Patents

Literature

38results about How to "Improve internal and external quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

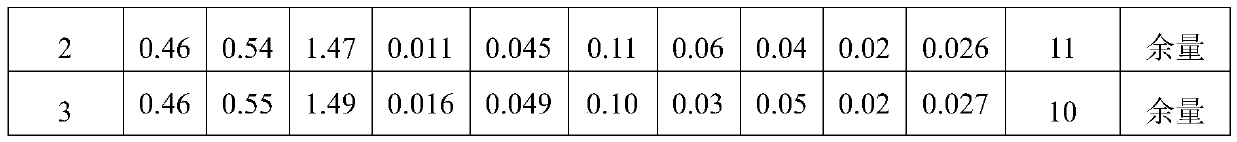

Production method of large-caliber high-pressure boiler tube

InactiveCN101890432AImprove internal and external qualityGuaranteed dimensional accuracyMetal rolling arrangementsPunchingEddy current

The invention provides a production method of a large-caliber high-pressure boiler tube, comprising the following steps: inspecting blank; saw cutting blanking; heating by an annular furnace; punching by a Mannesmann punching machine or punching by hydraulic pressure and punching by utilizing the Mannesmann punching machine; pre-punching a mandril; rolling by a pilger mill; carrying out hot-sawing on pilger heads; reheating by a walking beam furnace; externally descaling by high pressure water; sizing by a sizing mill; cooling by a cooling bed; carrying out thermal treatment; sampling; passing physical and chemical inspection; straightening; cutting head and end parts; carrying out manually initial check; polishing an inner surface and an outer surface or internally boring and externally raking; blowing soot; carrying out ultrasonic and eddy-current combination detection; manually rechecking; carrying out spectral inspection; measuring length and weighing; jet-printing; and finally packaging and warehousing. In the method, a steel billet is heated in the annular furnace, which comprises three processes of preheating, heating and soaking; and heating temperature and time in each process are rationally distributed to prevent heating unevenness and heating defects. During the tube rolling process, the feeding system of the pilger mill completes feeding release with the feeding quantity less than 0.5mm, thus achieving uniform and accurate feeding quantity in each rolling cycle.

Owner:HENGYANG VALIN STEEL TUBE

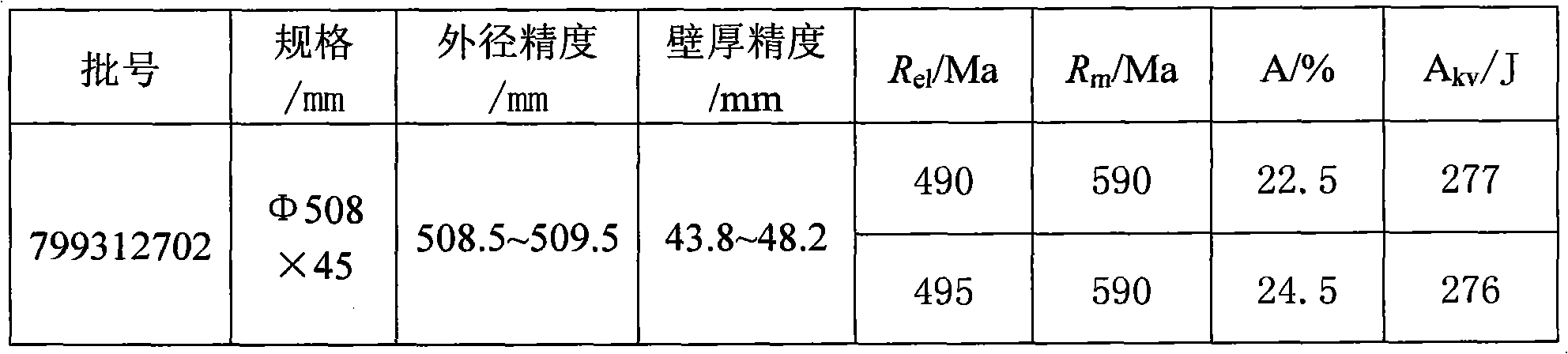

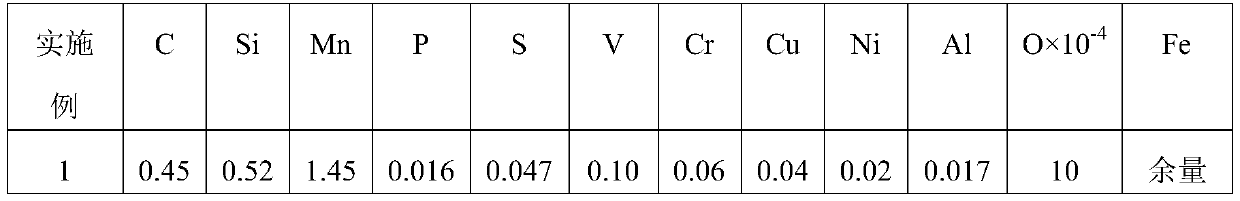

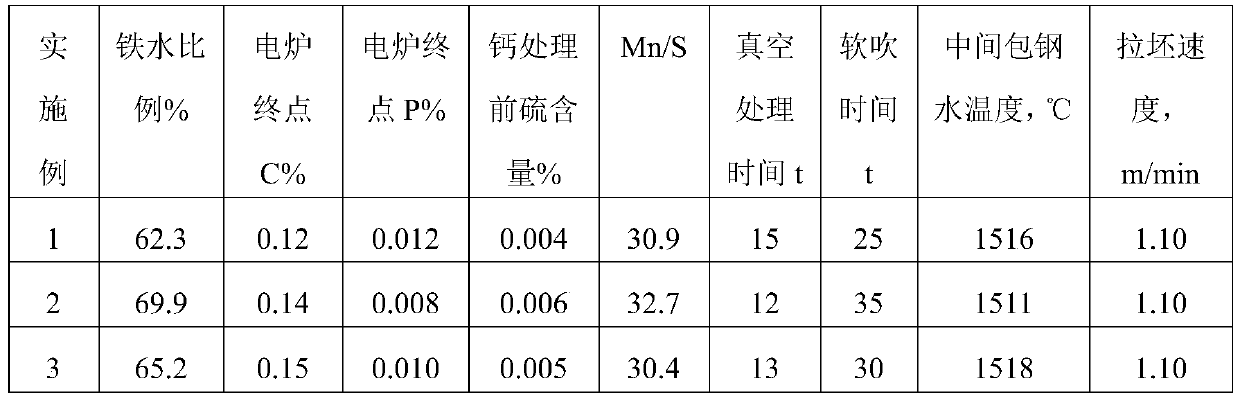

Non-quenched steel for camshafts and preparation method of non-quenched steel

InactiveCN110205547AMeet production needsImprove mechanical propertiesCalcium handlingContinuous casting

The invention belongs to the technical field of automobile steel and particularly relates to non-quenched steel for camshafts and a preparation method of the non-quenched steel. The steel is preparedfrom the chemical components in percentage by mass: 0.42%-0.49% of C, 0.30%-0.60% of Si, 1.00%-1.50% of Mn, 0.06-0.13% of V, 0.035%-0.075% of S, less than or equal to 0.035% of P, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Ni, less than or equal to 0.30% of Cu, 0.010%-0.040% of Alt, less than or equal to 15 ppm of [O], and the balance Fe and inevitable impurities, specifically, C+Si / 6+Mn / 4.5+1.8*V is equal to 1-1.1. Electric furnace smelting and LF refining are adopted, desulfuration, then sulfuration and proper calcium treatment process are adopted in the refining process, and Mn / S is controlled. The vacuum treatment time of the steel is longer than or equal to 12 minutes, and the soft blowing time is longer than or equal to 20 minutes. A casting blank is cast through continuous casting, the pulling speed and the superheat degree are controlled, and the continuous casting of twelve furnaces or more is achieved. The heating and soaking temperature, the heating time, the initial rolling temperature, the final rolling temperature, the cooling speed and the like are controlled in the rolling process, and finally, peeling and flaw detection are carried out, so that high-quality round steel is obtained; and the round steel can meet the requirement for direct cutting processing.

Owner:SHANDONG IRON & STEEL CO LTD

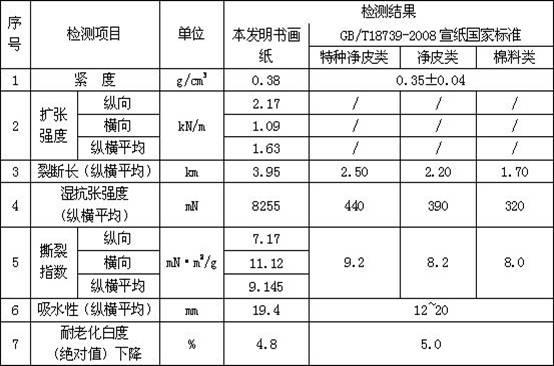

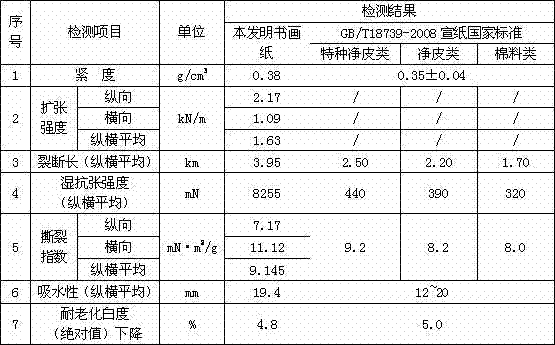

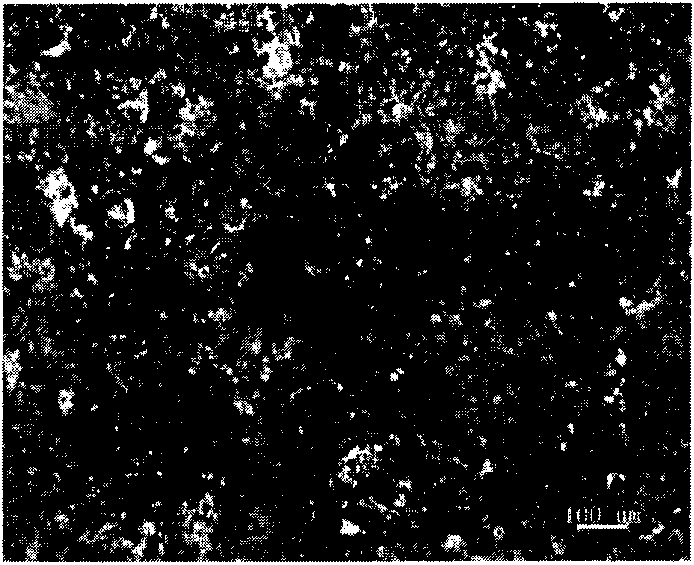

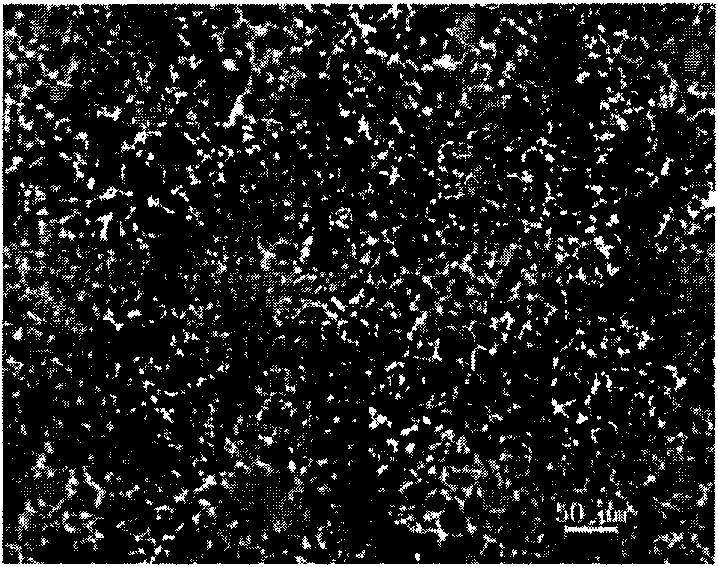

Writing and painting paper capable of preventing water, breakage, oxidation and moth eating

