Patents

Literature

37results about How to "Uniform processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant fiber-reinforced polypropylene composite material and preparation method thereof, and application of plant fiber-reinforced polypropylene composite material in preparation of automobile components

The invention discloses a plant fiber-reinforced polypropylene composite material and a preparation method thereof, and an application of the plant fiber-reinforced polypropylene composite material in preparation of automobile components. The composite material is prepared from the following raw materials in percentage by weight: 40%-77% of polypropylene, 20%-40% of a plant fiber, 1%-10% of vegetable oil, 1%-10% of a flexibilizer and 0.1%-5% of an assistant, wherein the plant fibers and the vegetable oil are from renewable biomass, and conform to the requirements of low-carbon, environment-friendly and sustained economic development. In addition, a low-density biomass material is capable of further promoting light weight of automobiles, and is of great significance in energy conservation and emission reduction. The plant fiber-reinforced polypropylene composite material for automobiles can be prepared by extrusion once, so that the method is simple, easy to operate and suitable for industrialized production.

Owner:NINGBO HOMELINK ECO ITECH CO LTD

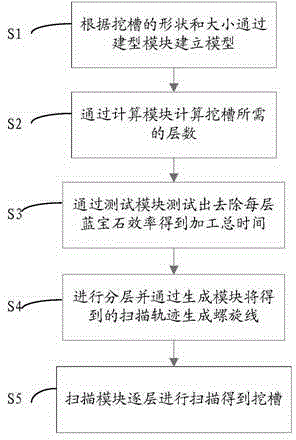

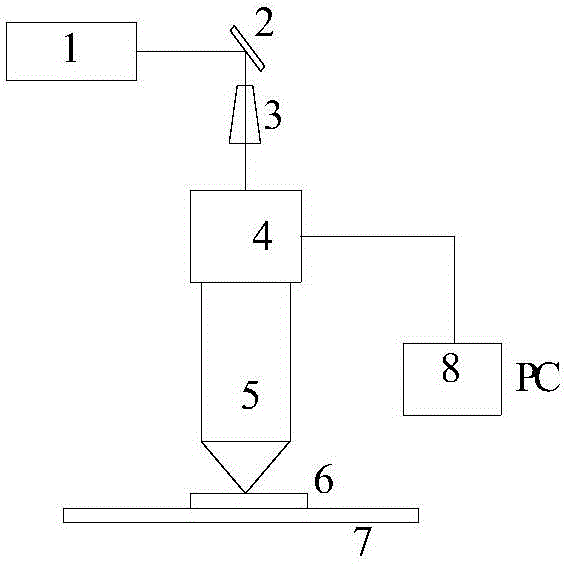

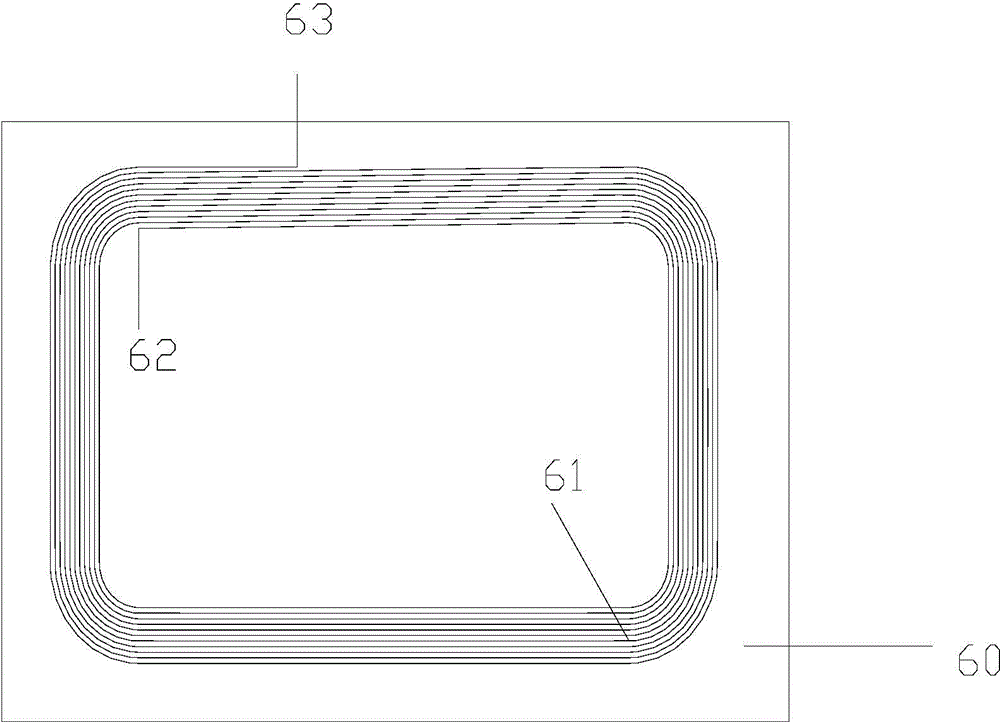

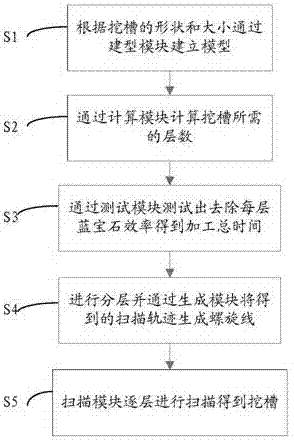

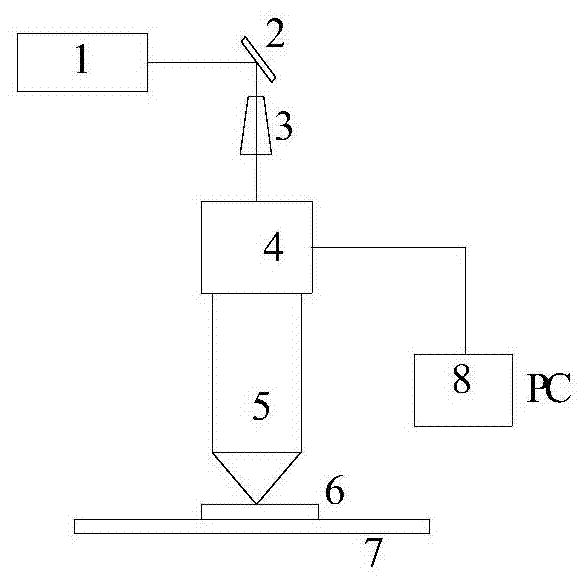

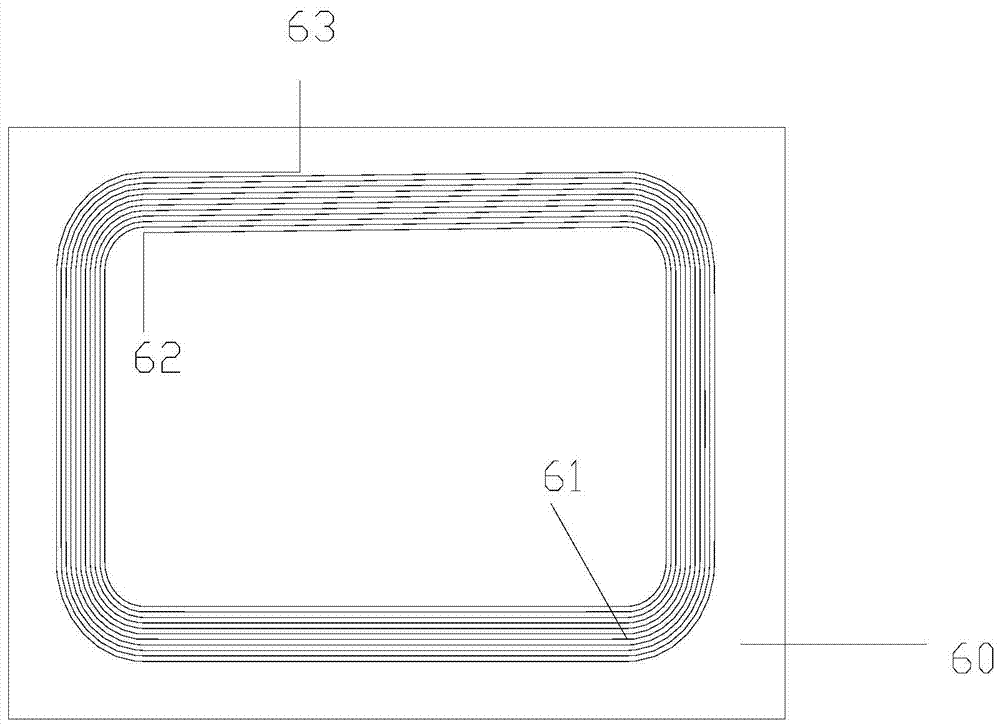

Sapphire laser grooving device and grooving method thereof

ActiveCN105458515ASimple structureFast processingLaser beam welding apparatusGalvanometerLaser scanning

The invention relates to the technical field of laser machining and discloses a sapphire laser grooving device and a grooving method thereof. The sapphire laser grooving device comprises a laser device, a reflecting mirror, a beam expanding lens, a galvanometer, a focusing mirror, a platform and a computer. A to-be-machined sapphire sample is arranged on the platform; the reflecting mirror, the beam expanding lens, the galvanometer and the focusing mirror are arranged above the to-be-machined sapphire sample in sequence from top to bottom; the center of the reflecting mirror, the center of the beam expanding lens, the center of the galvanometer, the center of the focusing mirror and the center of the to-be-machined sapphire sample are located on the same straight line; the laser device is located on one side of the reflecting mirror; the computer is connected with the galvanometer. Compared with a traditional filling type scanning mode, the sapphire laser grooving device and the grooving method thereof have the advantages that a continuous curve mode is adopted, so that the laser grooving effect of machined sapphires is good, the edge breakage quantity is small and cross sections are smooth; besides, scanning is performed according to a spiral line formed by each layer of scanning track so that the problem of poor machining of laser joints during conventional laser scanning can be solved through the scanning tracks, the skipping problem caused by filling type scanning can be avoided, and the machining accuracy can be improved.

Owner:HANS LASER TECH IND GRP CO LTD

Machining method of steam seal measuring snap-gauge

ActiveCN105563040AGuaranteed dimensional accuracyGuaranteed size requirementsMechanical measuring arrangementsMachiningEngineering

The invention relates to a machining method of a steam seal measuring snap-gauge, and solves the problems that in the prior art, a steam seal measuring snap-gauge is high in manufacturing cost, and long in machining period. The machining method comprises the following specific steps: 1, preparing a blank; 2, roughly machining the side surfaces of the blank; 3, machining a circular arc on the upper surface of the blank; 4, conducting clean-up processing; 5, polishing; 6, drilling threaded holes; 7, finely machining the side walls of a straight slot; 8, roughly machining a measuring tooth; 9, chamfering; 10, conducting heat treatment on the measuring tooth; 11, polishing the measuring tooth; 1, finely machining the measuring tooth; 13, finely grinding the measuring tooth; 14, finely grinding the slope of the measuring tooth; and 15, chamfering and finely grinding the measuring tooth. The machining method is used in the machining field of steam seal measuring snap-gauges.

