Cellulose compound water-treatment flocculant and application method thereof

A cellulose and flocculant technology, applied in the field of water treatment, can solve the problems of high price of polyacrylamide, limited use, residual toxic substances, etc., and achieve the effects of reducing the dosage of drugs, reducing treatment costs, and fast settling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

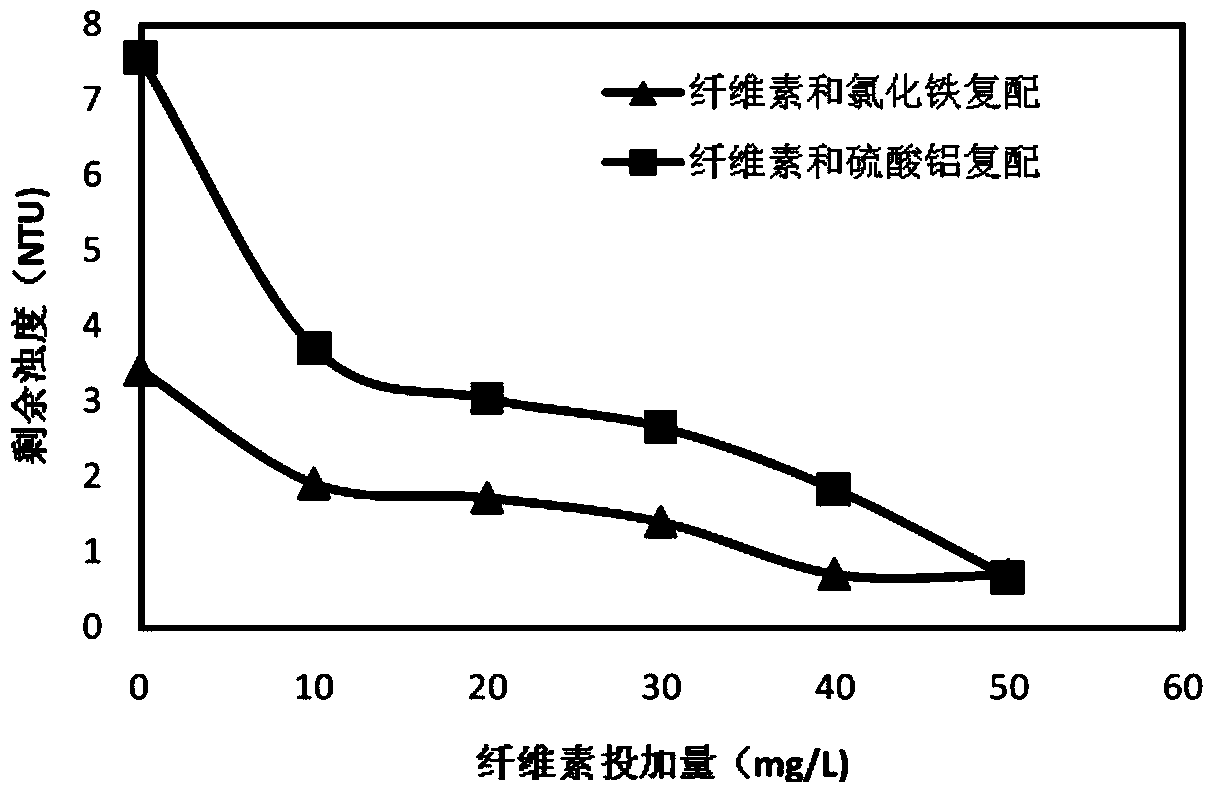

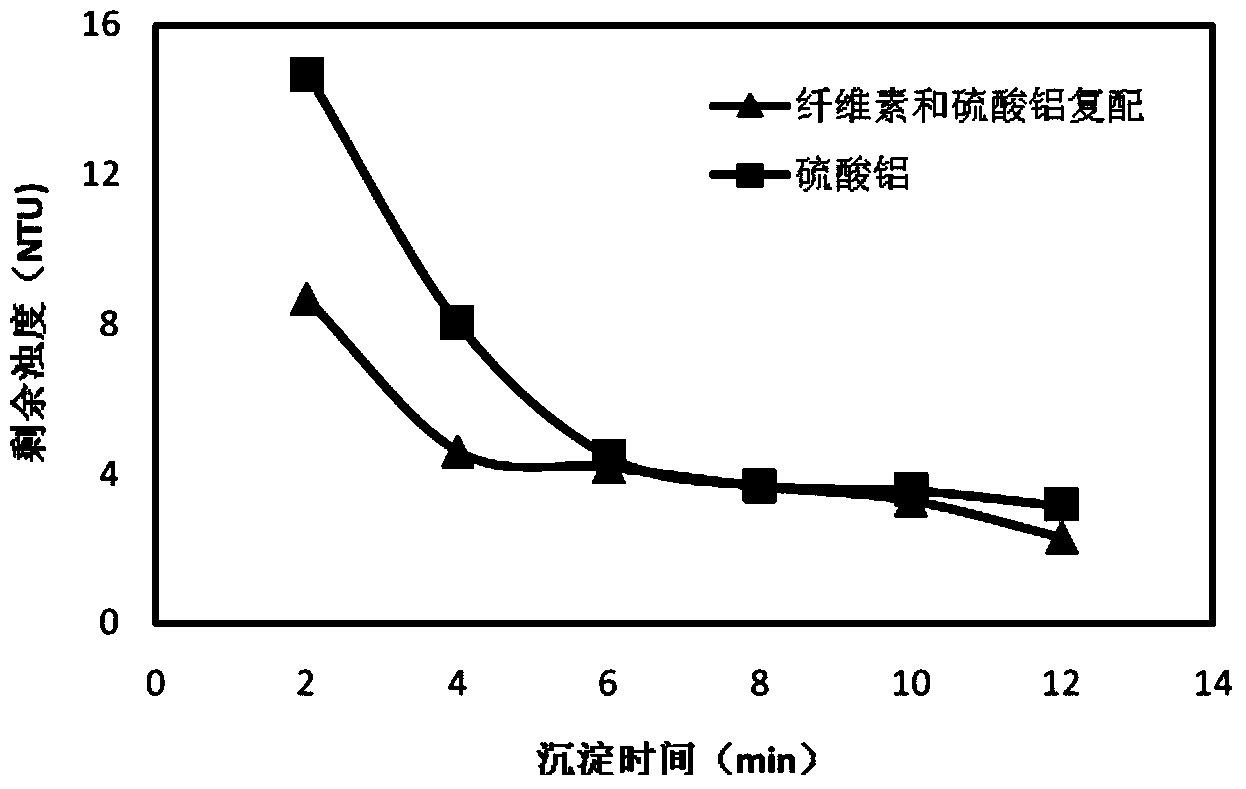

[0025] Taking lake water in the southern region as the treatment object, when the water temperature is 22°C and the turbidity is 17.63NTU, it belongs to low turbidity source water. First add aluminum sulfate to the water at a concentration of 20mg / L, stir rapidly at a speed of 300r / min for 60s, stop stirring, add cellulose at a concentration of 50mg / L, continue to stir rapidly for 60s, and neutralize at a speed of 100r / min Stir at a high speed for 5 minutes, then stir at a slow speed of 50r / min for 10 minutes, stop stirring, let it settle for 20 minutes, take the supernatant for detection, the remaining turbidity is 0.65NTU, and the remaining aluminum is 0.61mg / L. Under the same conditions, only aluminum sulfate was added, and the remaining turbidity of the effluent was 7.56 NTU, and the residual aluminum was 0.94 mg / L.

Embodiment 2

[0027] Taking lake water in the southern region as the treatment object, when the water temperature is 22°C and the turbidity is 17.63NTU, it belongs to low turbidity source water. First add ferric chloride to the water, the concentration is 20mg / L, stir rapidly at a speed of 300r / min for 60s, stop stirring, add cellulose, the concentration is 40mg / L, continue to stir rapidly for 60s, at a speed of 100r / min Stir at a medium speed for 5 minutes, then stir at a slow speed of 50r / min for 10 minutes, stop stirring, let it settle for 20 minutes, take the supernatant for testing, the remaining turbidity is 0.71NTU, and the remaining iron is 1.74mg / L. However, under the same conditions, the residual turbidity of the effluent was 3.41 NTU, and the residual iron was 2.43 mg / L.

