Automatic punching device of vehicle door outer pressing bar

An external beading and automatic punching technology, which is applied in the field of mechanical processing, can solve the problems of affecting the customer's sense of use, poor repeatability of the external beading, and increasing customer complaints, and achieve the effects of reducing equipment investment, low cost, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

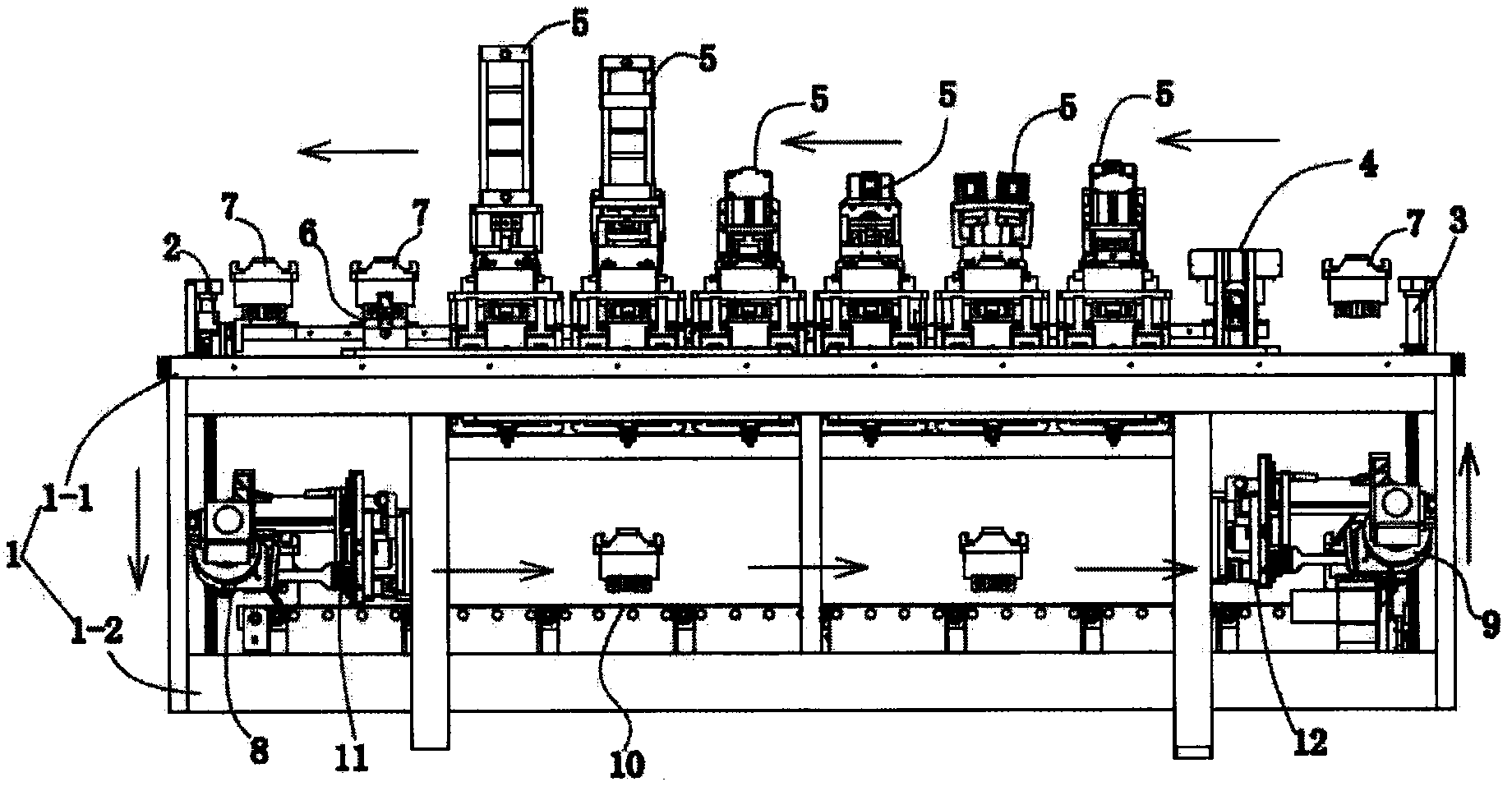