InactiveCN102444048ALifting of surface impuritiesImprove internal and external qualityNon-fibrous pulp additionPaper/cardboardFiberPapermaking

The invention relates to the field of manufacture of writing and painting paper, in particular to writing and painting paper capable of preventing water, breakage, oxidation and moth eating, which is prepared from raw and auxiliary materials through a pulping process and a papermaking process. The writing and painting paper comprises the following raw materials in parts by weight: 45-80 parts of bamboo pulp fiber, 10-30 parts of straw pulp fiber, 5-25 parts of wood pulp fiber and 5-25 parts of viscose fiber; and counted by tons of paper, the writing and painting paper comprises the following auxiliary materials in percent by weight: 0.5-2% of antibacterial agent, 3-15% of PVA (polyvinyl acetate), 0.5-5% of shrubby sophora extract, 1-3% of wormwood leaf extract and 1-5% of artemisia frigida P.E. The writing and printing paper has excellent functions of preventing water, breakage and oxidation, and especially, the functions of preventing water and burst are better than the wet-tensile strength index of national standard of GB / T18739-2008 rice paper by more than 10 times. In addition, matrine, chamaejasmine and wormwood leaf extract are uniformly adhered on the fiber by a dipping and spraying method, so that the function of preventing moth eating of the writing and printing paper is enhanced.

Owner:FUYANG JINYUAN PAPER

Water-resisting breaking-resisting oxidation-resisting calligraphy and painting paper

InactiveCN102454135AIncrease ink wettingReduce oxidative degradationNon-fibrous pulp additionSpecial paperFiberPaper manufacturing

The invention relates to the field of calligraphy and painting paper manufacturing, and specifically relates to a water-resisting breaking-resisting oxidation-resisting calligraphy and painting paper. The paper is prepared from raw materials and auxiliary materials through a pulping process and a paper making process. The raw materials comprise components of, by weight: 45-80 parts of bamboo pulp fiber, 10-30 parts of grass pulp fiber, 2-25 parts of wool pulp fiber, and 5-25 parts of viscose fiber. Each ton of the paper comprises auxiliary materials of, by weight: 0.5-2% of an antiseptic, and 3-15% of PVA. The calligraphy and painting paper provided by the invention has excellent water resistance, breaking resistance and oxidation resistance. The water-resisting and breaking-resisting functions are 10 times higher than a wet tensile strength index of a GB / T18739-2008 national standard of rice paper.

Owner:FUYANG JINYUAN PAPER

Method for controlling internal defects of steel

InactiveCN101618398AIncrease productivityImprove pass rateMetal rolling arrangementsHigh pressureHigh pressure water

The invention provides a method for controlling internal defects of steel so that the steel can satisfy the requirement of ultrasonic flaw detection of the diameter of 2mm. The method controls temperature gradients inside and outside a casting blank by adjusting high-pressure water jet descaling parameters and then controls pass reduction so that deformation conditions in a rolled piece are changed, the core defects of the rolled piece are fully welded, and the internal defects of the casting blank are controlled within the diameter of 2mm to satisfy the requirement of the ultrasonic flaw detection of the diameter standard of 2mm. The method can improve the qualified rate of the ultrasonic flaw detection for steel, can reduce rolling passes, decreases the production cost and improves the production efficiency.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

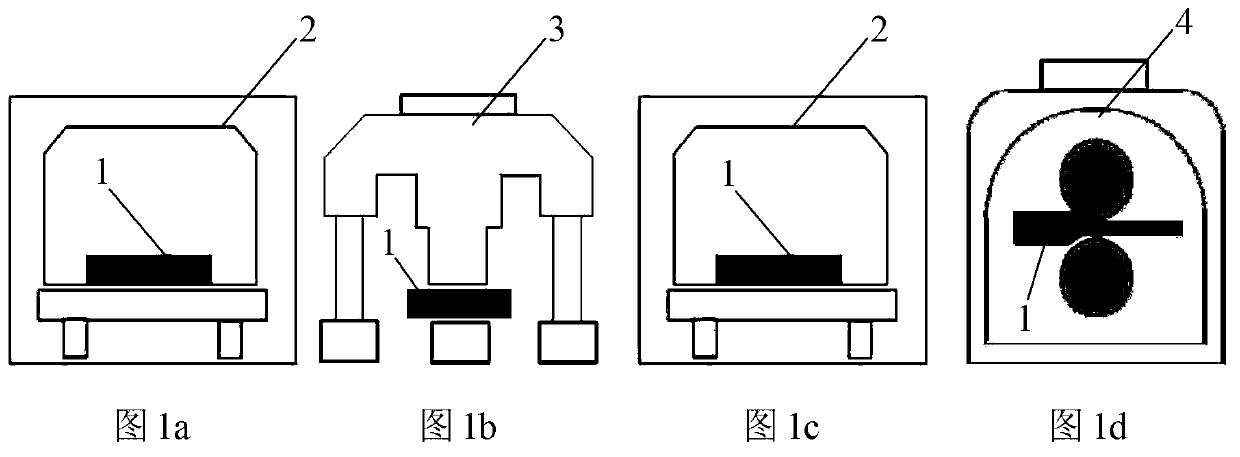

Forging-and-rolling compounded forming method for comprehensively promoting internal and external quality of wide and thick plate blanks

ActiveCN103273272AUniform strain distributionFine grainTemperature control deviceTension/compression control deviceSteel platesForming processes

The invention belongs to the field of pressure processing of steel materials, particularly relates to a forging-and-rolling compounded forming method for comprehensively promoting internal and external quality of wide and thick plate blanks. Numerical simulation technique is adopted to study internal strain distribution of the plate blanks formed by pure rolling, pure forging and the forging-and-rolling compounded forming method, and the forging-and-rolling forming method is provided and includes steps of 1), firstly heating the plate blanks to be cast; 2), subjecting the plate blanks to forging and deforming in a large hydraulic press after heating the same; 3), returning the plate blanks to be forged in a heating furnace for heat preservation after forging and deforming; and 4), delivering the forged plate blanks in a heated manner to a rolling mill to be rolled after heat preservation or cooling the same slowly to room temperature prior to being heated and rolled again. The forging-and-rolling compounded forming method has the advantages that the forging-and-rolling compounded forming method is applicable to forming process of various molded wide and thick plate blanks (slab ingot), especially to blanks with central looseness; by the method, the defect of core density loose of the wide and thick plate blanks can be overcome, micro-segregation can be alleviated, and texture of the plate blanks can be refined and distributed well; and meanwhile, surface quality of the steel plates can be guaranteed, working allowance can be reduced, and the finished wide and thick plate blanks with 'internal solidness and external refinement' can be realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

