Rapid deburring device for new energy automobile motor shell machining

A technology for new energy vehicles and motor casings, which is applied in electromechanical devices, grinding drive devices, metal processing equipment, etc., and can solve the problems such as the need to improve the burr removal ability of the heat sink of the motor casing, and the gaps in the heat sink, so as to save installation time , Guaranteed accuracy and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

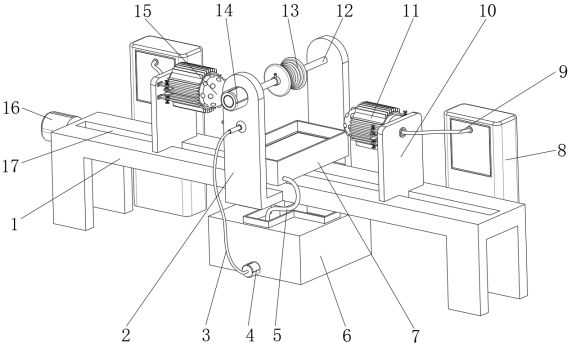

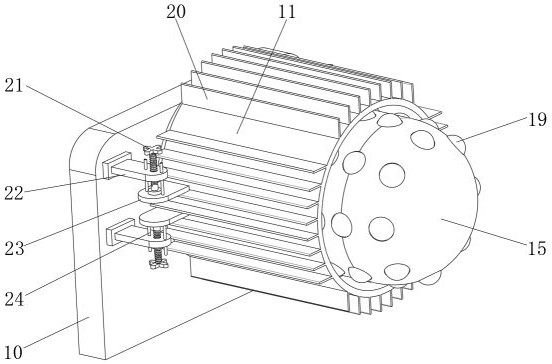

[0034] A fast deburring device for new energy vehicle motor shell processing, such as Figure 1-6As shown, it includes a workbench 1, the outer wall of the top of the workbench 1 is provided with a translation chute 17, and the outer wall of one side of the workbench 1 is fixed with a translation motor 16 by screws, and the output end of the translation motor 16 is rotationally connected through a coupling. There is a translation screw 34; the inner wall of the translation chute 17 is slidably connected with two mounting plates 10, and the mounting plates 10 are all connected to the outer wall of the translation screw 34 by threads, and the outer wall of the adjacent side of the two mounting plates 10 is fixed by screws for installation. The installation head 15 of the motor casing 11, the outer wall of the installation head 15 is embedded with an annular air bag 25, and one side of the workbench 1 is provided with an air pressure generating device 8, and the annular air bag 25...

Embodiment 2

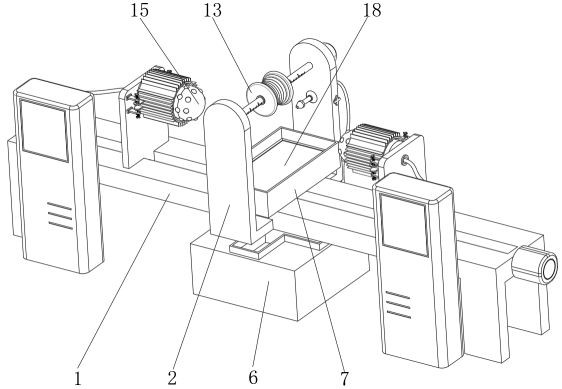

[0045] A fast deburring device for new energy vehicle motor casing processing, such as figure 1 As shown, in order to avoid the coolant pollution caused by the debris under grinding and the blockage of the nozzle 28; this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of the receiving box 7 is integrally provided with two clamping ribs 36. A sponge filter plate 18 is clamped between the two clamping ribs 36; many tests have shown that by setting the sponge filter plate 18, the burrs and debris mixed in the cooling liquid can be reliably filtered, avoiding the cooling liquid Contamination leads to clogging of the nozzle 28 and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com