Pneumatic type reinforcing machining equipment for machining bearing outer ring rolling way

A technology for bearing outer rings and processing equipment, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as property loss, processing of outer ring raceways that cannot be bearing, casualties, etc. Effects on performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical solutions of the present invention well understood by those skilled in the art, the present invention will be further described below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

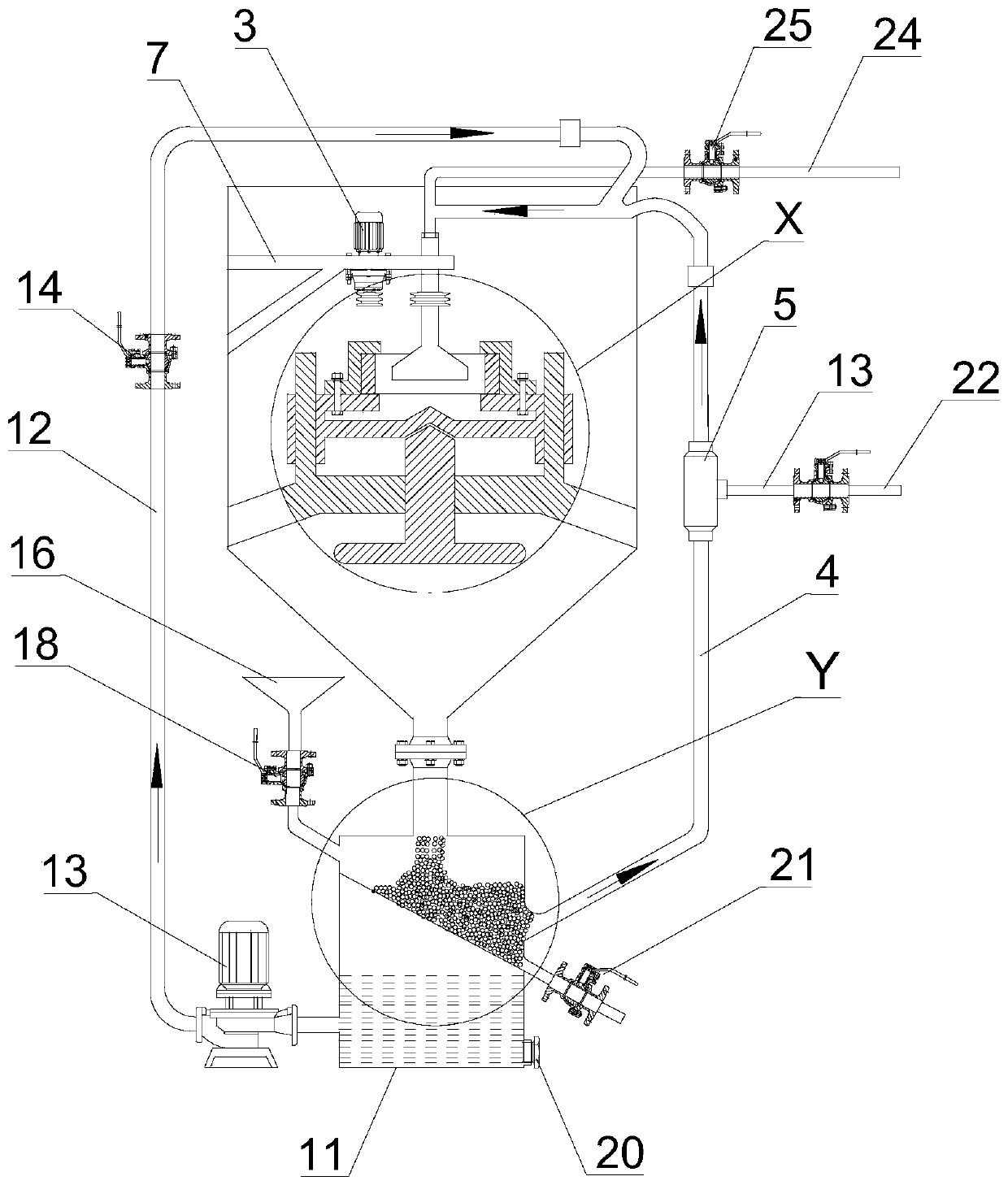

[0046] see figure 1 , The pneumatic strengthening processing equipment for processing the bearing outer ring raceway in this embodiment includes a strengthening processing module and a grinding feeding module, and the grinding feeding module includes a high-pressure feeding module, a liquid feeding mechanism and a solid-liquid feeding module. Separation mechanism; the strengthening processing module includes a processing box body 1 and a strengthening processing mechanism, and the strengthening processing mechanism is arranged in the processing box body 1 through a fixed connection structure.

