Die mold

A die-casting mold and mold technology, which is applied to the field of die-casting molds fed from the bottom of the slider, can solve the problems of increasing the cost of die-casting parts, the failure rate of castings that cannot be formed, and achieve the effect of improving internal and external quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

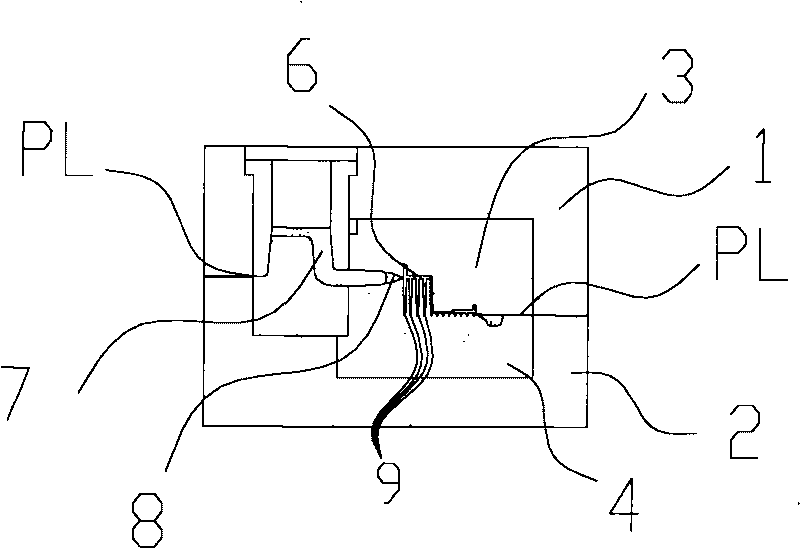

[0013] Such as figure 1 The die-casting mold of the prior art shown comprises one group of upper mold unit 1, one group of lower mold unit 2, one group of upper mold cavity unit 3 forming the cavity, and one group of lower cavity unit 4 forming the cavity. The main components and other components whose description is omitted are composed of structures and combined space types, a space 6 for forming die-casting parts, a feed channel 7 and a feed port 8 . During die-casting, the liquid raw material closes the inlet of the casting D part 9, forming a cavity space D part 9 that cannot discharge gas, and the small ribs D part 9 can only be filled in the form of pressure flow, and the forming effect is not good.

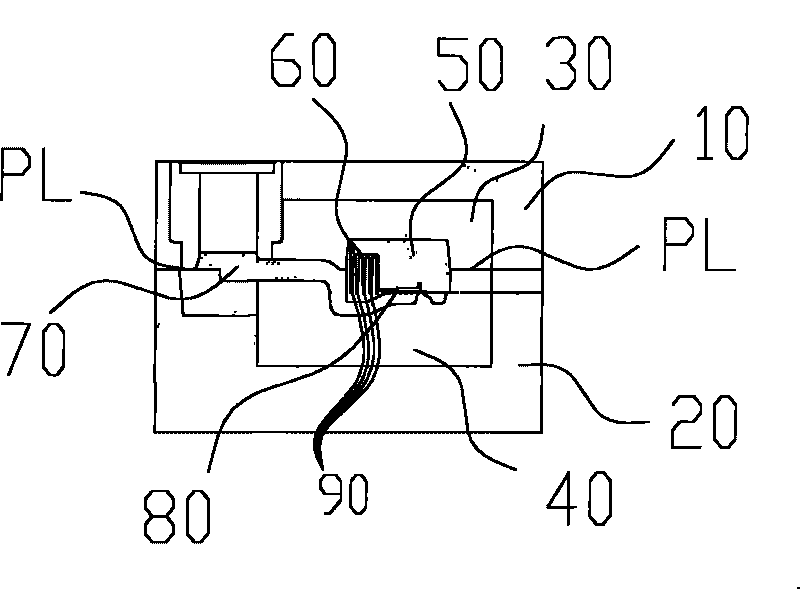

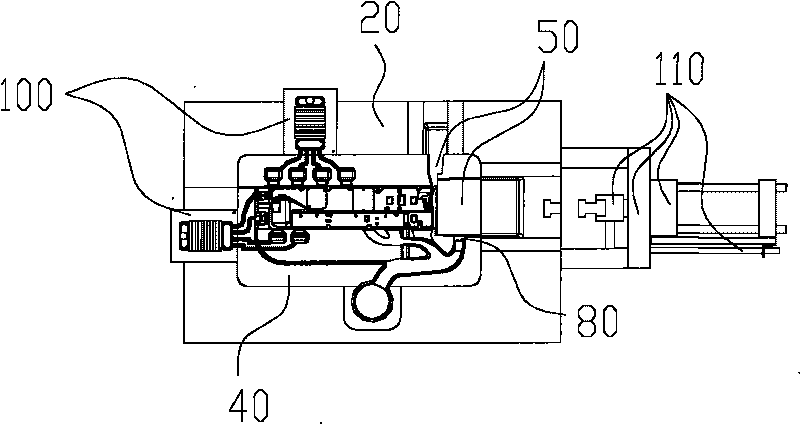

[0014] Such as figure 2 The die-casting mold of the present invention shown comprises one group of upper mold unit 10, one group of lower mold unit 20, one group of upper cavity unit 30 forming cavity, one group of lower cavity unit 40 forming cavity, one group of Slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com