Owner:HARBIN TURBINE

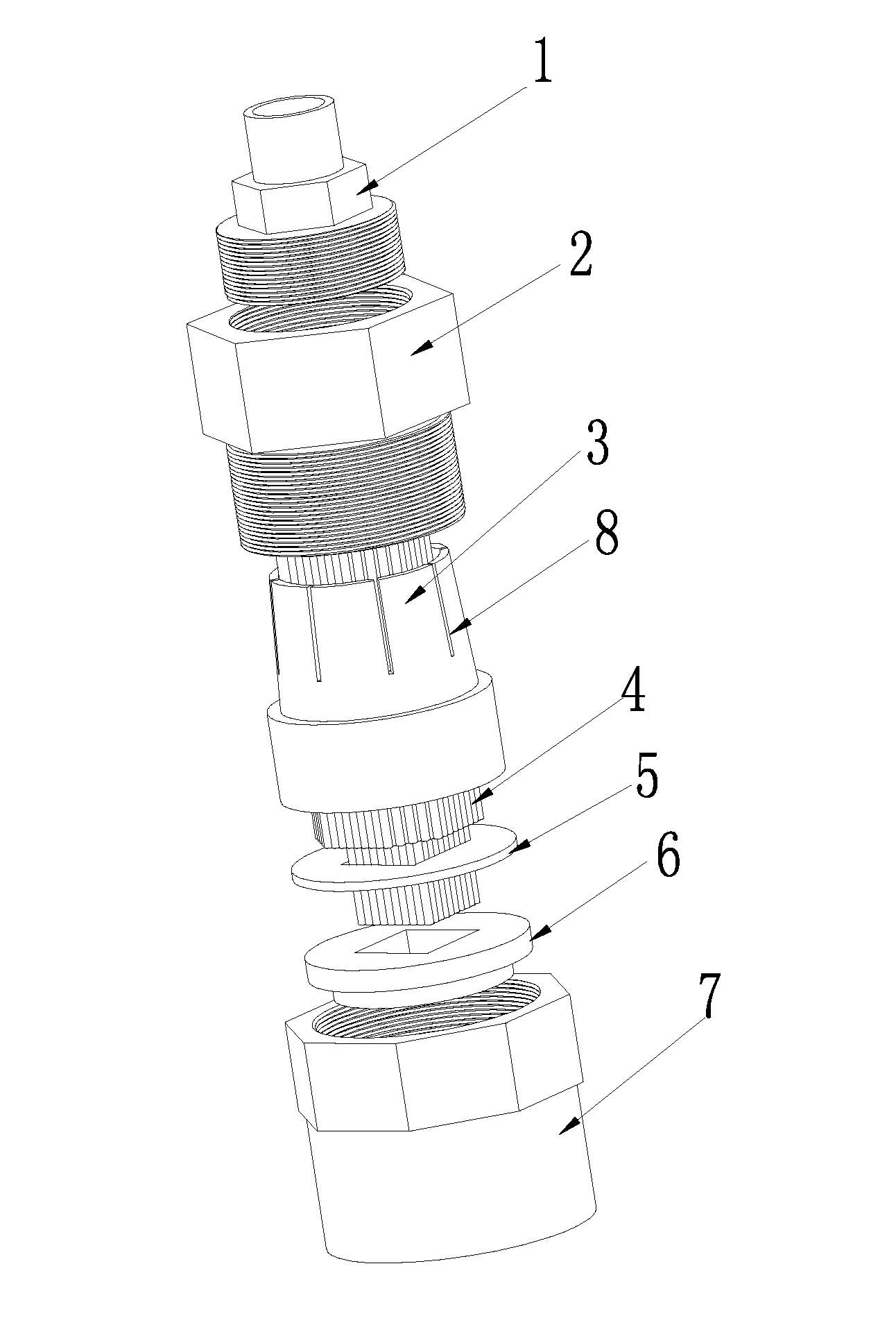

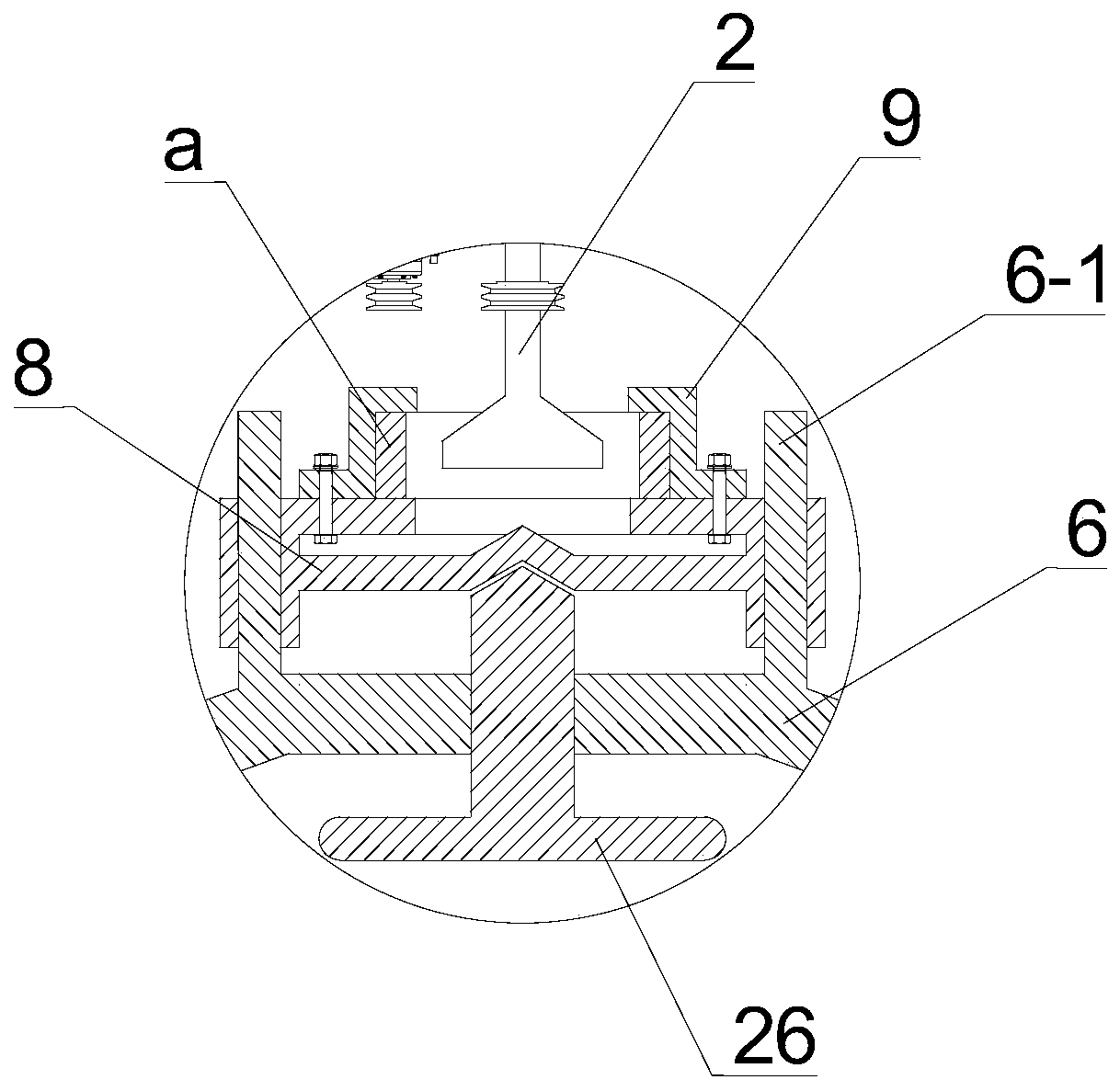

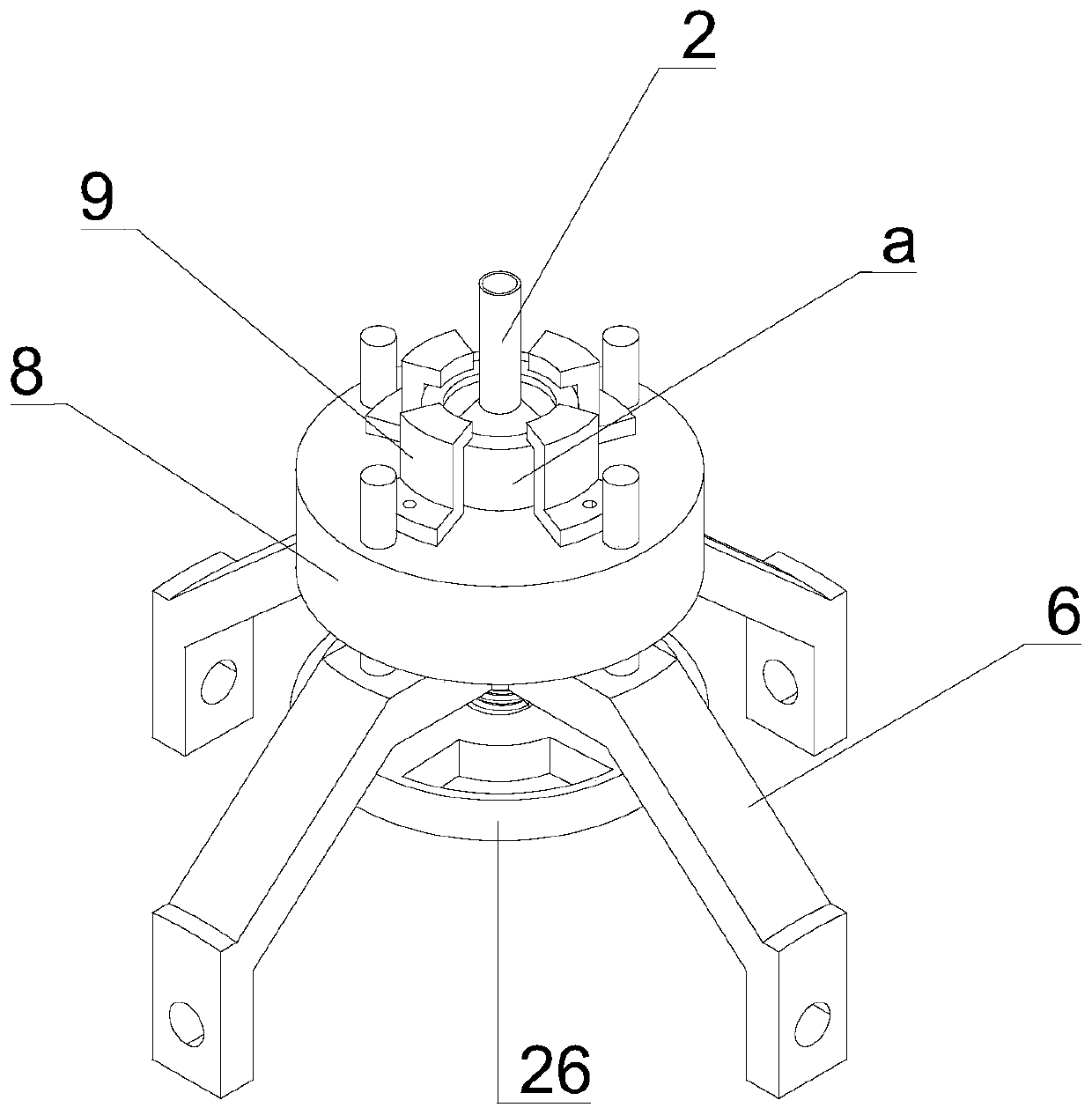

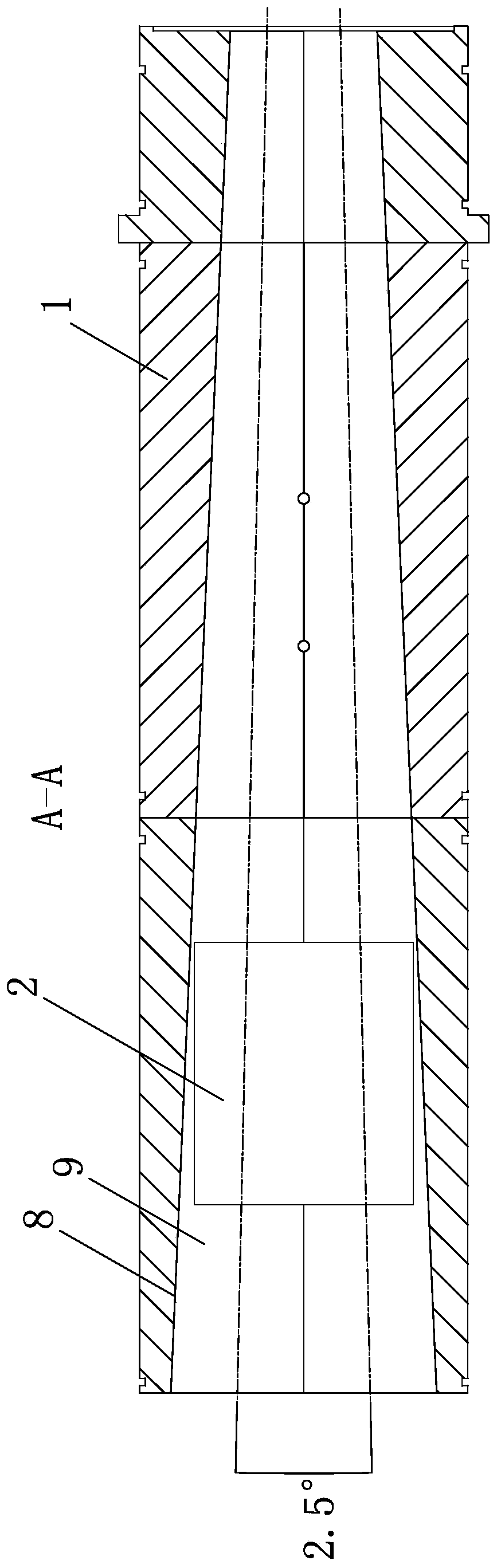

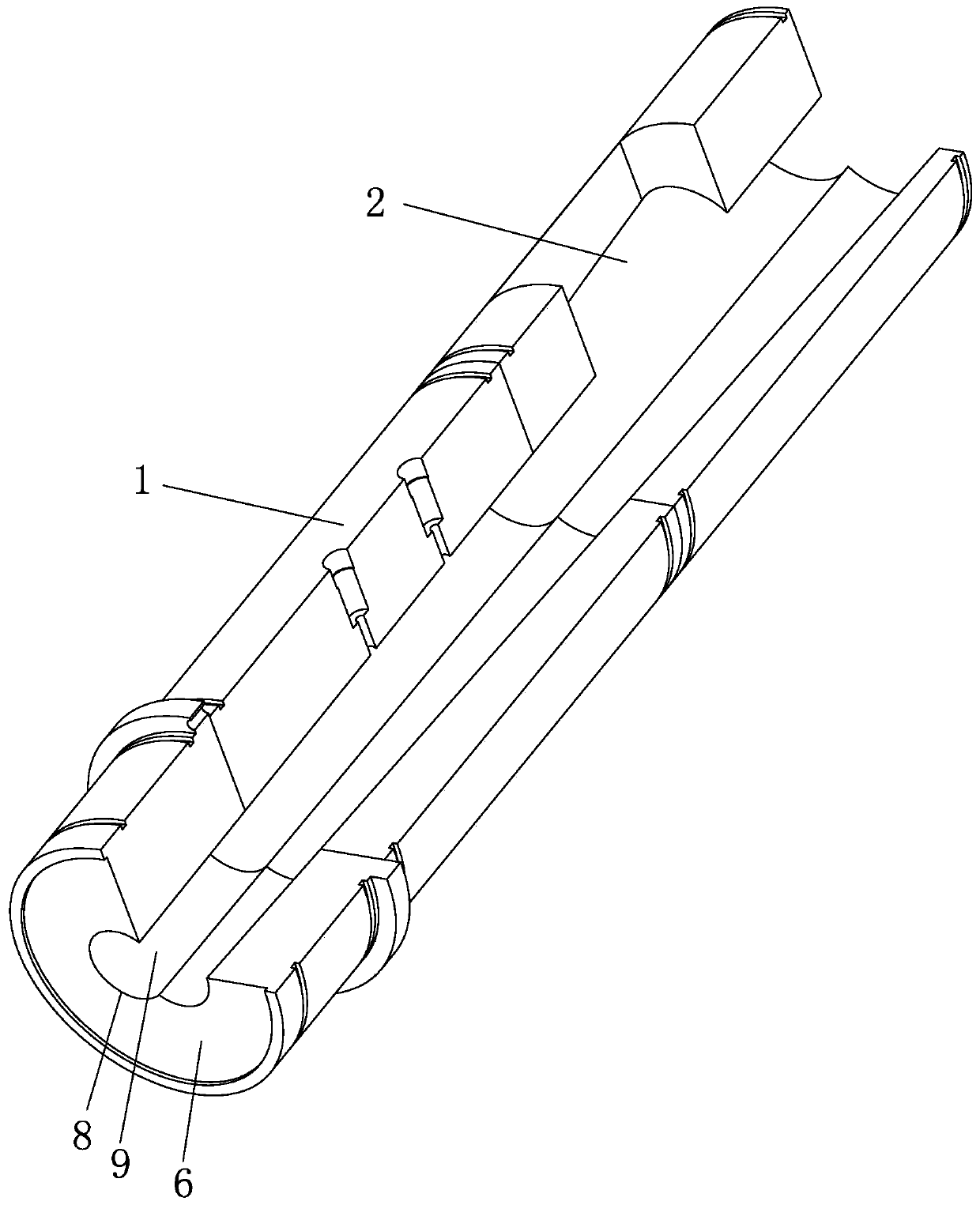

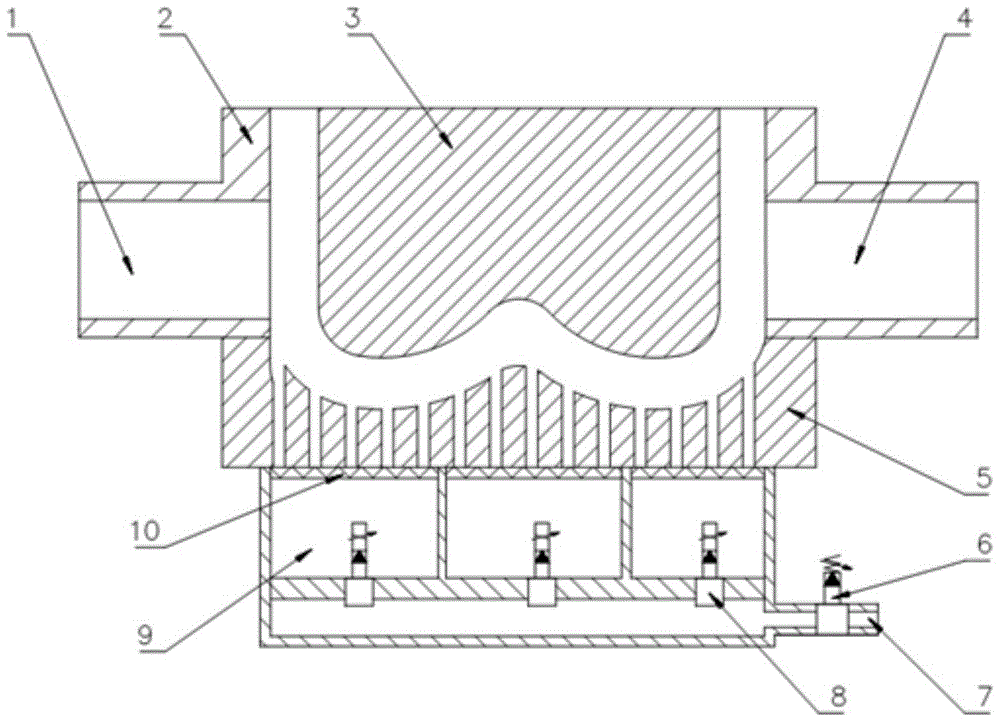

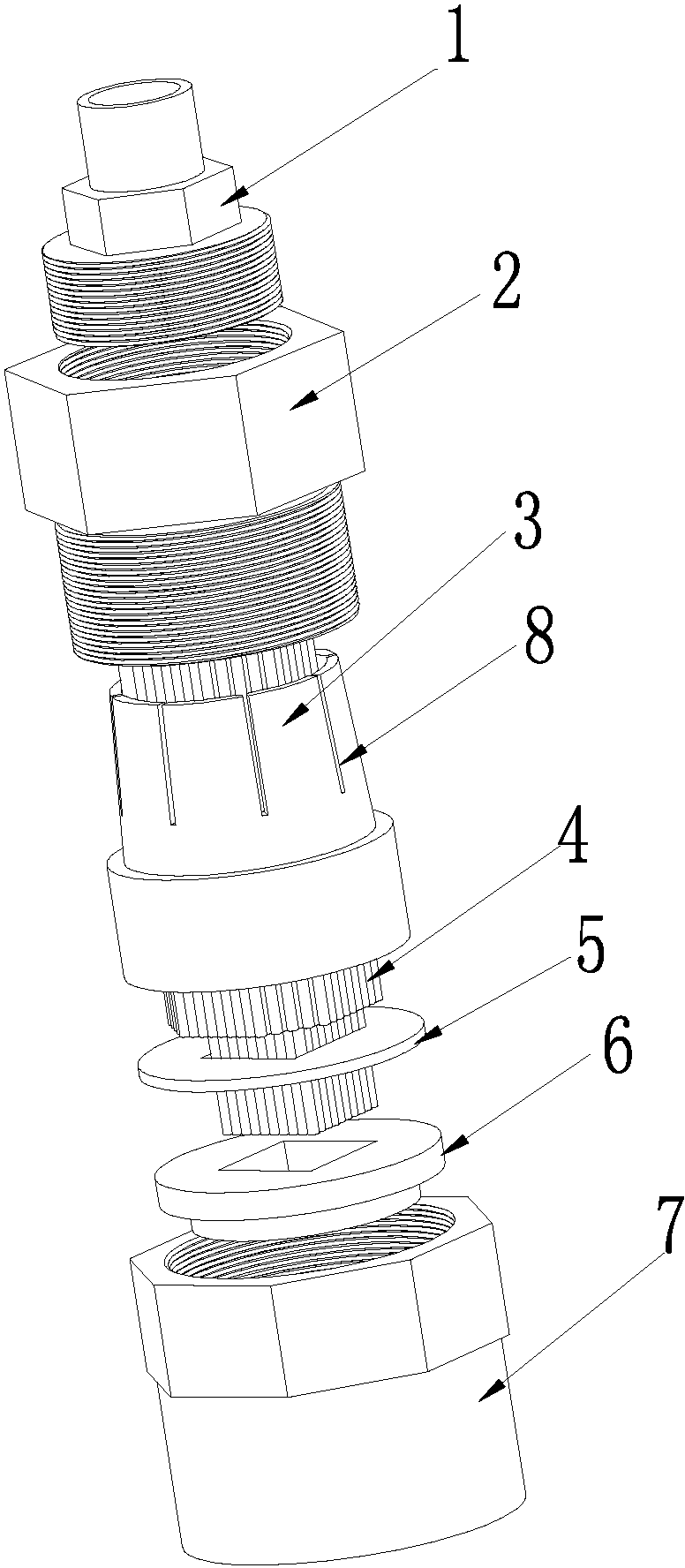

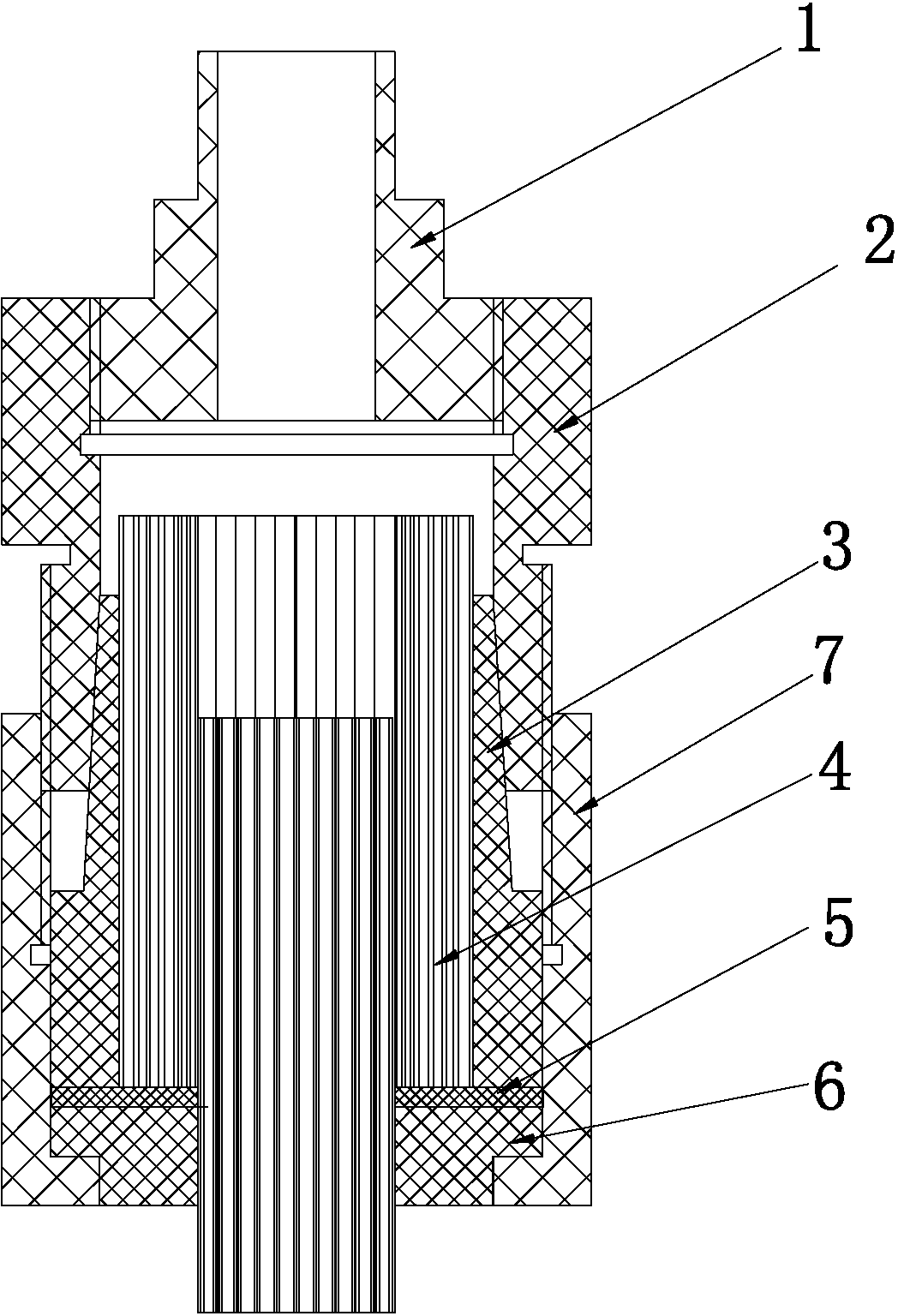

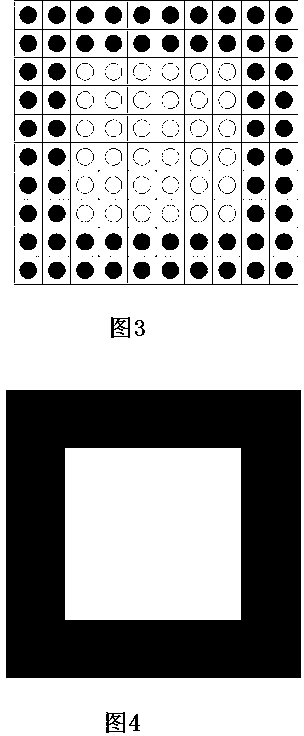

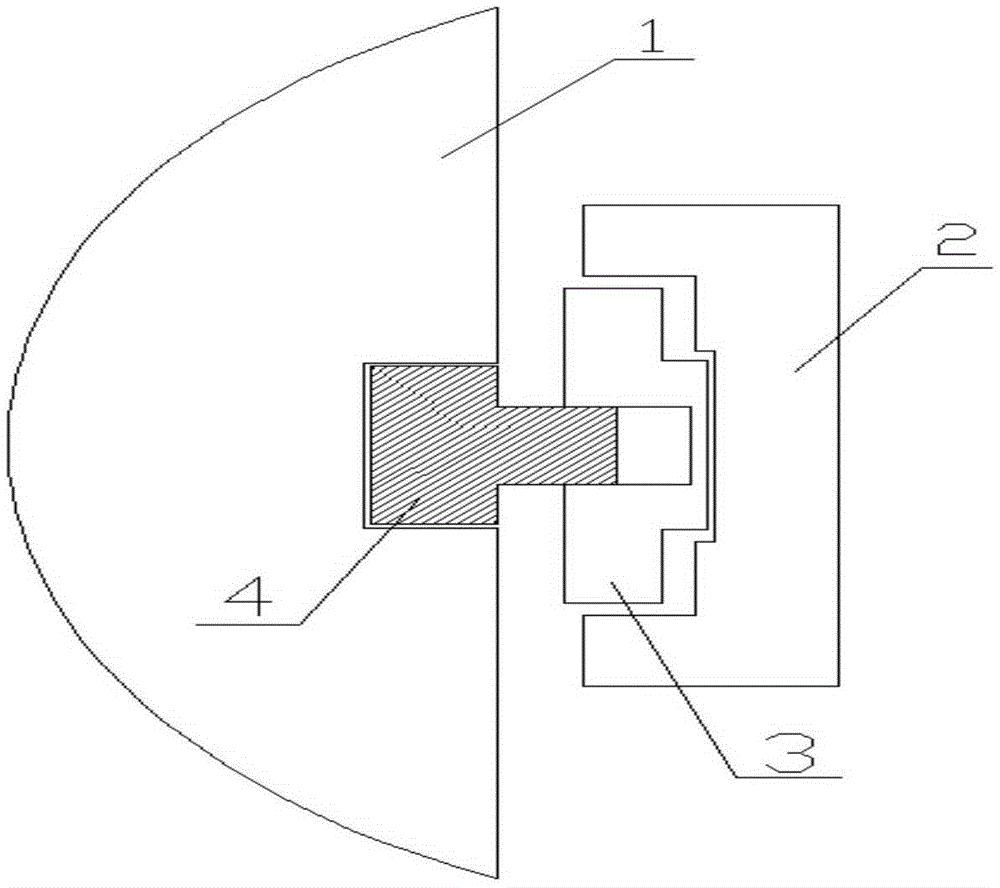

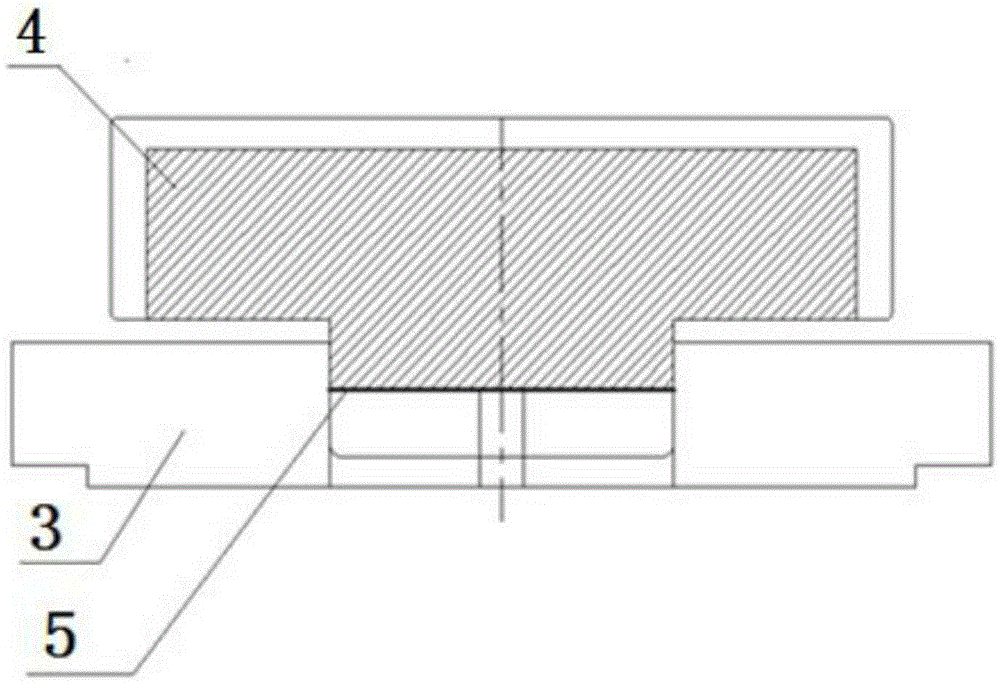

Array electrode cavity for jet electrodeposition

The invention provides an array electrode cavity for jet electrodeposition. The electrode cavity is characterized by comprising a top cover, a cavity, a sleeve, an array electrode, a sealing ring, a rigid retainer ring and a tightening nut, wherein the top cover is in threaded connection with the cavity; the sleeve clamps the array electrode; the elastic sealing ring and the retainer ring are sequentially connected on the array electrode in series; the cavity and the nut are in threaded connection; and the top of the sleeve is tightened by screwing the cavity and the nut, so that the array electrode is clamped, the elastic sealing ring and the retainer ring are pressed tightly, and the shape of the extending section of the array electrode is limited by the retainer ring. According to the array electrode cavity, an array electrode nozzle with an arbitrary section shape and profile can be formed at the bottom of the electrode cavity, so that uniform electric field and flow field in jet electrodeposition processing can be acquired, the current density of electric deposition is improved, local concentration of metal ions is improved, oxidation in electrodeposition is avoided, and efficiency and quality of electrodeposition are finally improved. Processing of electrodeposition parts with special structures can be realized by designing array electrode cavities with different shapes and controlling conduction of the electrode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

