On-site Machining Method of Generator Rotor Yoke Keyway

A technology of generator rotor and process method, which is applied in the direction of metal processing equipment, manufacturing tools, broaching machines, etc., which can solve problems affecting the insertion of gaskets and convex keys, uneven air gaps, unit vibration, etc., so as to facilitate repair and replacement , wide range of processing height and controllable feed speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A process method for on-site machining of generator rotor yoke keyways, the method comprising the following steps:

[0025] Step 1: Machining the yoke keyway

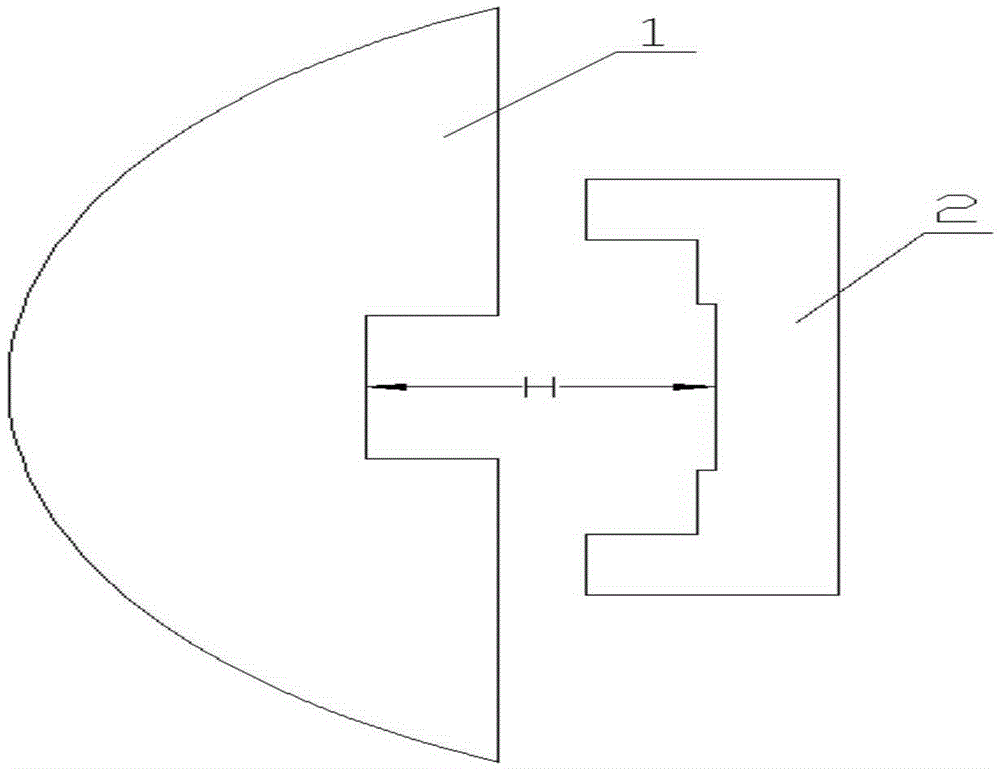

[0026] 1) if figure 1 As shown, after measuring the roundness, concentricity and verticality of the upper and lower sections of the yoke 1, measure the thickness of the keyway of the yoke 1;