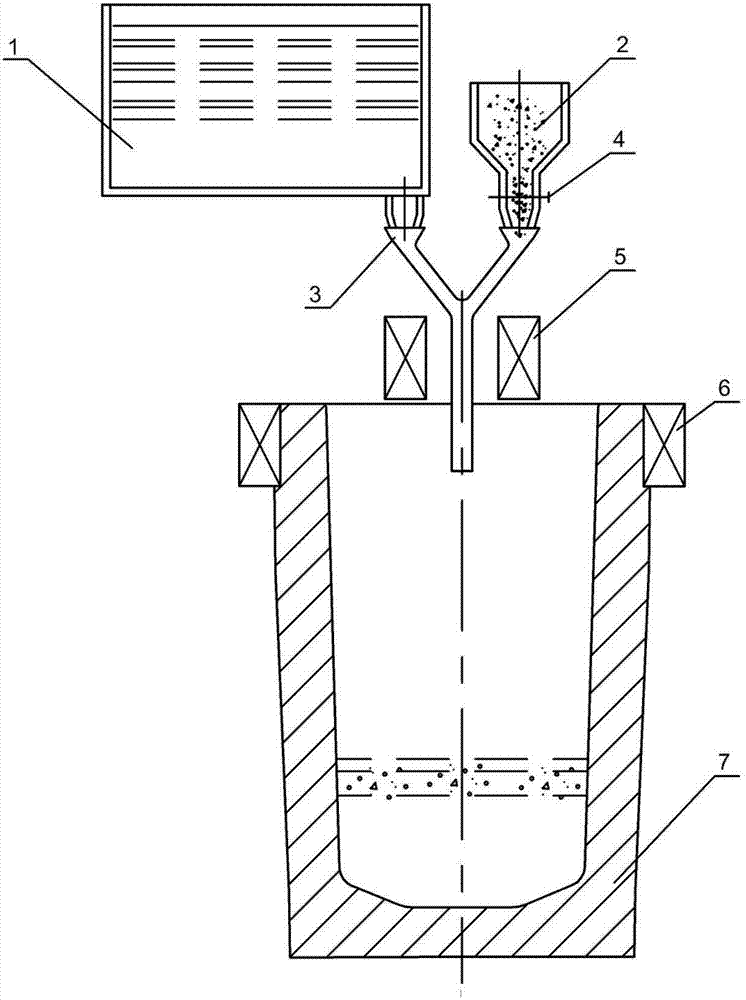

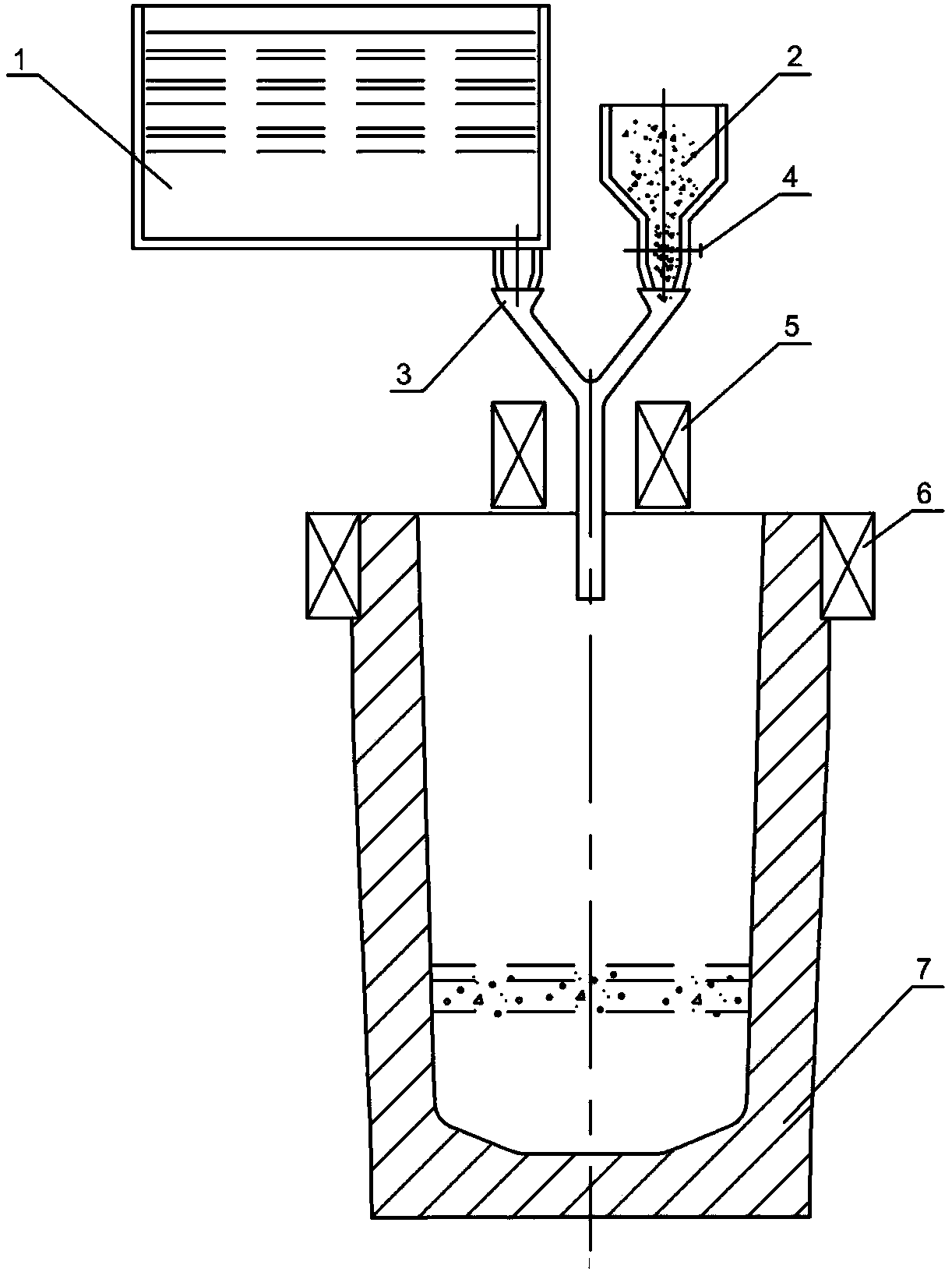

Method for manufacturing large ingot through electromagnetically-controlled self-inoculation treatment

The invention relates to a method for manufacturing a large ingot through electromagnetically-controlled self-inoculation treatment. The method comprises the steps as follows: (1) a Y-shaped double-phase conveying nozzle is adopted for molten metal casting, and an electromagnetic device I is arranged on the outer side of the straight section of the double-phase conveying nozzle; an electromagnetic device II is arranged on the outer side of an ingot mold riser; (2) an ingot mold and the double-phase conveying nozzle are preheated before casting; (3) argon shielding is performed during casting, an inoculant is added when the liquid level of molten metal rises to 1 / 2-2 / 3 of the height of an inner cavity of the ingot mold, meanwhile, the electromagnetic device I is started, and the electromagnetic device II is started when the liquid level of molten metal rises to the height of the ingot mold riser line; and both the electromagnetic device I and the electromagnetic device II run at the low frequency; (4) after casting is completed, the electromagnetic device I is shut down, the electromagnetic device II s adjusted to run at the intermediate frequency from the low frequency, and heat insulation is performed on the ingot mold riser part by the aid of the Joule heating effect of the intermediate-frequency magnetic field until the ingot is solidified. With the method, the solidification structure of the steel ingot can be refined, the center segregation can be reduced, the center porosity can be reduced, and thus the inner and outer quality of the ingot can be improved.

Owner:UNIV OF SCI & TECH LIAONING

Car transmission shaft machining technology

The invention provides a car transmission shaft machining technology which comprises the steps of forging, normalizing, rough turning, finish turning, deep hole drilling, hobbing, oil hole drilling, and then a series of washing of degreasing pretreatment, degreasing, hot water washing, cold water washing, activating treatment, ultrasonic rinsing, chemical agent washing and drying. A washed transmission shaft is clamped to a rotor of a machine tool, laser is used for carrying out irradiating with the intersection angle of 78-85 degrees on the annular surface of a rotating transmission shaft, when the temperature of a light spot center point of the annular surface which is hardened by heating reaches 1000-1200 DEG C, irradiating is over, and hardening is finished. Then, an outer circle grinding procedure is carried out, an outer circle which needs matching is ground to be in a certain shape, and finally a finished product is obtained. According to the car transmission shaft machining technology, the inner quality and the outer quality of the transmission shaft are both improved.

