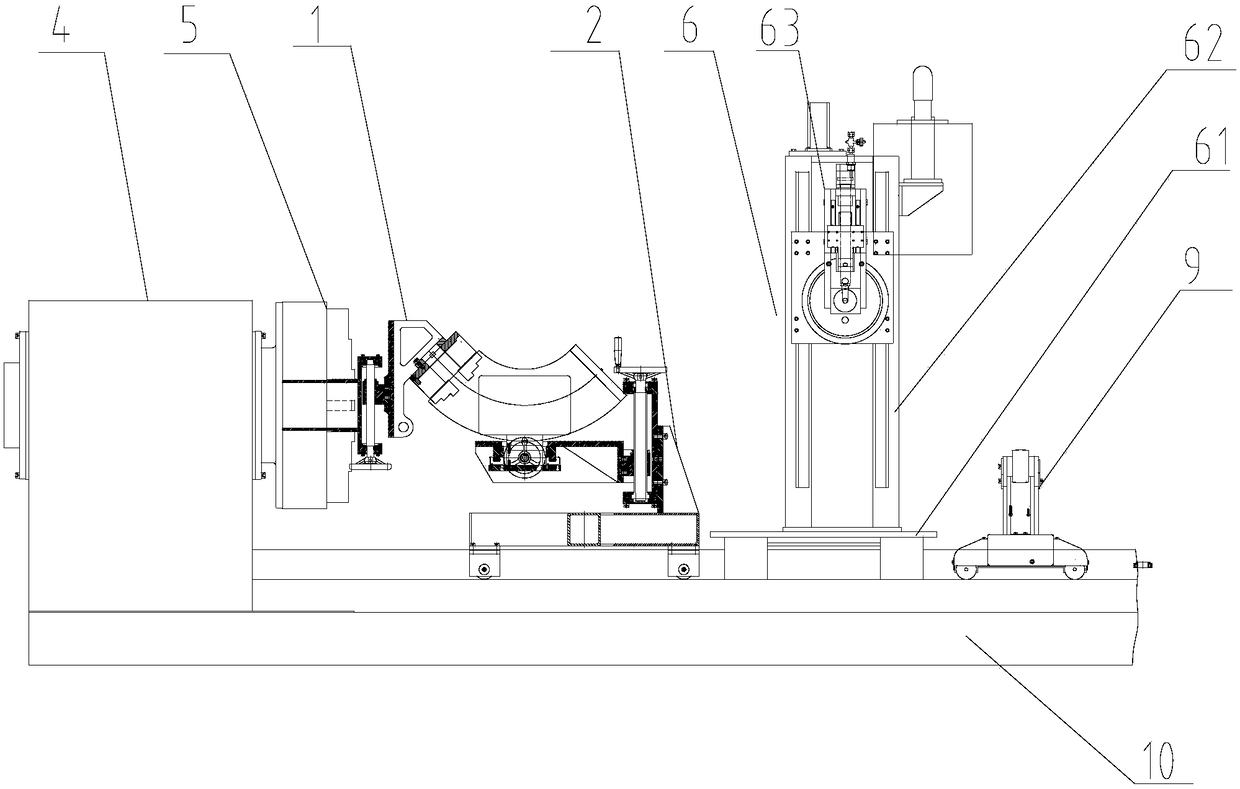

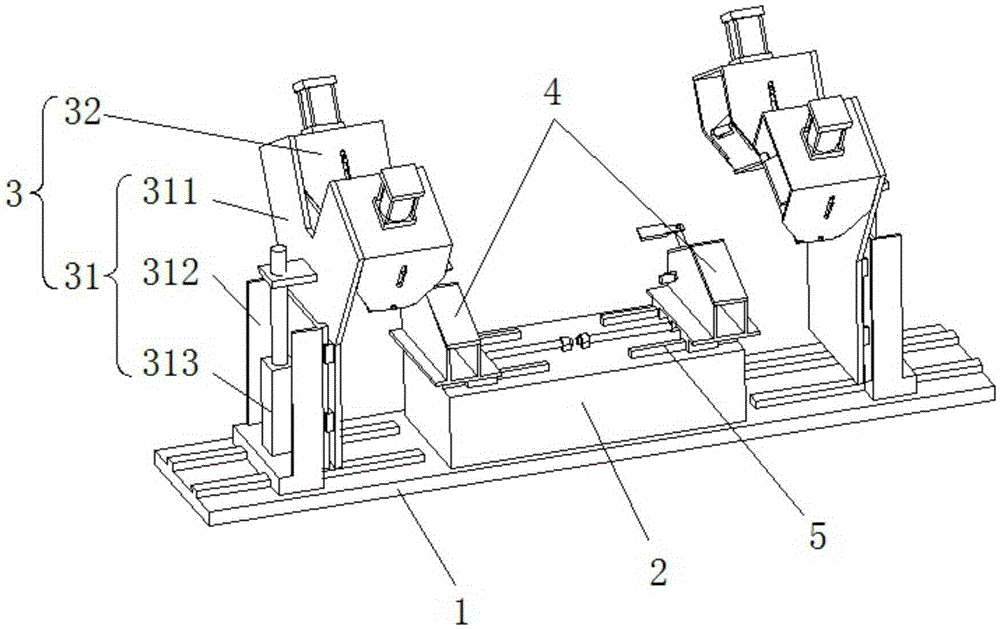

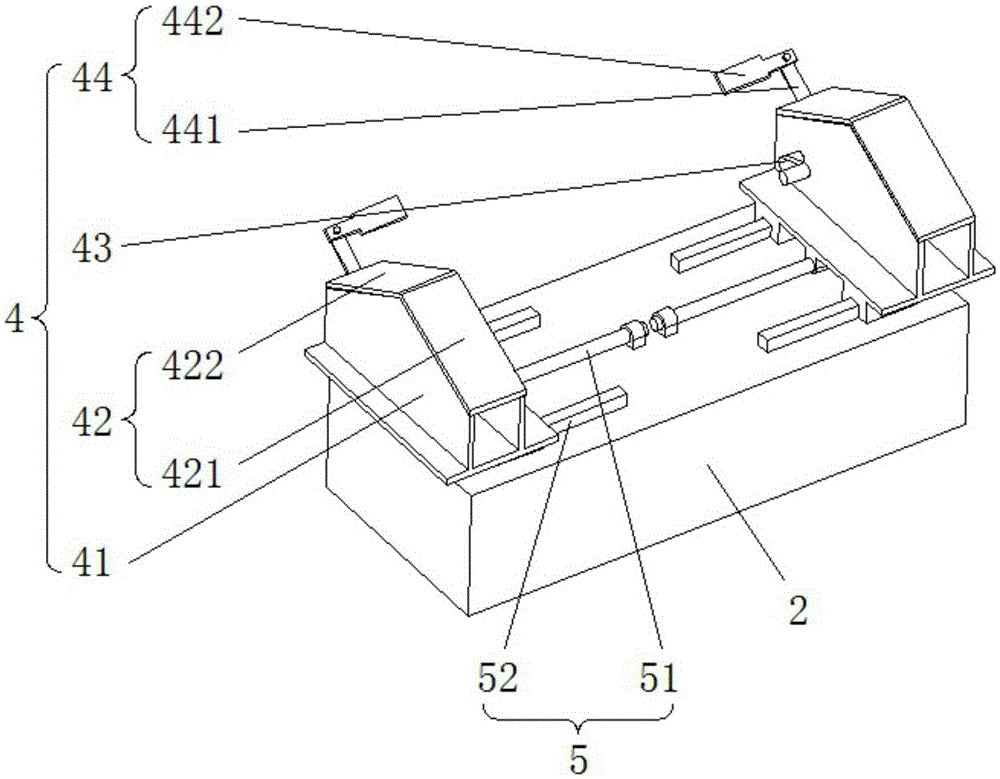

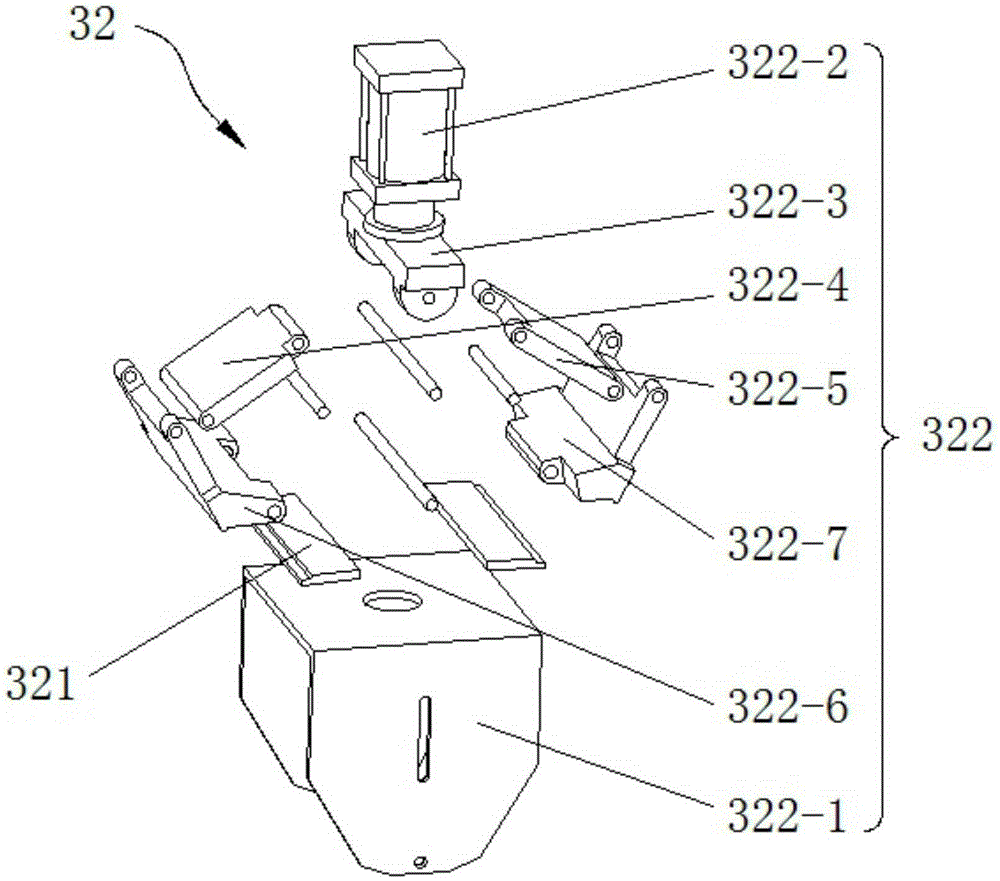

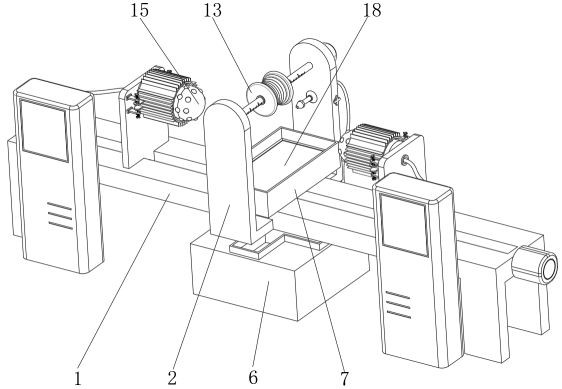

Intersecting line cutting equipment and use method thereof

PendingCN108115246AWide range of useEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesLateral moveEngineering

The invention discloses intersecting line cutting equipment. The intersecting line cutting equipment comprises a headstock, a main chuck, a mobile cutting torch set, a base, a first guide rail set anda second guide rail set; the first guide rail set and the second guide rail set are arranged on the base in parallel, the second guide rail set is arranged along the central axis of the main chuck, the main chuck is installed on the headstock, the mobile cutting torch set comprises a lateral moving trolley moving on the first guide rail set, a cutting torch lifting platform is installed on the lateral moving trolley, a tilting mechanism is arranged on the cutting torch lifting platform, a cutting torch is installed on the tilting mechanism, and the cutting torch conducts cutting along a pathof the surface of a tubular workpiece clamped to the rotating main chuck through coordinated motion of the lateral moving trolley, the cutting torch lifting platform, the tilting mechanism and the main chuck; the intersecting line cutting equipment further comprises a rotary fixing clamping device used for clamping the bend workpiece, and the rotary fixing clamping device is installed on the mainchuck through a connecting shaft. The intersecting line cutting equipment has the advantages of being easy and convenient to operate and low in maintenance cost, and improving the installation precision in cutting installation.

