Machining method of steam seal measuring snap-gauge

A processing method and card board technology, which can be applied to measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of complex structure, long processing cycle and high manufacturing cost, meet the requirements of uniform hardness, improve processing efficiency and reduce scrap rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

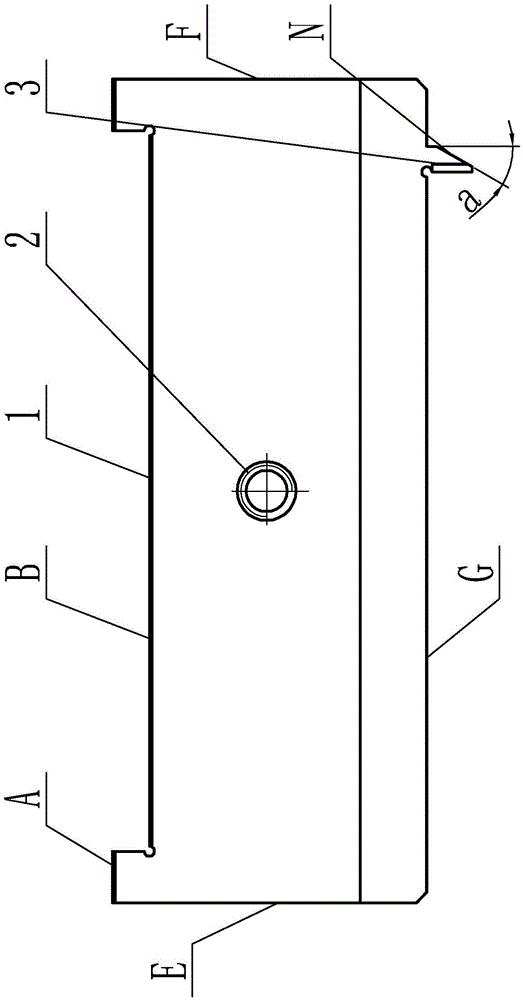

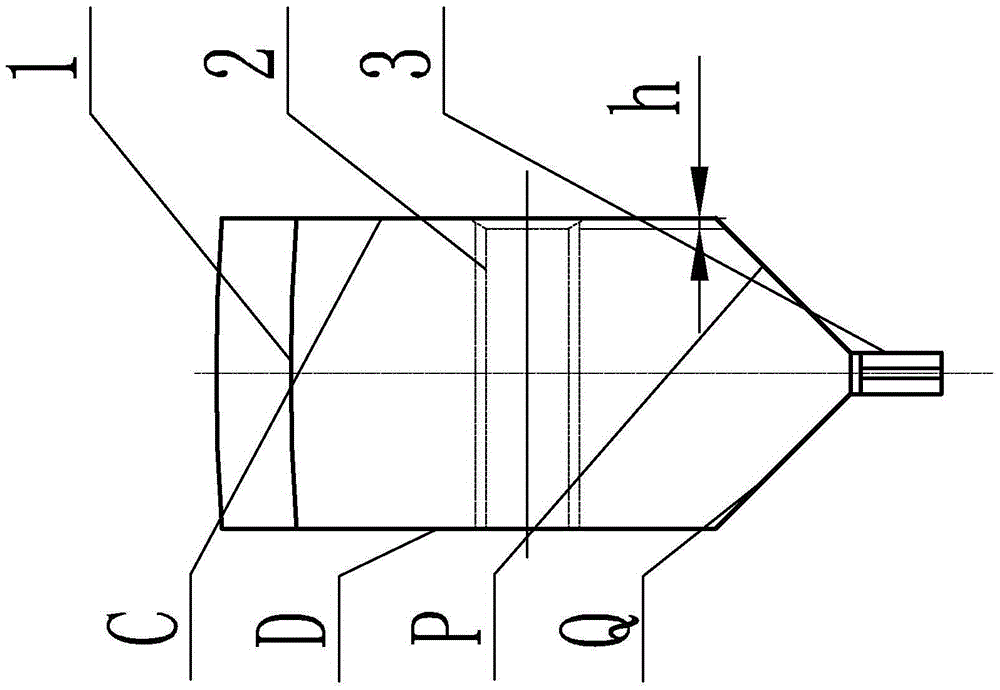

[0022] Specific implementation mode one: combine Figure 1-Figure 2 To illustrate this embodiment, the processing method of a steam seal measuring clamp described in this embodiment is carried out according to the following steps:

[0023] Step 1, prepare the rough blank: prepare the cuboid blank, and install the cuboid blank on the milling machine to mill the blank. The length of the blank milling process is 160.5mm, and the width of the blank milling process is 30.5mm. The height of the milling process is 74mm, the speed of the milling cutter is 350r / min, and the feed rate of the milling cutter is 0.4mm / r;

[0024] Step 2. Rough machining of the side of the blank: the rectangular parallelepiped blank is installed on a grinding machine to roughly grind the rectangular parallelepiped blank, and the four sides of the rectangular parallelepiped blank are ground with a size of 160.5mm×74mm. After grinding, the size of each side is 160mm ×74mm, grind the two end faces of the cubo...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination Figure 1-Figure 2 Describe this embodiment, a method for processing a steam seal measuring clamp described in this embodiment, the specific steps of the method are as follows: in the sixth step, the intersection of the first side C and the threaded hole 2 is processed with a chamfer. The width of the chamfer is h, and h is 1mm. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com