Owner:LIUZHOU JUNJIE AUTO PARTS MFG

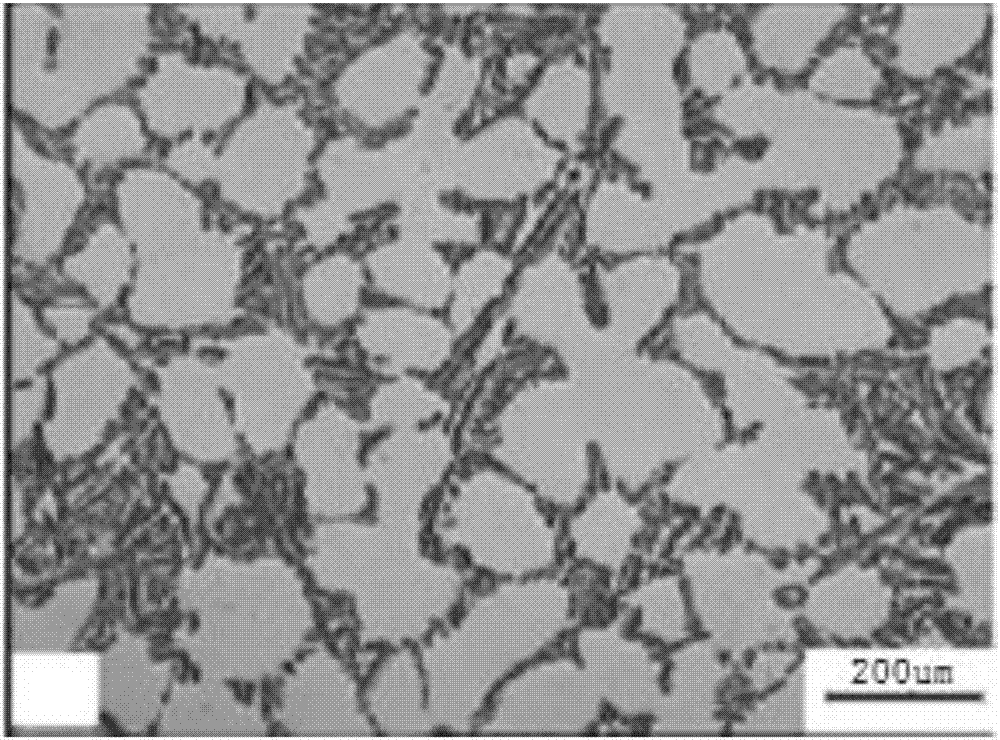

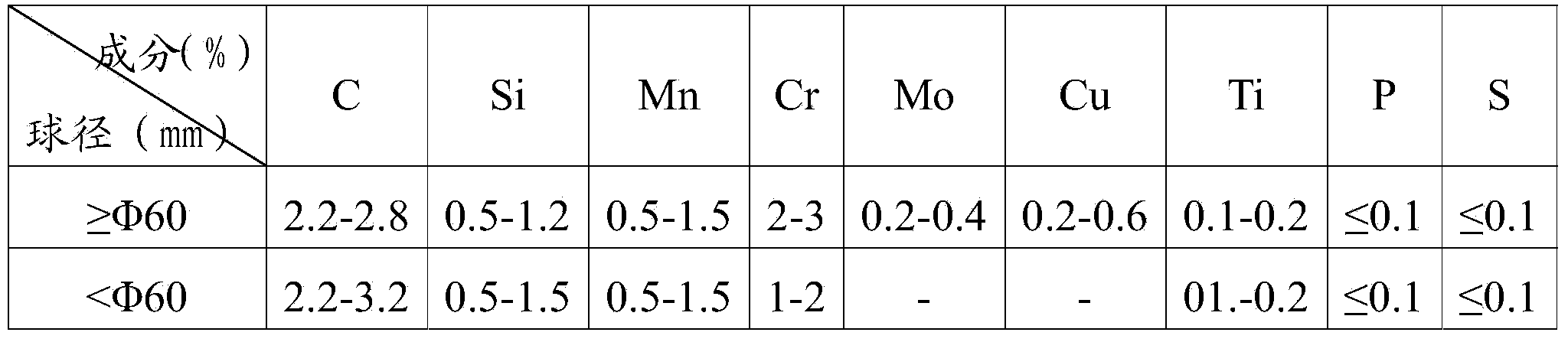

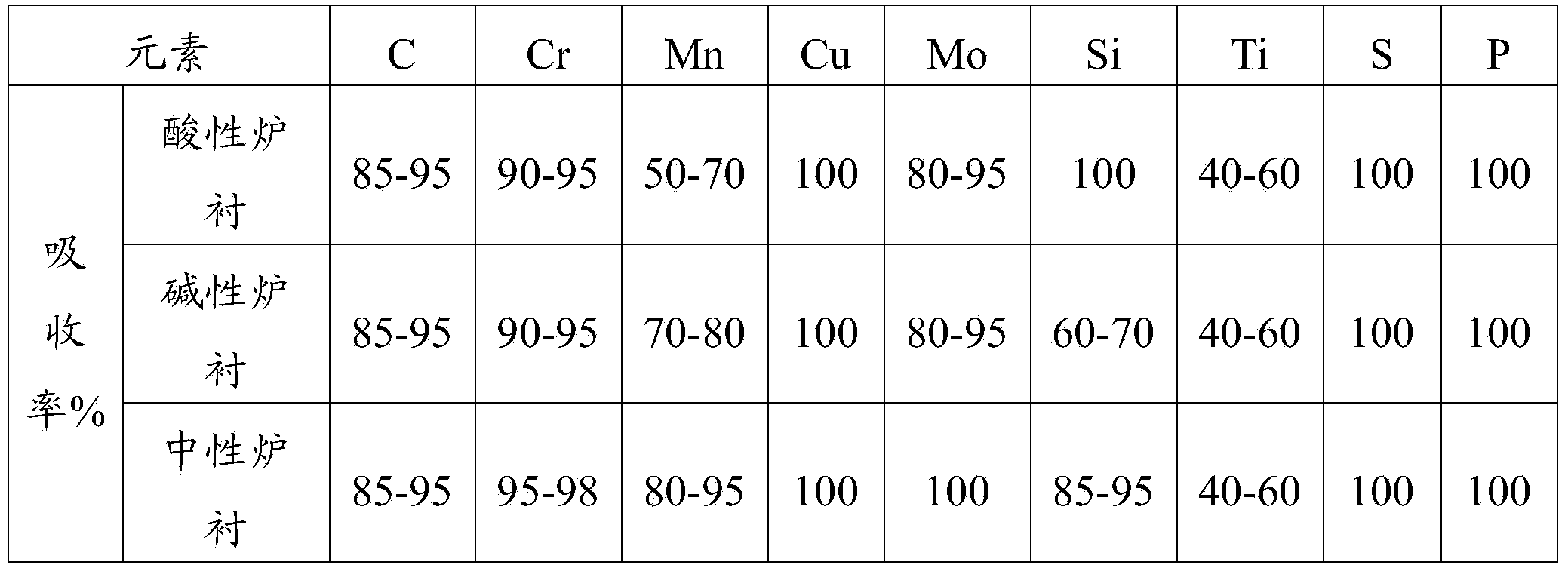

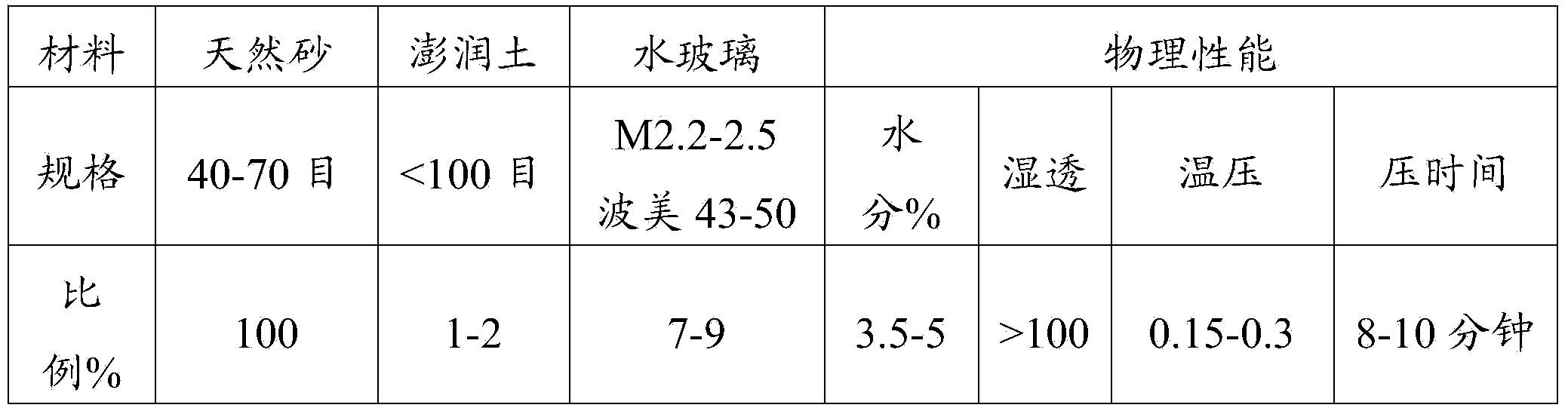

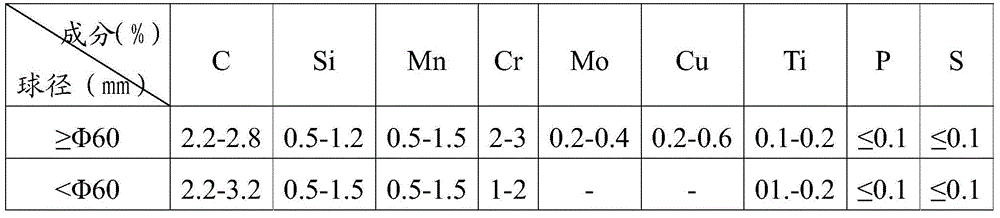

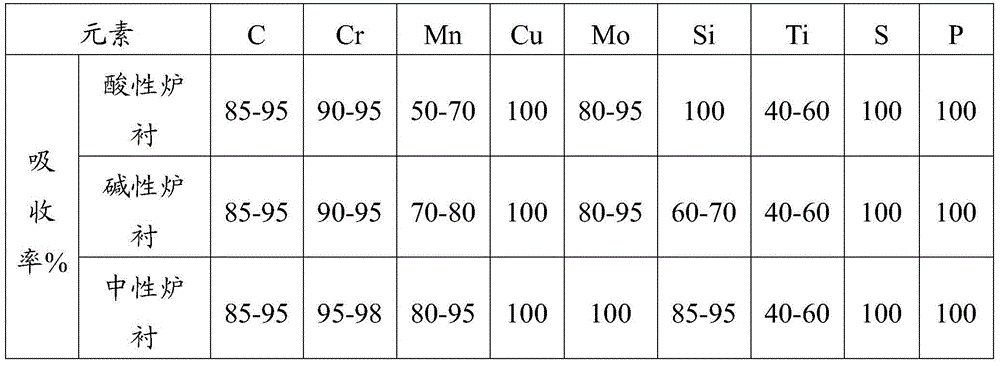

Process for producing low-chromium complex alloy grinding ball

InactiveCN103725950AImprove internal and external qualityImprove impact performanceFoundry mouldsFoundry coresChemical compositionAlloy

The invention relates to a process for producing a low-chromium complex alloy grinding ball. The process comprises the steps of melting, pouring, casting a metal mold and tempering, chemical components of the low-chromium complex alloy grinding ball are reasonably designed, and metal mold casting and tempering are carried out, so that the internal and external quality of the grinding ball can be improved, the product does not have the casting defects, such as sinkholes, pores, looseness and the like, the broken rate and no circularity of the grinding ball can be reduced, the fatigue impact resistance and wear resistance of the grinding ball can be improved, the product yield can be remarkably improved, the production process can be simplified, and the production cost can be reduced.

Owner:南平市双友金属有限公司

Casting method for main shaft of wind generating set

ActiveCN102921901AFast and smooth entryAvoid oxidation inclusion defectsFoundry mouldsMoulding machinesWind forceMaterials science

The invention relates to a casting method, in particular to a casting method for a main shaft of a wind generating set. The casting method provided by the invention comprises the following steps of: designing a pouring system, manufacturing a mould, shaping, manufacturing a core, assembling the mould, compounding, smelting, adopting a stokehold spheroidization process and multistage inoculation, pouring and shakeout clearing. The casting method for the main shaft of the wind generating set is unique, meets quality index requirements on size, performance, and internal and external quality, and can realize volume production for moving / fixed shafts.

Owner:KOCEL EQUIP

Heat treatment technology for low-temperature high impact toughness medium-thickness steel plate

InactiveCN101892373AShorten heat treatment cycleNo high temperature phase transition stressFurnace typesHeat treatment furnacesSheet steelEnergy consumption

The invention discloses heat treatment technology for a low-temperature high impact toughness medium-thickness steel plate. The heat treatment technology comprises the following steps of: putting the steel plate into a furnace and heating, wherein the heating temperature is 50 to 100 DEG C lower than the Al temperature; keeping the temperature for 40 to 80 minutes; and discharging and performing air cooling to obtain the low-temperature high-toughness medium-thickness steel plate. The heat treatment technology can effectively solve the problems of plate warp, high heat treatment energy consumption, high maintenance cost of heat treatment equipment, low production efficiency and the like due to high heating temperature when normalizing heat treatment is performed on a TMCP steel plate, and also can obtain the low-temperature high-toughness steel plate at the temperature of 40 DEG C below zero.

