Efficient organic wastewater pretreatment method

A kind of organic wastewater and pretreatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve threats to human health, pollute the environment, and have no degradation effect and other issues, to achieve the effect of reducing infrastructure investment and operating costs, high degree of automation, improving processing efficiency and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

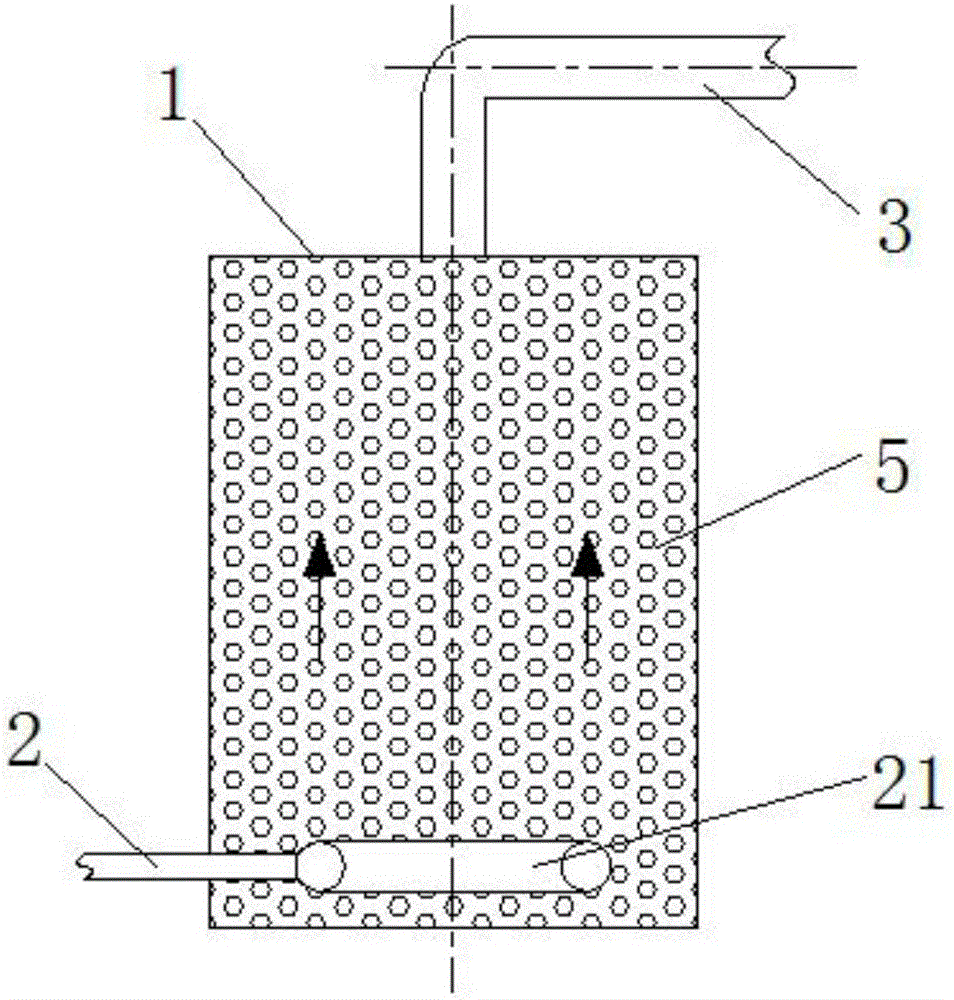

[0024] Such as figure 1 As shown, a certain high-concentration chemical wastewater (COD in the range of 10000-30000mg / L) was adjusted to pH 3-5, then hydrogen peroxide with an effective volume concentration of 0.1-5% was added, and the resulting mixed solution was fed from the inlet pipe 2 below the reactor. It is passed into the reactor and injected into the hollow shell 1 of the reactor from the water distribution pipe 21 inside the water inlet pipe 2. The shell 1 is filled with iron-carbon filler 5 accounting for 30-100% of the reactor volume, and the waste water will pass through the iron The carbon filler 5 is discharged from the outlet pipe 3 after staying for a period of time for reaction. The specific effects of the treatment are as follows:

[0025]

[0026] It can be seen from the above table that after treatment, the COD removal rate of wastewater reaches more than 40%. In the present embodiment, the acidic wastewater containing hydrogen peroxide entering the r...