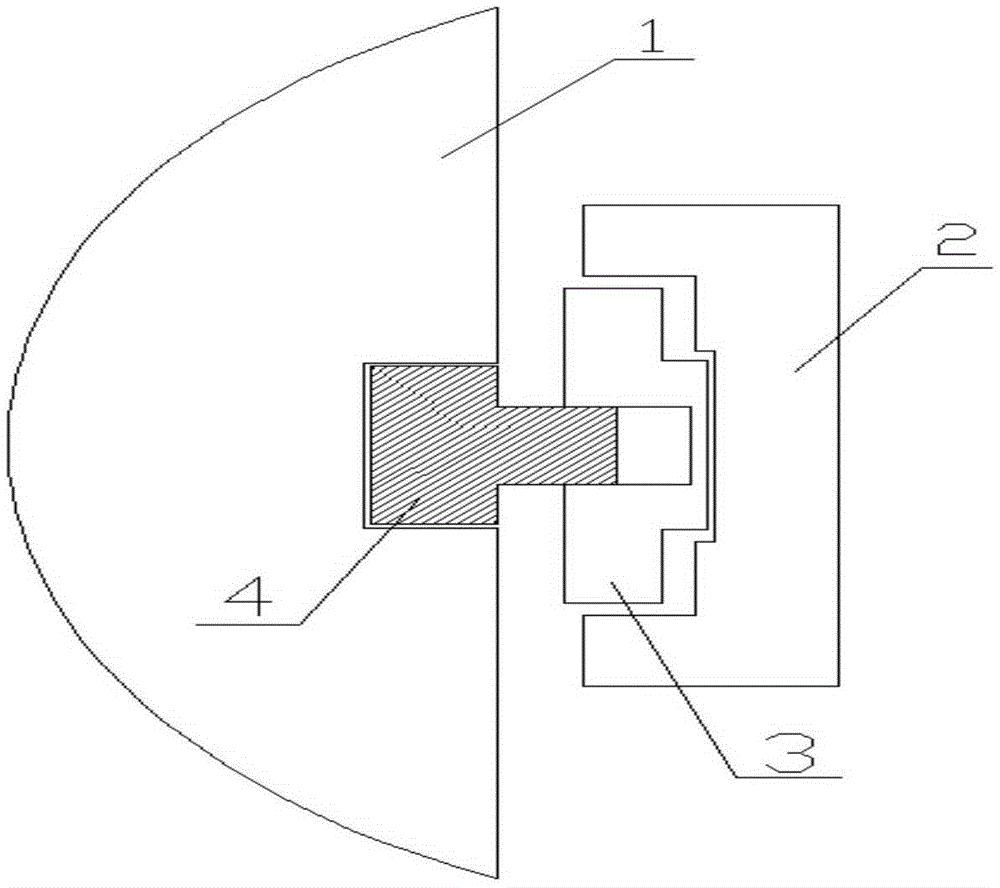

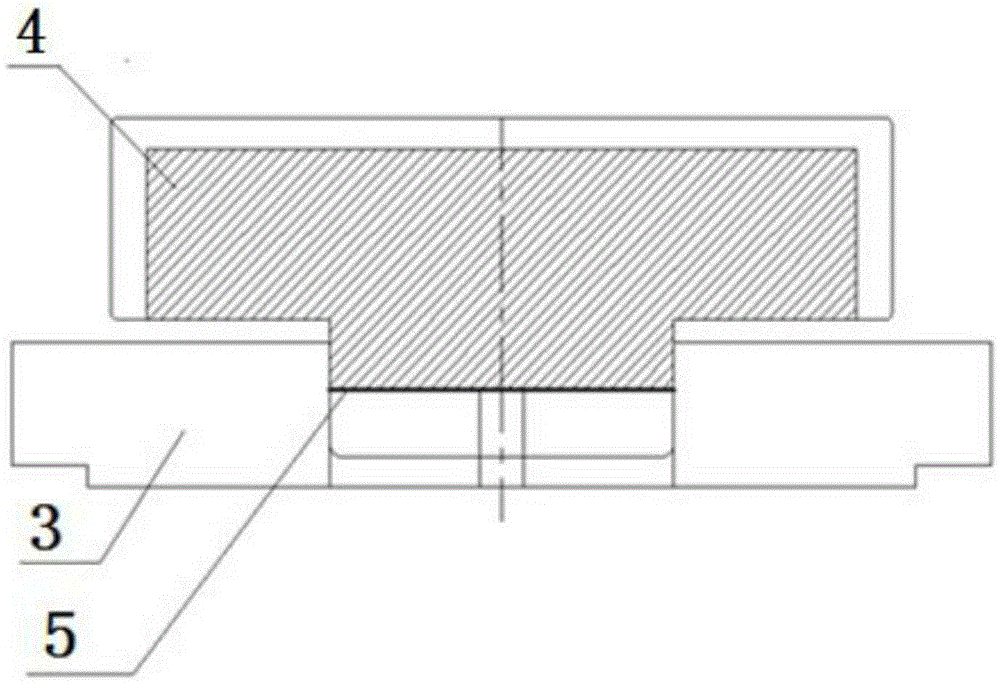

[0027] 2) Install the keyway push-pull knife and auxiliary tools. The keyway push-pull knife is composed of a knife body 4 and a supporting plate 3. The knife body 4 adopts a three-sided edge structure and is made of 9SiCr. The cutter body 4 and the supporting plate 3 are fixed with countersunk screws, and the milling direction is kept perpendicular to the punching surface of the yoke 1 during use, so that the cutting force can effectively act on the yoke 1, such as image 3 shown. A spacer 5 can be added between the cutter body 4 and the supporting plate 3 to effectively adjust the radial size of the tool. For laser cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com