Array electrode cavity for jet electrodeposition

A spray electrodeposition and array electrode technology, applied in the direction of electrodes, can solve the problems of low spray electrodeposition processing efficiency and poor deposition quality, achieve uniform spray electrodeposition processing electric field and flow field, increase local concentration, and shorten spacing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

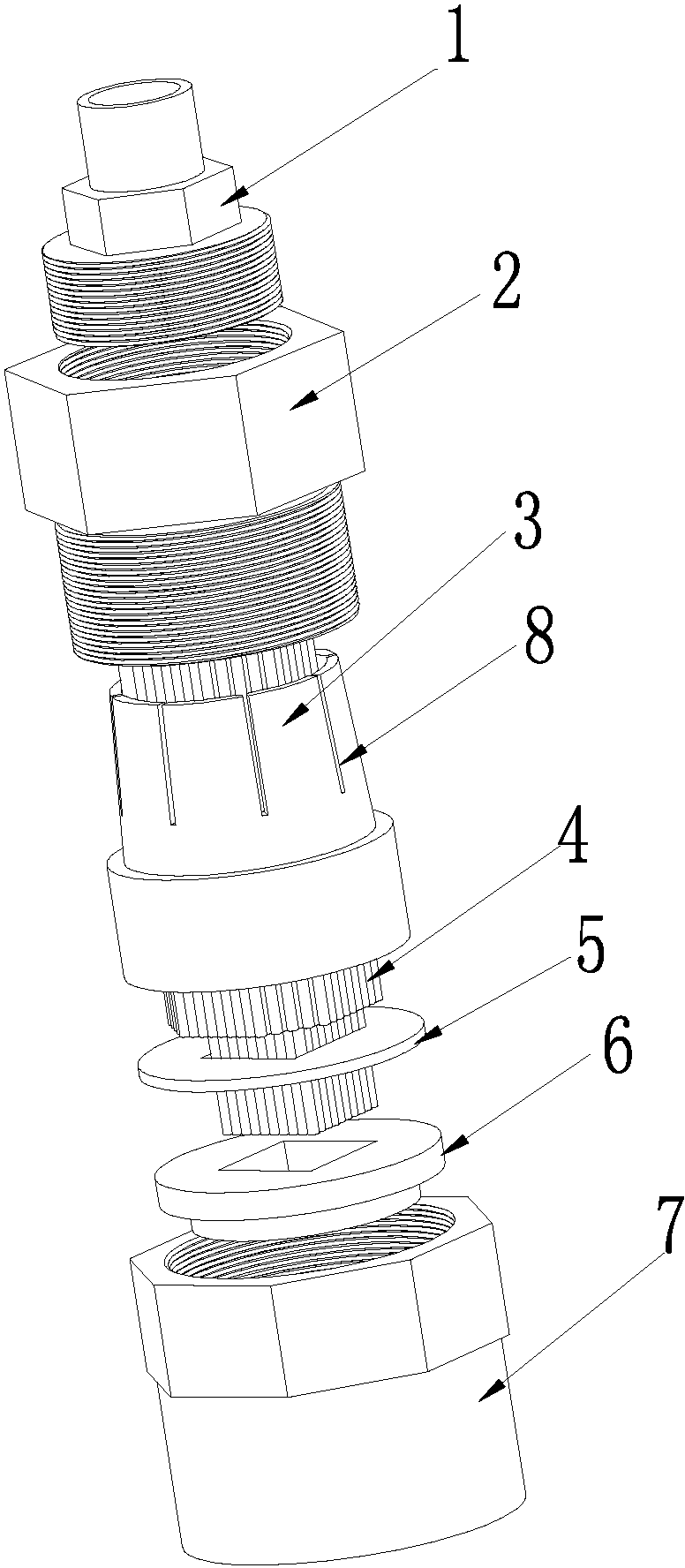

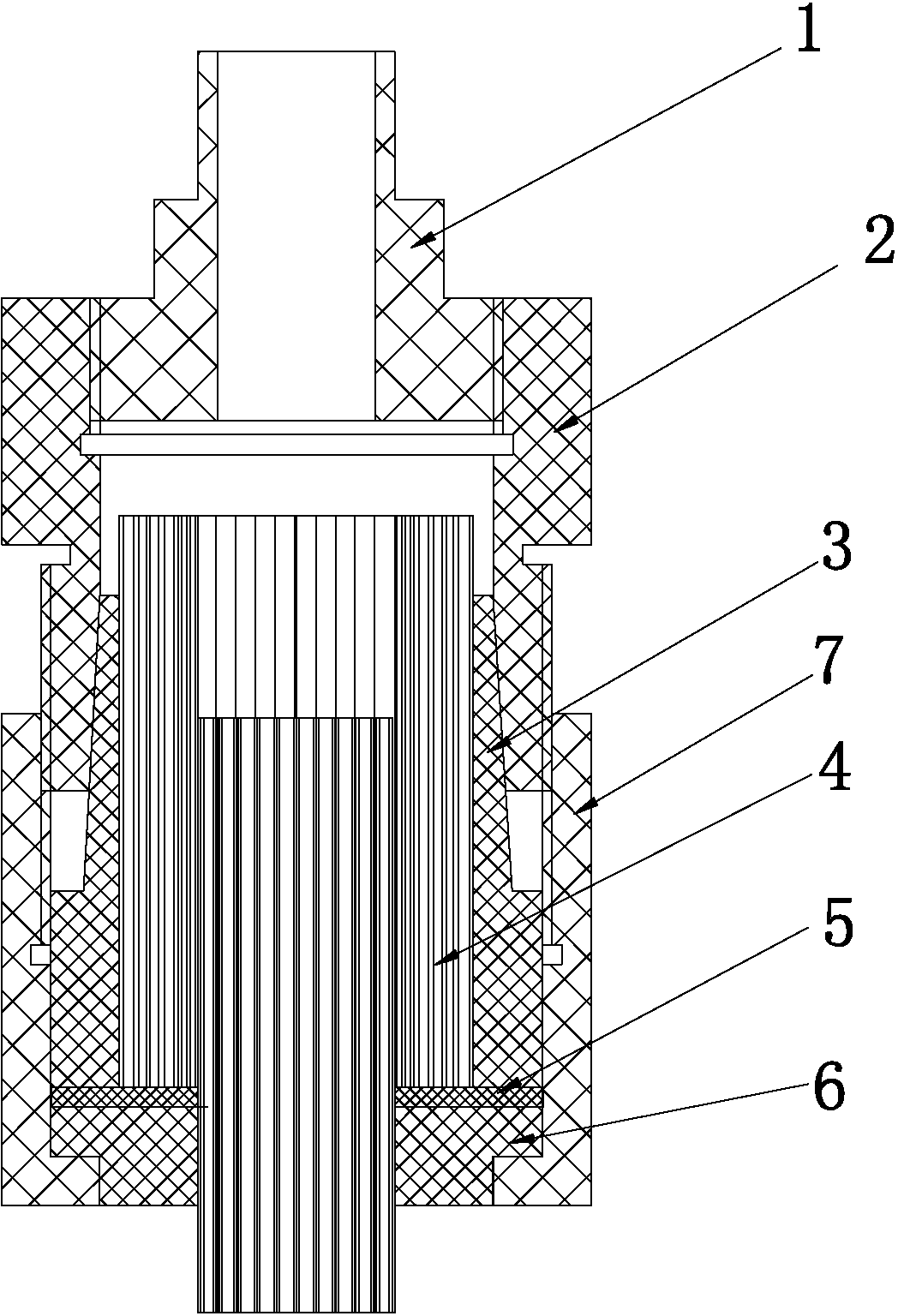

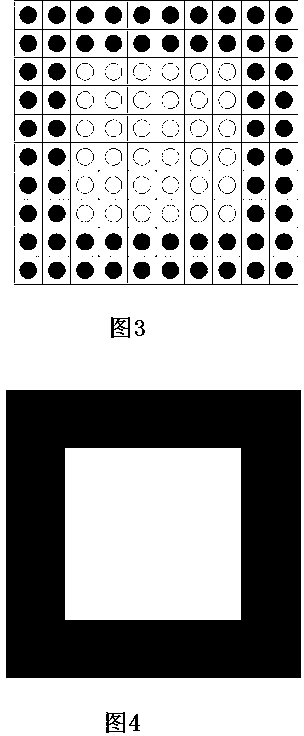

[0026] Such as figure 1 , 2 , 3, 4 shown.

[0027] An array electrode cavity for spray electrodeposition processing, such as Figure 1 to Figure 2 As shown, it has a top cover 1, a cavity 2, a casing 3, an array electrode 4, a sealing ring 5, a rigid stop ring 6 and a tightening nut 7. Wherein: the top cover 1 is threadedly connected with the cavity 2, the sleeve 3 clamps the array electrode 4, the array electrode 4 is connected in series with the sealing ring 5 and the rigid stop ring 6, and the cavity 2 and the tightening nut 7 are connected by threads. By tightening the cavity 2 and tightening the nut 7, the top of the casing 3 is tightened, the clamping of the array electrode 4 and the compression of the sealing ring 5 and the rigid stop ring 6 are realized, and the array electrode is restricted by the stop ring 6 The protruding cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com