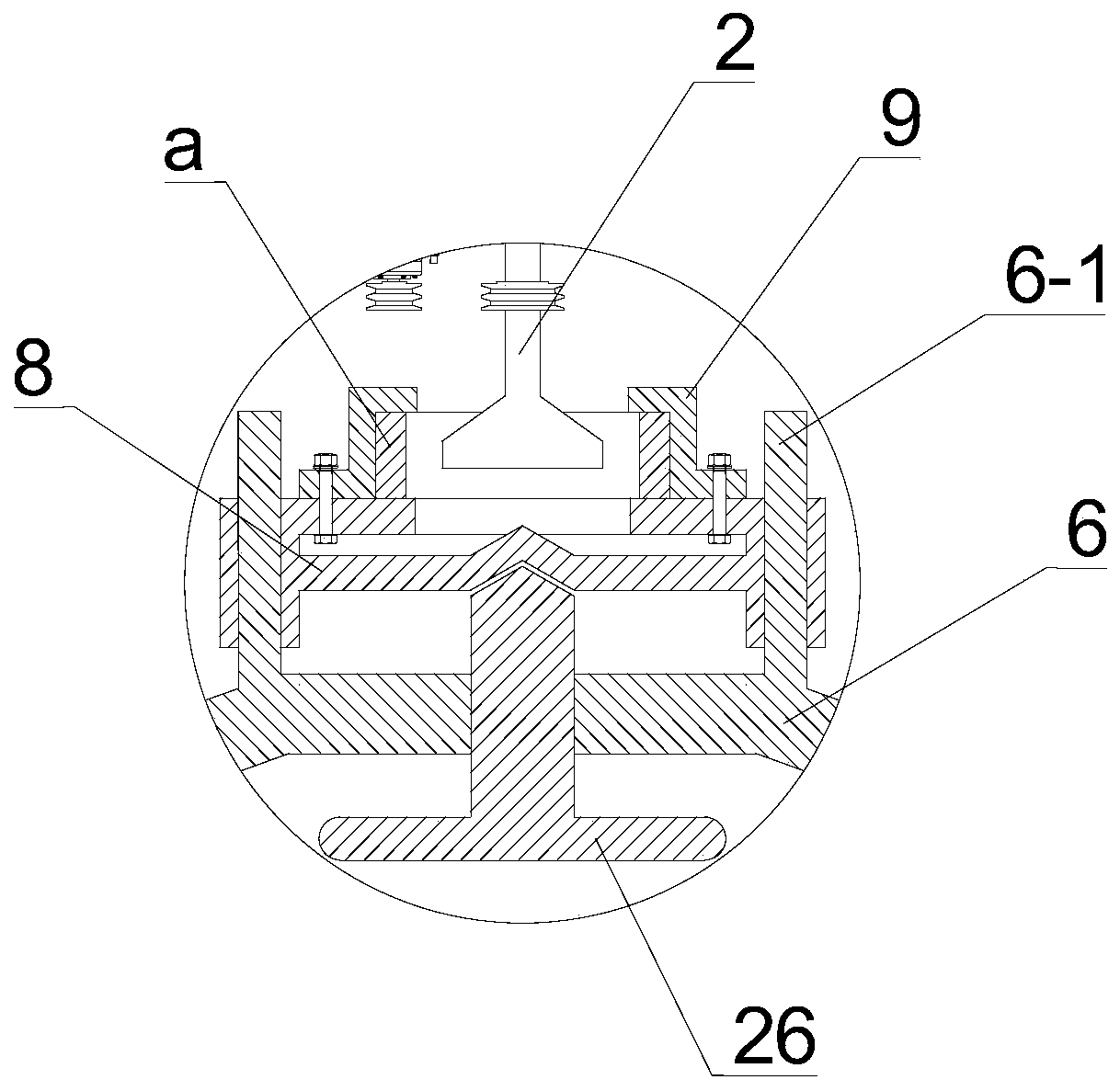

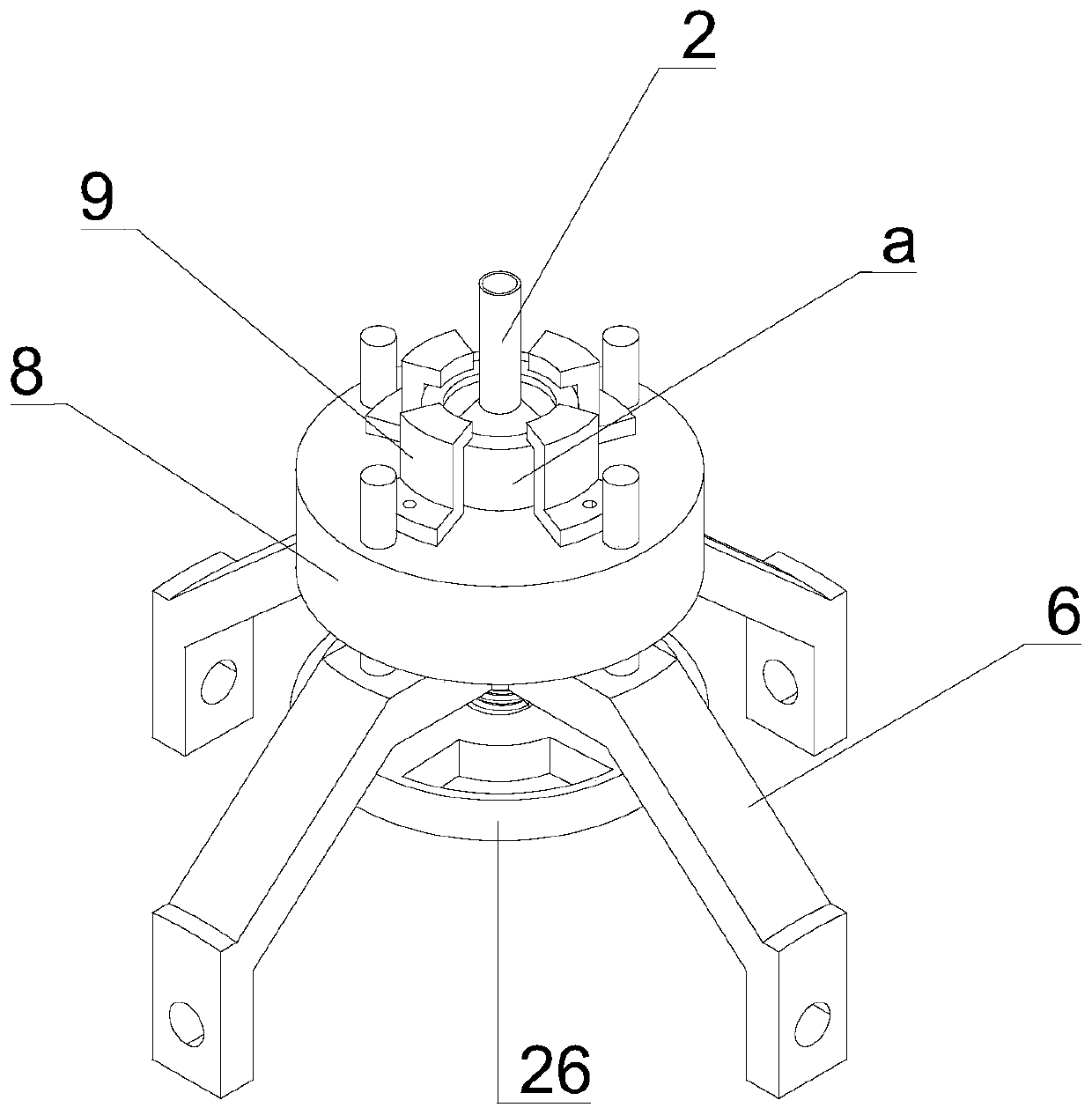

[0047] see Figure 1-4 , the strengthening processing mechanism includes a clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com