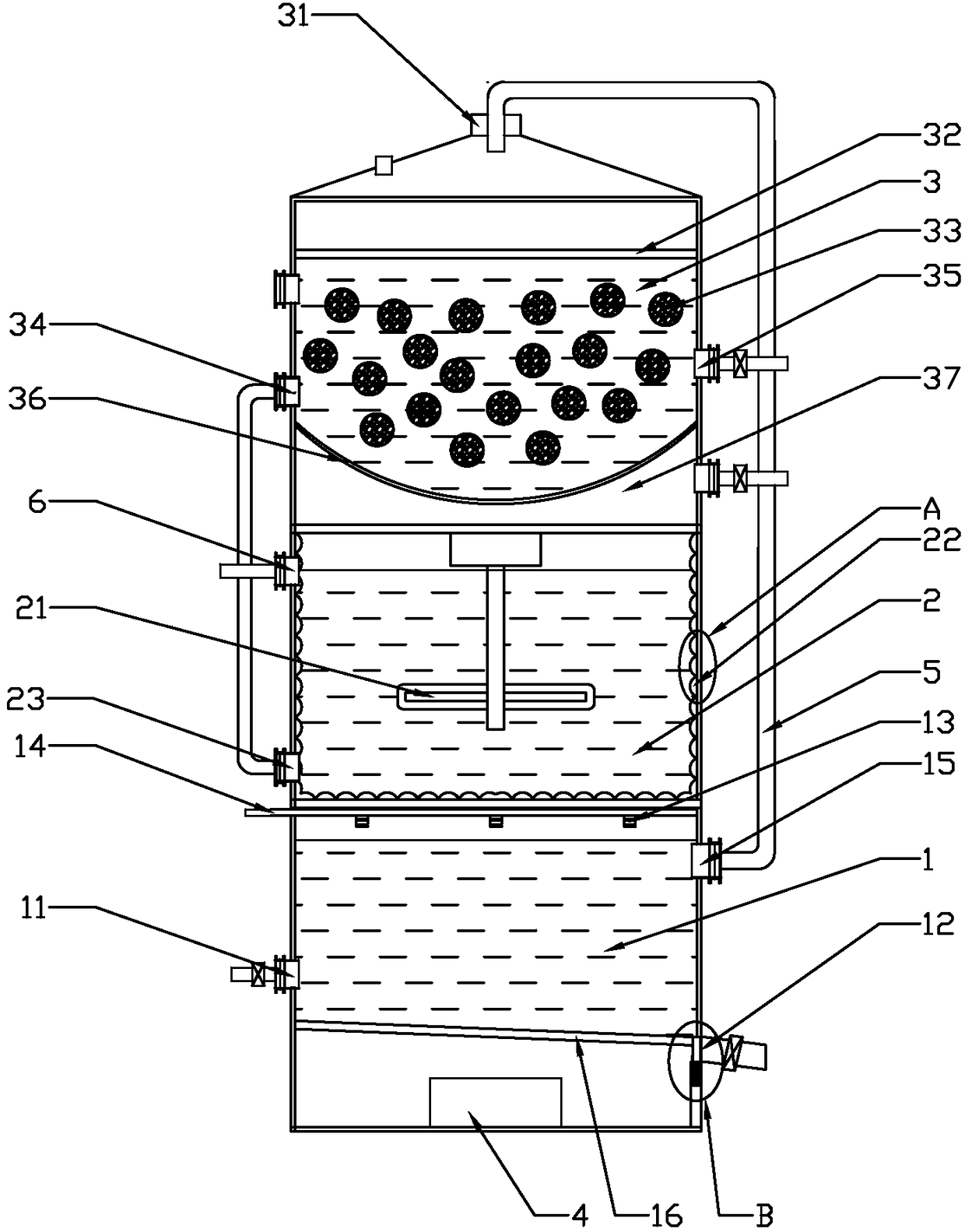

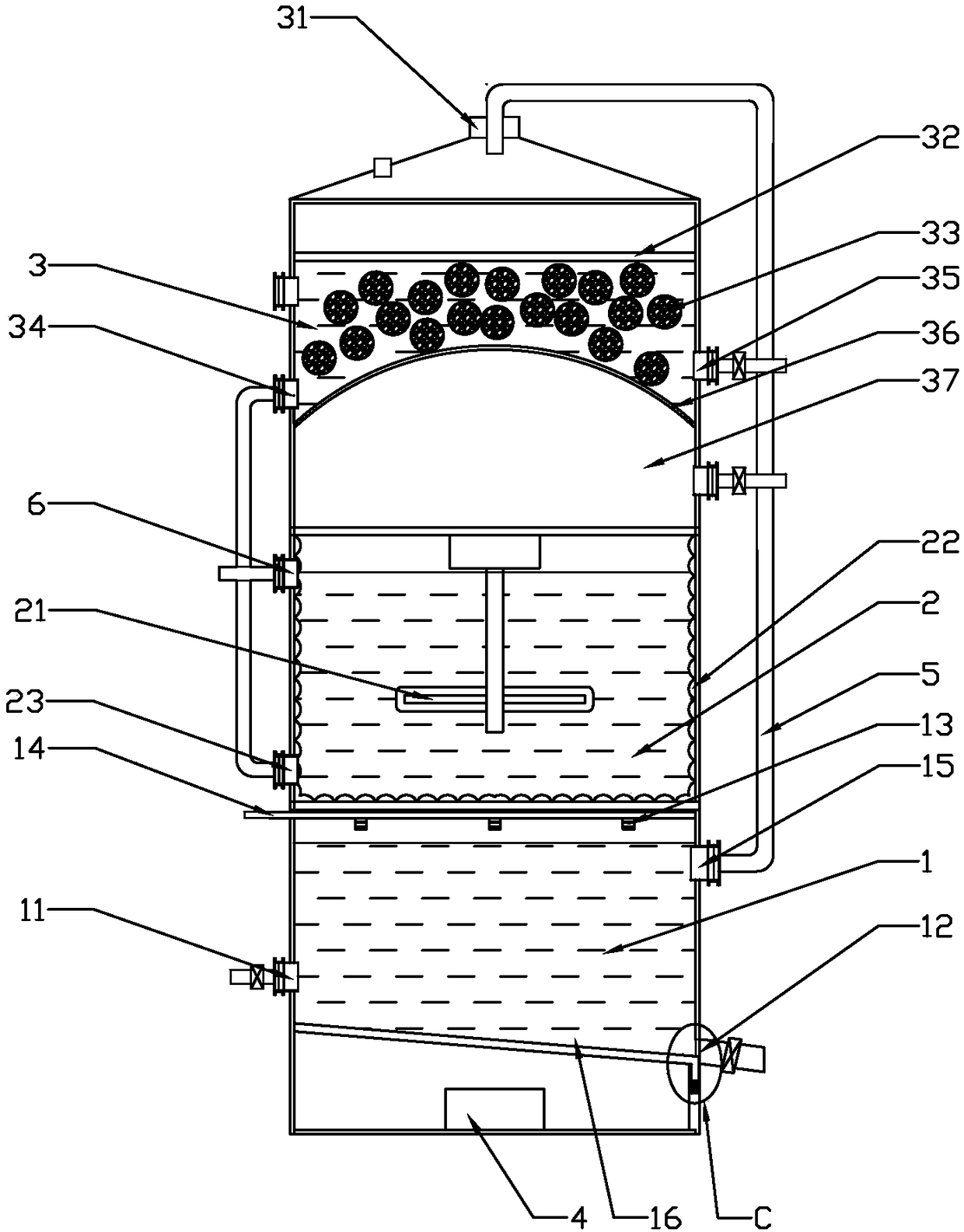

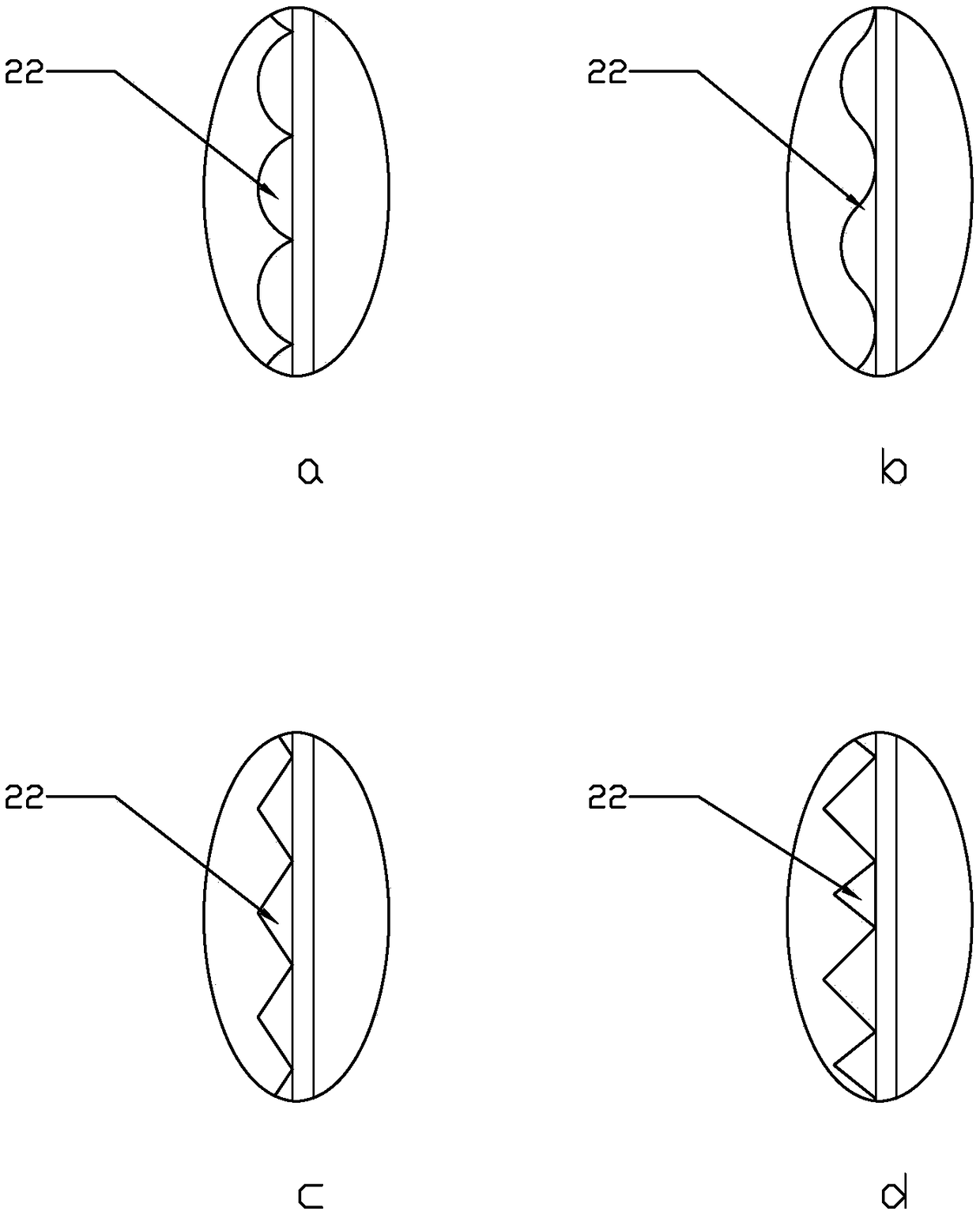

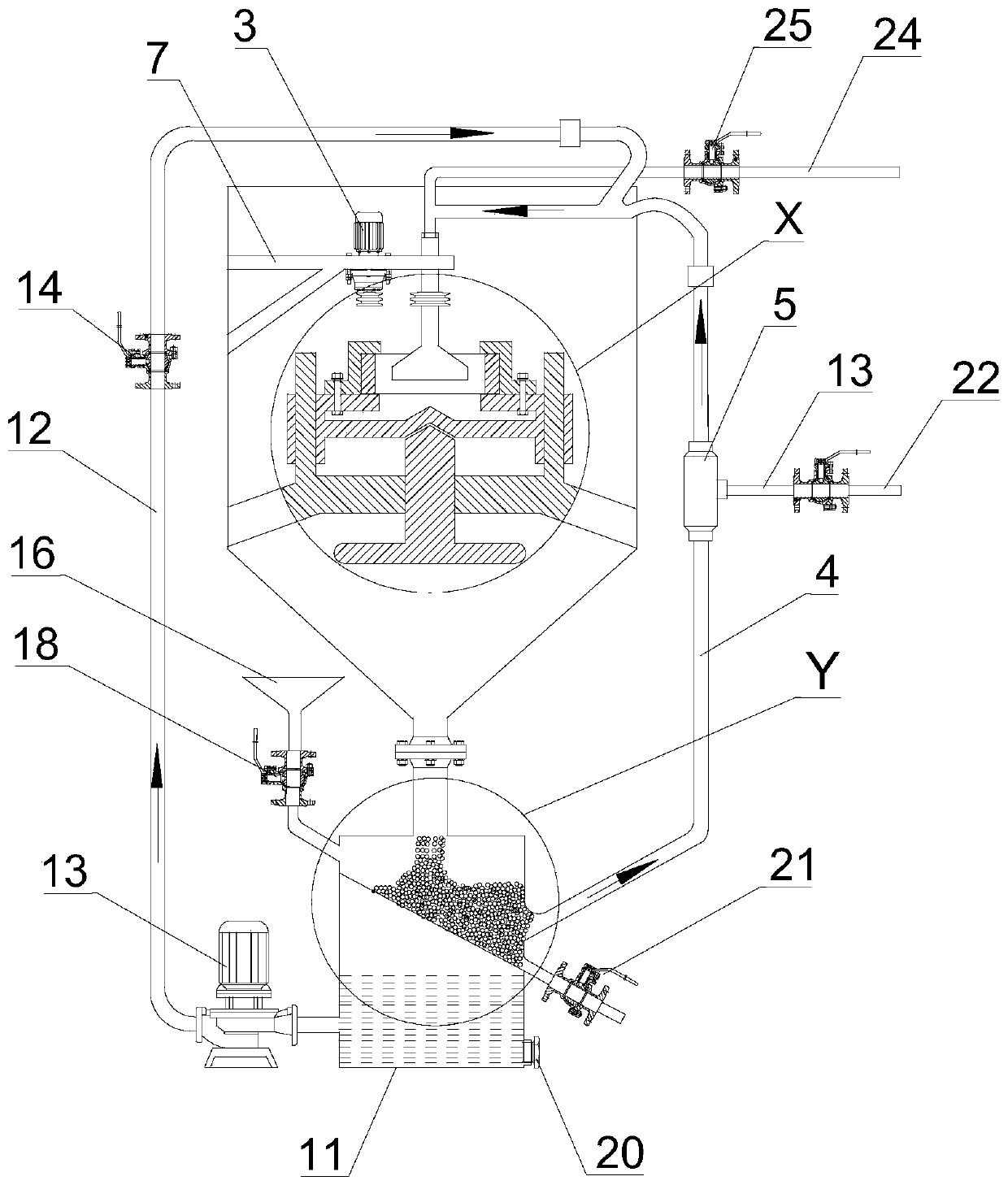

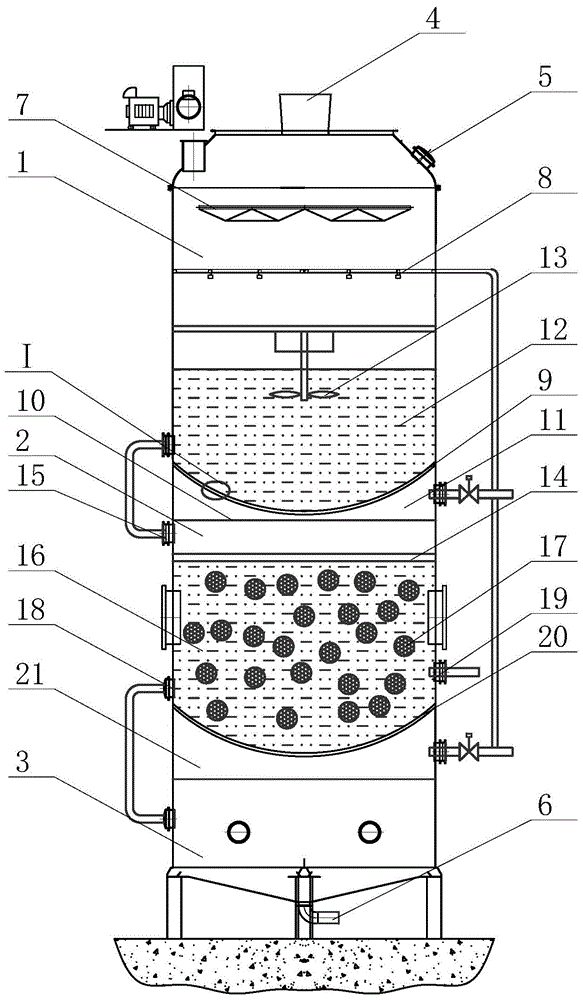

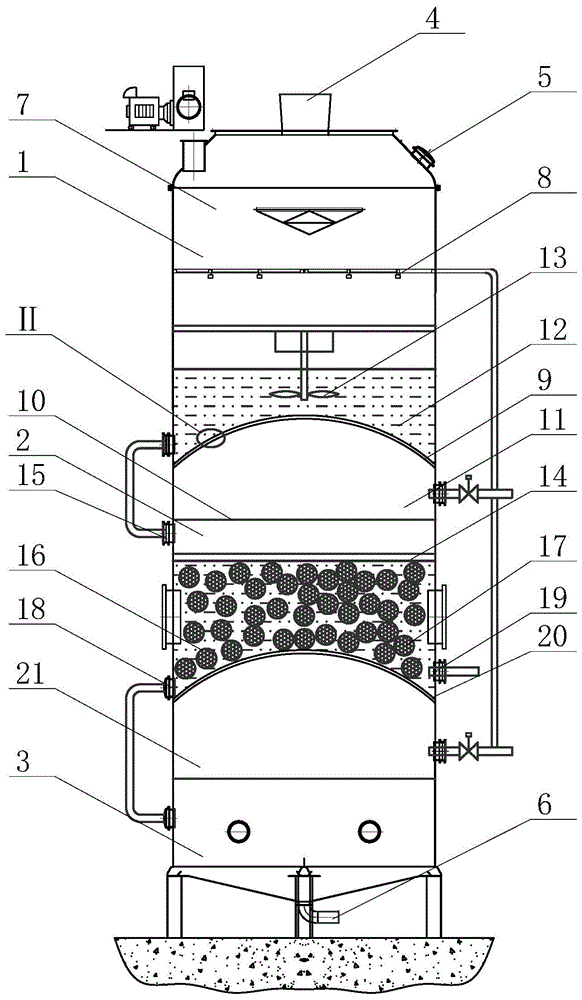

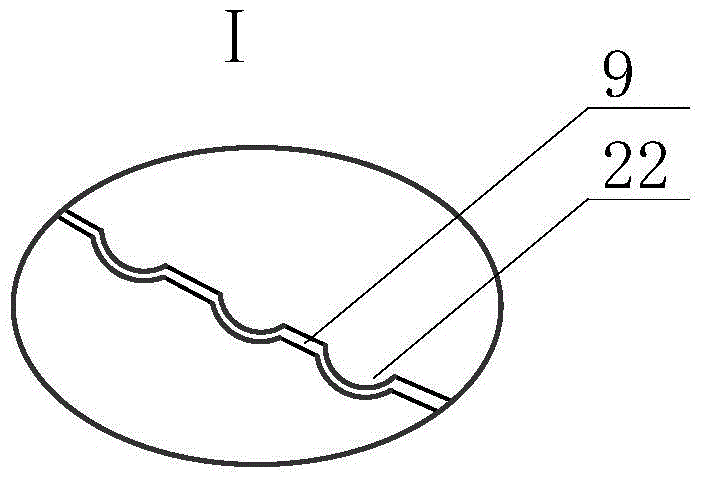

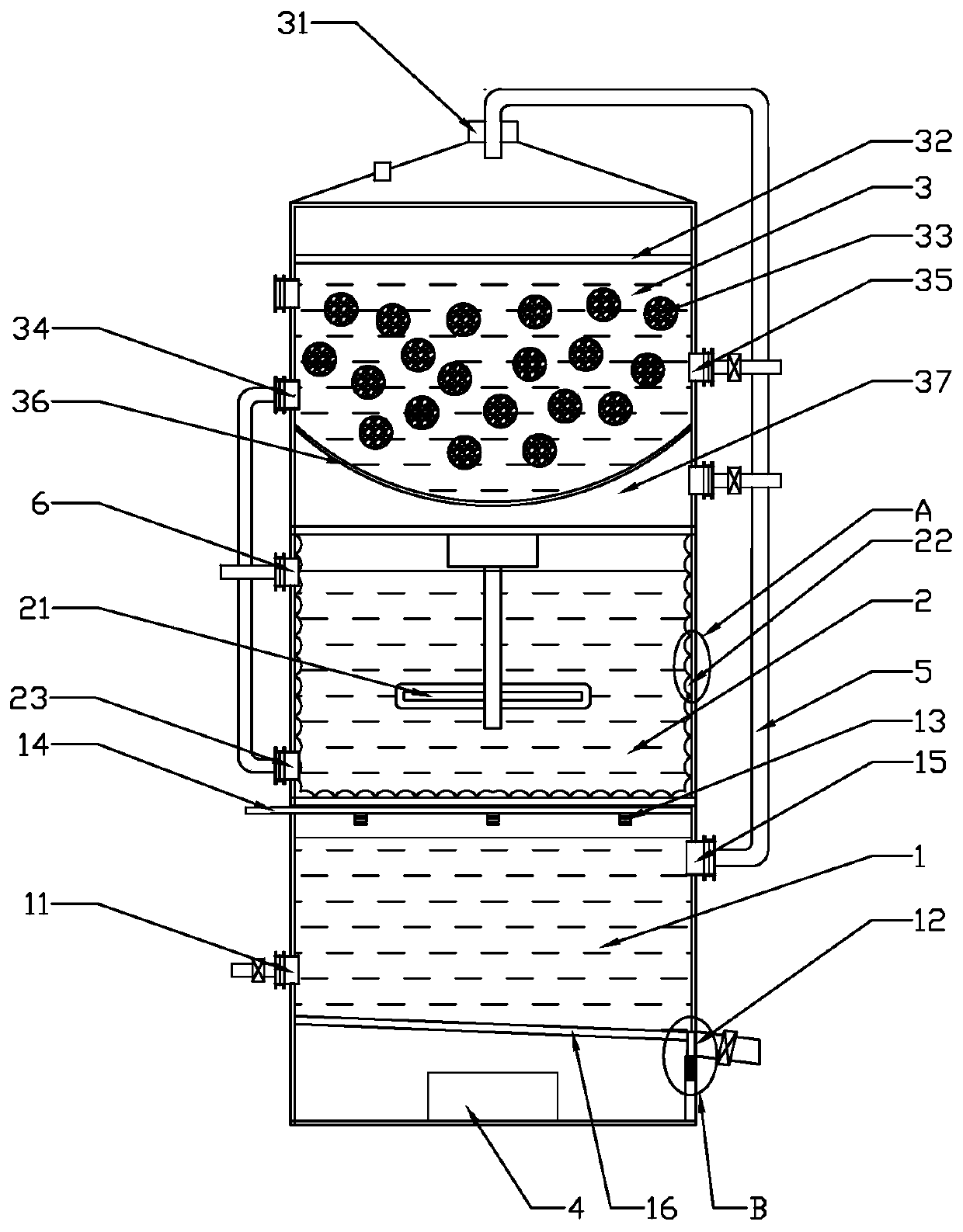

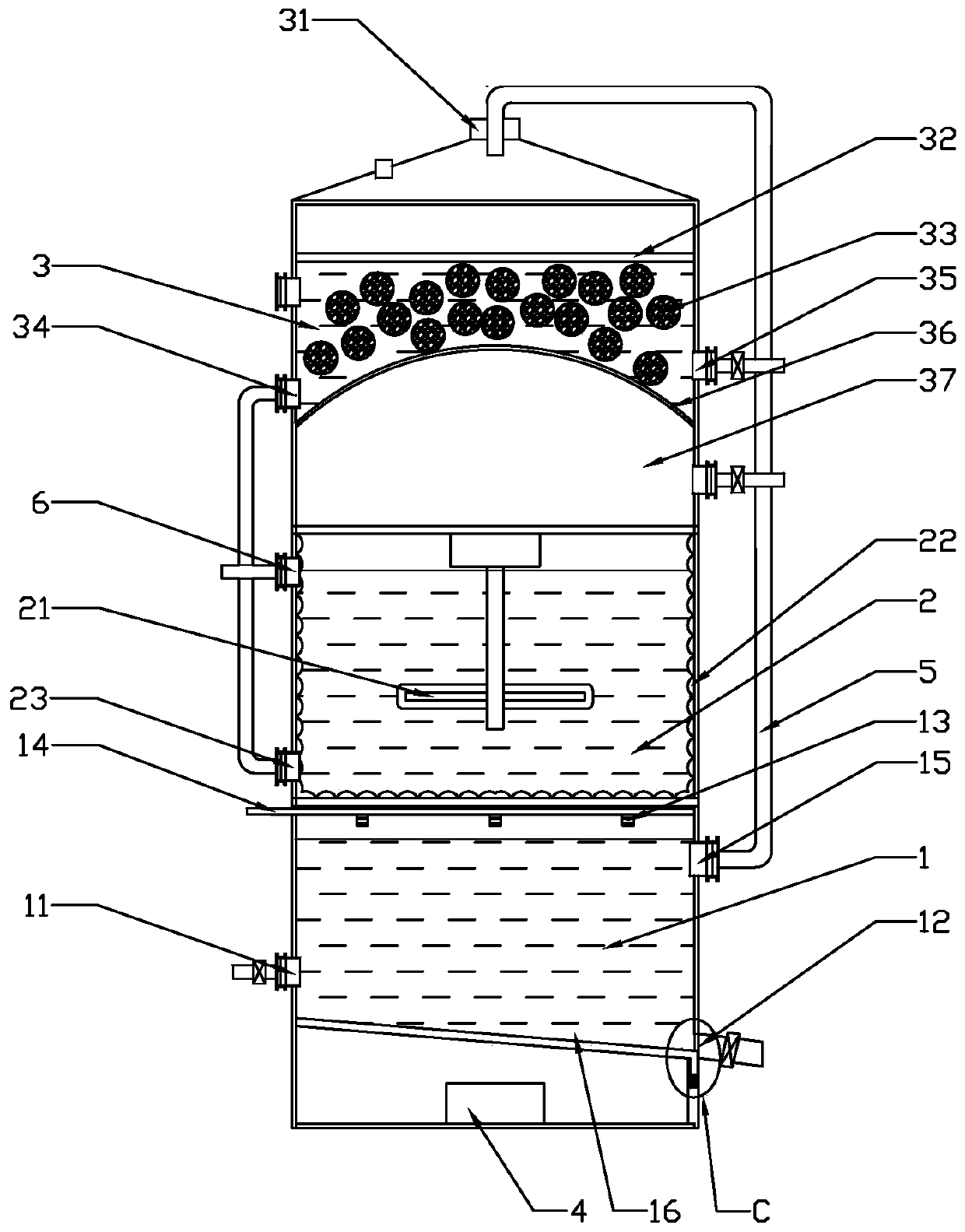

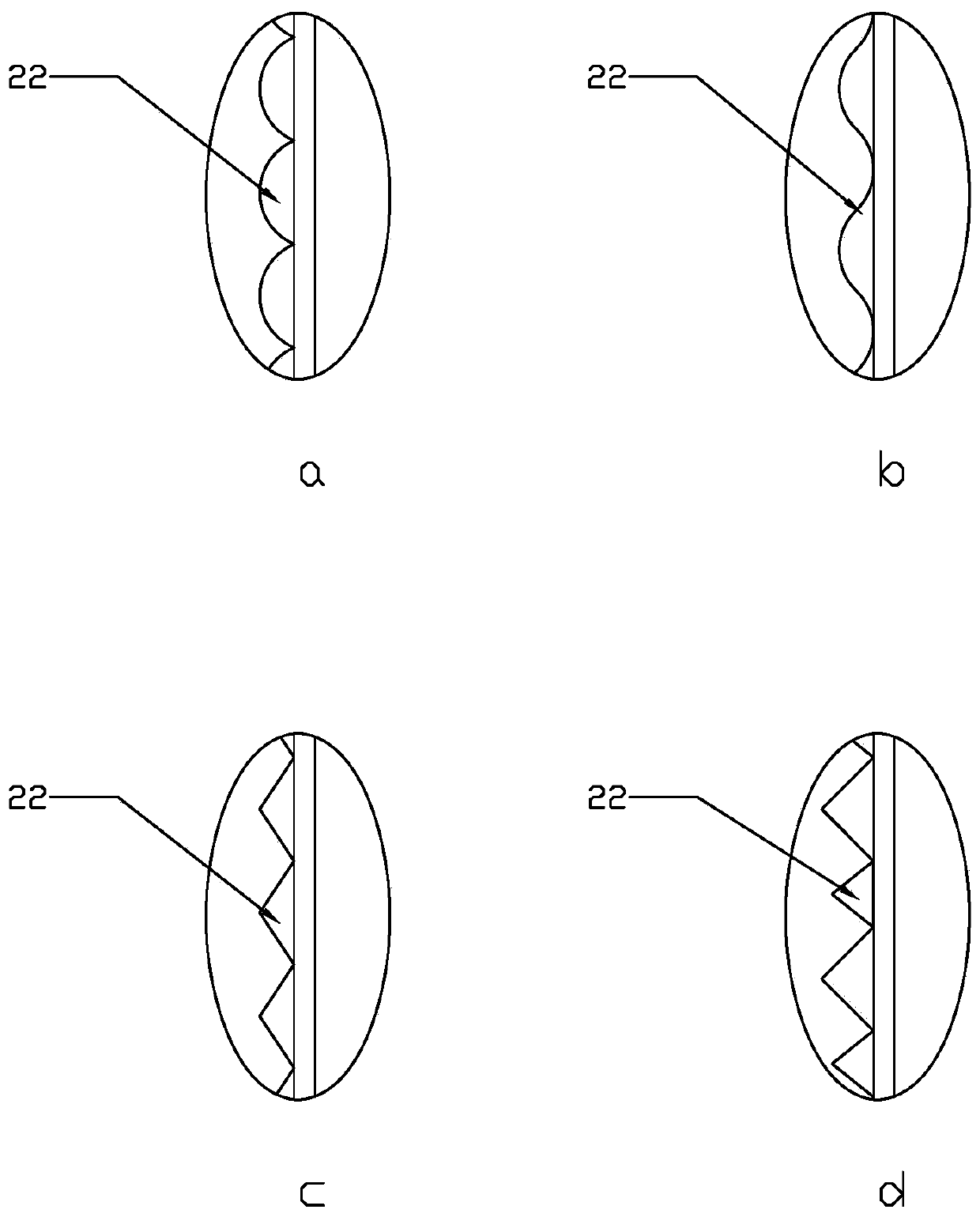

Water treatment and cyclic utilization system

ActiveCN108249661AImprove corrosion resistanceImprove mechanical propertiesWater/sewage treatment by irradiationOther chemical processesFlocculationUltraviolet

The invention provides a water treatment and cyclic utilization system. The water treatment and cyclic utilization system comprises a shell body, wherein the shell body is internally provided with a flocculation cavity, a sterilization cavity and an adsorption cavity; a controller is arranged at the bottom of the shell body; a water inlet and a sewage discharging opening are formed in two sides ofthe flocculation cavity; a flow guide plate is arranged at the bottom of the flocculation cavity; a groove is formed in the bottom of a pipe opening of a blow-off pipe; the groove is formed in the shell body; a stopping block matched with the pipe diameter of the blow-off pipe is arranged at one end of the flow guide pipe; an elastic structure is arranged at the lower end of the stopping block; the groove is internally provided with a first induction contact and an electromagnetic adsorption device; the stopping block is provided with a second induction contact and an electromagnetic adsorption part; the flocculation cavity is internally coated with polyurethane composite coating; the adsorption cavity is provided with a water inlet; the adsorption cavity is internally provided with a plurality of porous adsorption carriers; an adsorption cavity water outlet and a high-pressure washing water inlet are formed in two sides of the adsorption cavity respectively; the sterilization cavityis internally provided with a rotary ultraviolet lamp; a reflection layer is arranged on an inner wall of the sterilization cavity; a water outlet is formed in the sterilization cavity. The water treatment and cyclic utilization system provided by the invention has an automatic dirt cleaning function, can be used for comprehensively removing impurities, removing bacteria and removing undesirable odor and has a good river water treatment effect.

Owner:SHANDONG HUANNENG DESIGN INST

High molecular weight processing modifier for polyvinyl chloride low-foaming pipe

The invention relates to high molecular processing modifier used in a polyvinyl chloride low foaming tube, which is characterized in that: the total weight of polymeric monomer is calculated as 100 percent, which comprises 12-72 percent of methyl methacrylate, 21-66 percent of styrene and 7-22 percent of acrylonitrile. Chain extender is added into the compositions to carry out emulsion polymerization in redox system. The invention is characterized in that: the invention can improve plasticizing and the plasticizing can become more even, can improve melt strength to promote extending property, can improve surface quality to reduce melting pulsation and increase surface gloss and can improve processing property to reduce blooming and crazing, decrease the foaming density of the product and increase elongation and pulling speed. Because of higher relative molecular mass, the invention can greatly improve the melt strength. The invention is used for producing PVC foaming products which have dense and even stomata structure and lower density.