Owner:NANJING IRON & STEEL CO LTD +1

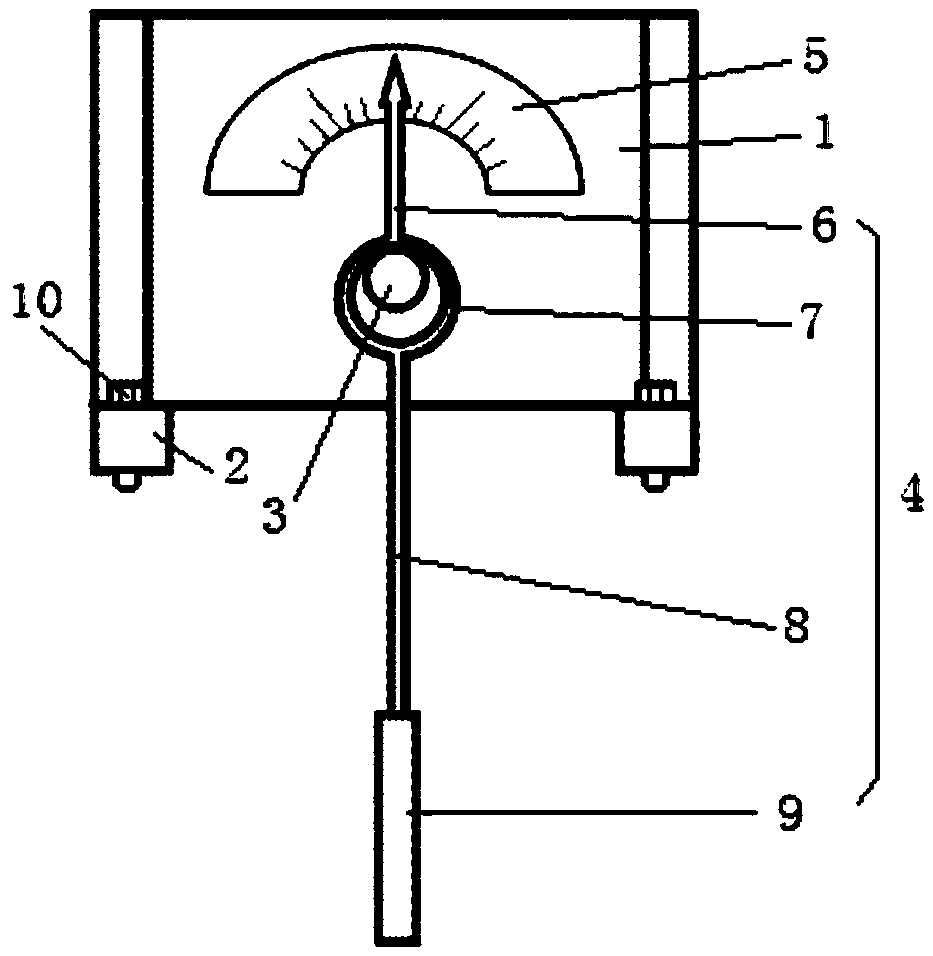

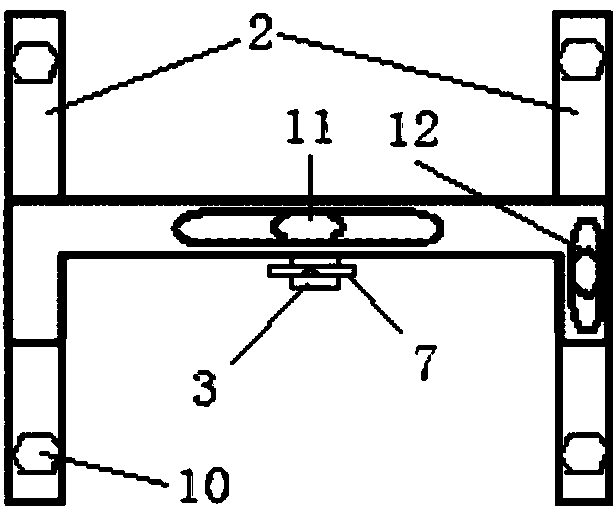

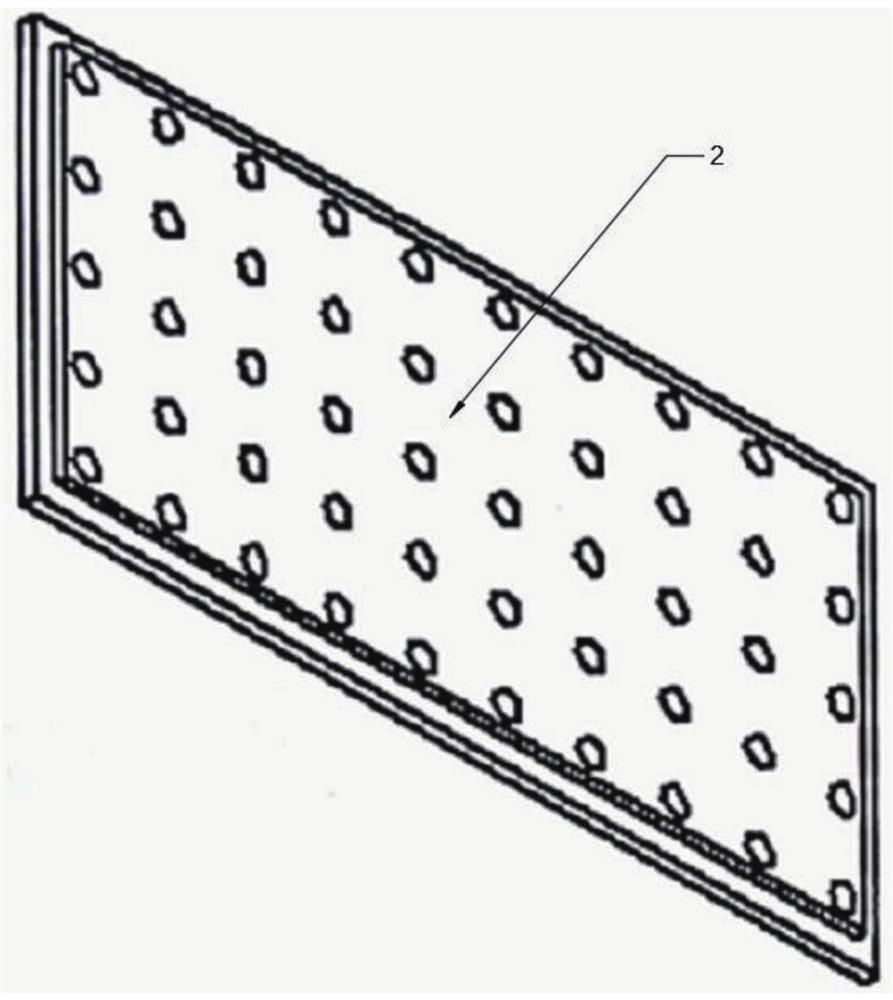

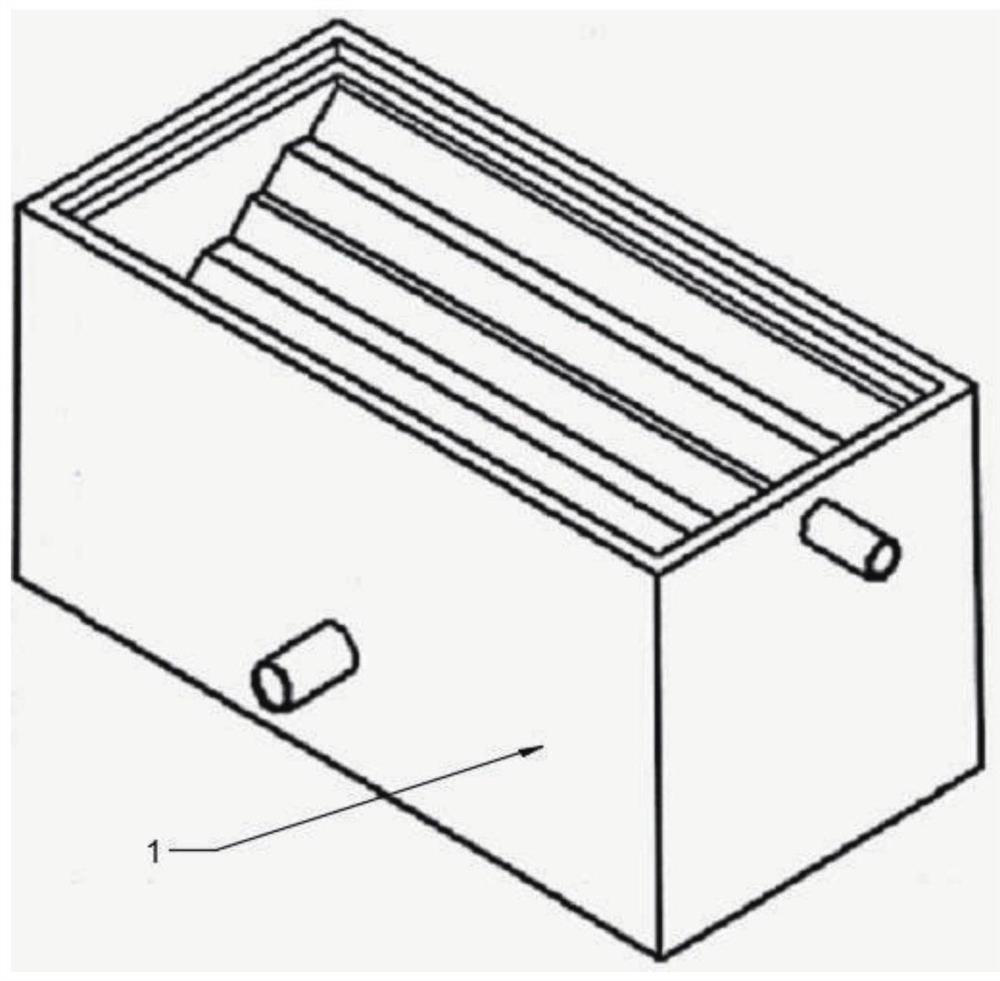

Method for measurement of flow-field direction and intensity in crystallizer and flow-field intensity indicator

InactiveCN103743539AImprove internal and external qualityInternal reinforcementHydrodynamic testingSlagStreamflow

The invention relates to the field of plate blank continuous casting and particularly relates to a method for measurement of flow-field direction and intensity in a crystallizer and a flow-field intensity indicator. The method is characterized in that the flow-field intensity indicator is used to monitor the flow-field intensity and direction in the crystallizer in a casting process and quantitative analysis on possibility of cutting slag of steel slag interfaces in the crystallizer is performed and used as the basis of adjustment of related parameters of the crystallizer. The flow-field intensity indicator is characterized by including a hanger, horizontal footstands, a hook and a flow measurement board. The flow measurement board is an integral structure which is formed through combination of a pointer, a hanging ring, a connecting rod and a floater. Compared with the prior art, the beneficial effects of the flow-field intensity indicator are that an operator is capable of detecting different conditions: different steel types, different pulling rates, different immersed water port insert depths and argon blowing flow and the like so that change rules of the flow field in the crystallizer under different conditions are obtained and thus flowing method of steel water in the crystallizer can be adjusted, controlled and optimized so as to improve external and internal qualities of casting blanks.

Owner:ANGANG STEEL CO LTD

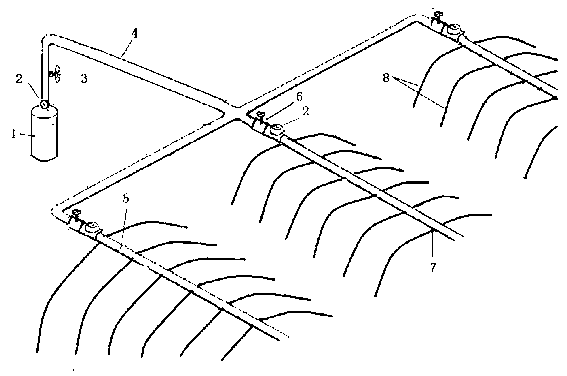

Air fertilizer applying device

InactiveCN103039280AIncrease concentrationImprove internal and external qualityHorticulture methodsEngineeringFertilizer

The invention relates to an air fertilizer applying device. The air fertilizer applying device comprises an air source device (1) and a main pipe (4). One end of the main pipe (4) is connected with an air outlet of the air source device (1), multiple branch pipes (5) are divided from the other end of the main pipe (4), and a plurality of micropore pipes (8) are connected onto each of multiple branch pipes (5). A pressure gauge (2) is arranged at the position of the air outlet of the air source device (1), and a pressure reducing valve (3) is installed on the main pipe (4). An adjusting valve (6) and the pressure gauge (2) are arranged at the connecting position of each of multiple branch pipes (5) and the main pipe (4). The air fertilizer applying device can improve plant yield.

