Preparation method of waxberry fruit wine

A production method and bayberry technology, which are applied in the preparation of alcoholic beverages, microorganism-based methods, biochemical equipment and methods, etc., can solve problems such as high price, and achieve the effects of low cost, weakening dark changes, and fast clarification time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

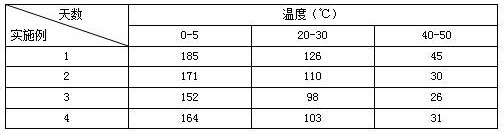

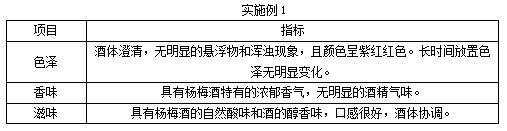

Embodiment 1

[0031] 1) Clean and dry the red bayberry with high maturity, freshness, and no rot and deterioration. The cleaning water is deoxygenated deionized water that is purged with nitrogen to reduce dissolved oxygen in the water;

[0032] 2) The dried red bayberry is denucleated and squeezed to obtain red bayberry juice, which is filtered through an ultrafiltration device for the first time and then sterilized by ultra-high temperature instantaneously at a sterilization temperature of 100-130° C. for 2-10 seconds. ;

[0033] 3) Take the red bayberry juice obtained in step 2), mix it with white sugar and grape yeast, 100 parts of red bayberry, 25 parts of white sugar, and 2 parts of grape yeast. Sealed fermentation at 25°C for 85 days to obtain red bayberry new wine;

[0034] 4) Filter and clarify the red bayberry new wine obtained in step 3). The agent used for clarification is chitosan-bentonite 0.6g / L (1:1), and cinnamic acid (18mg / L) is added to the filtrate obtained from clarifi...

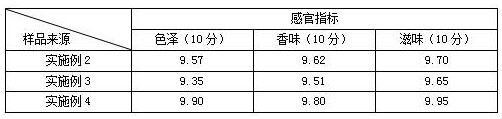

Embodiment 2

[0036] 1) Clean and dry the red bayberry with high maturity, freshness, and no rot and deterioration. The cleaning water is deoxygenated deionized water that is purged with nitrogen to reduce dissolved oxygen in the water;

[0037] 2) The dried bayberry is denucleated and squeezed to obtain bayberry juice, which is filtered through an ultrafiltration device for the first time and then sterilized by ultra-high temperature instantaneously at a sterilization temperature of 100-130° C. for 2-10 seconds. ;

[0038] 3) Take the red bayberry juice obtained in step 2), mix it with white sugar and grape yeast, 100 parts of red bayberry, 25 parts of white sugar, and 2 parts of grape yeast. Sealed fermentation at 22°C for 80 days to obtain red bayberry new wine;

[0039] 4) Filter and clarify the red bayberry new wine obtained in step 3). The agent used for clarification is chitosan-bentonite 0.5g / L (1:1), and cinnamic acid (15mg / L) is added to the filtrate obtained from clarification -...

Embodiment 3

[0041] 1) Clean and dry the red bayberry with high maturity, freshness, and no rot and deterioration. The cleaning water is deoxygenated deionized water that is purged with nitrogen to reduce dissolved oxygen in the water;

[0042]2) The dried red bayberry is denucleated and squeezed to obtain red bayberry juice, which is filtered through an ultrafiltration device for the first time and then sterilized by ultra-high temperature instantaneously at a sterilization temperature of 100-130° C. for 2-10 seconds. ;

[0043] 3) Take the red bayberry juice obtained in step 2), mix it with white sugar and grape yeast, 100 parts of red bayberry, 25 parts of white sugar, and 2 parts of grape yeast. Sealed fermentation at 22°C for 80 days to obtain red bayberry new wine;

[0044] 4) Filtrate and clarify the bayberry new wine obtained in step 3), the agent used for clarification is chitosan-bentonite 0.5g / L (2:1), add cinnamic acid (15mg / L) to the filtrate obtained from clarification -D- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com