Owner:SHANDONG RUIFENG CHEM

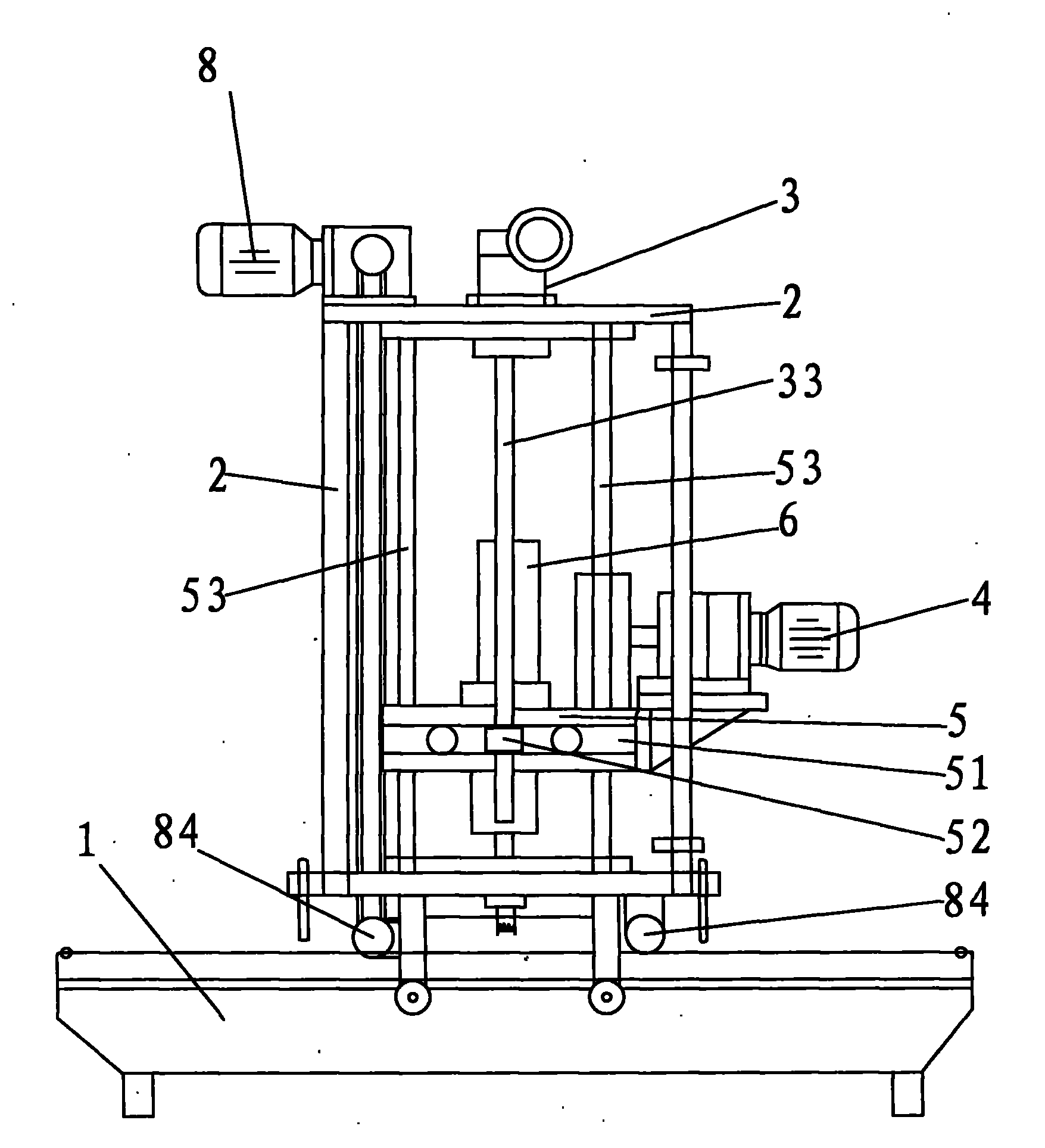

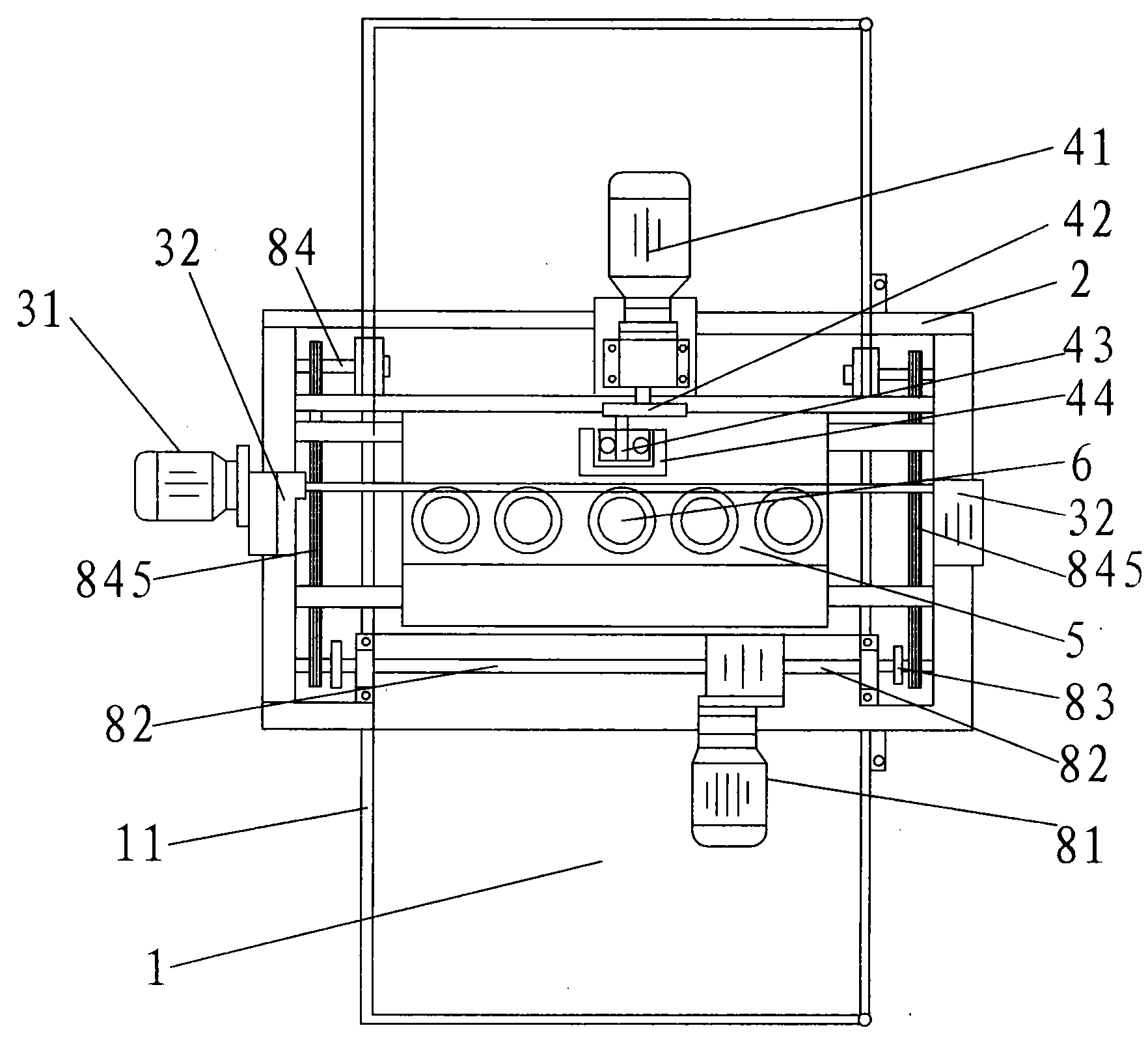

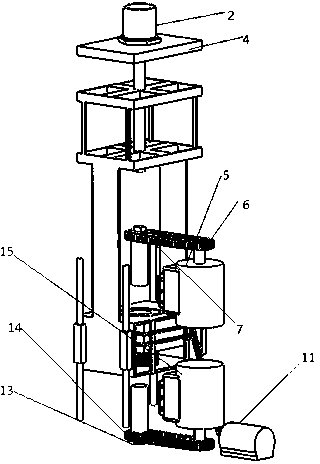

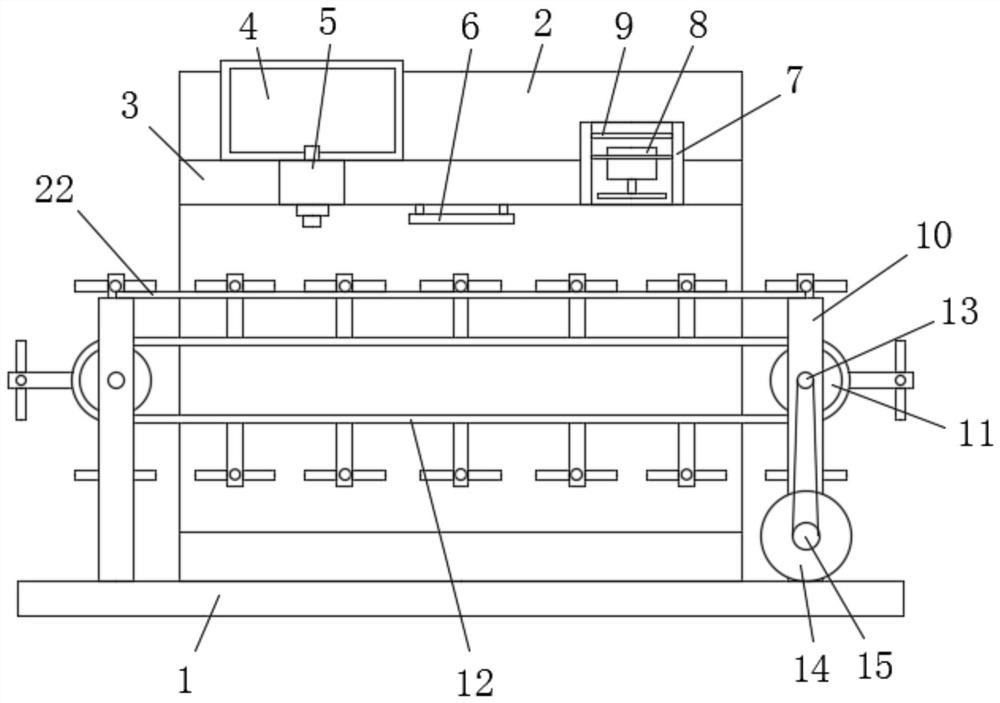

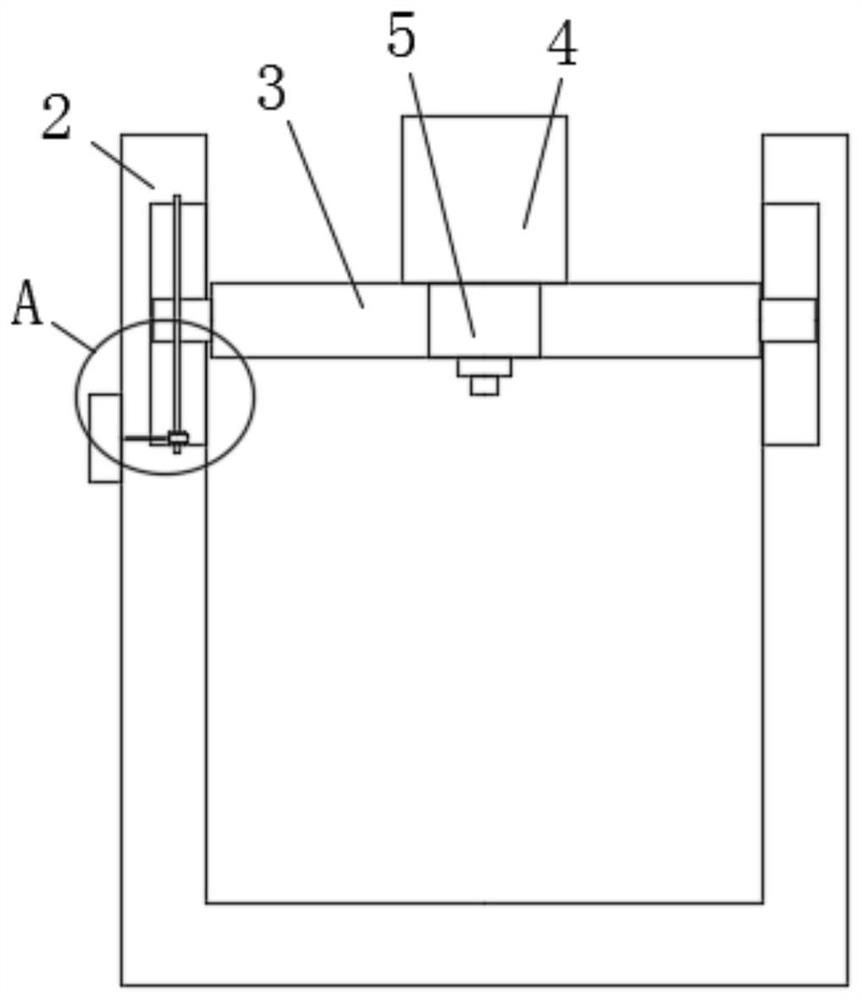

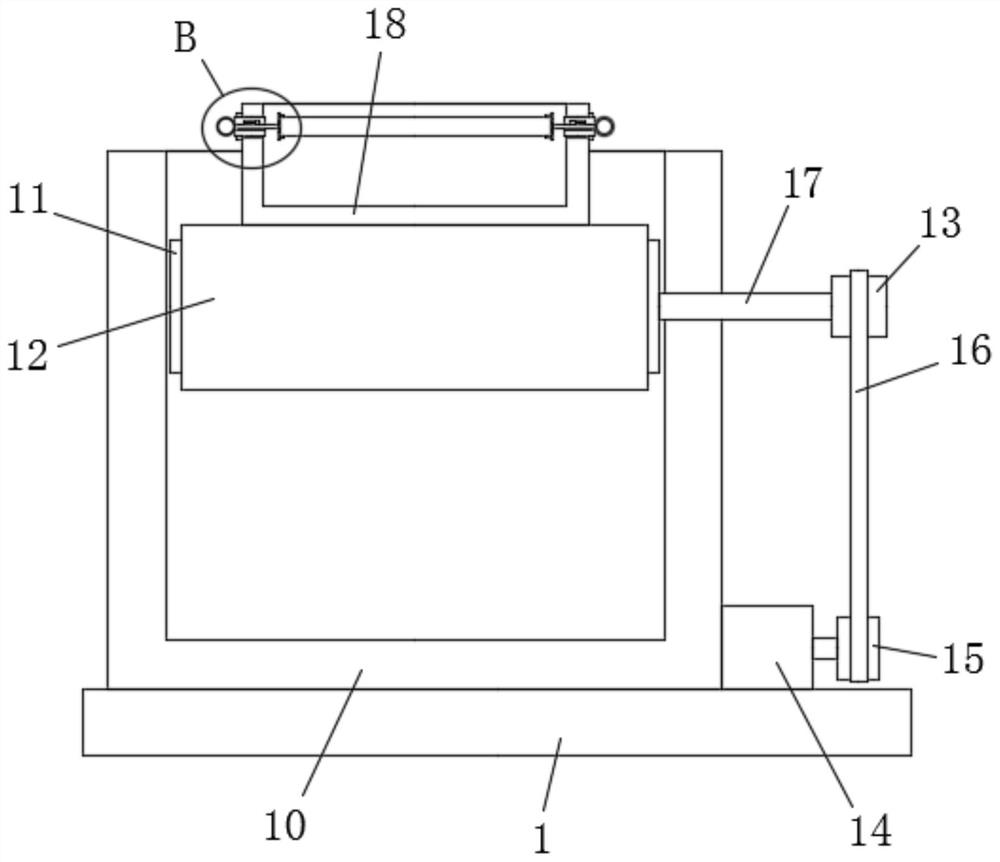

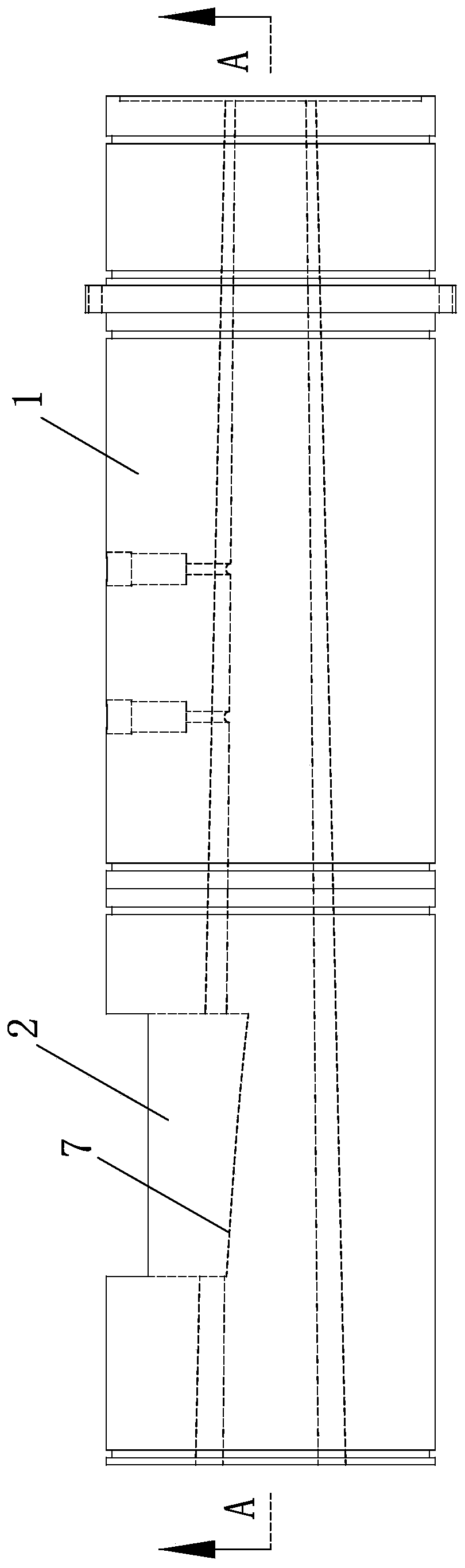

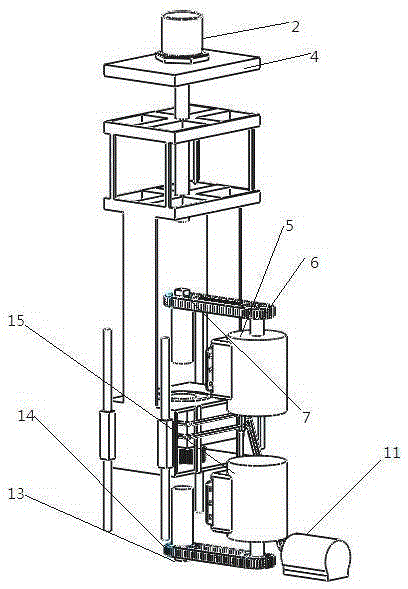

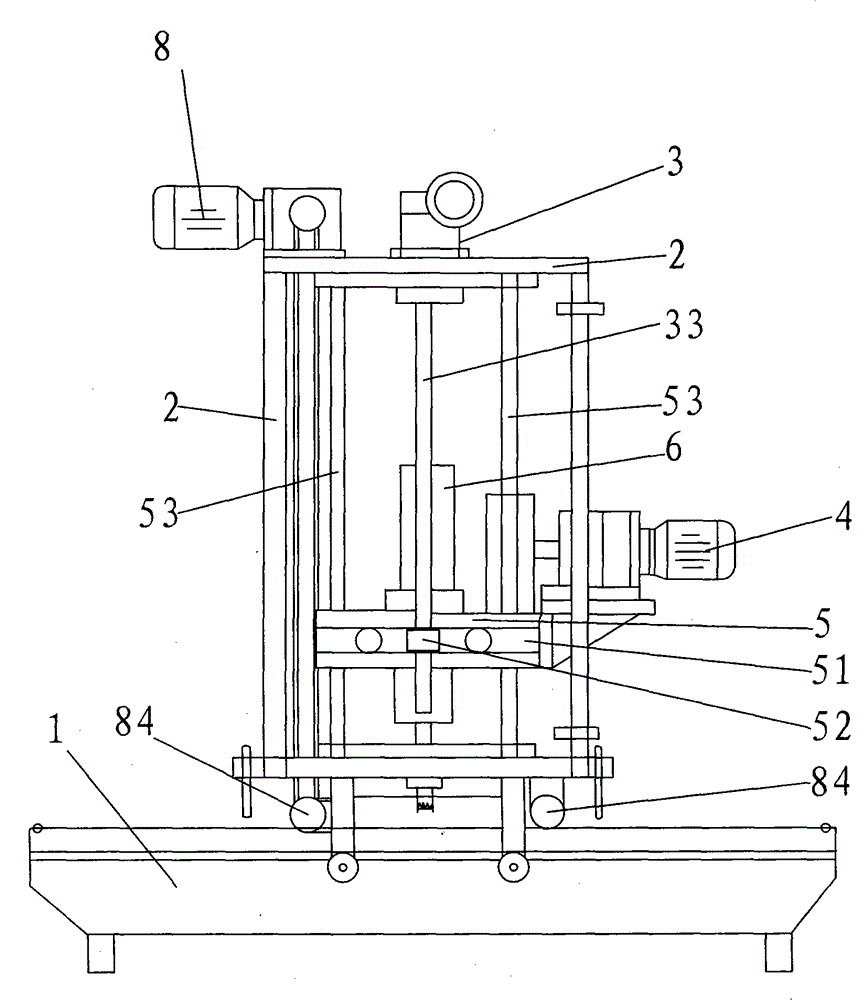

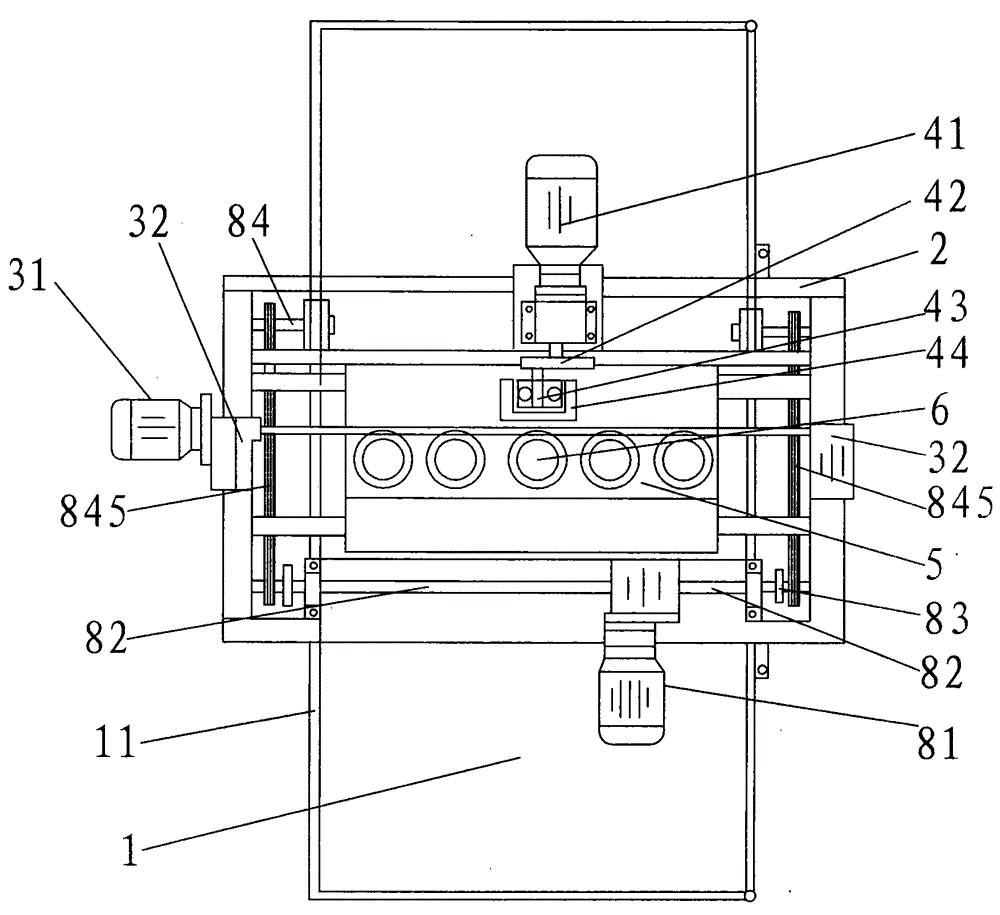

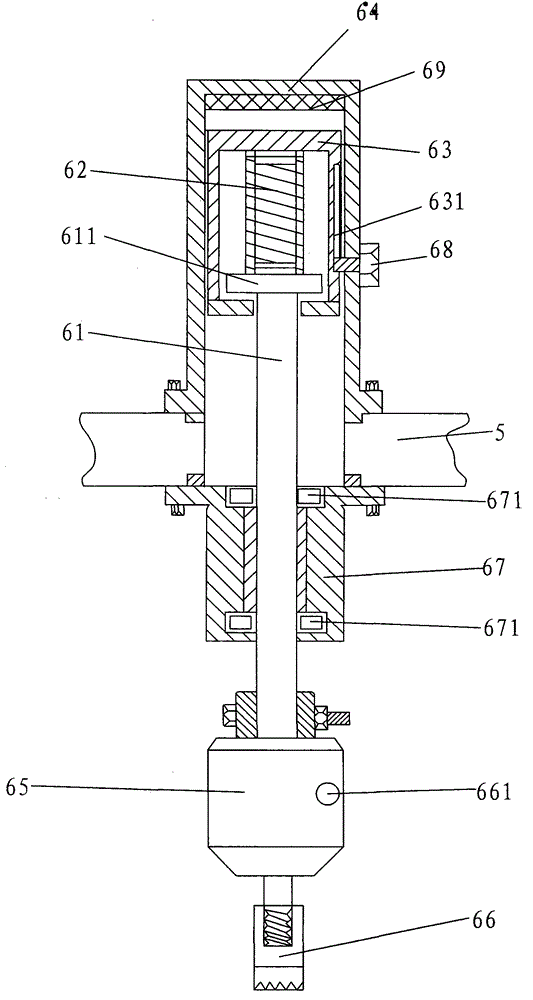

Stone bush-hammered surface hammering machine

InactiveCN101811330AIncrease productivityUniform processing effectStone-like material working toolsEngineeringMechanical engineering

The invention relates to a stone bush-hammered surface hammering machine, which comprises a worktable, a machine frame arranged on the worktable, a lifting assembly arranged on the machine frame, a left and right swing motor assembly arranged on the machine frame, a main plate seat arranged on the machine frame, a bush-hammered surface processing device arranged on the main plate seat and a left and right swing assembly arranged between the main plate seat and the machine frame. The bush-hammered surface hammering machine can process regular concaves and convexes on the surface of a stone to process a surface similar to the skin of leechee and is used in place of the traditional pneumatic hammer which is held manually and pushed to process the bush-hammered surface. The machine improves production efficiency, offers uniform and time-saving process, makes operation convenient, realizes uniform processing effect even through a workpiece has a thickness tolerance during the processing of the workpiece and can process the bush-hammered surface with processing pneumatic hammers selected randomly.

Owner:南安市鑫能机械有限公司

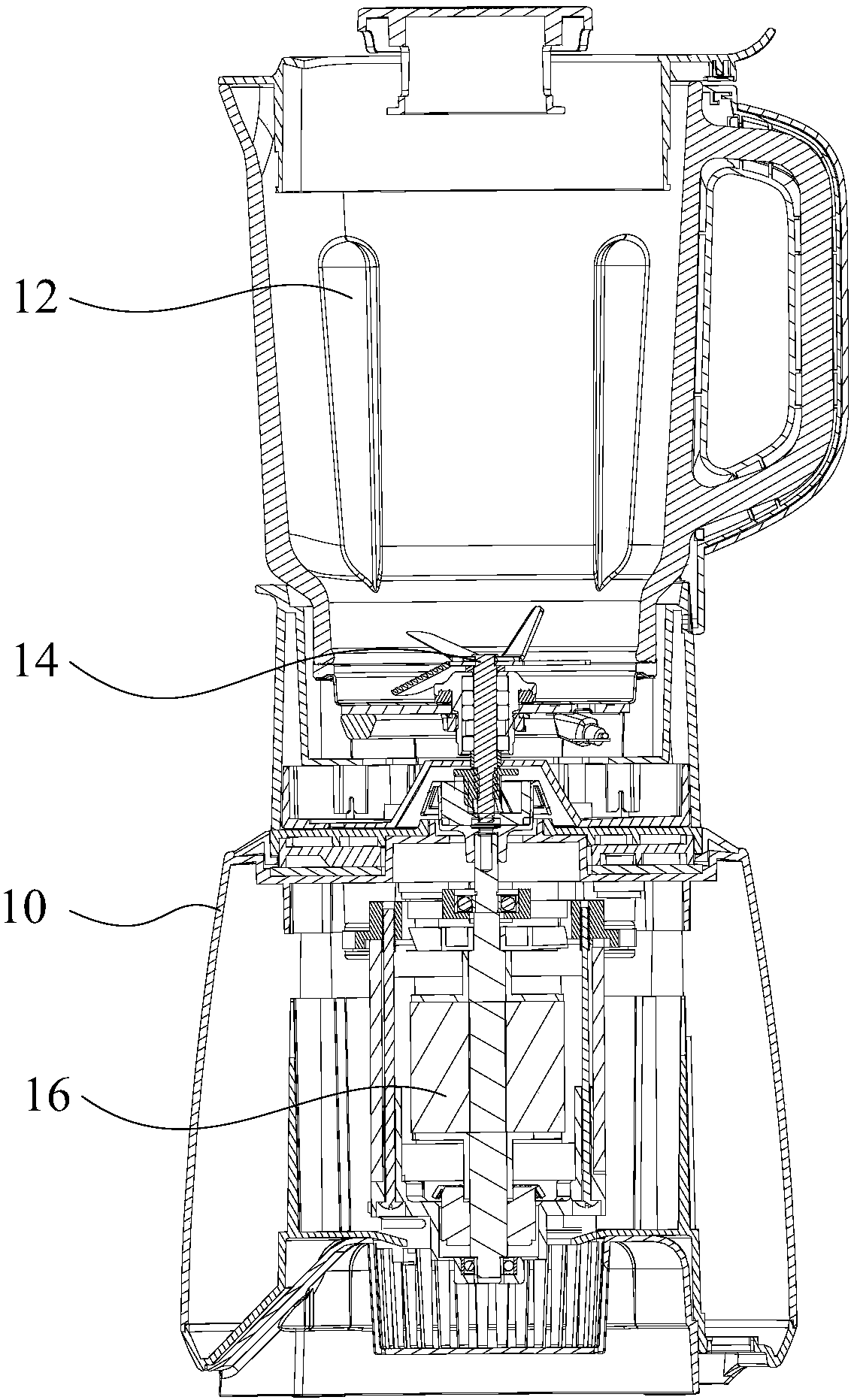

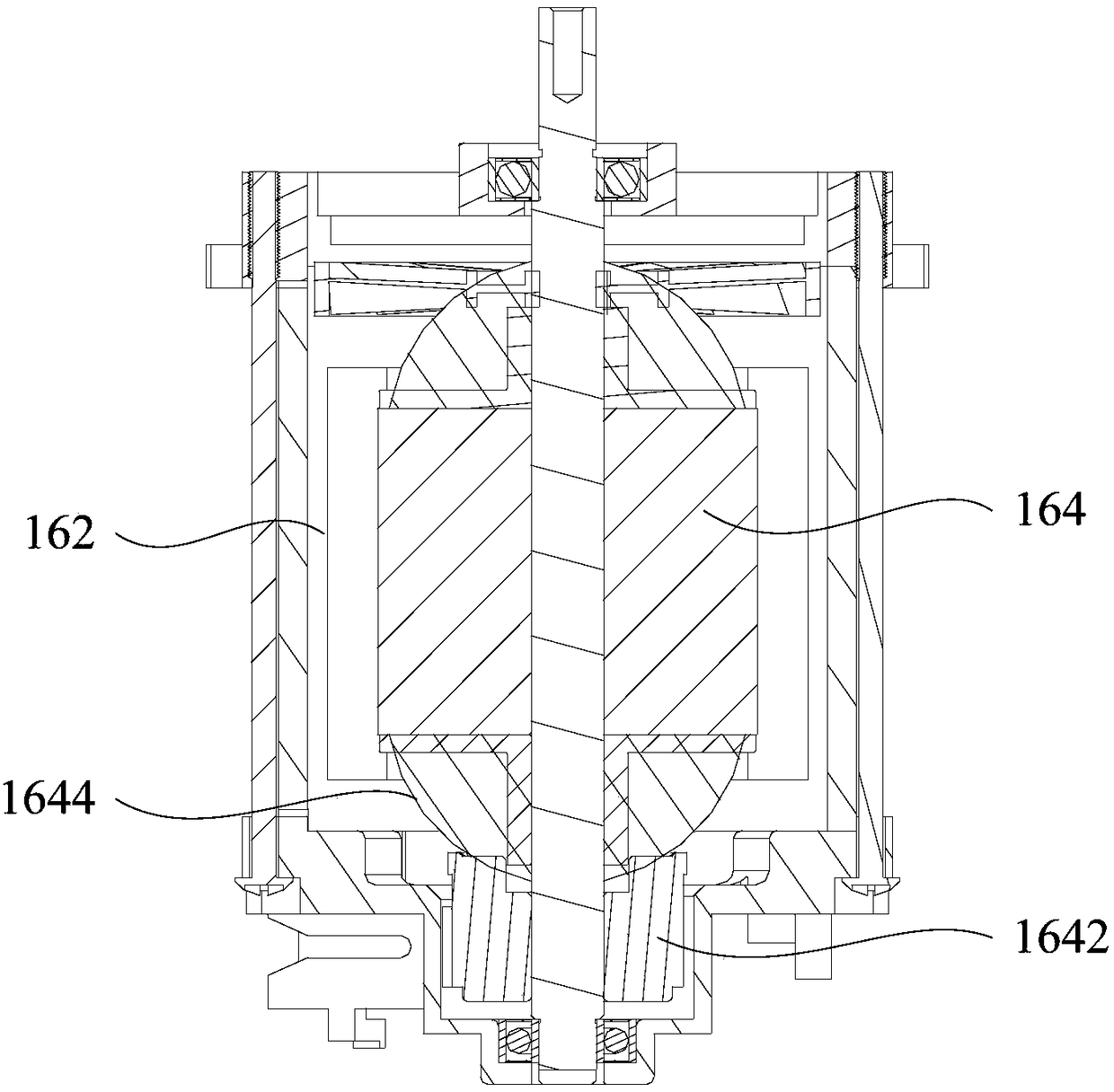

Food processor

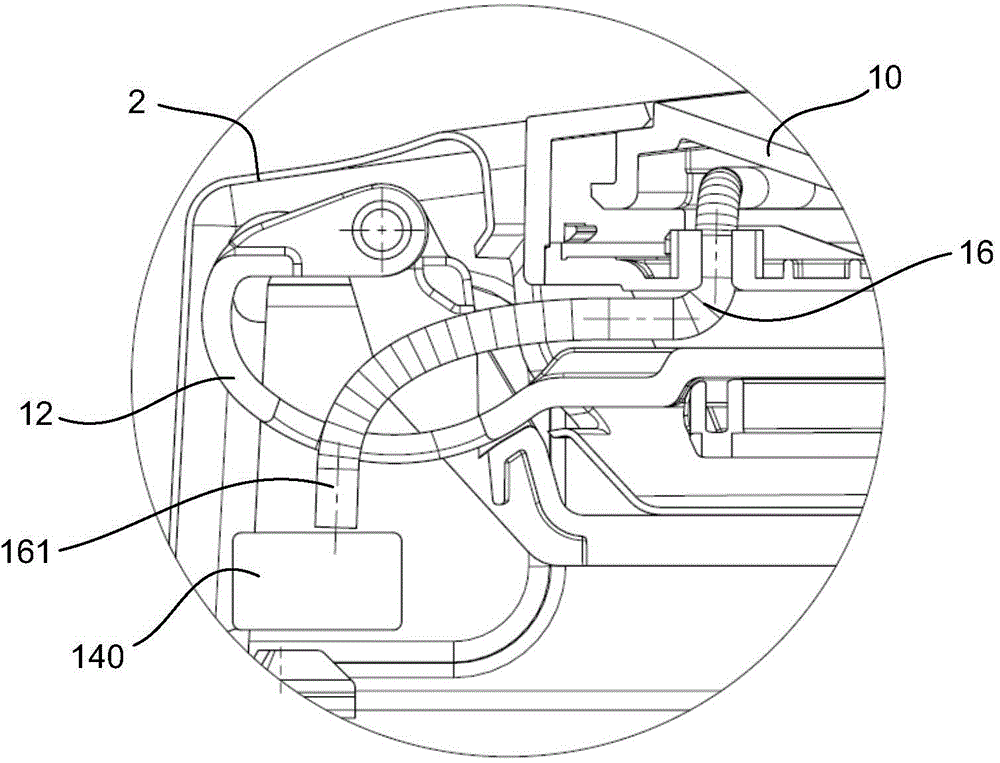

InactiveCN109199153AReduce speedGuaranteed crushing effectMagnetic circuit rotating partsKitchen equipmentPermanent magnet synchronous motorEngineering

The invention provides a food processor, comprising: a machine base having a receiving cavity; a cup body, with the cross-sectional area of the top end of the cup body being larger than the cross-sectional area of the lower end of the cup body, the cup body being arranged on the frame, and a spoiler rib being arranged on the inner wall of the cup body; a stirring assembly one end of which extendsinto the inside of the cup