Double-shaft bulking machine and working method thereof

A technology of extruder and output shaft, which is applied in the direction of feed, food forming, food science, etc., can solve the problems that are unfavorable for the development of extruder structure miniaturization, not being able to achieve sufficient length, and occupying a large area, so as to achieve greater benefits The effect of miniaturization of development, avoidance of beating or vibration, and improvement of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

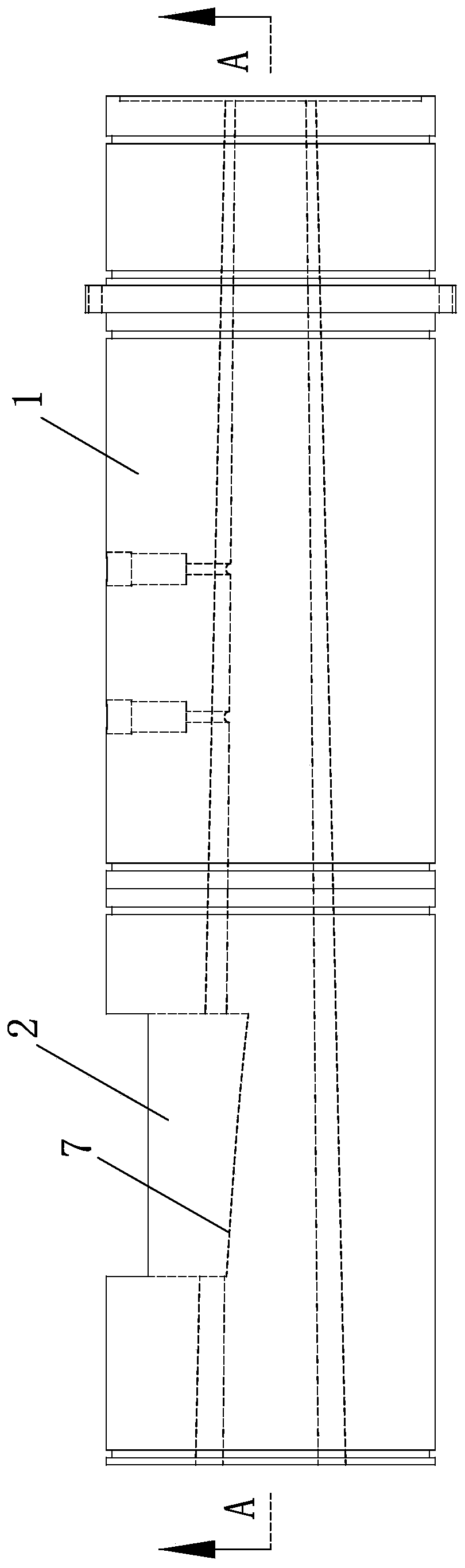

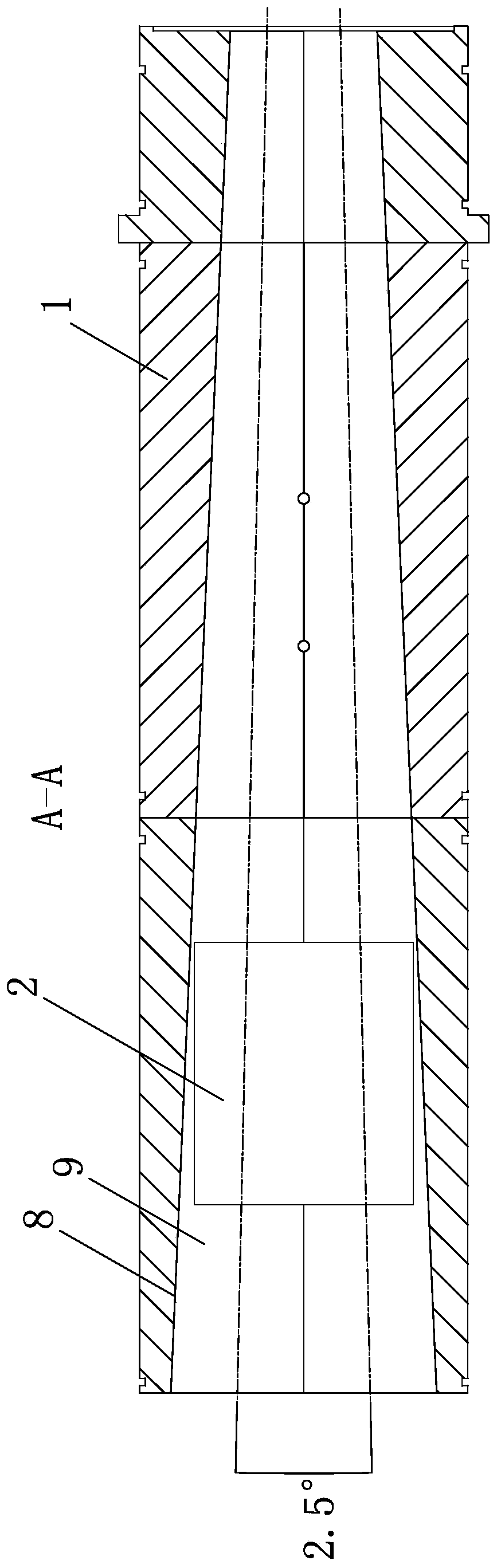

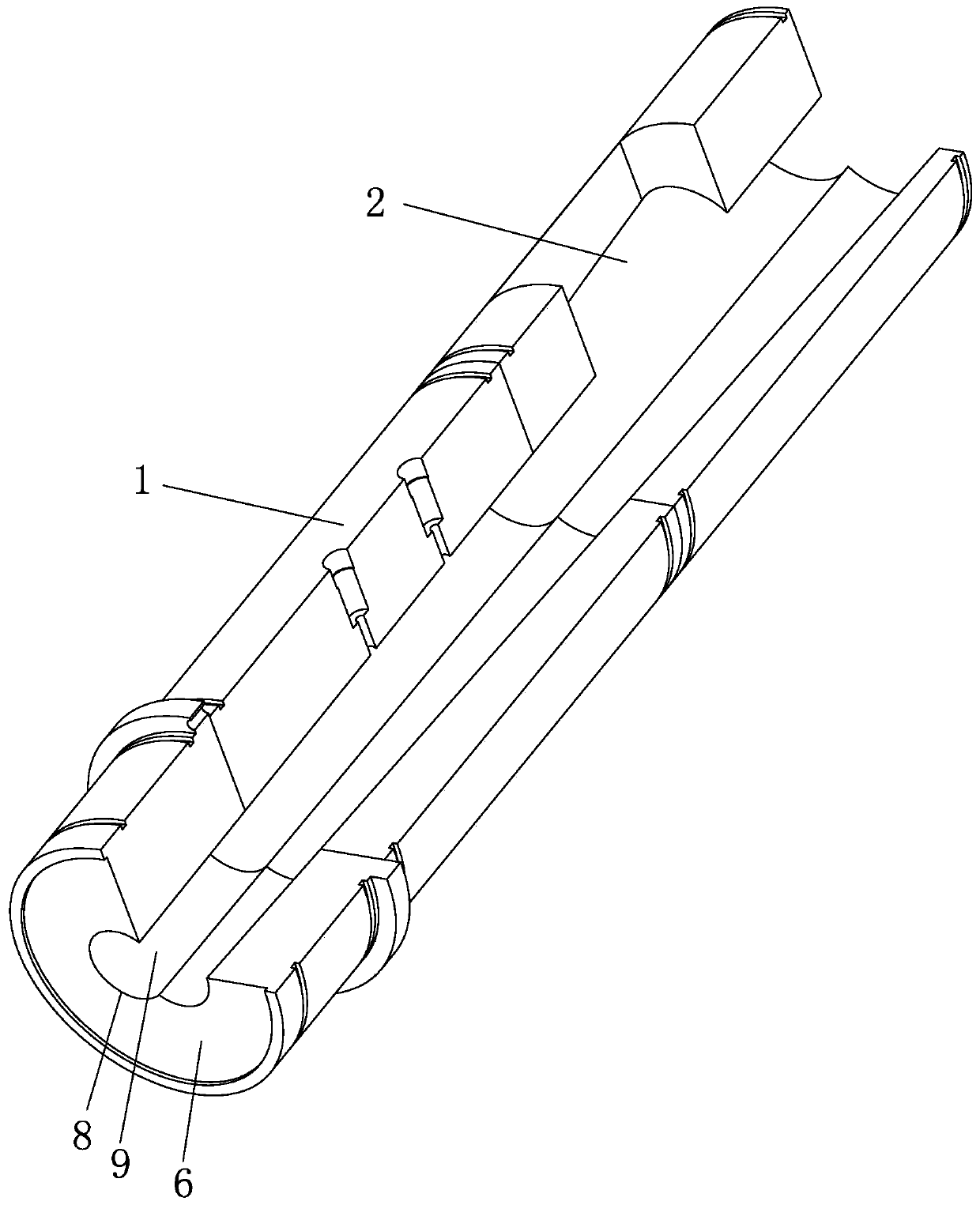

[0045] Example: such as Figure 1-16 As shown, the present invention provides a twin-shaft extruder, comprising an outer tube 1, a material inlet 2 is provided on the wall of the outer tube 1, a rotating support part 3 is formed at the front end of the outer tube 1, and a rotating support part 3 is provided on the rotating support part 3. There are two circular openings 4 in which a step 5 is provided.

[0046] Such as Figure 1-4 As shown, a bushing 6 is provided inside the outer tube 1, and the bushing 6 is arranged along the length direction of the outer tube 1; specifically, the bushing 6 is processed in sections along the length direction of the bushing 6, and is made of Made of ground alloy material, the adjacent two sections are spliced and then welded.

[0047] A notch 7 communicating with the material inlet 2 is left on the outer wall of the bush 6 , and when the material enters from the material inlet 2 , it enters the bush 6 from the notch 7 .

[0048] Inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com