Owner:SHANGHAI BAOYE ELECTROMECHANICAL TECH CO LTD

Riveting machine for refrigerator side plate

ActiveCN105414438ASimple structureHigh operating stabilityRefrigerated temperatureIndustrial engineering

The invention relates to a riveting machine for a refrigerator side plate. The riveting machine comprises a rack, a workbench and riveting mechanisms, wherein the workbench is fixedly arranged on the rack; the riveting mechanisms are symmetrically arranged at the two sides of the workbench; a positioning frame for placing a workpiece is arranged on the workbench; each riveting mechanism comprises a lifting device and a riveting device; each riveting device comprises a lifting plate, a pedestal and a lifting air cylinder; each lifting air cylinder is fixedly arranged on the pedestal; each lifting plate is arranged on the pedestal in a sliding mode; a telescopic pole of each lifting air cylinder is fixedly connected with the corresponding lifting plate; each riveting device is fixedly arranged on the corresponding lifting plate; each riveting device comprises a riveting clamp and a closing drive assembly for driving the riveting clamp to close; and each riveting clamp is fixedly arranged on the corresponding closing drive assembly. The riveting machine can meet the requirements of simultaneously riveting at multiple positions, realizes quick riveting and greatly improves production efficiency.

Owner:JIANGSU HENGHAO ELECTROMECHANICAL MFG

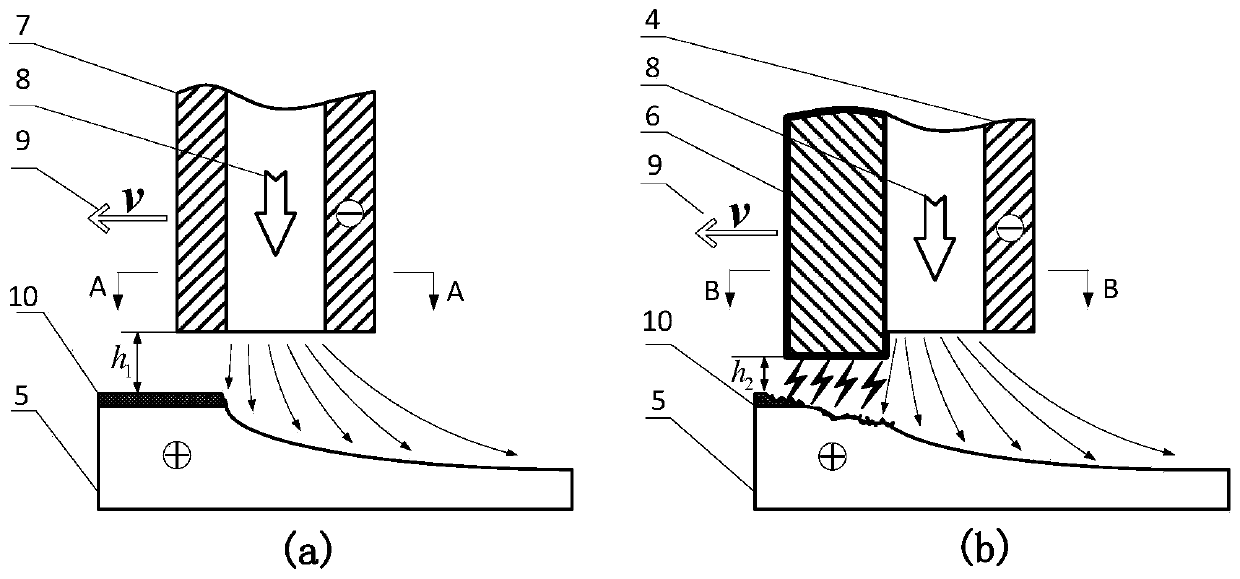

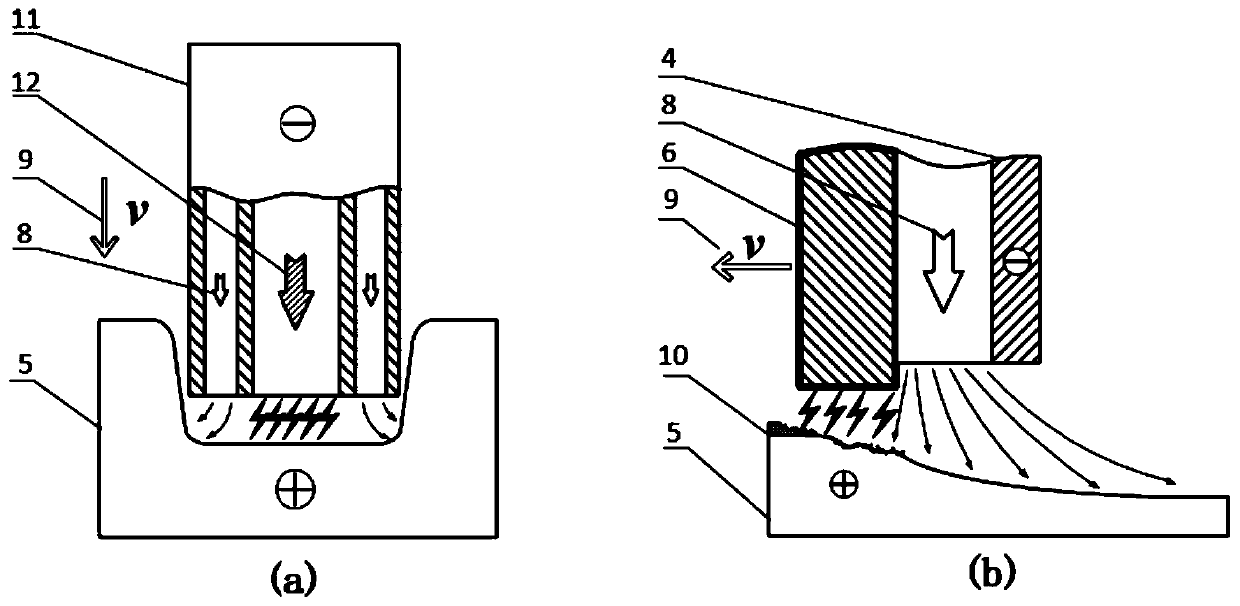

Electric spark and electrolytic continuous machining method and tool for efficient plane milling

The invention relates to an electric spark and electrolytic continuous machining method and tool for efficient plane milling, and belongs to the field of electric spark and electrolytic machining. A cathode of the tool is mainly formed by combining a copper-tungsten alloy electric spark electrode and a stainless steel electrolytic electrode. The initial machining gap of the copper-tungsten alloy electric spark electrode and the to-be-machined surface of a workpiece is set to be a small value, when a large voltage is applied, air in the machining gap is subjected to breakdown, generated electric sparks rapidly remove an oxidation layer and a large number of metal bodies on the surface of the alloy workpiece in a corrosion manner, and the time needed for oxidization layer removal in subsequent electrolytic machining is saved; and then materials are further efficiently removed by the electrolytic electrode through the electrolytic function, and the uneven surface subjected to electric spark machining is subjected to electrolytic machining to be level and smooth. Through electric spark and electrolytic continuous machining, titanium alloy materials can be efficiently removed, and the significance on improving the titanium alloy machining efficiency is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