body, and the other end of which is connected with a permanent magnet direct current motor; a permanent magnet dc motor disposed in the accommodation chamber, wherein the speed range of the permanent magnet dc motor is from 10000 rpm to 18000 rpm. By keeping the rotational speed of the permanent magnet dc motor between 10000 rpm and 18000 rpm, As a result, when too manyingredients are added to the food processor, namely when the load is large, the speed of the permanent magnet dc motor will not be lower than 10000rpm, which effectively ensures the crushing effect ofthe food materials, and when the load is small, the speed of the permanent magnet dc motor will not exceed 18000rpm, which effectively reduces the noise of the food processor and improves the user experience.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

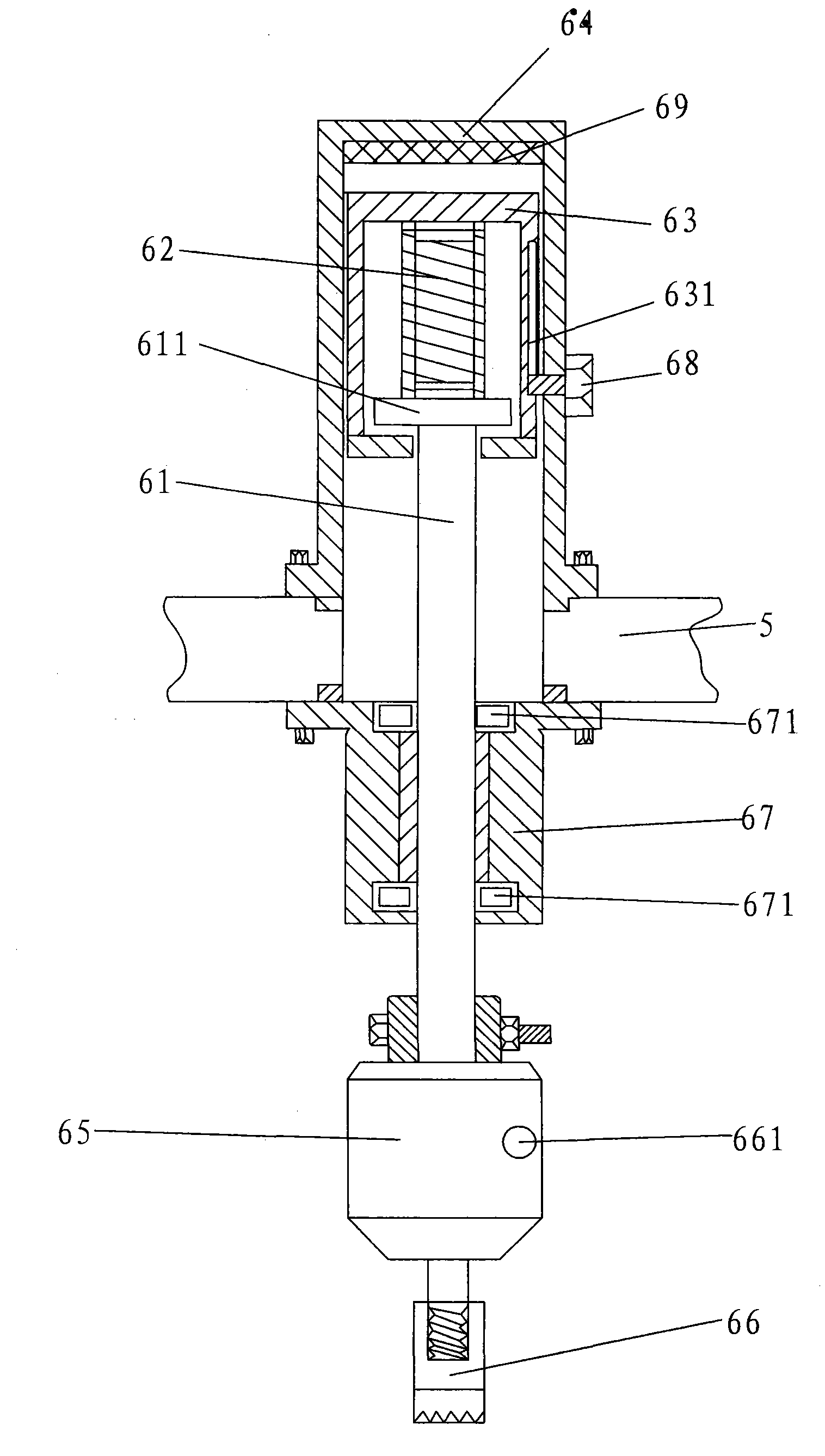

Pneumatic type reinforcing machining equipment for machining bearing outer ring rolling way

InactiveCN110653727AImprove mechanical performance and service lifeImprove mechanical propertiesAbrasive feedersGrinding/polishing apparatusElectric machineryStructural engineering

The invention discloses pneumatic type reinforcing machining equipment for machining a bearing outer ring rolling way. The pneumatic type reinforcing machining equipment comprises a reinforcing machining module and a grinding feed module. The grinding feed module comprises a high-pressure feed module. The reinforcing machining module comprises a machining box and a reinforcing machining mechanism.The reinforcing machining mechanism comprises a clamping mechanism and a peripheral jet mechanism. The peripheral jet mechanism comprises a peripheral nozzle and a rotary driving motor. The peripheral nozzle comprises a feed end and a distribution end. The distribution end is arranged in the center of a clamped bearing outer ring. An inner cavity of the feed end forms a feed channel. One end of the feed channel communicates with a tail end feed pipeline of the high-pressure feed module. The other end of the feed channel communicates with the distribution end. A plurality of jet channels are formed in the distribution end. The head ends of the jet channels communicate with the feed channel. The tail ends of the jet channels extend to the exterior of the distribution end. The reinforcing machining equipment can conduct reinforcing machining on the bearing outer ring rolling way and is especially suitable for machining an outer ring rolling way of a micro bearing.