Owner:孔才春

Banana protecting material and disease preventing cover

InactiveCN101019495APromote photosynthesisPromote growthSynthetic resin layered productsPlant protective coveringsFrostEngineering

The present invention relates to banana protecting material and disease preventing cover. The banana protecting material of paper, polyethylene film and applied glue film layer is produced into disease preventing cover for enclosing banana to reduce frost damage, promote banana growth, raise the quality of banana and increase banana yield. It may be reused for several times.

Owner:蔡新民 +1

Application of mPE (metallocene polyethylene) in improving pressure resistance of HDPE (high density polyethylene) tube as well as HDPE tube and preparation method thereof

InactiveCN103333389AImprove liquidityImprove appearance qualityRigid pipesLow-density polyethyleneHigh density

The invention discloses an application of mPE (metallocene polyethylene) in improving pressure resistance of an HDPE (high density polyethylene) tube. During the production of the HDPE tube, the mPE is added as a raw material, and the mPE, the main raw material namely HDPE and a pigment are subjected to processes of stirring, mold blank extruding, cooling, shaping, hauling and cutting to manufacture the HDPE tube. The invention simultaneously discloses the HDPE tube and a preparation method thereof. The invention has the beneficial effects that in an HDPE system, after the mPE is added, the HDPE tube has excellent physical and mechanical properties and very good molding performance because of abundant branched chain structures of the mPE. Moreover, due to the excellent processability of the mPE, the flow property of the HDPE during the production of the tube can be improved and then the appearance quality of the tube is improved, so that the internal and external quality of the tube is integrally improved.

Owner:林品榕

Forging-and-rolling compounded forming method for comprehensively promoting internal and external quality of wide and thick plate blanks

ActiveCN103273272BPromote healingReduce scrapTemperature control deviceTension/compression control deviceThick plateRoom temperature

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Remelting method for electroslag ingot for cold roller

ActiveCN108950134AImprove hardenability and wear resistanceAvoid production cracksFurnace typesProcess efficiency improvementSlagFerrous metallurgy

The invention discloses a remelting method of an electroslag ingot for a cold roller, and belongs to the technical field of ferrous metallurgy. The technical problem to be solved is how to prepare thehigh-quality electroslag ingot for the cold roller through electroslag remelting. The invention provides the remelting method of the electroslag ingot for the cold roller. The remelting method comprises the steps of electrode rod baking, slag system selection, baking, melting protection slag, electroslag remelting process, and annealing process and the like. According to the method, chemical components of the electrode rod are improved, the proper slag system is selected, the electrode rod and slag material are baked, the electroslag remelting and the annealing process are adjusted, so that the electricslag ingot for the cold roller with good internal and external quality is prepared, defects such as ripples or slag runners are avoided, quality requirement of first-stage blank is met through high and low time inspection, and favorable conditions are provided for subsequent working procedure to guarantee product quality.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

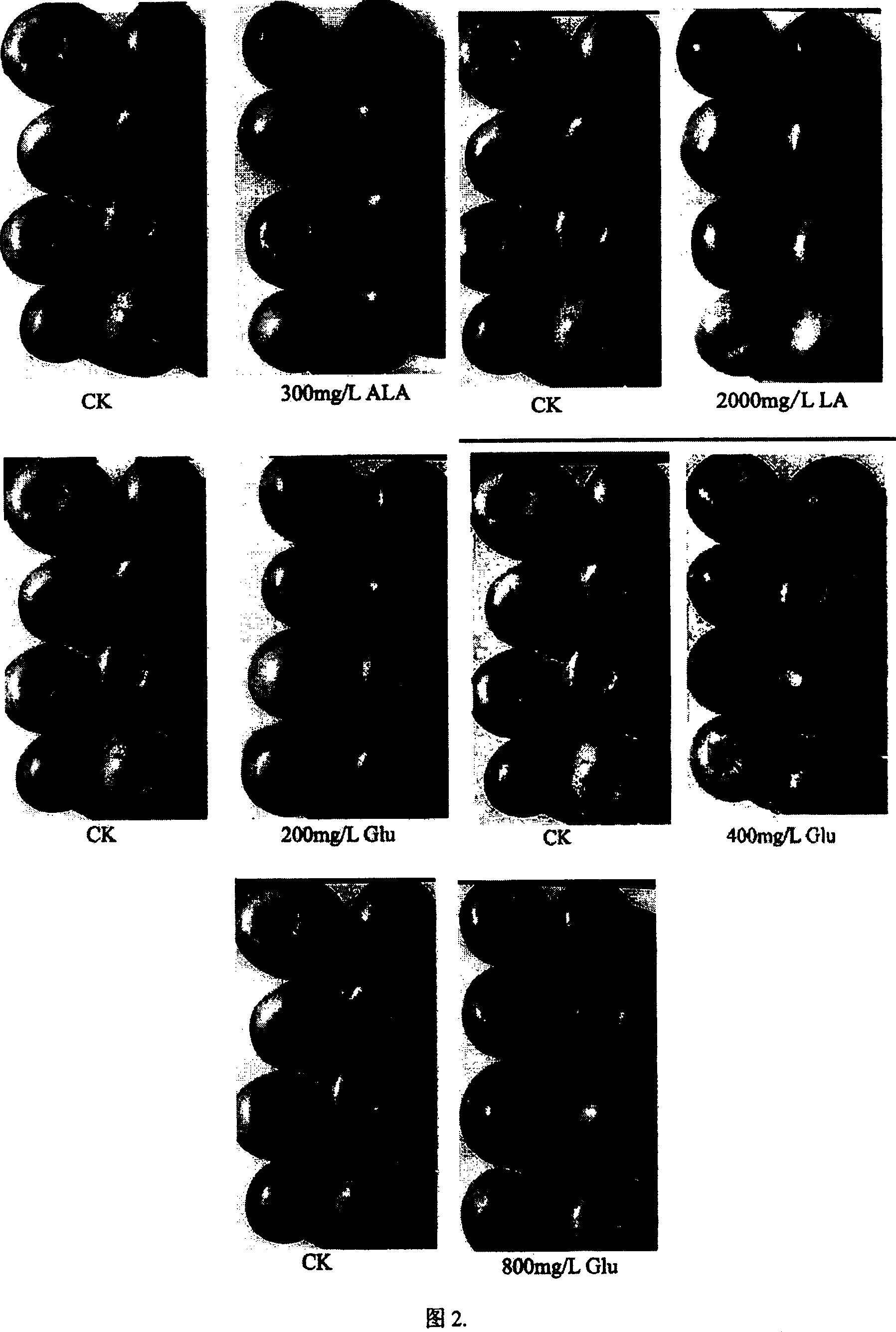

Method for improving fruit color

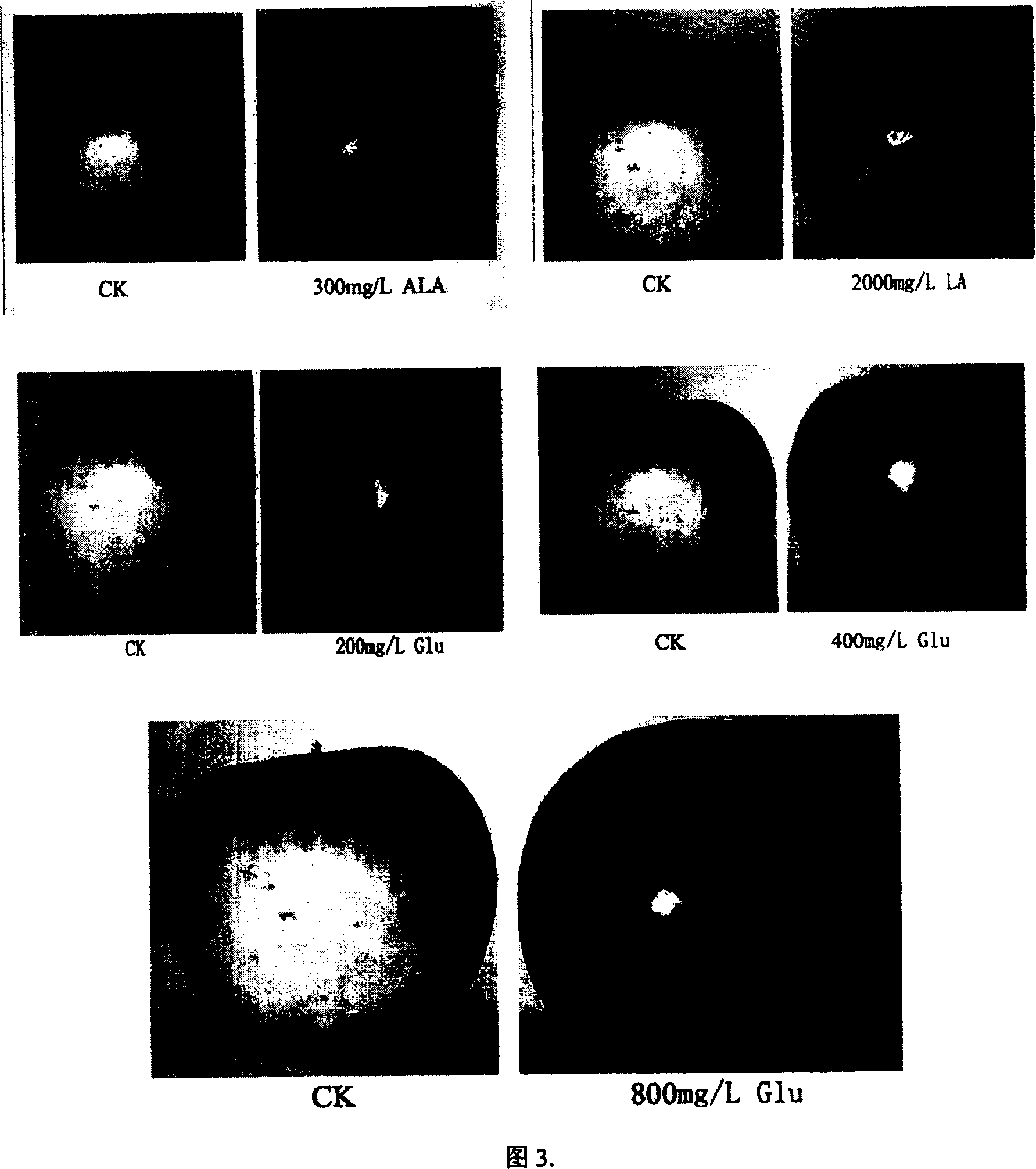

InactiveCN1302697CImprove internal and external qualityIncreased soluble solids contentHorticulture methodsPEARAmino-Levulinic Acid