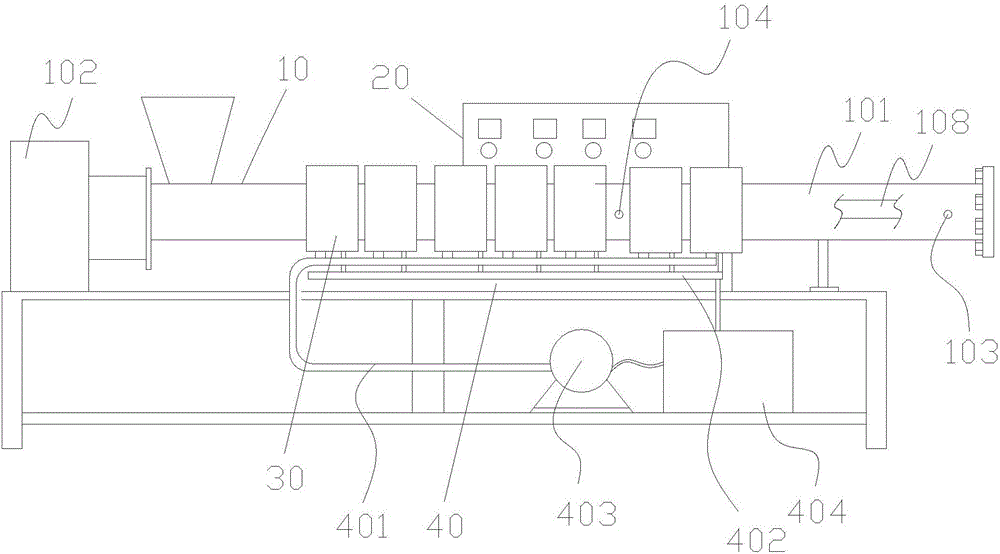

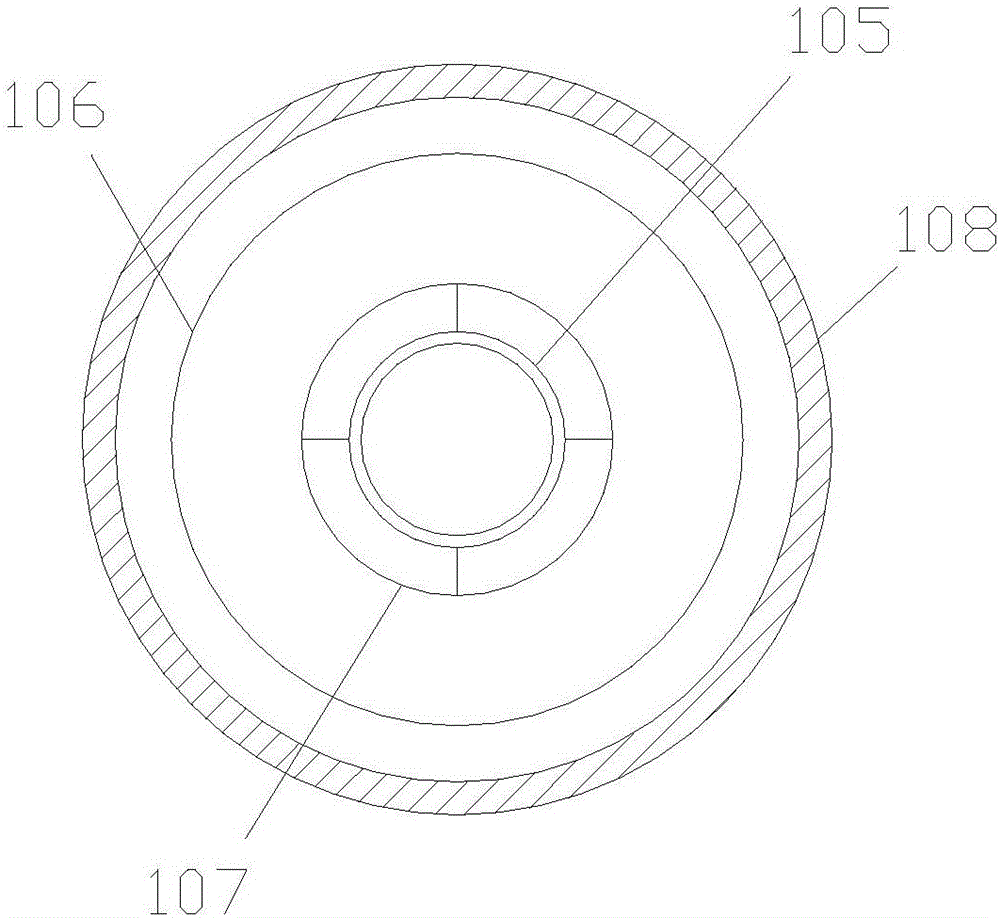

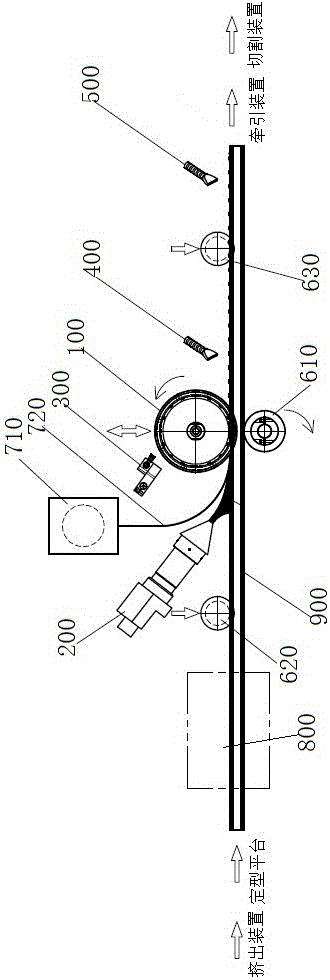

Forming machining method for mariculture net cage pedal antiskid structure

The invention relates to the technical field of pedal machining forming and specifically discloses a forming machining method for a mariculture net cage pedal antiskid structure. An antiskid structure is machined on the surface of a sectional material in a rolling manner to form a pedal, and the forming machining method specifically comprises the following steps: S1, the sectional material continuously moves forwards after extrusion; S2, a heating device is adopted to carry out continuous heating on the surface of the sectional material, and a film medium extruded by a film medium extrusion device is pasted on the surface of the heated sectional material; and S3, a forming roll device tightly presses the surface of the sectional material and rolls along with the sectional material, the film medium is combined with the sectional material after being rolled by the forming roll device, an antiskid structure layer is formed on the surface of the sectional material, and thus forming the pedal. The forming machining method is wide in specification range of application products, and is suitable for forming machining of antiskid salient points, floral designs (overlapping curves, decorative patterns, patterns, symbols and letters, various relief patterns and the like), and a mixture of the salient points and the floral designs of floating bridge pedals and sectional material pedals of various specifications and sizes.