Owner:GUANGZHOU UNIVERSITY

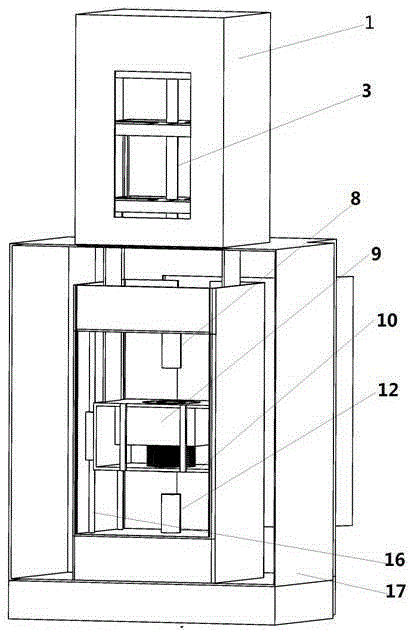

Coaxial double-head diamond boring lathe and fine boring method thereof

InactiveCN103949688AUniform processing effectReduce labor intensityBoring/drilling machinesEngineeringAlternating current

The invention discloses a coaxial double-head diamond boring lathe and a fine boring method thereof. The coaxial double-head diamond boring lathe comprises a supporting frame, a step motor, a lead screw, a connecting frame, an upper alternating current motor, an upper transmission belt, an upper encoder, an upper main shaft, a clamp, a workbench, a hydraulic device, a lower main shaft, a lower encoder, a lower transmission belt, a lower alternating current motor, guide rails and a lathe body. The coaxial double-head diamond boring lathe can perform semi-fine boring and fine boring successively after one clamping, so that under the condition of coaxial machining, semi-fine boring and fine boring machining allowances are ensured and the balance of the fine boring allowance is ensured; by adopting a four-rail enclosed moving structure, the stability of a workpiece in the machining process and high precision are ensured; and after the workpiece is machined, through control of the hydraulic device, manual knife stripping is not required, but just the knife is taken by two hands, and through positioning of the encoders, the knife automatically drops from a cylinder sleeve. The coaxial double-head diamond boring lathe is simple to use, can reduce the labor intensity of working staff and improves the production efficiency.

Owner:QUZHOU UNIV +1

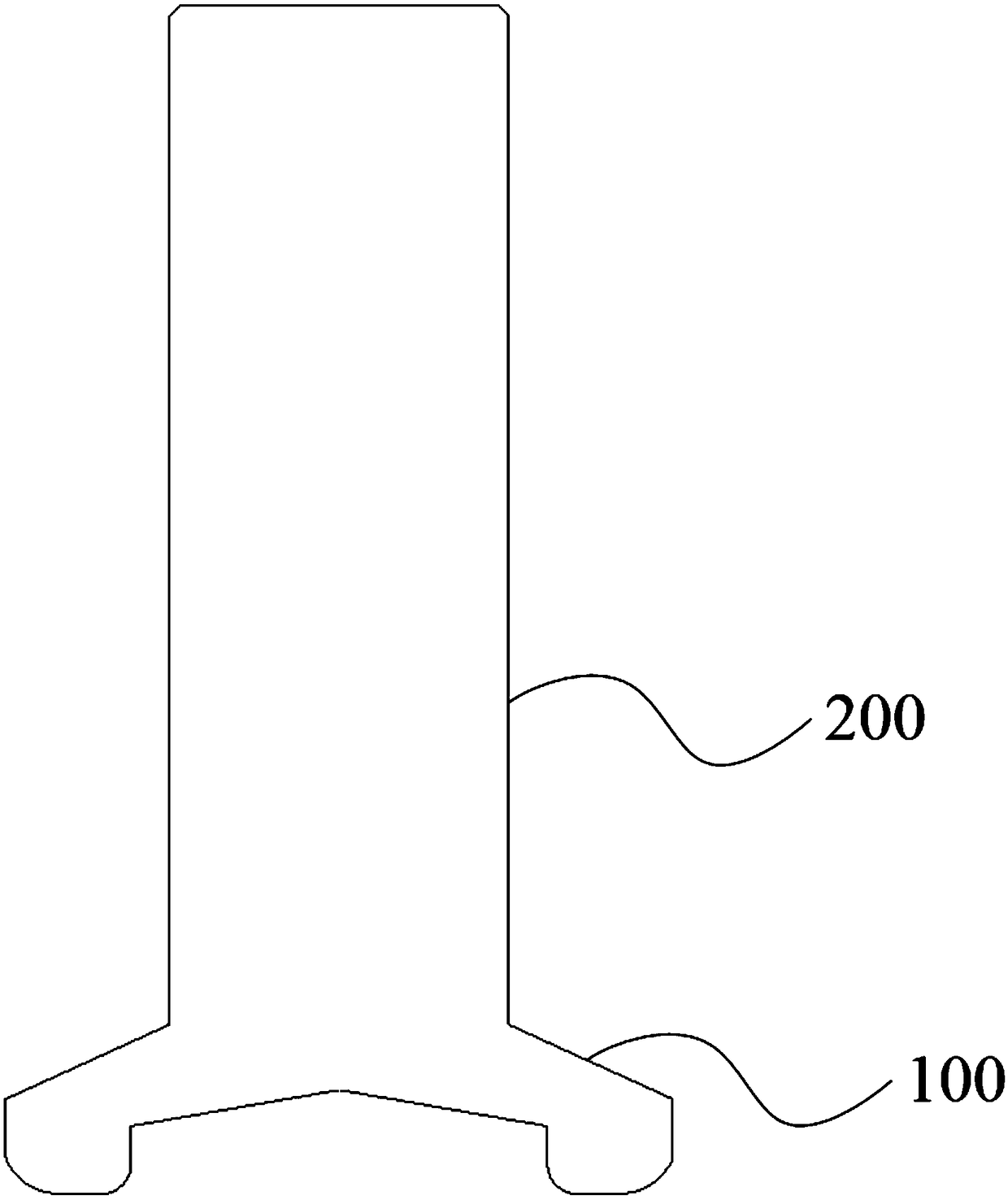

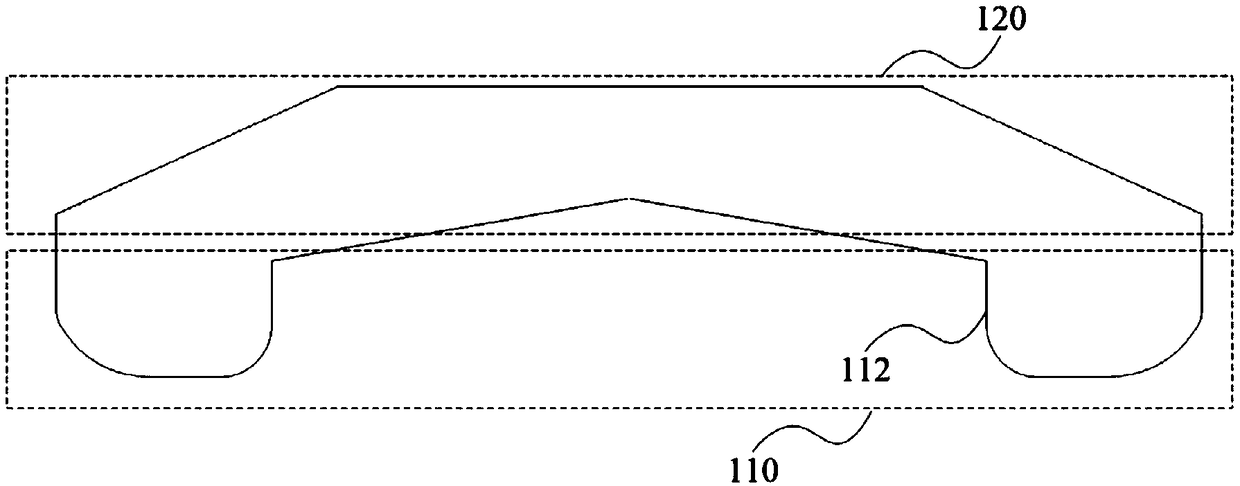

Fine finish polishing tool

PendingCN108890544AReduce usageRealize small area processingBonded abrasive wheelsCircular coneEngineering

The invention provides a fine finish polishing tool. The fine finish polishing tool comprises a grinding body and an installing connecting rod. The installing connecting rod is cylindrical, and the grinding body is disc-shaped. The installing connecting rod is coaxially connected with the grinding body, and a specific value of a diameter of the grinding body and a diameter of the installing connecting rod is 1.2-2.4. The grinding body comprises a connecting part and a polishing part. The connecting part is truncated cone-shaped, and has circular top face and bottom face, and a side face of which a shape is a circular conical surface. A diameter of the top face is less than a diameter of the bottom face. The top face is coaxially connected with the installing connecting rod. The polishing part is formed on the bottom face. The polishing part is annular and protruded and installed at the peripheral part of the bottom face of the connecting part, and the polishing part is provided with multiple discharging channels for discharging wastes generated in a polishing process. It can be clearly shown that the described fine finish polishing tool is capable of meeting multiple polishing requirements through a high-precision small-scale design, improving processing efficiency, and improving a processing success rate.

Owner:CONPROFE TECH GRP CO LTD +1

Full-automatic intelligent carbonizing and drying all-in-one machine for bamboo materials

InactiveCN112265095AProcessing lastsUniform processing effectSpraying apparatusDrying solid materialsProcess engineeringMaterials processing

The invention belongs to the field of bamboo material processing equipment, and particularly relates to a full-automatic intelligent carbonizing and drying all-in-one machine for bamboo materials. Thefollowing scheme is provided currently in order to solve the problems that existing bamboo material processing equipment is low in processing efficiency, poor in processing continuity, incapable of continuously processing the bamboo materials and poor in generality, the full-automatic intelligent carbonizing and drying all-in-one machine comprises a mounting plate, a processing frame is fixedly mounted at the top of the mounting plate, an adjusting plate is slidably mounted in the processing frame, a steam box is fixedly mounted at the top of the adjusting plate, a steam spraying head is fixedly mounted at the bottom of the adjusting plate and connected with the steam box, a drying plate is fixedly mounted at the bottom of the adjusting plate, a mounting hole is formed in the top of the adjusting plate, and an air blowing pipe is fixedly mounted in the mounting hole. The full-automatic intelligent carbonizing and drying all-in-one machine is reasonable in structure, convenient to operate, high in processing efficiency, uniform in bamboo material processing effect, good in processing continuity, capable of continuously processing the bamboo materials and good in universality.

Owner:储李梅

Double-shaft bulking machine and working method thereof

InactiveCN110916235AImprove processing efficiencyImprove machining accuracyFeeding-stuffFood shapingSpiral bladeStructural engineering

The invention discloses a double-shaft bulking machine and a working method thereof. The double-shaft bulking machine comprises an outer pipe, a material inlet is formed in the pipe wall of the outerpipe, a lining is arranged in the outer pipe, a notch is reserved in the outer wall of the lining, two conical inner pipes which are arranged in the length direction of the lining and are open in thefront and the back are formed in the lining, and two inner cavities are staggered and communicated in the radial direction; the conical inner pipes are large in front end opening and small in tail endopening, an included angle is formed between the central axes of the two conical inner pipes, a conical screw rod is arranged in each inner cavity in a penetrating mode, spiral blades are wound on the peripheries of the conical screw rods, and the spiral blades on the two conical screw rods are arranged in a staggered mode. According to the double-shaft bulking machine, the conical screw is prevented from jumping or vibrating through the arranged lining and the conical inner pipe, so that energy is concentrated in the conical inner pipe, bulking materials can be extruded out of finer templateholes, the finer and more uniform feed processing effect is achieved, and the double-shaft bulking machine is small in occupied area and high in practicability. The smaller development of the structure of the bulking machine is facilitated.

Owner:嘉兴润阳机械有限公司

Cold-resistant and antifreeze composite material for plastic windows and doors

The invention discloses a cold-resistant and antifreeze composite material for plastic windows and doors. The composite material is prepared from the following ingredients in parts by mass: 50-80 parts of PVC, 35-50 parts of ABS, 15-20 parts of talcum powder, 30-50 parts of calcium carbonate, 15-20 parts of wood flour, 10-15 parts of polyamide fibers, 0.5-1 part of foamer, 1-2 parts of foaming regulator, 4-8 parts of polyethylene wax, 2-5 parts of toughener, 2-3 parts of calcium stearate, 2-6 parts of couplant, 3-6 parts of flame retardant, 1-2 parts of anti-aging agent, 1-2 parts of ACR modifier and 1-2 parts of paraffin. According to the cold-resistant and antifreeze composite material, through jointly using the PVC and the ABS and comprehensively using a stabilizer, the flame retardant,the polyamide fibers and the like, products with good strength and toughness are obtained, have excellent heat resistance, wear resistance and flame retardance and are low in expansion ratio and lowin thermal shrinkage, thereby being ideal plastic-wood floorboard articles.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

Outdoor PVC transparent film and preparation method thereof

InactiveCN111286134AAddress issues such as insufficient researchGood weather resistancePlasticizerFilm material

The invention belongs to the technical field of transparent film materials, and particularly relates to an outdoor PVC transparent film. The outdoor PVC transparent film is prepared from the followingraw materials in parts by weight: 90-120 parts of PVC resin powder, 10-15 parts of nano powder, 1-3 parts of methyltin, 2-4 parts of plasticizer, 4-7 parts of an impact modifier, 1-3 parts of a gelling agent, 0.3-1 part of an ink absorbent, 1-3 parts of an antistatic agent, 8-15 parts of titanium dioxide and 3-8 parts of a plastic anti-wrinkle agent. The outdoor PVC transparent film and the preparation method have the beneficial effects that the raw materials are easy to obtain; and the film has good antistatic property and stability, can still maintain good mechanical properties in a high-temperature environment for a long time, is not prone to embrittlement and fragility, and is long in service life.

Owner:东阳市李氏塑胶有限公司

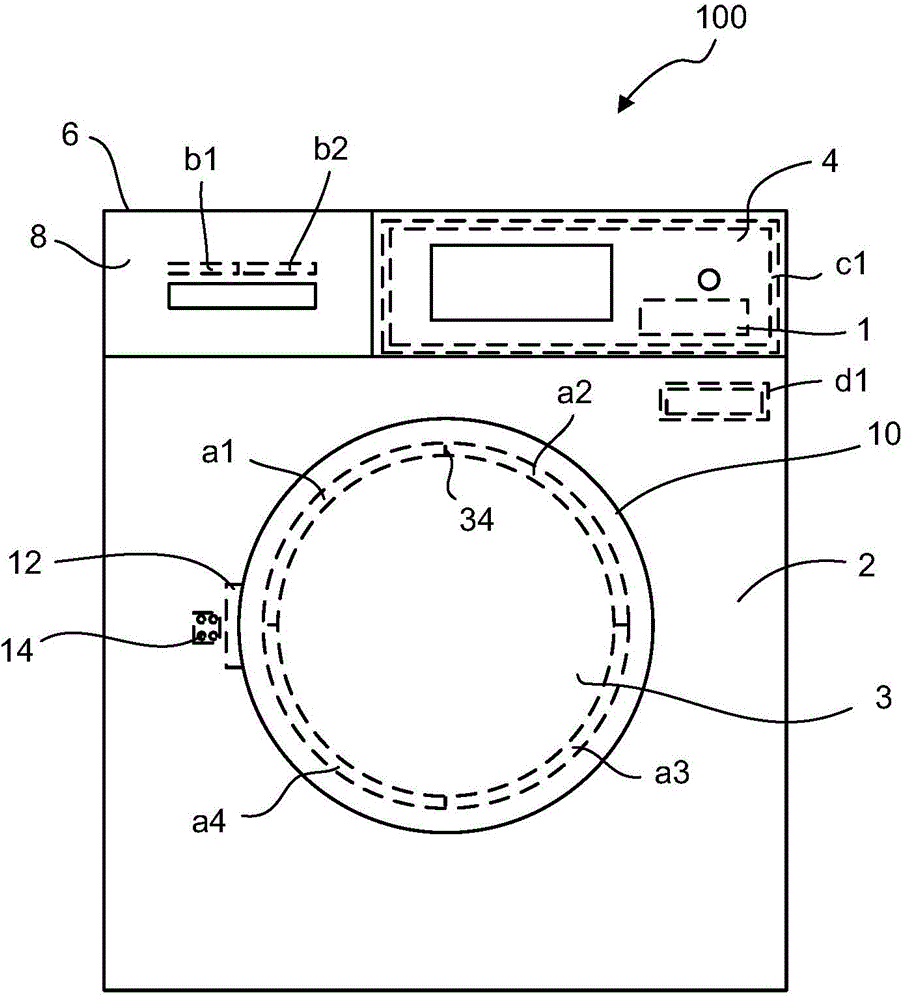

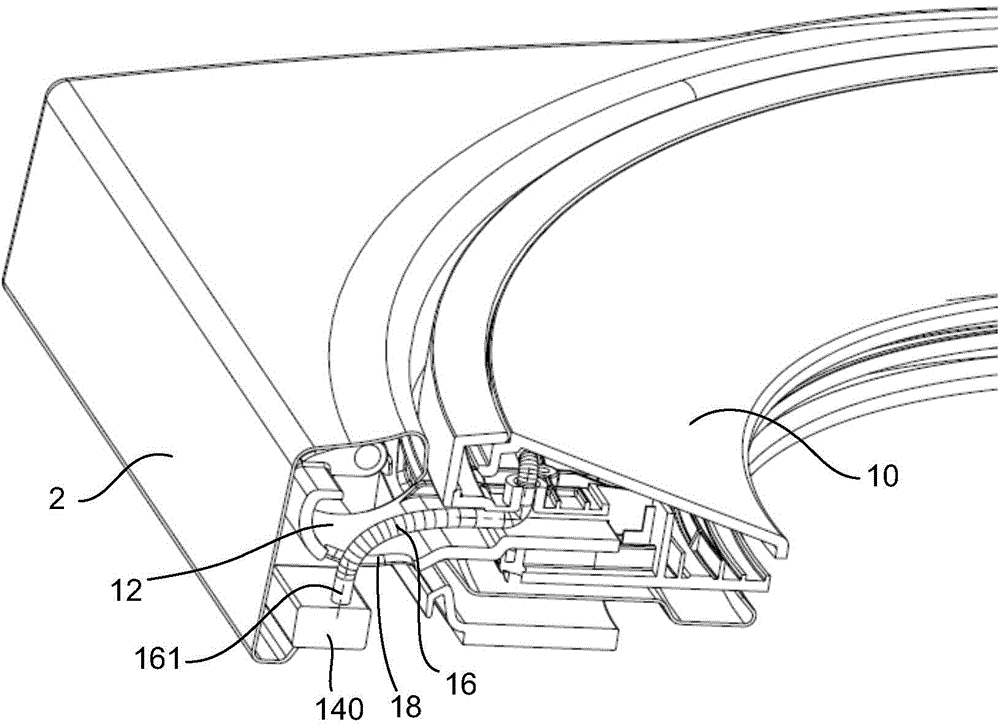

Household appliance with light-emitting assemblies

InactiveCN105782938AUniform outputLow costMechanical apparatusDomestic stoves or rangesEngineeringLight guide

The invention discloses a household appliance with light-emitting assemblies. The household appliance comprises shell assemblies for forming the appearance of the household appliance. The shell assemblies are internally provided with the light-emitting assemblies controlled by a control device. The light-emitting assemblies comprise light sources and light guiding parts. The light guiding parts are side-light-guiding long-strip-shaped light guiding strips. The side-light-guiding light guiding strips all can obtain homogeneous and uniformly distributed light ray output within a long length, and the manufacturing cost is low.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

