Water-resisting breaking-resisting oxidation-resisting calligraphy and painting paper

A calligraphy and painting paper, anti-oxidation technology, applied in the direction of special paper, paper, papermaking, etc., can solve the problems of small market application range, unstable physical and chemical index data, etc., to improve the anti-mildew function, reduce the dependence on the environment and technology, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

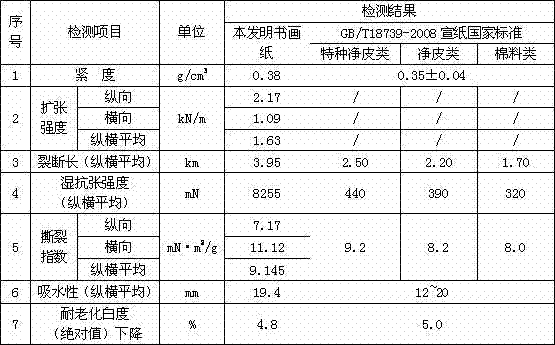

Image

Examples

Embodiment 1

[0034] A kind of anti-water, anti-break and anti-oxidation calligraphy and painting paper, prepared according to the following method:

[0035] 1. Raw material preparation, the ratio of raw and auxiliary materials is as follows:

[0036] (1) The components and parts by weight of raw materials are:

[0037] Bamboo pulp fiber 80 parts,

[0038] 30 parts of grass pulp fiber,

[0039] Softwood pulp fiber 25 parts,

[0040] Viscose fiber (Φ14-16D, length 10 mm) 25 parts;

[0041] (2) Calculated by ton of paper, the composition and weight percentage of auxiliary materials are:

[0042] RZ-4 antibacterial agent (Nantong Guangsheng) 2%,

[0043] PVA0588 (Suzhou Yongsheng Chemical Technology Co., Ltd.) 15%.

[0044] 2. Pulping

[0045] ① First, the straw pulp fiber is pulped into the hydropulper according to the ratio, and then into the disc refiner for refining. After the beating degree reaches 65oSR, it enters the pulping tank.

[0046] ②Bamboo pulp fiber is crushed according...

Embodiment 2

[0056] A kind of anti-water, anti-break and anti-oxidation calligraphy and painting paper, prepared according to the following method:

[0057] 1. Raw material preparation, the ratio of raw and auxiliary materials is as follows:

[0058] ((1) The components and parts by weight of the raw materials are:

[0059] Bamboo pulp fiber 45 parts,

[0060] 20 parts of grass pulp fiber,

[0061] Softwood pulp fiber 15 parts,

[0062] Viscose fiber (Φ14-16D, length 12 mm) 15 parts;

[0063] (2) Calculated by ton of paper, the composition and weight percentage of auxiliary materials are:

[0064] RZ-4 antibacterial agent (Nantong Guangsheng) 0.5%,

[0065] PVA1788 (Shanghai Sirui Chemical Co., Ltd.) 3%.

[0066] 2. Pulping

[0067] ① First, the straw pulp fiber is pulped into the hydropulper according to the ratio, and then into the disc refiner for refining. After the beating degree reaches 40oSR, it enters the pulping pool.

[0068] ②Bamboo pulp fiber is crushed according to the...

Embodiment 3

[0078] A kind of anti-water, anti-break and anti-oxidation calligraphy and painting paper, prepared according to the following method:

[0079] 1. Raw material preparation, the ratio of raw and auxiliary materials is as follows:

[0080] (1) The components and parts by weight of raw materials are:

[0081] Bamboo pulp fiber 70 parts,

[0082] 10 parts of grass pulp fiber,

[0083] Softwood pulp fiber 5 parts,

[0084] Viscose fiber (Φ14-16D, length 10 mm) 5 parts;

[0085] (2) Calculated by ton of paper, the composition and weight percentage of auxiliary materials are:

[0086] RZ-4 antibacterial agent (Nantong Guangsheng) 1%,

[0087] PVA T-350 (Nippon Synthetic Chemical Industry Co., Ltd.) 10%.

[0088] 2. Pulping

[0089] ① First, the straw pulp fiber is pulped into the hydropulper according to the ratio, and then into the disc refiner for refining. After the beating degree reaches 60oSR, it enters the pulping tank.

[0090] ②Bamboo pulp fiber is crushed according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com