Owner:NANJING AGRICULTURAL UNIVERSITY

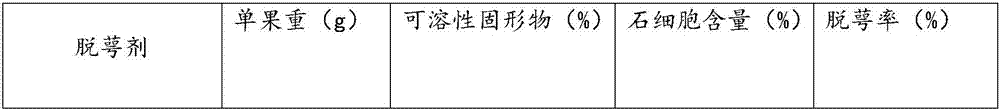

Method for improvement of calyx leaving rate of fruits of Nanguo pears

InactiveCN107182584AImprove calyx removal rateImprove internal and external qualityHorticulture methodsBoric acidBoron

The invention provides a method for improvement of the calyx leaving rate of fruits of Nanguo pears. A 200-fold PBO solution is sprayed on all flowers at the full-bloom stage, and a 200-fold calcium-boron mixed solution is sprayed on all young fruits at the fading stage; the 200-fold PBO solution is prepared by dissolving PBO in the proportion of 1 g PBO to 200 ml water; the 200-fold calcium-boron mixed solution is prepared by dissolving CaCl2 and boric acid in the proportion of 1 g CaCl2 to 1 g boric acid to 200 ml water. According to the method for improvement of the calyx leaving rate of the fruits of Nanguo pears, specific chemical agents are sprayed on flower organs at the full-bloom stage and the fading stage of the Nanguo pears respectively, so that not only is the calyx leaving rate of the fruits improved, but the stone cell content is reduced, and the internal and external qualities of the fruits are improved.

Owner:SHENYANG AGRI UNIV

Method for controlling internal defects of steel

InactiveCN101618398BAchieve weldingImprove the passing rate of flaw detection inspectionMetal rolling arrangementsHigh pressure waterHigh pressure

The invention provides a method for controlling internal defects of steel so that the steel can satisfy the requirement of ultrasonic flaw detection of the diameter of 2mm. The method controls temperature gradients inside and outside a casting blank by adjusting high-pressure water jet descaling parameters and then controls pass reduction so that deformation conditions in a rolled piece are changed, the core defects of the rolled piece are fully welded, and the internal defects of the casting blank are controlled within the diameter of 2mm to satisfy the requirement of the ultrasonic flaw detection of the diameter standard of 2mm. The method can improve the qualified rate of the ultrasonic flaw detection for steel, can reduce rolling passes, decreases the production cost and improves the production efficiency.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Remelting method of electroslag ingot for cold roll

ActiveCN108950134BImprove hardenabilityImprove wear resistanceFurnace typesProcess efficiency improvementChemical compositionSlag

The invention discloses a method for remelting electroslag ingots for cold rolling rolls, belonging to the technical field of iron and steel metallurgy. The technical problem to be solved by the present invention is how to prepare high-quality electroslag ingots for cold rolling rolls through electroslag remelting. The invention provides a method for remelting electroslag ingots for cold rolling rolls, which includes the steps of baking electrode rods, selecting and baking slag systems, melting protective slag, electroslag remelting process, annealing process and the like. The present invention improves the chemical composition of the electrode rod, selects a suitable slag system, bakes the electrode rod and slag material, adjusts the electroslag remelting and annealing process, and prepares an electroslag ingot with good internal and external quality for cold rolling rolls. There are no defects such as ripples or slag grooves, and the high and low magnification inspections meet the quality requirements of the first-level billet, providing favorable conditions for the subsequent process to ensure product quality.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

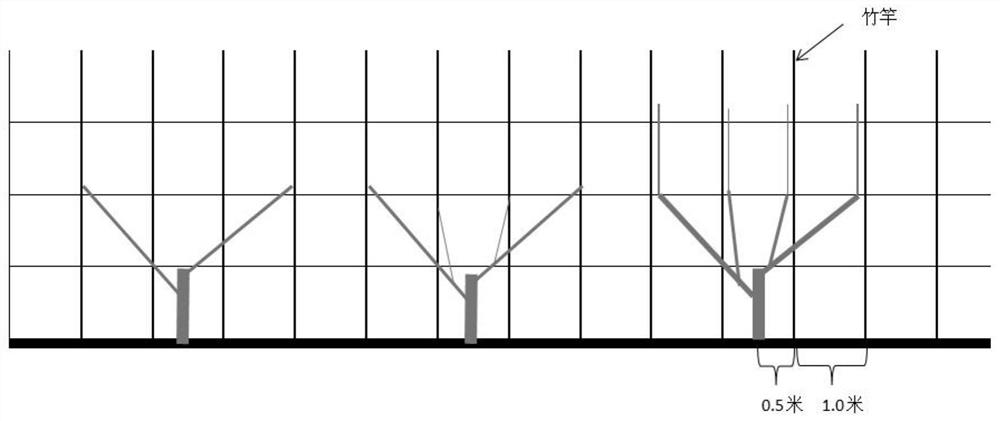

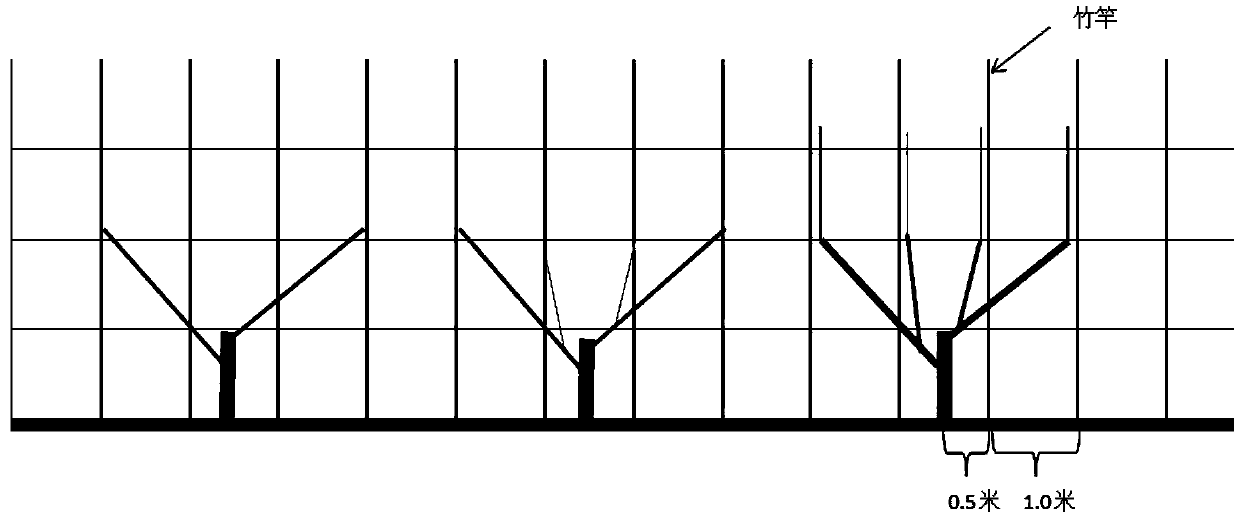

A pruning method of planar four-main-branch tree shape and its application in cultivation

ActiveCN109618799BGood colorHigh sweetnessCultivating equipmentsHorticulture methodsTree shapedAgronomy

The invention provides a method for pruning a planar tree shape of four main branches and its application in cultivation, and relates to the technical field of peach tree cultivation. The pruning method of the present invention comprises: 1) setting the stem at 30-50 cm above the grafting joint of the peach tree; 2) selecting two strong branches in the north-south direction from May to June as the main trunk; , respectively insert two bamboo poles on both sides of the peach tree plant, and pull the main trunk to the outermost two bamboo poles respectively; New main trunks are drawn to the inner bamboo poles respectively; the new main trunks grow vertically upwards. The tree shape of the present invention can disperse nutrition to each main trunk, the number of elongated branches of the tree body is small, and the overall pruning requires less labor; the fruit yield in the upper part of the tree body is increased, the proportion and quality of large fruits are increased; and the row space is increased.

Owner:SHANGHAI ACAD OF AGRI SCI +1

Production Technology of Large Unit Weight Extra Thick Chromium Molybdenum Steel Plate

ActiveCN110193574BAvoid stress concentrationImprove internal and external qualityTemperature control deviceWork heating devicesSlagHeat conservation

The invention discloses a production process of a large-piece-weight extra-thick chromium molybdenum steel plate. The production process comprises the steps of forging, preheating, heating and rolling, wherein the preheating procedure comprises the steps of heating a forged blank to 180-200 DEG C at a heating rate of less than or equal to 30 DEG C / h after the forged blank is placed in a furnace, simmering the steel for 4-5 hours with soft fire, then heating the steel in the furnace with the temperature raised to 400-450 DEG C at a heating rate of less than or equal to 50 DEG C / h, keeping thetemperature for more than or equal to 10 hours, and discharging the steel plate from the furnace. After the process is adopted, the blank and the finished steel plate do not have defects such as rupture and cracking, forging defects such as surface cracks, slag inclusion and internal tearing are effectively eliminated, and the forged blank and the steel plate have smooth surfaces, good quality andwide application value.

Owner:WUYANG IRON & STEEL

A method for manufacturing large-scale ingots through electromagnetic regulation and self-inoculation treatment

The invention relates to a method for manufacturing large-scale ingots through electromagnetic regulation and self-inoculation treatment, comprising: 1) a Y-shaped two-phase feeding nozzle is adopted for molten metal casting, and an electromagnetic device I is arranged outside the straight section of the two-phase feeding nozzle; an ingot mold Electromagnetic device II is installed on the outside of the riser; 2) Preheating of the ingot mold and the two-phase feeding nozzle before casting; 3) Argon protection during the casting process, and the liquid metal level rises to 1 / 2 to 2 / 3 of the height of the inner cavity of the ingot mold Add the inoculant from time to time, turn on the electromagnetic device I at the same time, and turn on the electromagnetic device II when the metal liquid level rises to the height of the riser line of the ingot mold; both the electromagnetic device I and the electromagnetic device II operate at low frequency; 4) After the casting is completed, turn off the electromagnetic device Ⅰ. Adjust the electromagnetic device II from low-frequency operation to medium-frequency operation, and use the Joule heating effect of the medium-frequency magnetic field to keep the riser of the ingot mold warm until the ingot is solidified. The invention can refine the solidification structure of the steel ingot, reduce the center segregation, reduce the center porosity, thereby improving the internal and external quality of the ingot.