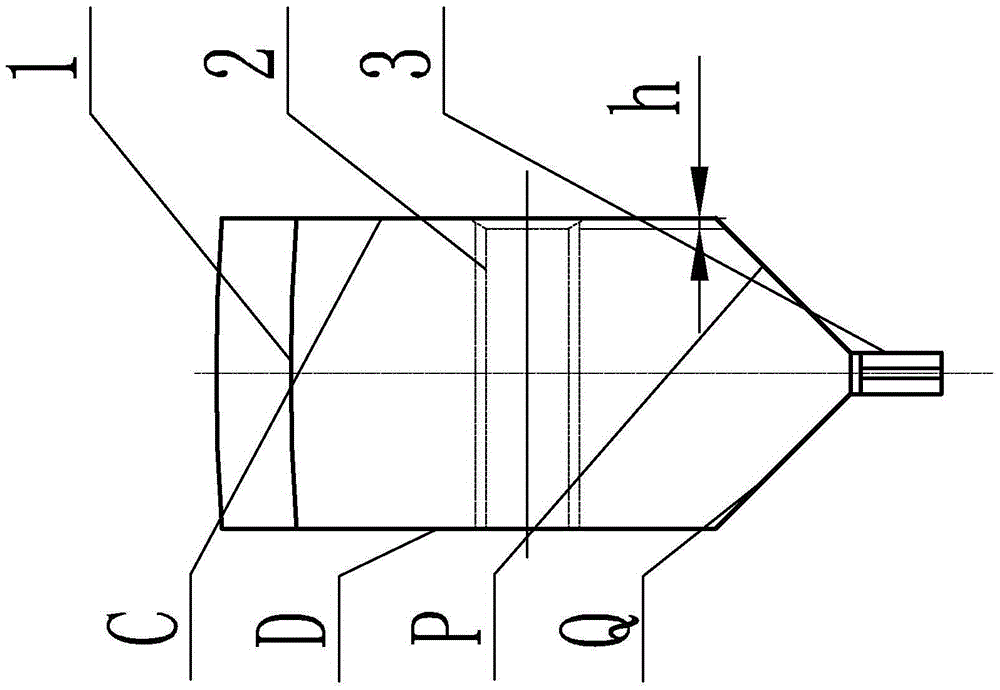

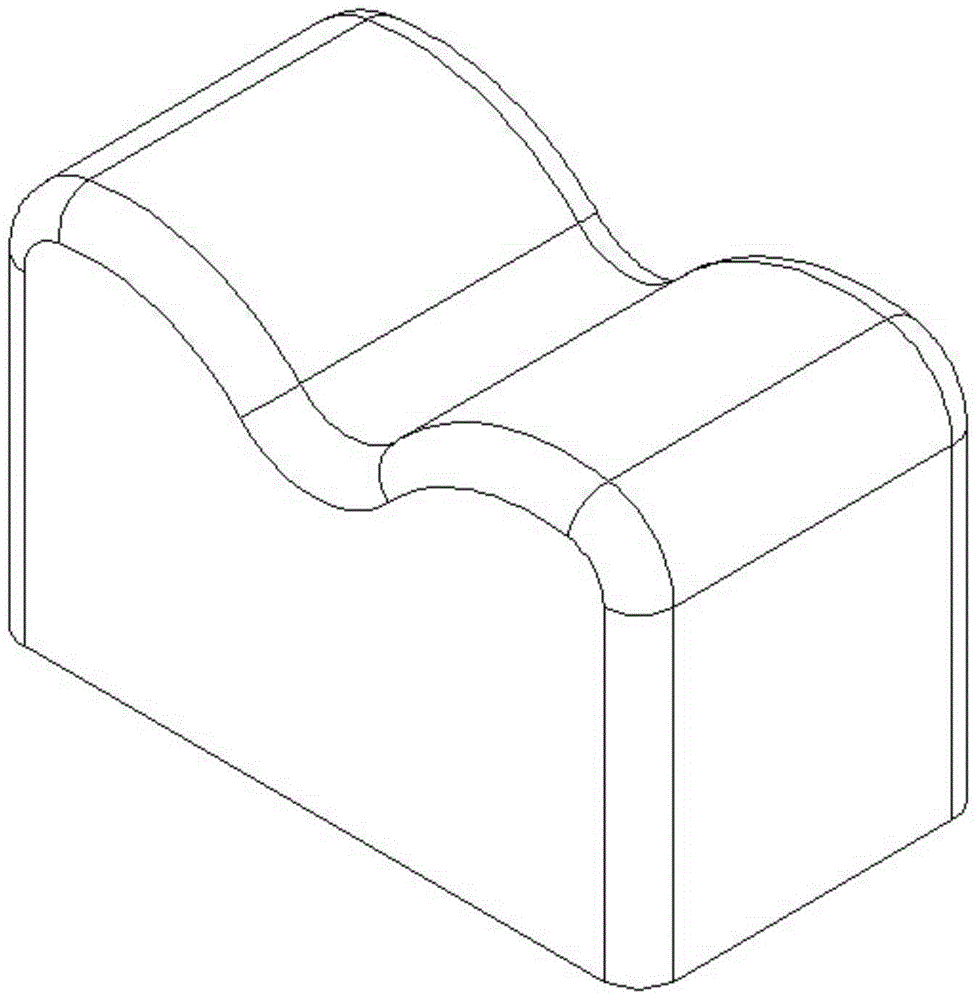

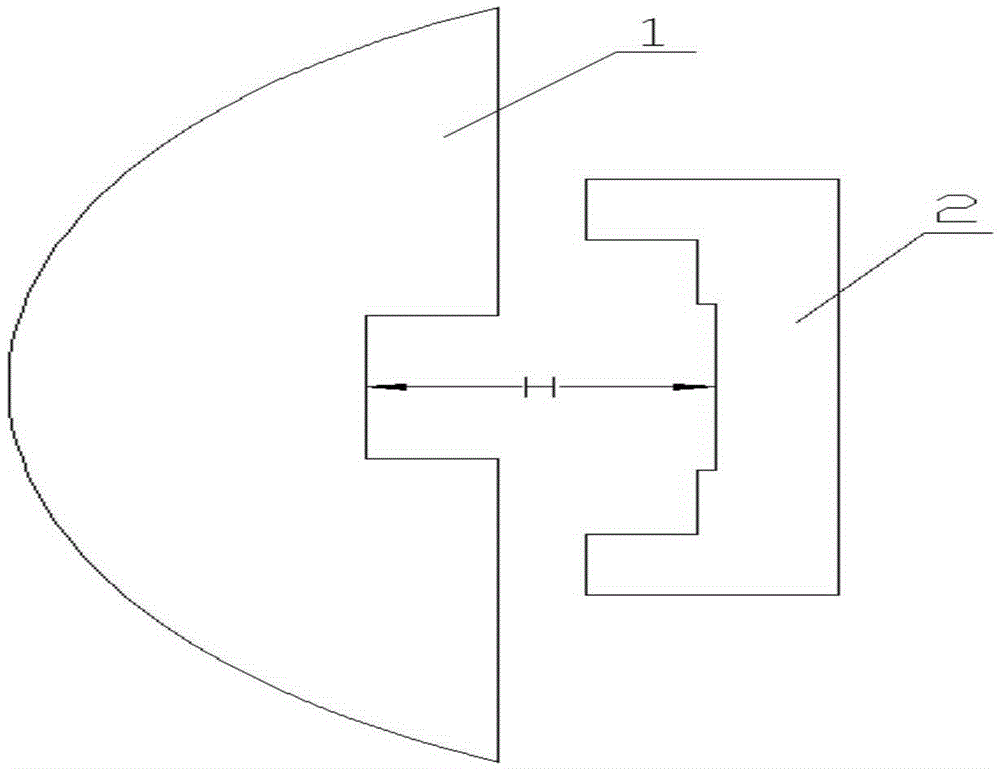

Method and device for turbulent precision machining of curved surface of titanium alloy artificial joint

ActiveCN104690632BImprove machining accuracyUniform processing effectEdge grinding machinesPolishing machinesParticle flowArtificial joints

The invention discloses a titanium alloy artificial joint surface turbulence precision machining method and device. The titanium alloy artificial joint surface turbulence precision machining method is characterized in that a special square machining device is used to form a copying flow passage for machining a titanium alloy artificial joint prosthesis with the titanium alloy artificial joint prosthesis, the rapid flow of a solid-liquid two-phase abrasive particle flow in the copying flow passage is used for forming full turbulence, and abrasive particles in the solid-liquid two-phase abrasive particle flow are used for performing unordered micro force and micro cutting on the titanium alloy artificial joint prosthesis; in the machining process, high-pressure gas is intermittently introduced into the copying flow passage and impacts the abrasive particles to distribute towards workpieces so as to improve the probability of collision of the abrasive particles to the surface of the titanium alloy artificial joint prosthesis and prevent the abrasive particles from submerging into the bottom of the copying flow passage. The titanium alloy artificial joint surface turbulence precision machining device is simple in structure and easy in design; a copying end cover forms good copying with the surface of the titanium alloy artificial joint prosthesis; the soft abrasive particle flow can be in good contact with the surface of the titanium alloy artificial joint prosthesis, so that the machining precision of a titanium alloy artificial joint is higher, and the processing effect is more uniform.

Owner:北京惠胜光电科技有限公司

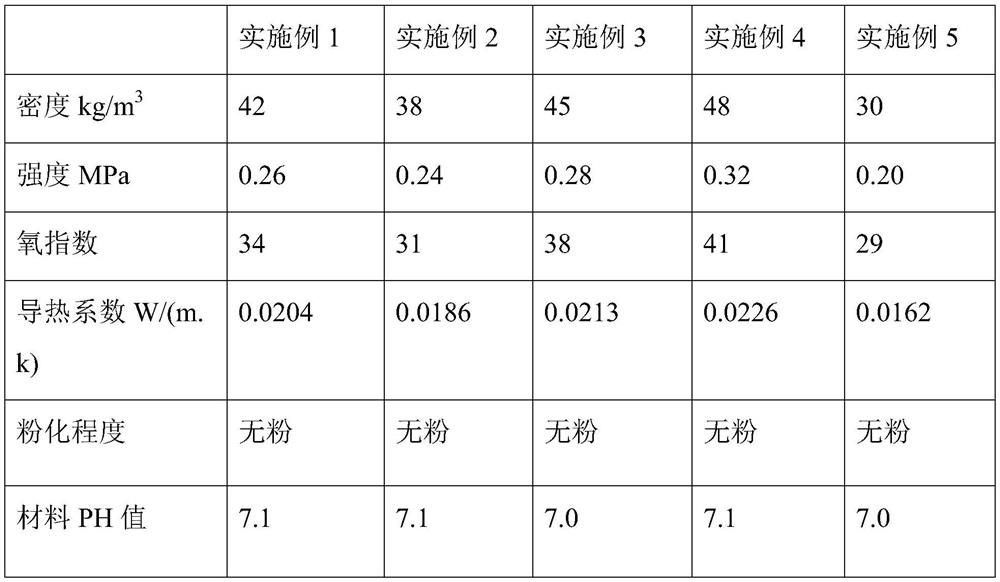

Flame-retardant ultralow-heat-conductivity-coefficient PFU foam and manufacturing method thereof

The invention relates to flame-retardant ultralow-heat-conductivity-coefficient PFU foam and a manufacturing method thereof. The flame-retardant ultralow-heat-conductivity-coefficient PFU foam is prepared from PFU resin, a foam stabilizer, a catalyst, a modifier, a foaming agent and the like. The preparation method comprises steps: mixing the raw materials in proportion and then stirring to be uniform to obtain a mixture; mixing the mixture with isocyanate, uniformly stirring at a high speed, and injecting into a mold; and foaming, curing and molding the mold at the temperature of 55-65 DEG Cto obtain the flame-retardant ultralow-heat-conductivity-coefficient PFU foam. Compared with the prior art, the PFU foam disclosed by the invention not only has excellent physical properties of polyurethane foam, but also has excellent properties of phenolic foam, such as flame retardancy, acid corrosion resistance, surface carbonization when meeting fire, self-extinguishing when leaving fire andthe like; in addition, the highest oxygen index can reach 30 or above, and the combustion performance grade can reach the flame-retardant B1 grade; the heat conductivity coefficient of the material isextremely low and can reach 0.0162 W / K.m. In addition, the material has excellent properties of heat insulation, light weight, high strength and the like, so that the material has the best heat preservation effect in organic heat preservation materials.

Owner:SHANGHAI ADVANCED ENG MATERIALS

River water pretreatment device

InactiveCN105084601BImprove solubilityEasy to separateMultistage water/sewage treatmentActivated carbonImpeller

The invention discloses a river water pretreatment device. A gas sterilizing chamber, an adsorption chamber and a water collection chamber are arranged in a tank; a water distribution device is arranged in the gas sterilizing chamber, and is communicated with a water inlet, gas sprayers are arranged below the water distribution device, and are communicated with an external gas source pump by means of a gas transmission pipeline, the lower part of the gas sterilizing chamber is provided with a first flexible diaphragm, a first gas cavity is formed between the first flexible diaphragm and a bottom plate of the gas sterilizing chamber, a gas sterilizing chamber water sump is formed between the first flexible diaphragm and the sprayers, and a rotary impeller is mounted in the gas sterilizing chamber water sump; a homogeneous water pore plate is arranged in an adsorption chamber, the adsorption water sump is arranged below the homogeneous water pore plate, the adsorption chamber is filled with a plurality of lightweight porous adsorption carriers, and the lightweight porous adsorption carriers are made from activated carbon materials. The river water pretreatment device provided by the invention integrally adopts a vertical structure, is small in floor space, and suitable for transforming in an existing waterworks or building renewedly and installing, the process is simple, the operation is convenient, the energy consumption and operation cost are low, and a better river water pretreatment effect is realized.

Owner:内乡县水利局

A coaxial double-head diamond boring machine and fine boring method thereof

InactiveCN103949688BUniform processing effectReduce labor intensityBoring/drilling machinesTransmission beltEngineering

The invention discloses a coaxial double-head diamond boring lathe and a fine boring method thereof. The coaxial double-head diamond boring lathe comprises a supporting frame, a step motor, a lead screw, a connecting frame, an upper alternating current motor, an upper transmission belt, an upper encoder, an upper main shaft, a clamp, a workbench, a hydraulic device, a lower main shaft, a lower encoder, a lower transmission belt, a lower alternating current motor, guide rails and a lathe body. The coaxial double-head diamond boring lathe can perform semi-fine boring and fine boring successively after one clamping, so that under the condition of coaxial machining, semi-fine boring and fine boring machining allowances are ensured and the balance of the fine boring allowance is ensured; by adopting a four-rail enclosed moving structure, the stability of a workpiece in the machining process and high precision are ensured; and after the workpiece is machined, through control of the hydraulic device, manual knife stripping is not required, but just the knife is taken by two hands, and through positioning of the encoders, the knife automatically drops from a cylinder sleeve. The coaxial double-head diamond boring lathe is simple to use, can reduce the labor intensity of working staff and improves the production efficiency.

Owner:QUZHOU UNIV +1

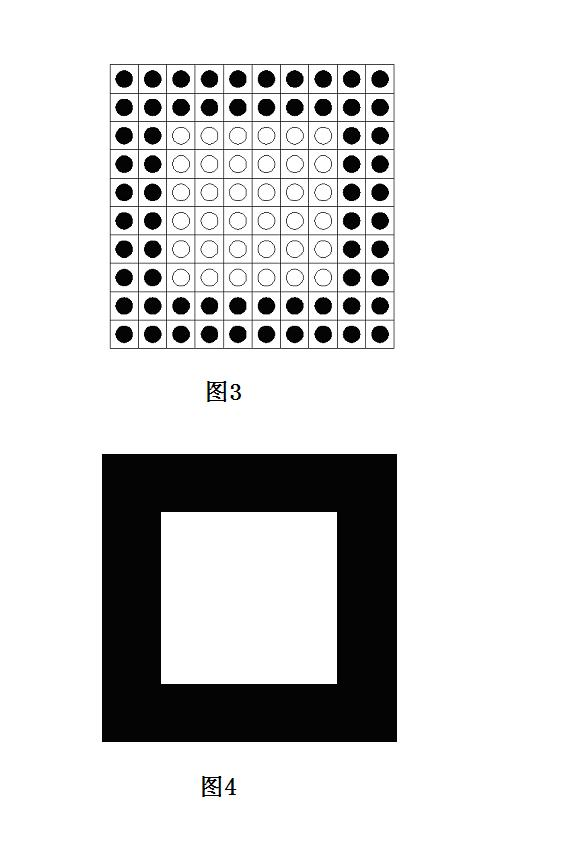

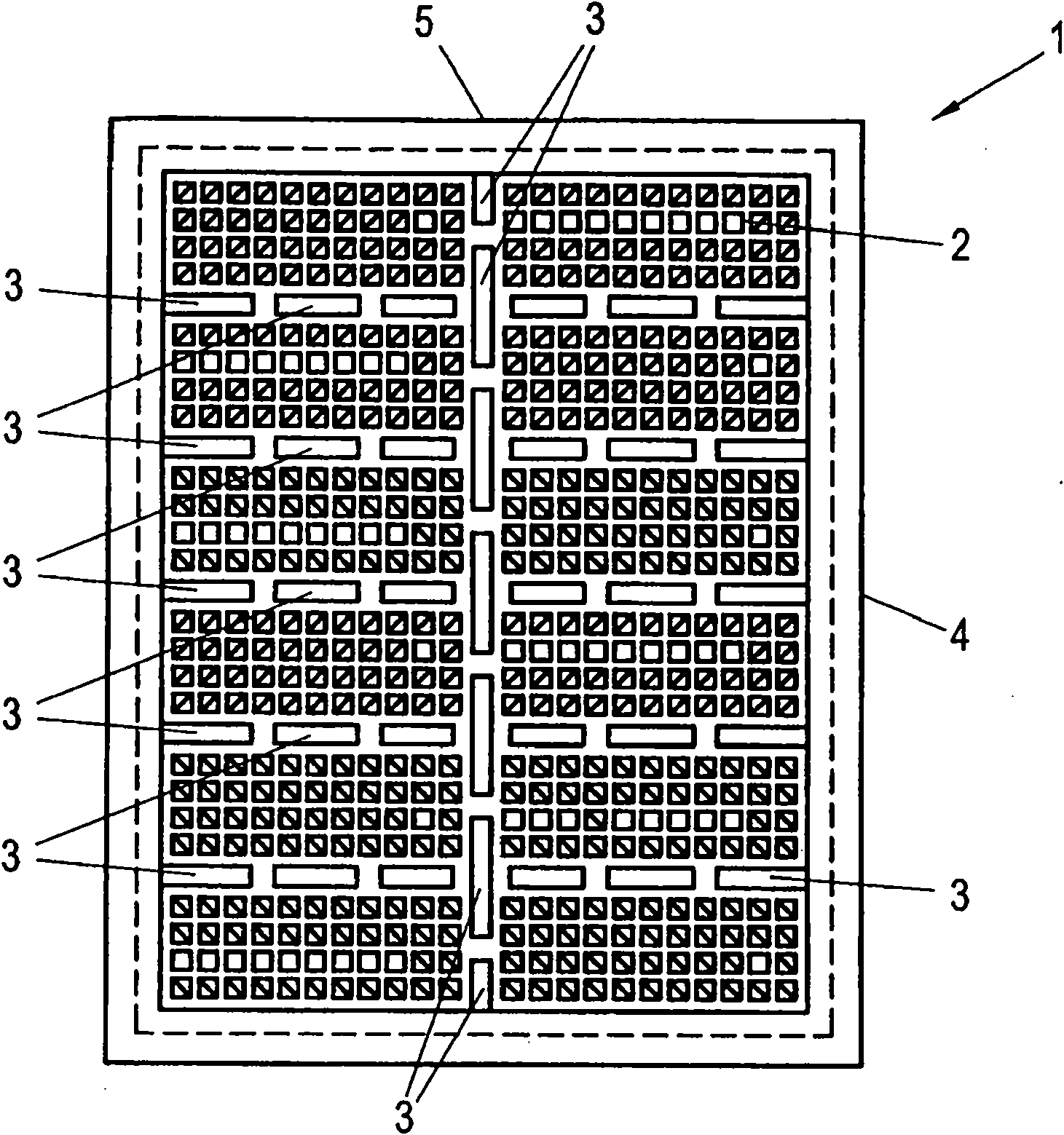

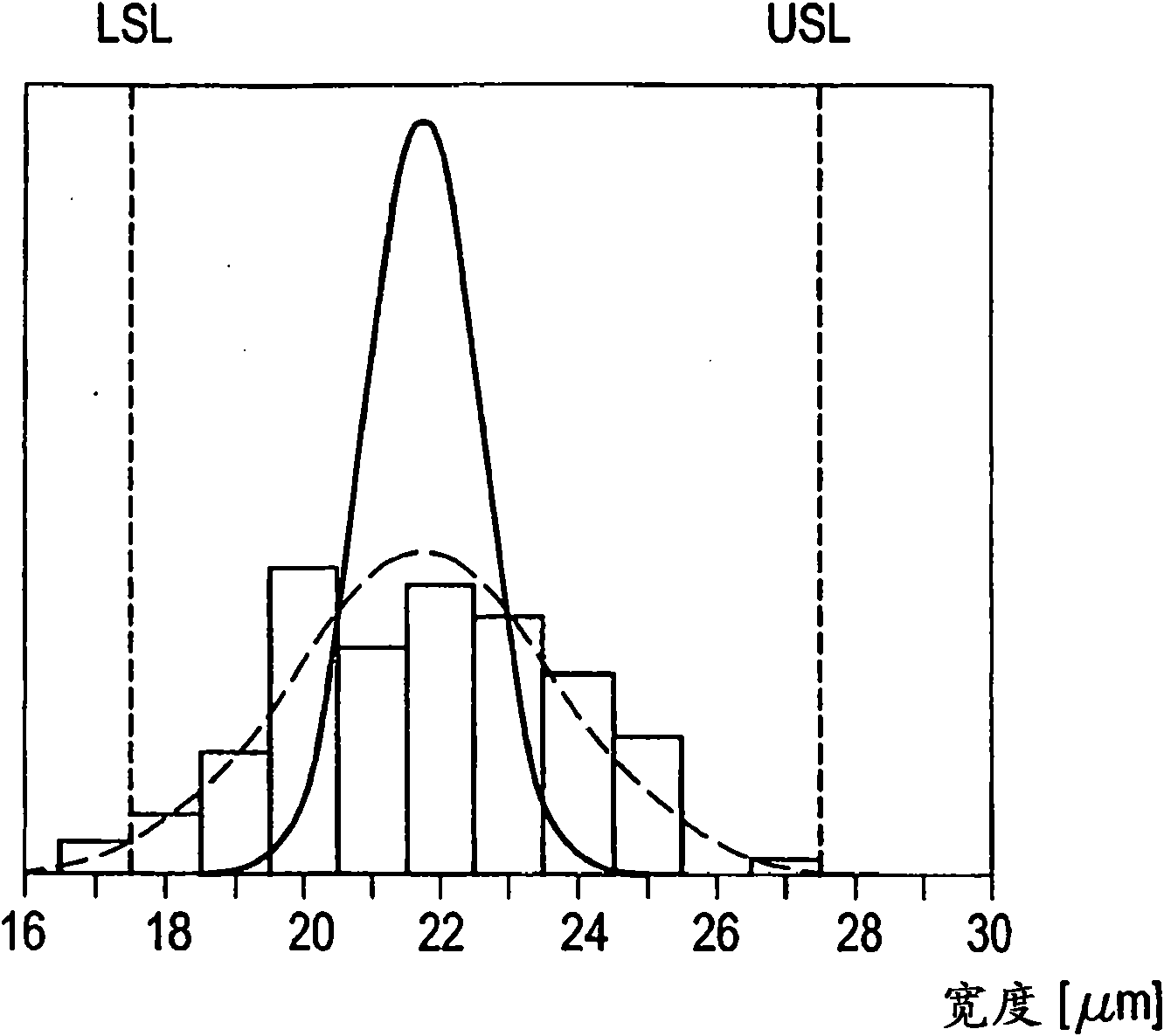

Method for treating the surface of a planar object, planar object and use

ActiveCN102172108AHigh precisionShort durationPrinted circuit liquid treatmentStatic indicating devicesLiquid mediumEngineering

The present invention relates to a method for treating the surface of a planar object (1) by applying a liquid medium (6) to the surface (2) so as to change the structure and / or property of the surface (2) by at least partially removing material from the surface (2) due to the action of the liquid medium (6) on the material of the surface (2), wherein the liquid medium (6) that is applied or employed for treating the surface is removed therefrom at the boundary or edge regions (4, 5) of the surface disposed substantially horizontally during the treatment, it is proposed to additionally removethe liquid medium (6) applied for treating the surface (2) from the surface (2) to be treated in at least one area located at a distance from the boundary or edge regions (4, 5) of the surface (2), whereby evening of the surface (2) and / or the structures to be produced thereon can be achieved while the treatment or processing is performed. Such a method and such a planar object can preferably be used to produce printed circuit boards.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

Hemp fiber reinforced polypropylene engineering composite material and its preparation method and application

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Array electrode cavity for jet electrodeposition

