Production method of large-caliber high-pressure boiler tube

A high-pressure boiler tube and production method technology, which is applied in the field of seamless steel tube manufacturing, can solve the problems of poor comprehensive performance, poor quality and dimensional accuracy of the inner and outer surfaces of steel tubes, and insufficient control precision of the feeding system, so as to achieve dense and uniform internal structure, improve The effect of improving the quality of steel pipes and improving the quality of internal and external surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

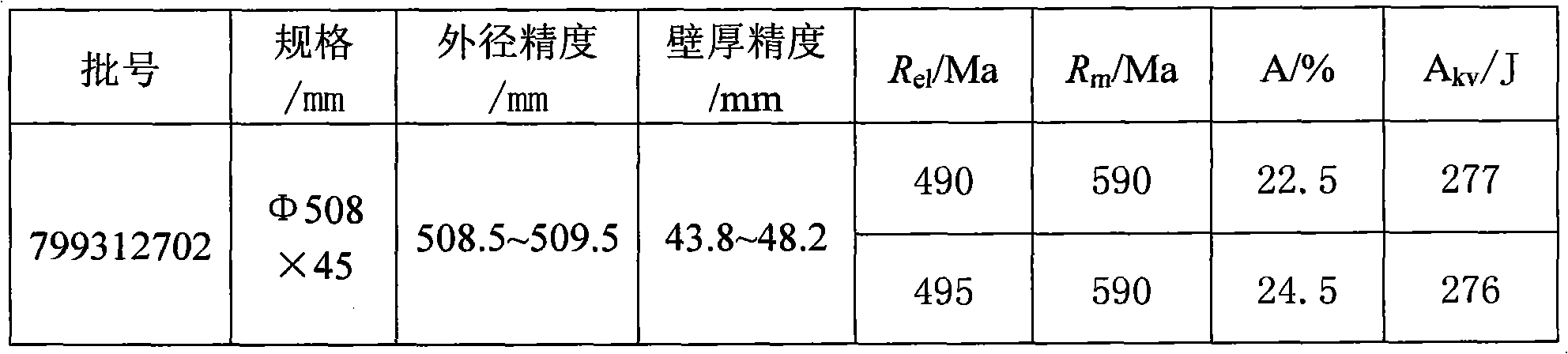

[0019] In this embodiment, the ∮720 branch factory of Hengyang Valin Steel Pipe Co., Ltd. adopts the production method provided by the present invention to produce a large-diameter high-pressure boiler tube with a brand name of 12Cr1MoVG and a specification of Φ508×45mm.

[0020] The composition of large-diameter high-pressure boiler tubes is expressed in mass%, specifically: C: 0.08-0.15, Si: 0.17-0.37, Mn: 0.40-0.70, P: ≤0.025, S: ≤0.010, Cr: 0.90-1.20, Mo : 0.25 ~ 0.35, V: 0.15 ~ 0.30, the rest is Fe and unavoidable impurities.

[0021] The production process includes:

[0022] Billet inspection→sawing and blanking→ring furnace heating→mandrel piercing machine piercing→mandrel pre-piercing→rolling mill rolling→hot sawing pilger head→stepping furnace reheating→high pressure water descaling→sizing machine Sizing→Cooling on cooling bed→Heat treatment→Sampling→Qualified physical and chemical inspection→Straightening→Cut head and tail→Manual preliminary inspection→Grinding inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com