Owner:HESHAN LESSO IND DEV

Efficient organic wastewater pretreatment method

InactiveCN105858820AImprove processing efficiencyImprove biodegradabilityWater contaminantsWater/sewage treatment using germicide/oligodynamic-processActivated carbonFlocculation

The invention belongs to the environmental-friendly technical field, and relates to an efficient organic wastewater pretreatment method. The efficient organic wastewater pretreatment method comprises the following steps: regulating the pH value of the wastewater to 3-5, adding hydrogen peroxide with effective volume concentration being 0.1-5%, introducing obtained mixed liquor into a reactor containing an iron-carbon filler therein to react, and finally discharging the mixed liquor. According to the efficient organic wastewater pretreatment method, the wastewater is simultaneously subjected to iron-carbon microelectrolysis, Fenton oxidation, flocculation precipitation, active carbon catalytic oxidization and the like, so that the treatment efficiency and biodegradability of the wastewater are greatly improved, and the investment and operation cost of capital construction can be reduced.

Owner:SINGAPORE SUZHOU IND PARK ENVIRONMENTAL PROTECTION TECH CO LTD

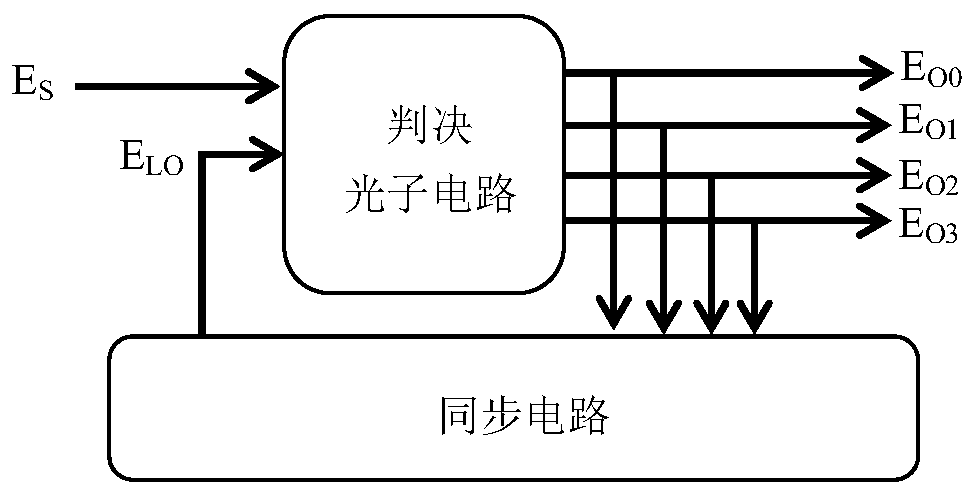

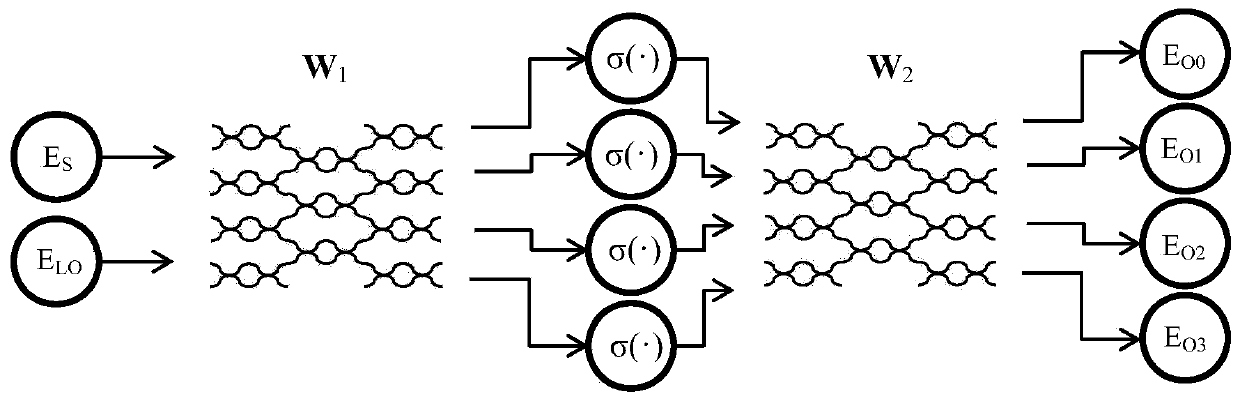

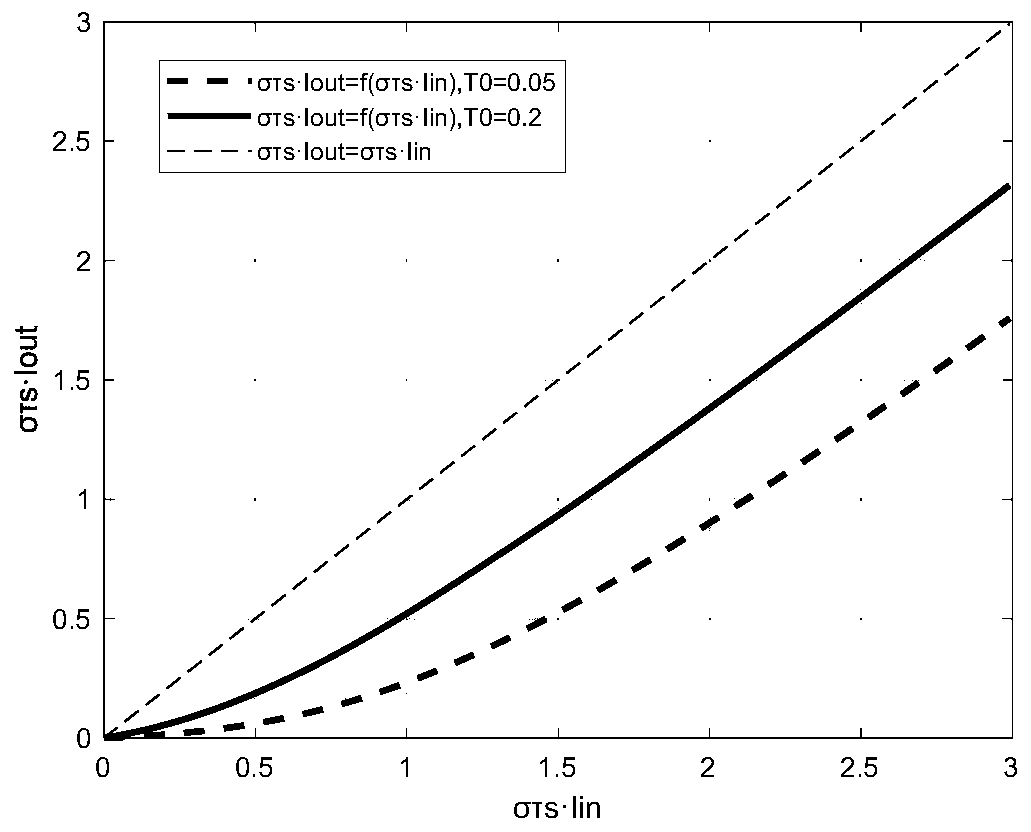

Coherent light QPSK judgment method and system based on optical neural network

ActiveCN110289914AFlexible Optical ProcessingAdapt to processing needsElectromagnetic receiversLocal oscillator signalDecision system