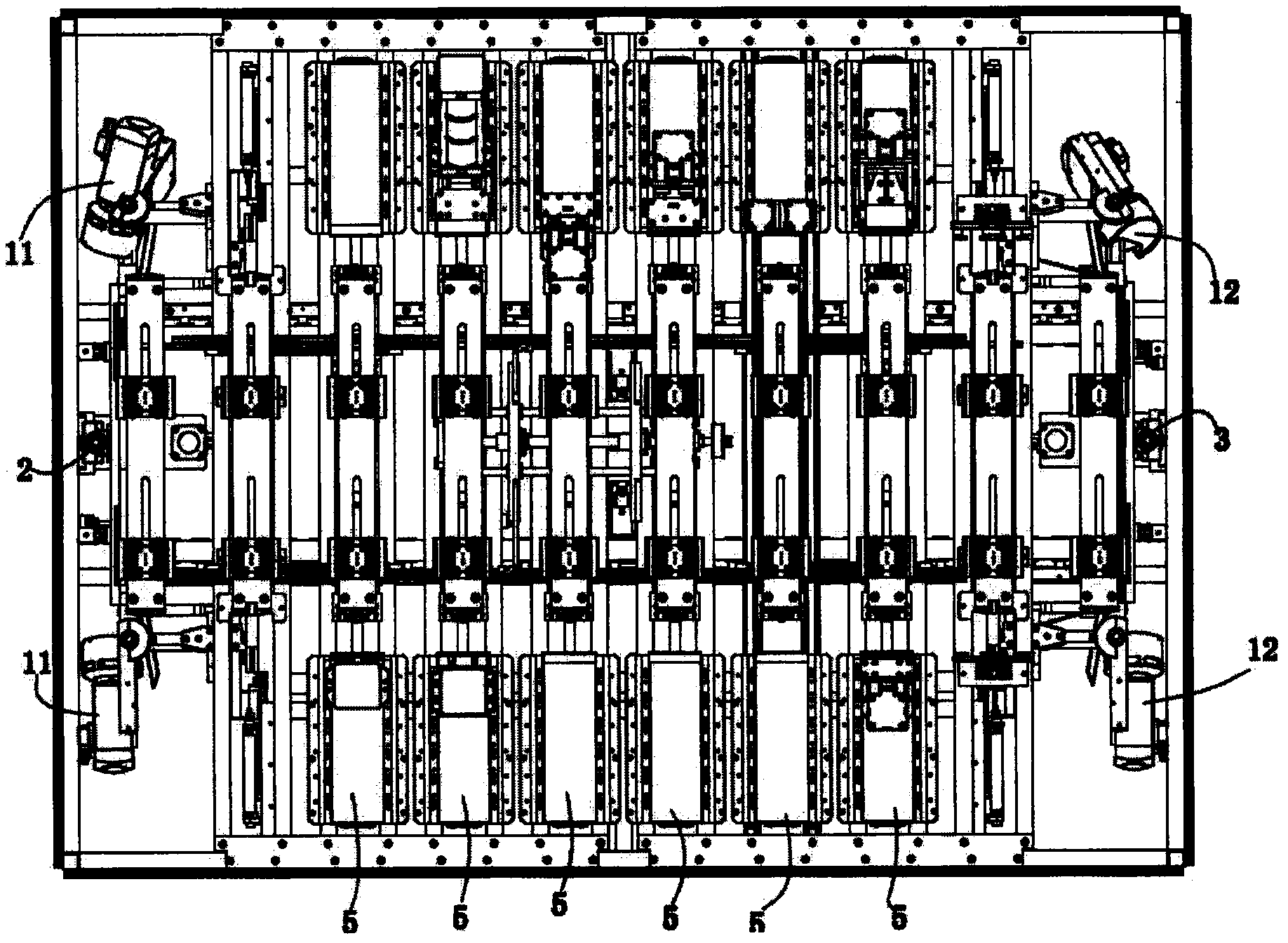

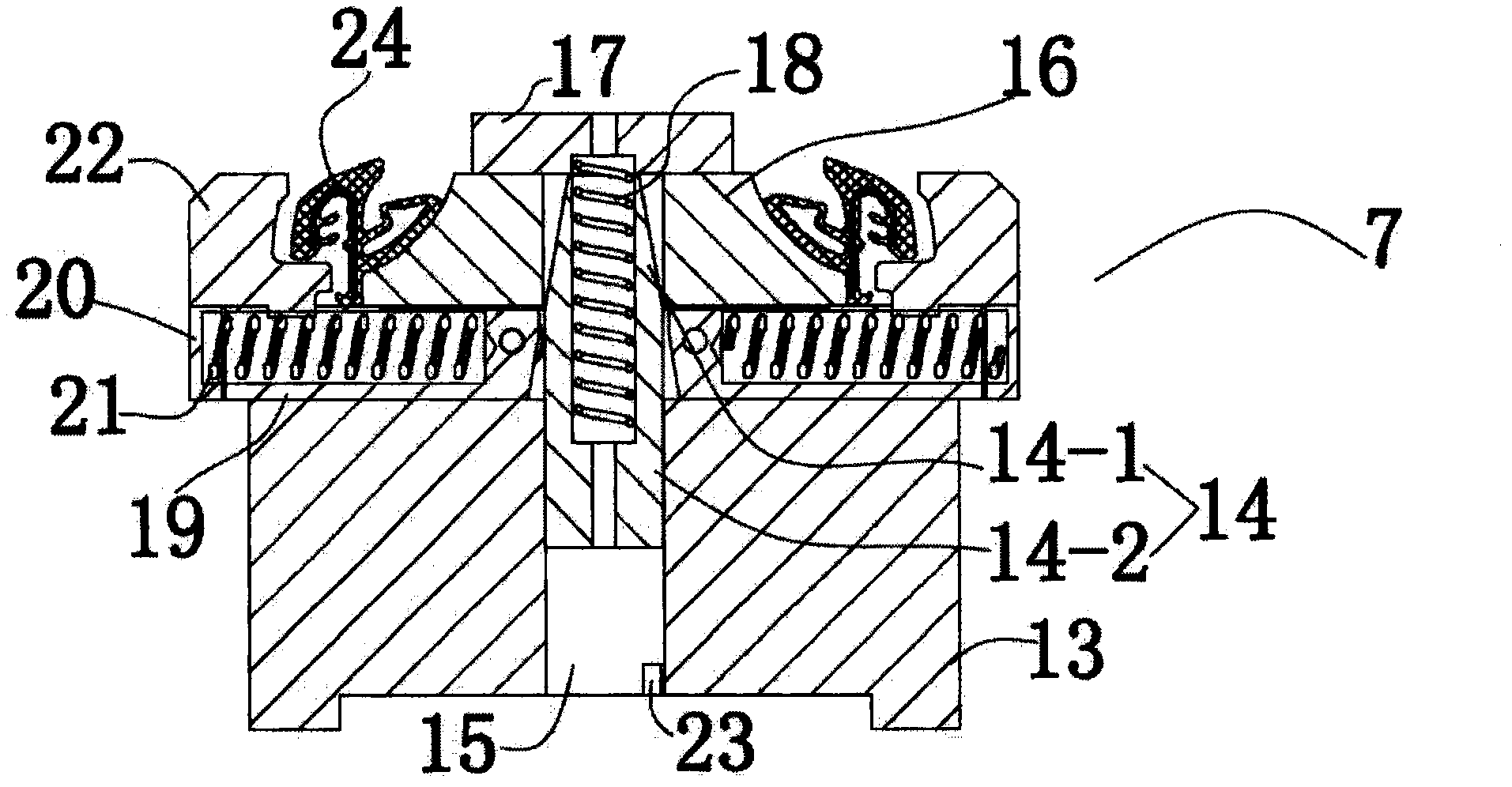

[0025] like figure 1 , 2 As shown, a kind of automatic punching device for car door beading of the present invention comprises a frame 1, and the frame includes an upper frame 1-1 and a lower frame 1-2, and one end of the upper frame 1-1 is provided with The lower station 2, the other end is provided with a rising station 3, between the rising station 3 and the falling station 2, there are successively a pick-and-place station 4, a punching die 5, and a vertical riser for driving the punching die 5 The driving mechanism of the punching die that moves back and forth between the position 3 and the lowering station 2 and the reserved station 6, the punching dies 5 have a total of twelve and are symmetrically located between the lowering station 2 and the pick-and-place material. On both sides of the connecting line of the station 4, there are two reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com