Embodiment 2

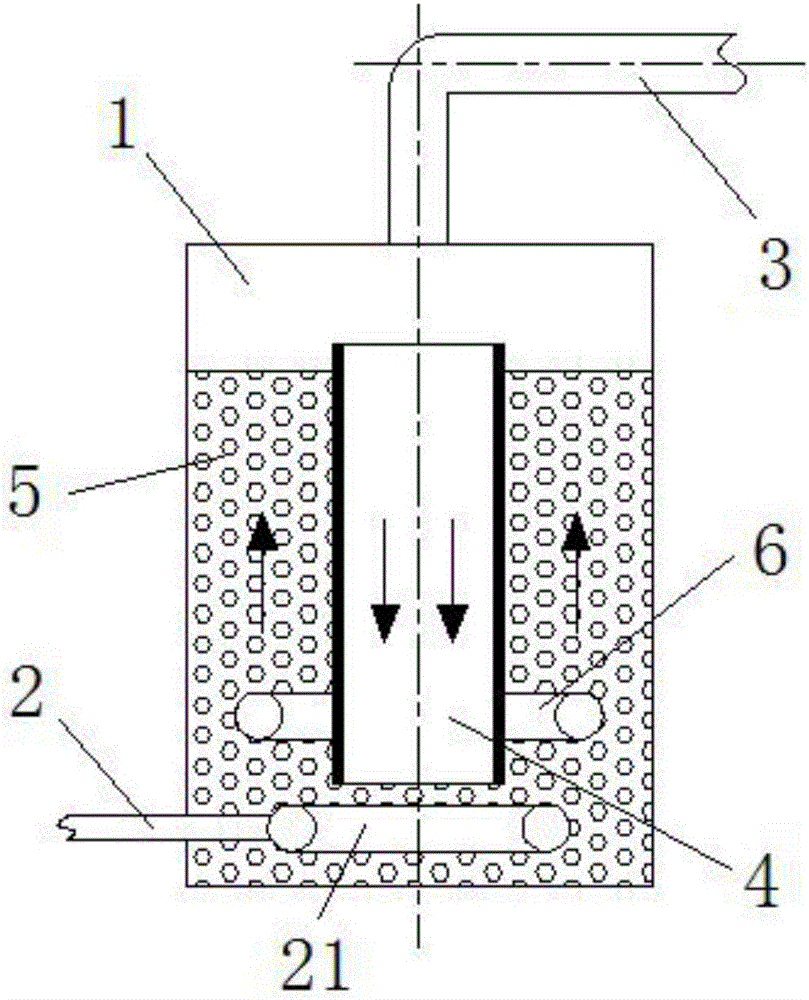

[0045] Such as figure 2 As shown, a high-concentration pharmaceutical wastewater (COD at 10,000-50,000 mg / L) was adjusted to pH 3-5, and then hydrogen peroxide solution with a volume concentration of 0.1-5% was added, and the resulting mixed solution was fed from the inlet pipe 2 below the reactor. It is injected into the shell 1 through the annular water distribution pipe 21, and the shell 1 is provided with a cylindrical guide tube 4, and the outside of the guide tube 4 is filled with iron-carbon filler 5 accounting for 30% to 90% of the reactor volume. There is also an annular aeration pipe 6 on the outside of the pipe 4. When the wastewater passes through the iron-carbon filler 5, the aeration pipe 6 continues to aerate and reflux. The reflux ratio is 0.5-2. The specific effects of the treatment are as follows:

[0046]

[0047] It can be seen from the above table that after treatment, the COD removal rate of wastewater reaches more than 50%. In this embodiment, the ...

Embodiment 3

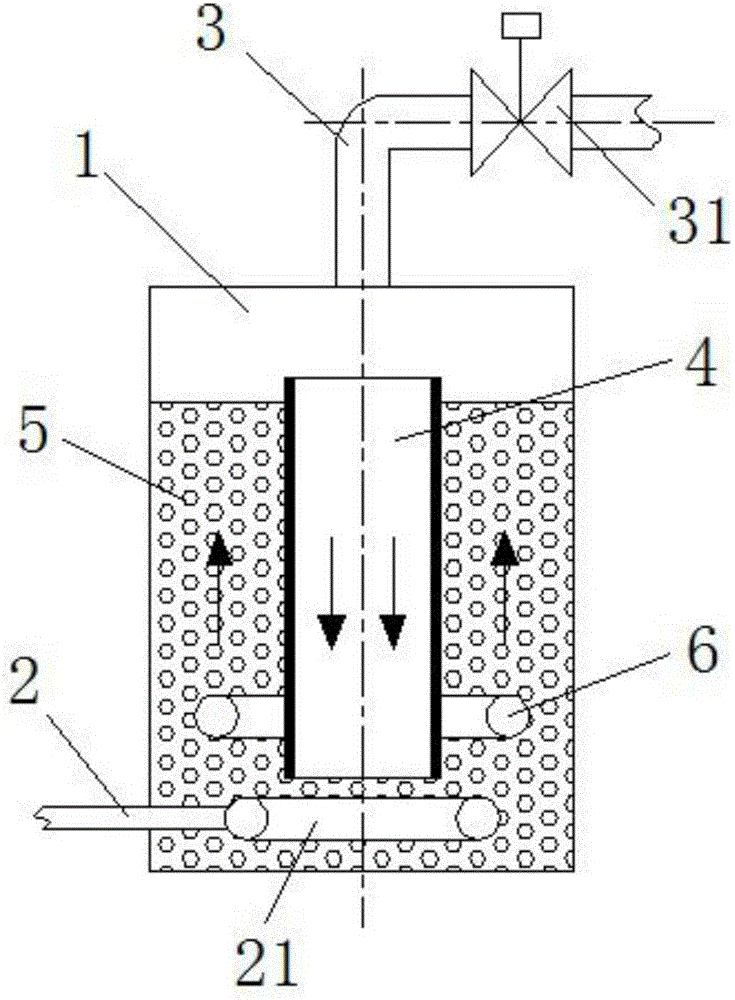

[0052] Such as image 3 As shown, a high-concentration coking wastewater (COD in the range of 10,000-40,000 mg / L) was adjusted to pH 3-5, and then hydrogen peroxide solution with a volume concentration of 0.1-5% was added, and the resulting mixed solution was fed from the inlet pipe 2 below the reactor. into the reactor, where the reactor figure 2 On the basis of the water outlet pipe 3, an outlet valve 31 (normally open or periodic switch state can be adopted), and the waste water is discharged from the outlet pipe 3 after staying for a period of time.

[0053]

[0054]

[0055] It can be seen from the above table that after treatment, the COD removal rate of the wastewater reaches more than 50%, and the switching cycle of the outlet valve 31 has a certain positive effect on the improvement of the COD removal rate. In this embodiment, the outlet valve 31 can control the reactor to treat wastewater intermittently or continuously, and the outlet valve 31 can set the switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com