The invention discloses a coherent light QPSK judgment method based on an optical neural network. The method comprises the steps that firstly, according to a QPSK judgment problem, an optical neural network ONN model structure is designed, model parameters are trained, a judgment photon circuit is set up and set up according to the parameters, and the judgment photon circuit is a 2 * 4 optical network and is provided with two input ports and four output ports; and then, the QPSK receiving signal and the local oscillator signal are input into two input ports of a judgment photon circuit respectively at the same time, then processed and output through four output ports, and the phase difference between the receiving signal and the local oscillator signal is judged according to the port with the highest output power so as to complete QPSK judgment. The judgment method can meet the requirements of an all-optical communication network and an optical mobile communication system, received signals and local oscillation signals are directly processed in an optical band, and judgment or branching of the optical signals is directly completed according to phase difference information of two paths of input signals. The invention also discloses a coherent light QPSK decision system based on the optical neural network.

Owner:SOUTHEAST UNIV

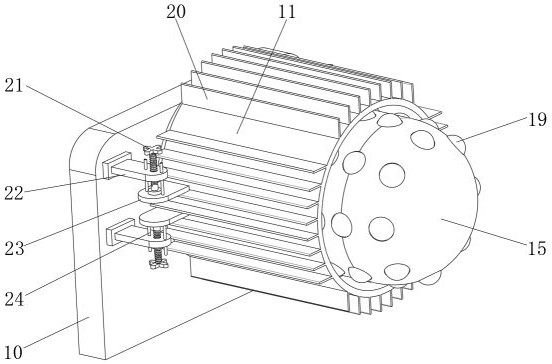

Rapid deburring device for new energy automobile motor shell machining

InactiveCN113059428AStable supportControl mounting head displacementEdge grinding machinesGrinding drivesNew energyCoupling

The invention discloses a rapid deburring device for new energy automobile motor shell machining, and relates to the technical field of deburring devices for motor shell machining. The processing efficiency is improved. The rapid deburring device specifically comprises a workbench, a translation sliding groove is formed in the outer wall of the top of the workbench, a translation motor is arranged on the outer wall of one side of the workbench, the output end of the translation motor is rotatably connected with a translation screw through a coupler, the inner wall of the translation sliding groove is slidably connected with two mounting plates, and the mounting plates are connected to the outer wall of the translation screw through threads. By arranging a mounting head, an annular air bag and other structures, a motor shell can be mounted on the mounting head, and an air pressure generating device is controlled to work to inflate the annular air bag, so that the annular air bag is expanded to reliably support the motor shell, and mounting is rapid and convenient; and by arranging a grinding piece assembly, the translation motor and other structures, the translation motor can be controlled to drive the mounting head on the mounting plate to move, so that grinding is realized under the rotation of the grinding piece assembly.

Owner:孙雪峰

Full-automatic intelligent carbonizing and drying all-in-one machine for bamboo materials

InactiveCN112265095AProcessing lastsUniform processing effectSpraying apparatusDrying solid materialsProcess engineeringMaterials processing

The invention belongs to the field of bamboo material processing equipment, and particularly relates to a full-automatic intelligent carbonizing and drying all-in-one machine for bamboo materials. Thefollowing scheme is provided currently in order to solve the problems that existing bamboo material processing equipment is low in processing efficiency, poor in processing continuity, incapable of continuously processing the bamboo materials and poor in generality, the full-automatic intelligent carbonizing and drying all-in-one machine comprises a mounting plate, a processing frame is fixedly mounted at the top of the mounting plate, an adjusting plate is slidably mounted in the processing frame, a steam box is fixedly mounted at the top of the adjusting plate, a steam spraying head is fixedly mounted at the bottom of the adjusting plate and connected with the steam box, a drying plate is fixedly mounted at the bottom of the adjusting plate, a mounting hole is formed in the top of the adjusting plate, and an air blowing pipe is fixedly mounted in the mounting hole. The full-automatic intelligent carbonizing and drying all-in-one machine is reasonable in structure, convenient to operate, high in processing efficiency, uniform in bamboo material processing effect, good in processing continuity, capable of continuously processing the bamboo materials and good in universality.