The invention provides an array electrode cavity for jet electrodeposition. The electrode cavity is characterized by comprising a top cover, a cavity, a sleeve, an array electrode, a sealing ring, a rigid retainer ring and a tightening nut, wherein the top cover is in threaded connection with the cavity; the sleeve clamps the array electrode; the elastic sealing ring and the retainer ring are sequentially connected on the array electrode in series; the cavity and the nut are in threaded connection; and the top of the sleeve is tightened by screwing the cavity and the nut, so that the array electrode is clamped, the elastic sealing ring and the retainer ring are pressed tightly, and the shape of the extending section of the array electrode is limited by the retainer ring. According to the array electrode cavity, an array electrode nozzle with an arbitrary section shape and profile can be formed at the bottom of the electrode cavity, so that uniform electric field and flow field in jet electrodeposition processing can be acquired, the current density of electric deposition is improved, local concentration of metal ions is improved, oxidation in electrodeposition is avoided, and efficiency and quality of electrodeposition are finally improved. Processing of electrodeposition parts with special structures can be realized by designing array electrode cavities with different shapes and controlling conduction of the electrode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

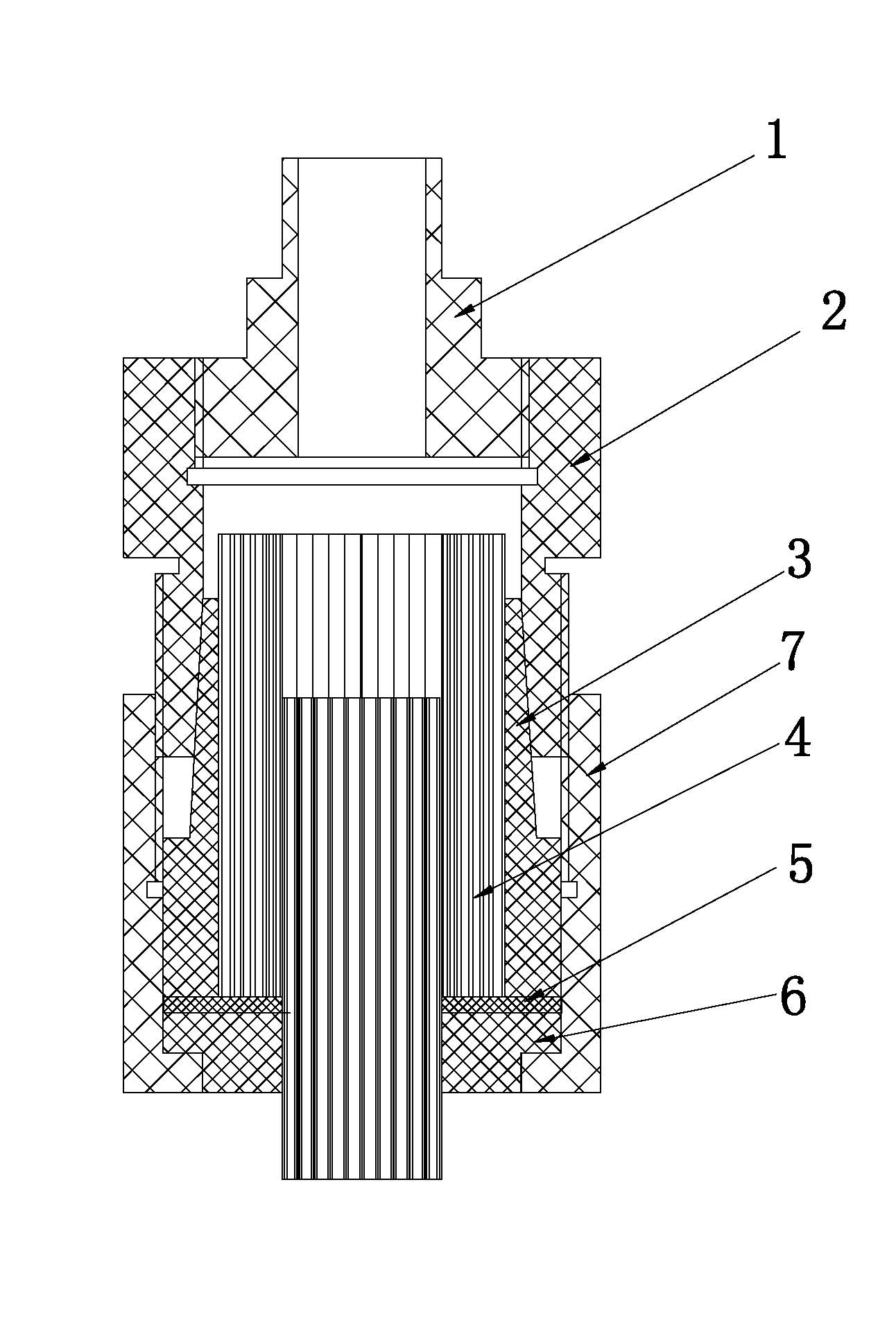

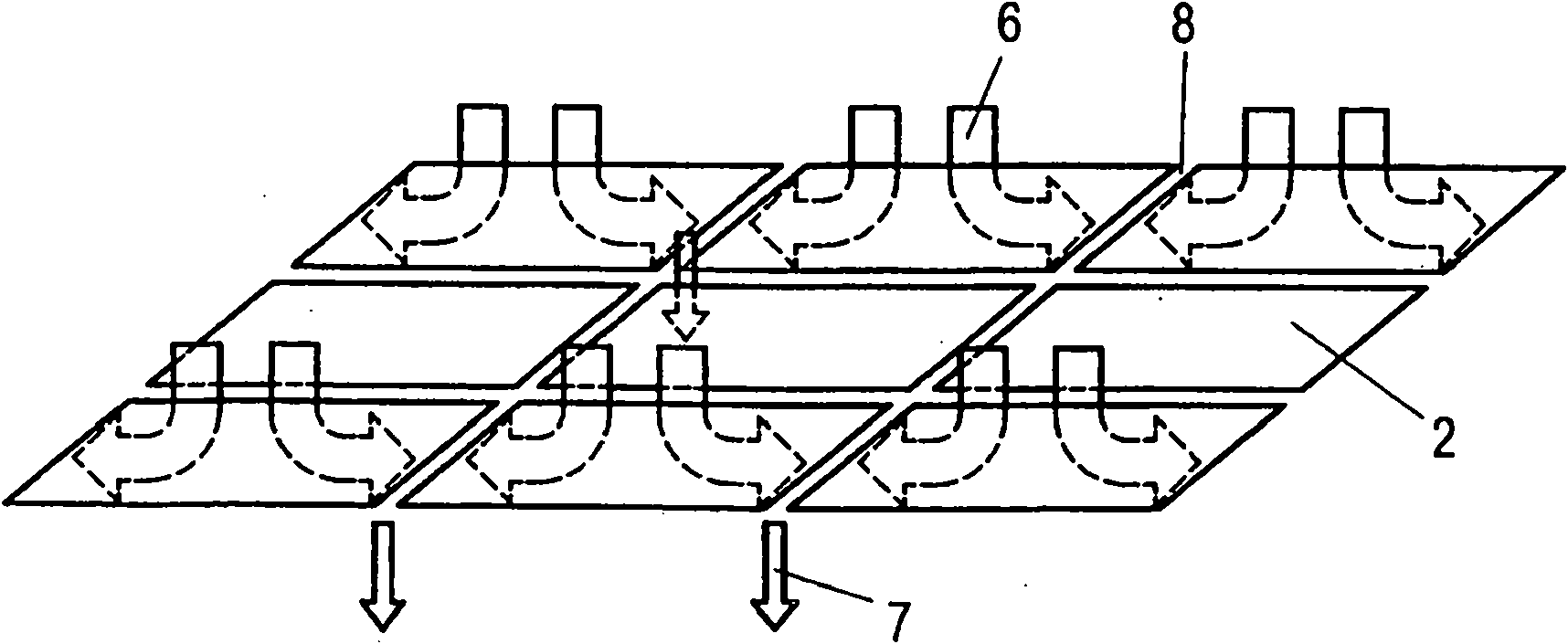

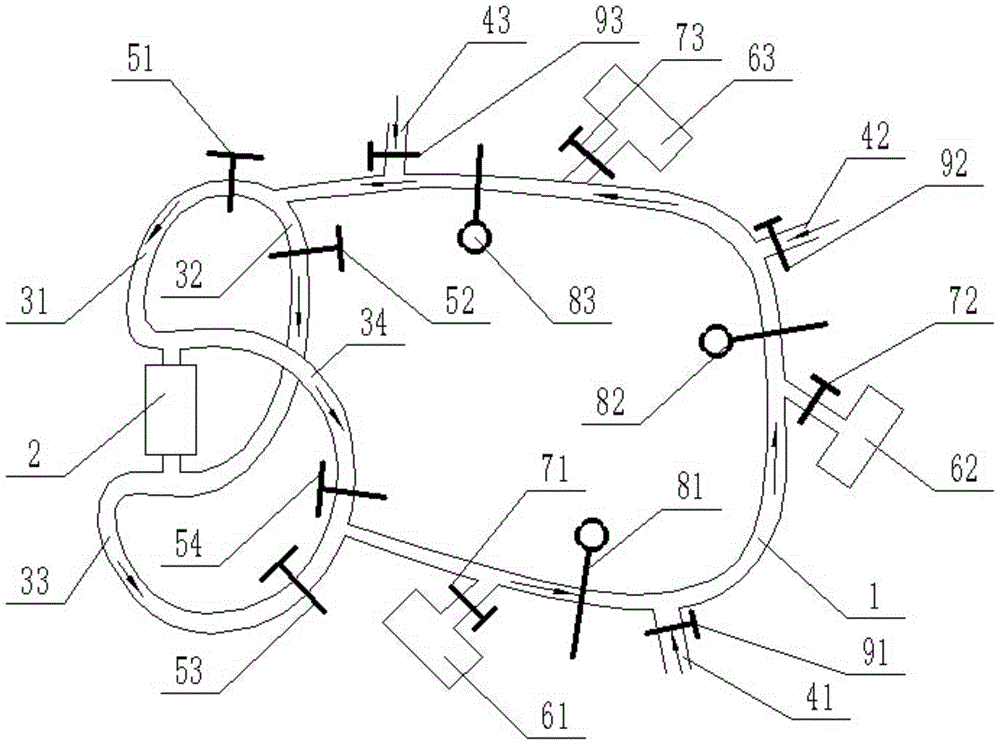

Three-way fluid polishing device for curved surface of human body joint and control method thereof

ActiveCN104690651BGet rid of the bondageImprove machining accuracyAbrasive blasting machinesParticle flowArtificial joints

The invention discloses a three-way human body joint curved-surface fluid polishing device. The three-way human body joint curved-surface fluid polishing device comprises a processing passageway and a fluid main pipe, wherein soft abrasive particle flow which is formed by mixing abrasive particles and water is stored in the fluid main pipe, two ends of an inlet and an outlet of the processing passageway are respectively connected with a three-way connector, two ends of the fluid main pipe are respectively connected with the three-way connectors on two ends of the inlet and the outlet of the processing passageway by virtue of a first branch pipe, a second branch pipe, a third branch pipe and a fourth branch pipe, and the processing passageway, the first branch pipe, the second branch pipe, the third branch pipe, the fourth branch pipe and the fluid main pipe are connected together to form a closed fluid circulating system. The three-way human body joint curved-surface fluid polishing device is simple and compact in structure and low in production cost; by adopting the three-way fluid passageway, two sides of an artificial joint can be uniformly polished by virtue of the soft abrasive particle flow; the gas is used as the power source of the abrasive particle flow, so that the probability of the abrasive particles for colliding with a workpiece can be increased, and the processing efficiency is improved; the entire processing flow can be completely automatically controlled, and the restriction for polishing the artificial joint by utilizing a tool can be avoided.

Owner:陕西斯坦特生物科技有限公司

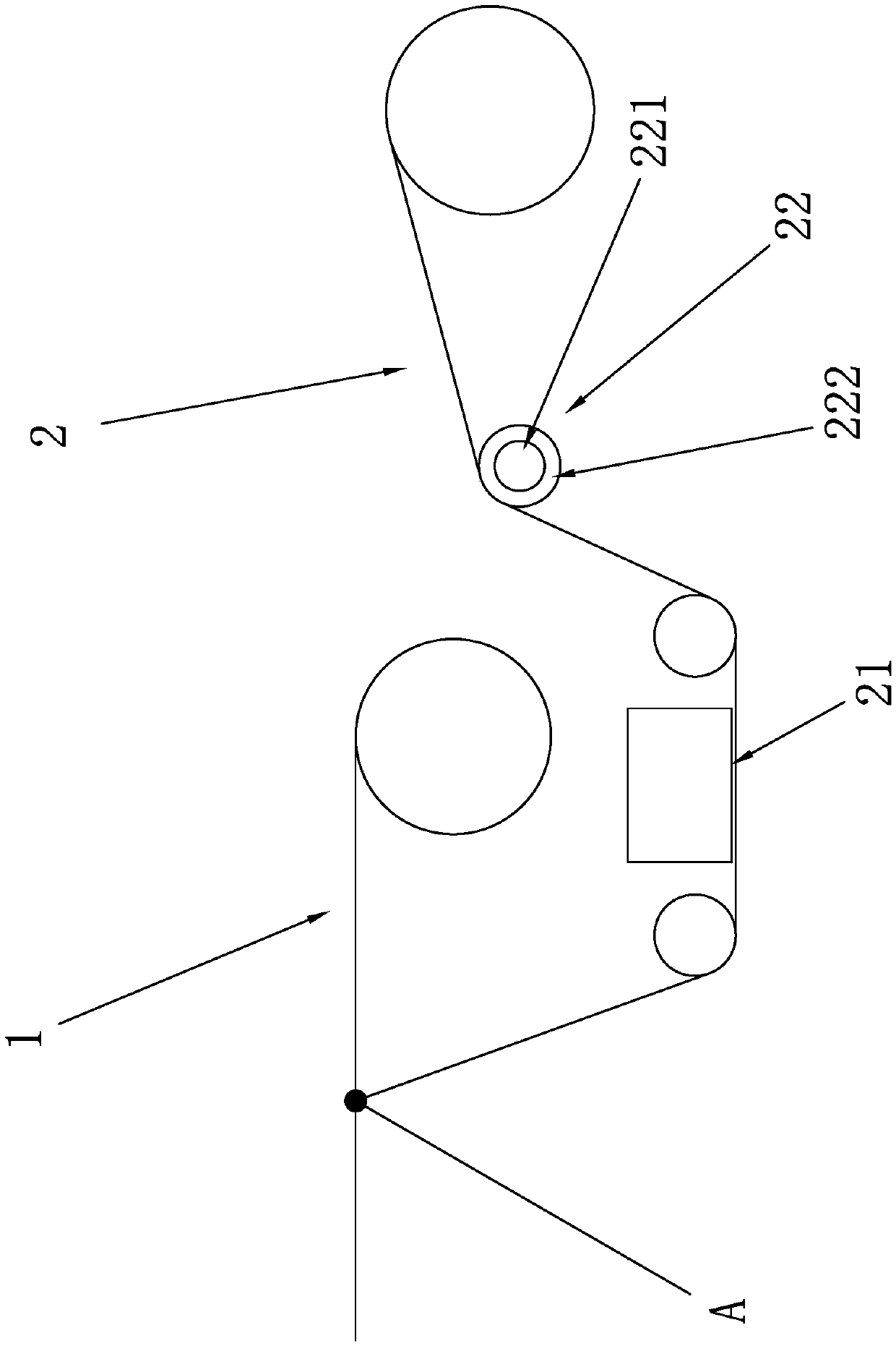

Metal sheet paper coating device

InactiveCN108674756AControl moisture contentUniform processing effectPackagingMetal sheetPulp and paper industry

The invention discloses a metal sheet paper coating device. The metal sheet paper coating device comprises a rack; a metal sheet conveying line and a cushion paper conveying line are arranged on the rack; the metal sheet conveying line and the cushion paper conveying line converge at a composite node; the cushion paper conveying line comprises a corona treatment mechanism and a drying mechanism; and the drying mechanism is located before the corona treatment mechanism. The metal sheet paper coating device disclosed by the invention has the advantages that the moisture rate of cushion paper isfavorably controlled through the additionally arranged drying mechanism, so that a uniform treatment effect is realized after the cushion paper passes through the corona treatment mechanism subsequently. The metal sheet paper coating device can be applied to metal cutting equipment, and production efficiency can be effectively improved; the defective rate is lowered; and the competitiveness of anenterprise is enhanced.

Owner:佛山宝钢不锈钢贸易有限公司

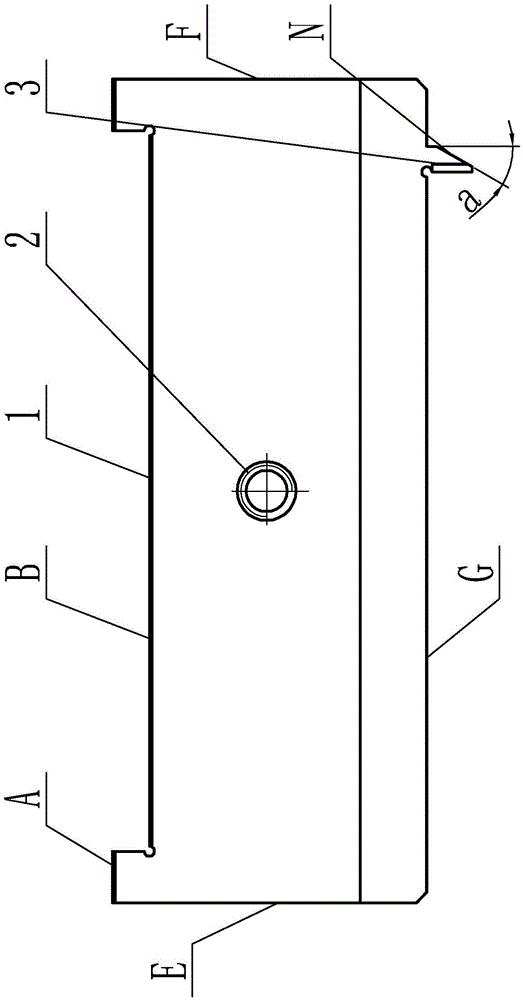

On-site Machining Method of Generator Rotor Yoke Keyway

ActiveCN103978344BEasy to operateWide range of processing heightsBroaching machinesPunch pressReciprocating motion

The invention relates to a technology method for processing a magnetic yoke key groove of a generator rotor in a construction site. The technology method is characterized in that a dedicated tool is utilized for processing, a push-pull cutter is placed in a main vertical rib 2 of a rotor support, guiding is carried out by a magnetic yoke key groove cutter body 4 during processing, the bottom surface of a supporting plate 3 is not used for locating, and interference and abrasion are avoided; the tool does reciprocating motion along the axial direction of the magnetic yoke key groove during the processing, the magnetic yoke key groove is processed in the construction site, the wave degree in the magnetic yoke key groove is removed, and the magnetic yoke key groove is enabled to be smooth for conveniently adding a gasket. The technology method adopting the tool can be applied to a magnetic yoke punching sheet in higher edge hardness by laser cutting and blanking and can also be applied to a magnetic yoke punching sheet by blanking of a punching machine, and the application range is wide; the normal injecting of the gasket and a magnetic yoke convex key after a magnetic yoke 1 is heated can be ensured by utilizing the cutter for processing the key groove, a numerical value of thermal sleeving amount of the magnetic yoke can be effectively ensured, and necessary protection is provided for safe and stable running of the generator rotor and a unit.

Owner:HARBIN ELECTRIC MASCH CO LTD

A stone lychee noodle knocking machine

InactiveCN101811330BIncrease productivityUniform processing effectStone-like material working toolsEngineeringMechanical engineering

The invention relates to a stone bush-hammered surface hammering machine, which comprises a worktable, a machine frame arranged on the worktable, a lifting assembly arranged on the machine frame, a left and right swing motor assembly arranged on the machine frame, a main plate seat arranged on the machine frame, a bush-hammered surface processing device arranged on the main plate seat and a left and right swing assembly arranged between the main plate seat and the machine frame. The bush-hammered surface hammering machine can process regular concaves and convexes on the surface of a stone to process a surface similar to the skin of leechee and is used in place of the traditional pneumatic hammer which is held manually and pushed to process the bush-hammered surface. The machine improves production efficiency, offers uniform and time-saving process, makes operation convenient, realizes uniform processing effect even through a workpiece has a thickness tolerance during the processing of the workpiece and can process the bush-hammered surface with processing pneumatic hammers selected randomly.

Owner:南安市鑫能机械有限公司

PC/ABS composite material with high chemical resistance and preparation method thereof

The invention provides a PC / ABS composite material with high chemical resistance and a preparation method thereof. The composite material comprises the following components in percentage by weight: 60-85% of polycarbonate; 15-40% of ABS; 0.5-5% of a compatilizer; and 3-10% of a rheology modifier. The preparation method comprises the following steps: mixing the components in the raw materials according to a certain ratio at room temperature, and carrying out melt extrusion through double screws to prepare the PC / ABS composite material which is easy to process, excellent in mechanical propertiesand high in chemical resistance, and the preparation method of the PC / ABS composite material. The prepared composite material is excellent in mechanical property and easy to process, meanwhile, excellent chemical resistance is kept, and the product is excellent in appearance.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

A kind of sapphire laser slotting device and slotting method thereof

ActiveCN105458515BSimple structureFast processingSemiconductor/solid-state device manufacturingLaser beam welding apparatusBeam expanderHelical scan

The invention relates to the technical field of laser processing, and discloses a sapphire laser slotting device and a slotting method thereof. The slotting device includes a laser, a reflector, a beam expander, a vibration mirror, a focusing mirror, a platform and a computer, and The sapphire sample is set on the platform, and the reflector, beam expander, vibrating mirror and focusing mirror are arranged above the sapphire sample to be processed in sequence from top to bottom. The center is located on the same straight line, the laser is located on one side of the reflector, and the computer is connected to the vibrating mirror; the invention adopts the continuous curve method, compared with the traditional filling scanning, the processed laser groove has better processing effect and less edge collapse The volume is small and the cross-section is smooth. In addition, according to the scanning trajectory of each layer, helical lines are generated for scanning. Such scanning trajectory can solve the phenomenon of poor processing of laser joints in conventional laser scanning, and can also avoid the jump problem caused by filling scanning. Precision.

Owner:HANS LASER TECH IND GRP CO LTD

Water treatment recycling system

ActiveCN108249661BImprove corrosion resistanceImprove mechanical propertiesWater/sewage treatment by irradiationOther chemical processesUltravioletSewage outfall

The invention provides a water treatment and cyclic utilization system. The water treatment and cyclic utilization system comprises a shell body, wherein the shell body is internally provided with a flocculation cavity, a sterilization cavity and an adsorption cavity; a controller is arranged at the bottom of the shell body; a water inlet and a sewage discharging opening are formed in two sides ofthe flocculation cavity; a flow guide plate is arranged at the bottom of the flocculation cavity; a groove is formed in the bottom of a pipe opening of a blow-off pipe; the groove is formed in the shell body; a stopping block matched with the pipe diameter of the blow-off pipe is arranged at one end of the flow guide pipe; an elastic structure is arranged at the lower end of the stopping block; the groove is internally provided with a first induction contact and an electromagnetic adsorption device; the stopping block is provided with a second induction contact and an electromagnetic adsorption part; the flocculation cavity is internally coated with polyurethane composite coating; the adsorption cavity is provided with a water inlet; the adsorption cavity is internally provided with a plurality of porous adsorption carriers; an adsorption cavity water outlet and a high-pressure washing water inlet are formed in two sides of the adsorption cavity respectively; the sterilization cavityis internally provided with a rotary ultraviolet lamp; a reflection layer is arranged on an inner wall of the sterilization cavity; a water outlet is formed in the sterilization cavity. The water treatment and cyclic utilization system provided by the invention has an automatic dirt cleaning function, can be used for comprehensively removing impurities, removing bacteria and removing undesirable odor and has a good river water treatment effect.

Owner:SHANDONG HUANNENG DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com