Owner:UNIV OF SCI & TECH LIAONING

Casting method for main shaft of wind generating set

ActiveCN102921901BFast and smooth entryAvoid oxidation inclusion defectsFoundry mouldsMoulding machinesWind forceMaterials science

The invention relates to a casting method, in particular to a casting method for a main shaft of a wind generating set. The casting method provided by the invention comprises the following steps of: designing a pouring system, manufacturing a mould, shaping, manufacturing a core, assembling the mould, compounding, smelting, adopting a stokehold spheroidization process and multistage inoculation, pouring and shakeout clearing. The casting method for the main shaft of the wind generating set is unique, meets quality index requirements on size, performance, and internal and external quality, and can realize volume production for moving / fixed shafts.

Owner:KOCEL EQUIP

Trimming method of planar four-main-branch tree form and application in culturing thereof

ActiveCN109618799AGood colorHigh sweetnessCultivating equipmentsHorticulture methodsMain branchShoot

The invention provides a trimming method of a planar four-main-branch tree form and application in culturing thereof, and relates to the technical field of peach tree culturing. The method comprises the steps that one, heading is conducted at the part 30-50 cm above a grafting hole of a peach tree; 2), two branches with strong growing trend growing in the row in the direction from south to north are selected as trunks from May to June; 3), two bamboo poles are inserted on the two sides of a peach tree plant in July, and the two trunks are drawn towards the two bamboo poles on the outermost sides respectively; 4), secondary shoots close to a heading point on the trunks are selected as new trunks in August, and the new trunks are drawn to the bamboo poles on the inner sides respectively; thenew trunks grow vertically upwards. According to the method, nutrients can be dispersed to each trunk by the tree form, the number of spindling branches of a tree body is low, the labor force used onintegrally trimming is less, fruit yield on the upper middle part of the tree body is increased, big fruit proportion is increased, the quality is improved, and the space in row direction is increased.

Owner:SHANGHAI ACAD OF AGRI SCI +1

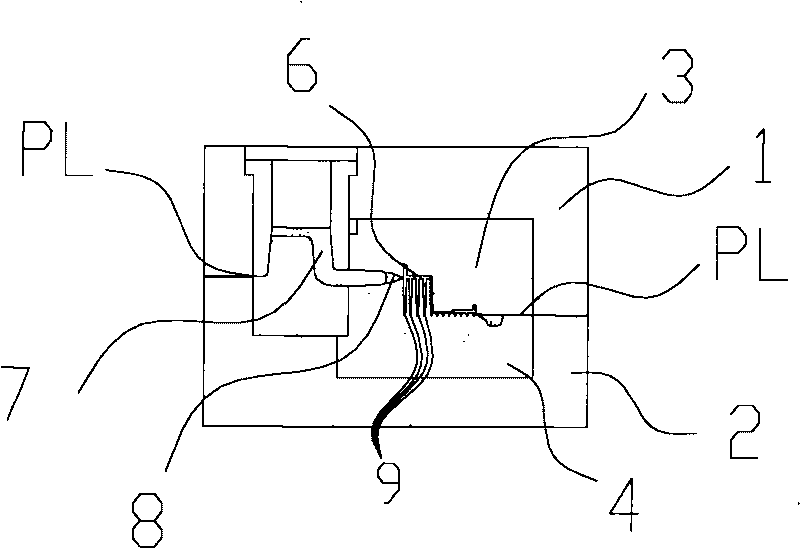

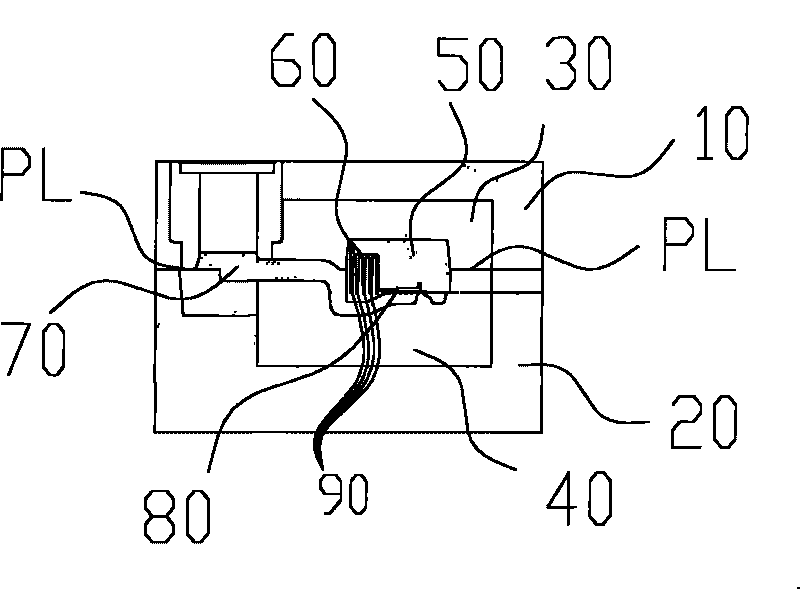

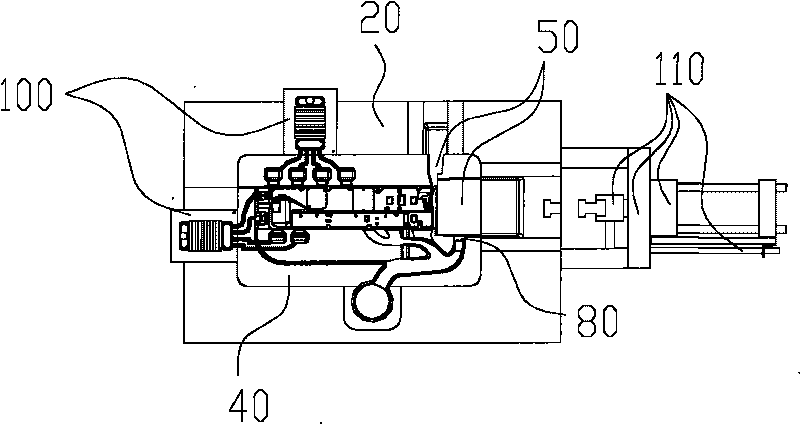

Die mold

The invention relates to a die mold comprising an upper mold unit, a lower mold unit and a slide block unit, wherein the upper mold unit is provided with an upper mold cavity unit, and the lower mold unit is provided with a lower mold cavity unit; the upper mold cavity unit cooperates with the lower mold cavity unit; the slide block unit is arranged in the space formed by the cooperation of the upper mold cavity unit and the lower mold cavity unit; the bottom of the slide block unit is provided with a material inlet; the die mold also comprises an oil hydraulic slide block drawing device used for drawing out the slide block unit; and three side surfaces of the slide block unit are respectively provided with a unilateral angle of 2 degrees. The scheme of the invention comprises the tunnel-type material feeding structure on the bottom of the slide block unit of the die mold and the oil hydraulic slide block drawing device; the material inlet is arranged in the positions beneficial to filling and forming of the casting by utilizing the slide block unit; and gas in the space fills a lot of space obtaining the cavity by the substitution of the raw material, thereby overcoming many defects in form filling and die casting.

Owner:苏州市永创金属科技有限公司

Hot processing process for normalizing thin steel plate with thickness no more than 12 mm

InactiveCN100584965CImprove internal and external qualityImprove performanceFurnace typesHeat treatment furnacesSheet steelRoom temperature

The invention provides a thermal treatment technique of a thin format steel plate and is characterized in that a furnace cooling process is added between the heat preserving process and the air cooling process;parameter requirements of each process comprise: 1. a steel plate in a heat treatment furnace is heated to a temperature of Ac1-Ac3 in the heating process; 2. the holding temperature of the steel plate in the heat treatment furnace is Ac1-Ac3 and the heat-preserving time is 1H-3H in the heat preserving process; 3. the temperature of the steel plate at the furnace port is 350 DEG C - 650 DEG C in the furnace cooling process; 4. the steel plate took out from the furnace is cooled in the air to the room temperature.Comparing with a general technique of normalization and cold leveling, the technique of the invention has characteristics of low equipment investment, low energy-consumption, short line of production, low producing cost and better inside and outside quality of the steel plates.

Owner:新余钢铁股份有限公司

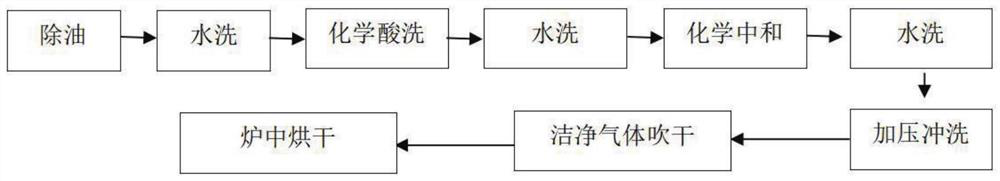

Cleaning method for long-service-life and high-reliability universal valve for spacecraft

PendingCN114713555ASolve cleaning problemsReduce dosageDrying gas arrangementsCleaning using liquidsStructural engineeringProcess engineering

The invention relates to the technical field of battery management systems, and discloses a cleaning method for a long-service-life high-reliability universal valve for a spacecraft. Cleaning is conducted through a cleaning box, the cleaning box comprises a water tank and an upper cover, the interior of the water tank is of a stepped structure and used for containing products of different lengths, and a water inlet hole is formed in the upper end of the side face of the water tank; the lower end of the other side face is provided with a water outlet hole which is in a flowing state in the cleaning process. The cleaning box is made of plastic, the proportion of the cleaning solution is suitable for cleaning different propelling product materials, and the cleaning problem of different materials is solved. The device is simple in structure and convenient in clamping process, saves solution consumption through an internal stepped structure, is suitable for cleaning products with different lengths, and improves production efficiency. After the cleaning process is adopted, the cleaned inner hole part does not contain redundant materials, and the internal and external quality is improved.

Owner:空天合一(北京)空间科技有限公司

A production process of low-chromium multi-element alloy casting ball

InactiveCN103725950BImprove internal and external qualityImprove impact performanceFoundry mouldsFoundry coresChemical compositionCasting defect

The invention relates to a process for producing a low-chromium complex alloy grinding ball. The process comprises the steps of melting, pouring, casting a metal mold and tempering, chemical components of the low-chromium complex alloy grinding ball are reasonably designed, and metal mold casting and tempering are carried out, so that the internal and external quality of the grinding ball can be improved, the product does not have the casting defects, such as sinkholes, pores, looseness and the like, the broken rate and no circularity of the grinding ball can be reduced, the fatigue impact resistance and wear resistance of the grinding ball can be improved, the product yield can be remarkably improved, the production process can be simplified, and the production cost can be reduced.

Owner:南平市双友金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com