Embodiment 3

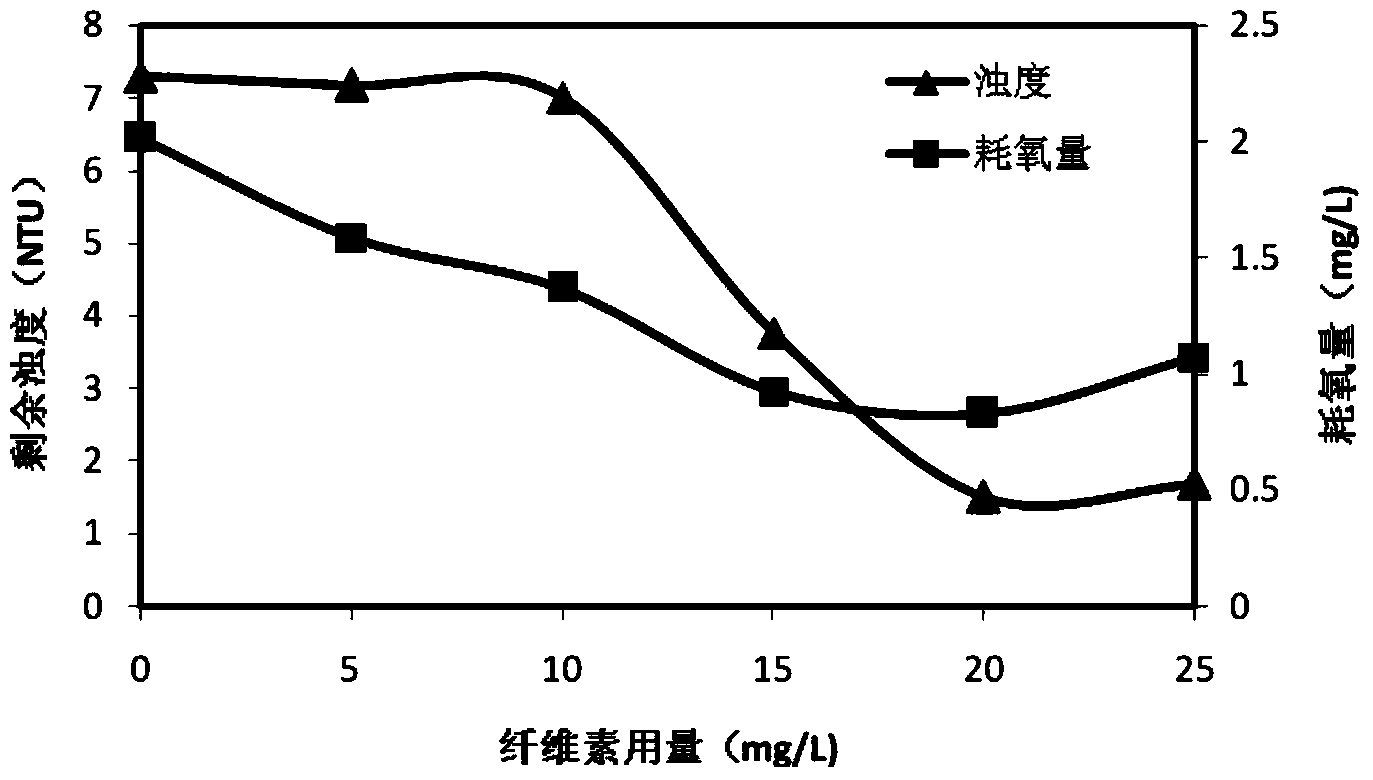

[0029] Taking lake water in the southern region as the treatment object, the raw water temperature is 19°C, the turbidity is 67.73NTU, and the oxygen consumption is 5.17mg / L. First add ferric chloride to the water with a concentration of 30mg / L, stir rapidly at a speed of 500r / min for 30s, stop stirring, add cellulose at a concentration of 15mg / L, and continue to stir rapidly at a speed of 300r / min for 30s, Stir at a medium speed at a speed of 200r / min for 5min, stir at a slow speed at a speed of 100r / min for 10min, stop stirring, let it settle for 20min, take the supernatant for testing, the remaining turbidity is 4.21NTU, and the oxygen consumption is 1.53 mg / L. However, under the same conditions, only ferric chloride was added, the residual turbidity of the effluent was 11.81NTU, and the oxygen consumption was 2.24mg / L.

[0030]In winter lake water in South China, when the water temperature is 12-14°C, the turbidity is 10-20NTU, and the oxygen consumption is 2.36-3.69mg / L,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com