Owner:储李梅

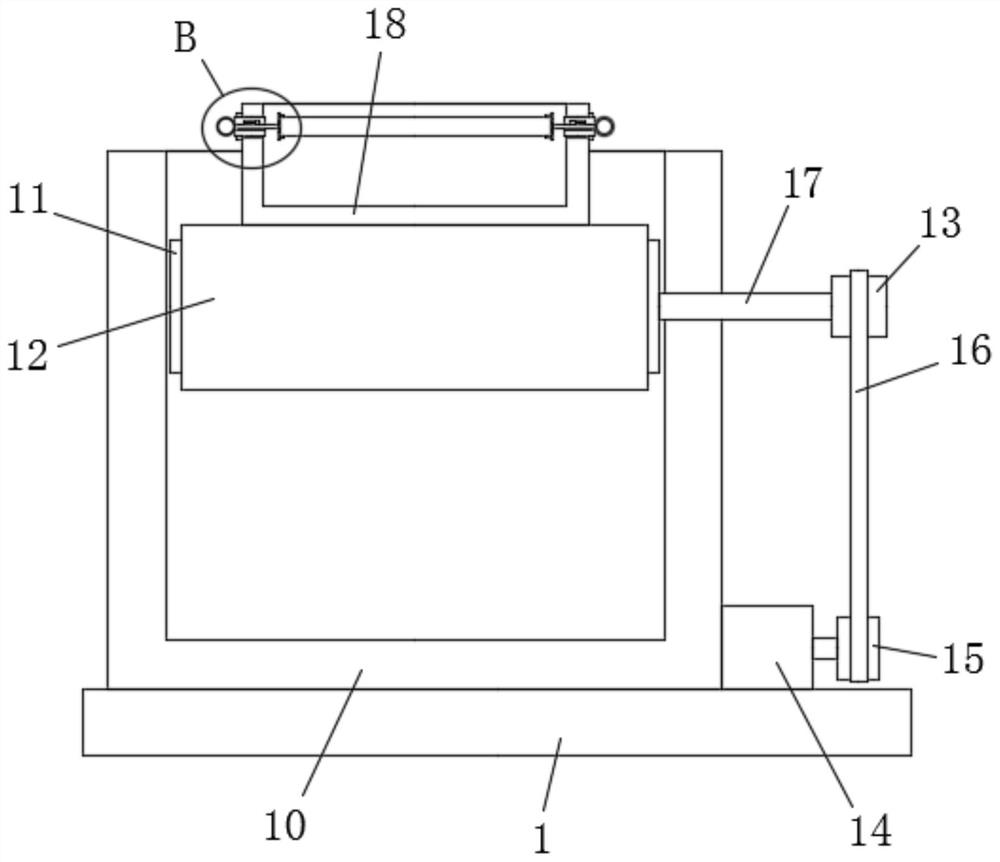

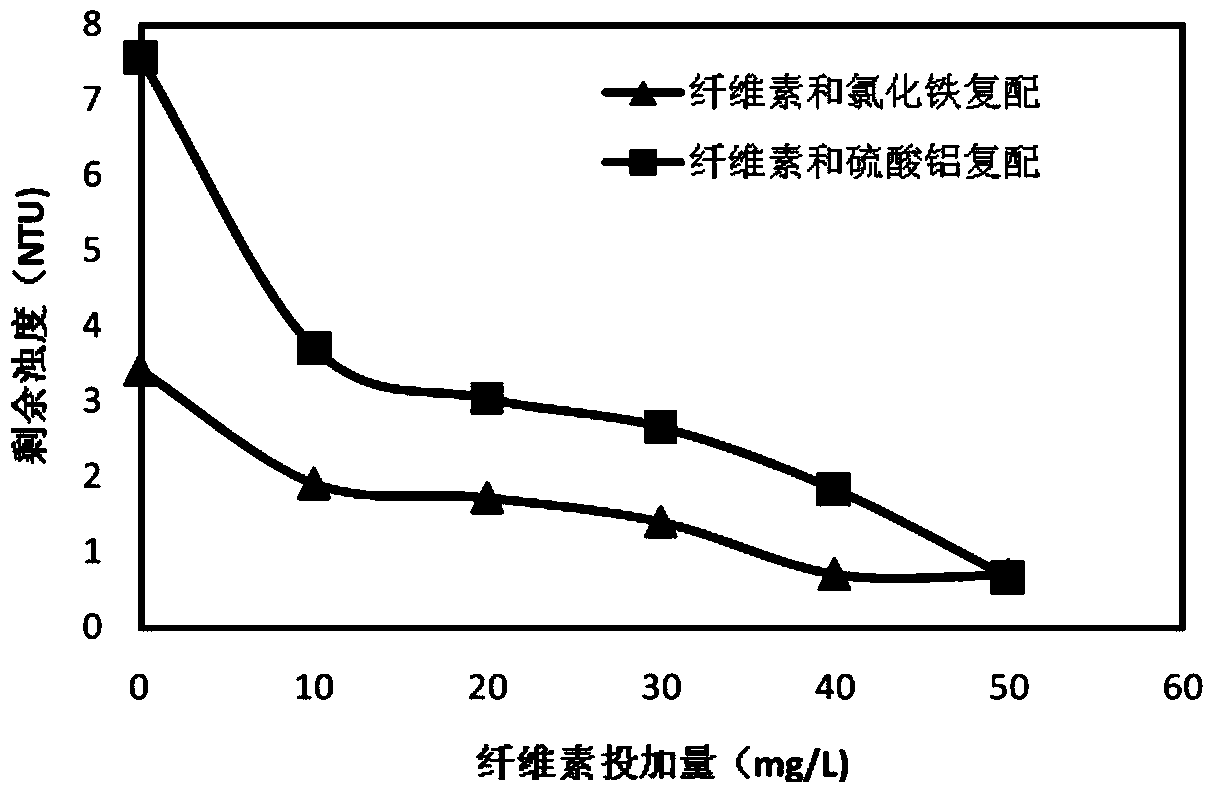

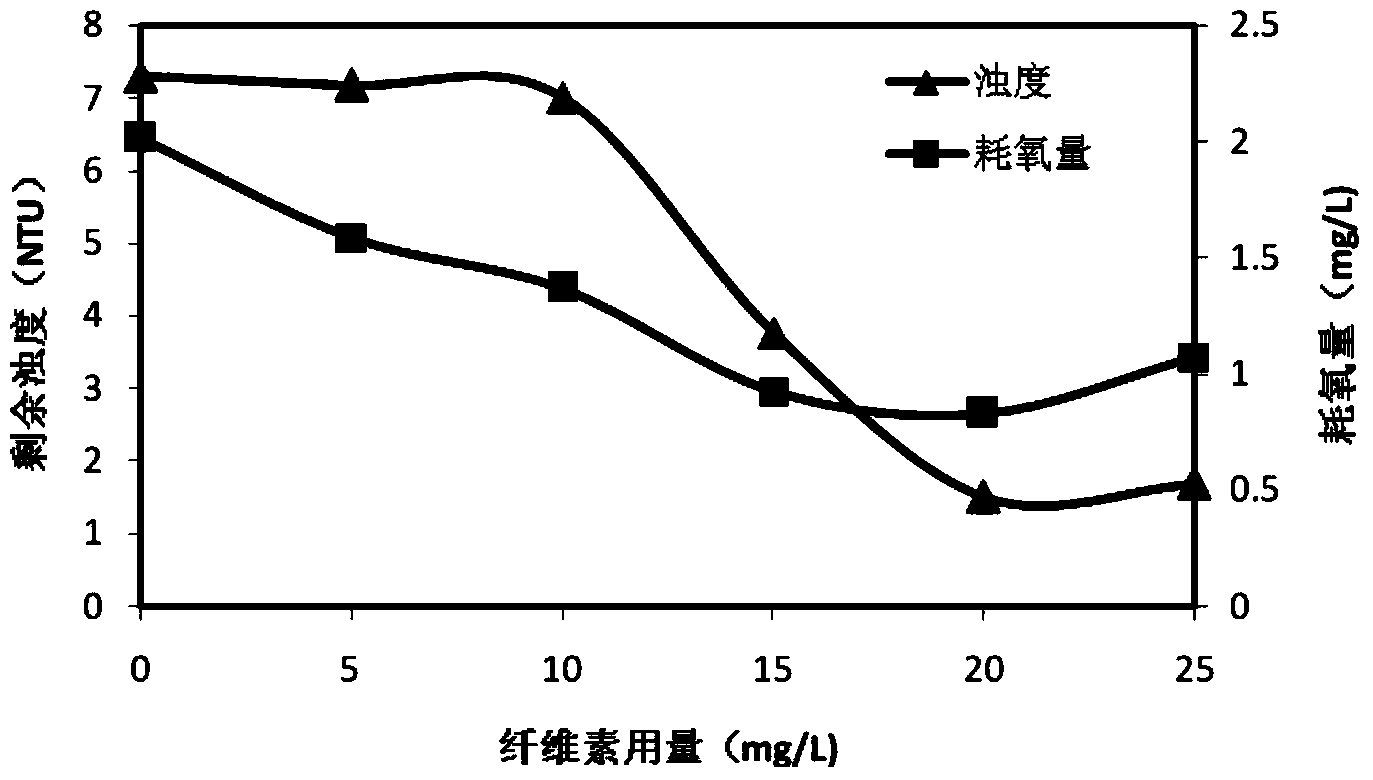

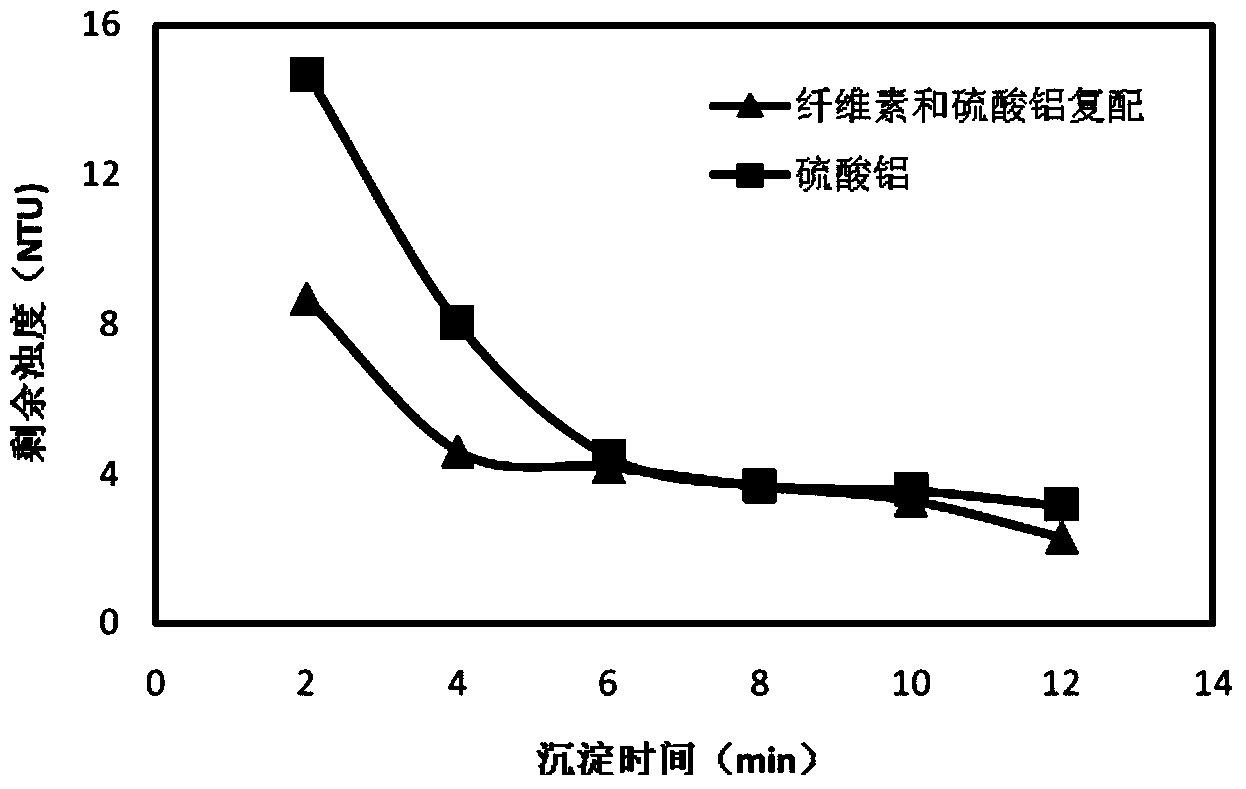

Cellulose compound water-treatment flocculant and application method thereof

ActiveCN104058489AAdapt to processing needsGuaranteed treatment effectWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateCellulose compounds

The invention provides a cellulose compound water-treatment flocculant and an application method thereof, and relates to a water treatment technology. The water-treatment flocculant is prepared from the following components in parts by mass: 1 to 5 parts of cellulose and 1 to 3 parts of a coagulant, wherein the flocculant is selected from aluminum sulfate, ferric chloride or aluminium polychlorid and the like. The application method comprises the following steps: firstly, adding the flocculant into water and stirring for 30 to 60 seconds under a revolving speed of 300r / min to 500r / min (Revolutions Per Minute); then adding the cellulose and further stirring for 1 minute at the revolving speed of 200r / min to 300r / min; further stirring for 5 minutes at the revolving speed of 100r / min to 200r / min; finally, stirring for 10 minutes at the revolving speed of 50r / min to 100r / min; standing for sedimentation for 15 to 20 minutes after the stopping of stirring. According to the method, the adding amount of the conventional flocculant is reduced; the sedimentation performance of the flocculant body is improved; the treatment cost is lowered; the standing time of a sedimentation basin is shortened; the occupation area of the sedimentation basin is reduced and the like. The cellulose can also be used for removing partial soluble pollutants.

Owner:XIAMEN UNIV

Injection molding pipe machining device

ActiveCN108161033ASolve the problem of difficulty in machining spiral groovesSolve problemsAuxillary equipmentTurning machinesEngineeringInjection molding machine

The invention relates to the technical field of plastic machining, in particular to an injection molding pipe machining device. The device comprises a cylindrical machining table and a first outer gear, the machining table is vertically arranged, the first outer gear is coaxially and rotatably connected to the upper end face of the machining table, two horizontal parallel rotation shafts are arranged below the machining table, and are rotatably connected with the machining table, the two rotation shafts are located on the two sides of the vertical central axis of the machining table, frictionwheels are fixedly connected to the two rotation shafts, a cavity is formed in the first outer gear, and a machining mechanism is arranged in the cavity. According to the injection molding pipe machining device, injection molding pipes of different specifications can be directly machined, and according to the diameter of an injection molding pipe, the cutting depth of a cutter can be adjusted.

Owner:宁波高新区新柯保汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com