Low-VOC and low-migration polypropylene composite material and preparation method thereof

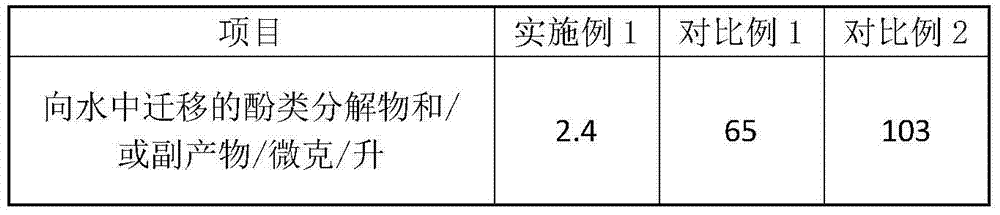

A composite material and polypropylene technology, applied in the field of modified materials, can solve problems such as hidden dangers, poor VOC removal, short mixing time, etc., and achieve the effects of small addition, good compatibility, and low migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

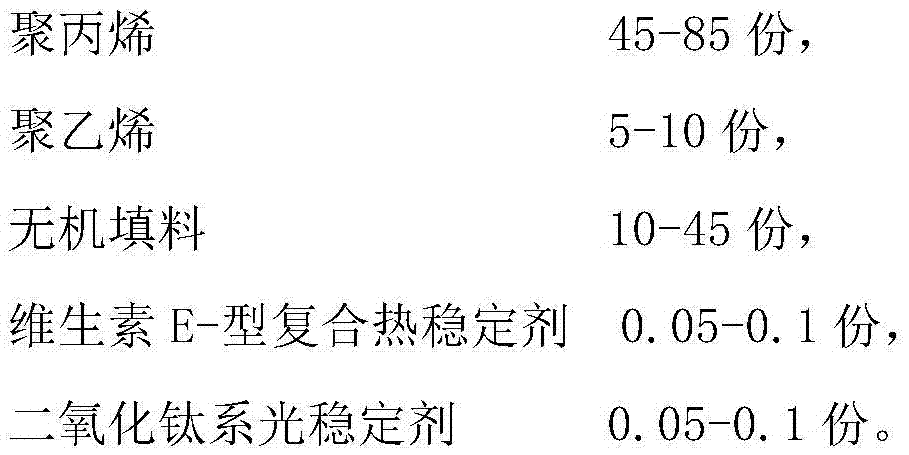

Method used

Image

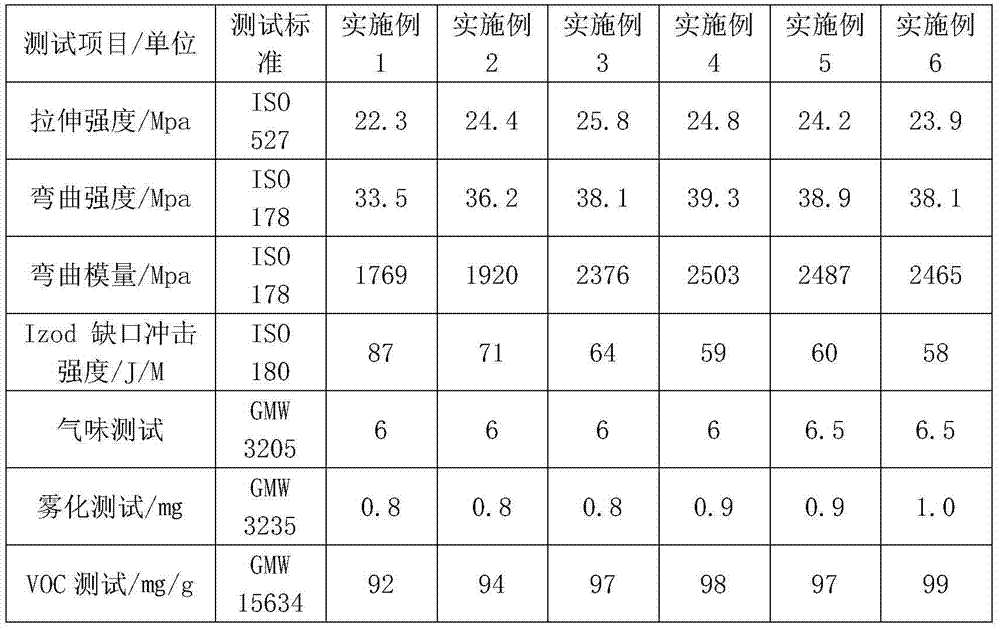

Examples

Embodiment 1

[0024] Add 40 parts of copolymerized polypropylene, 45 parts of homopolypropylene, 5 parts of low-density polyethylene, 10 parts of inorganic filler wollastonite, 0.05 parts of vitamin E-type composite heat stabilizer and 0.1 part of titanium dioxide light stabilizer Mix in a high mixer with a temperature of 60°C for 5 minutes;

[0025] The blend after the above raw materials are uniformly mixed is extruded and granulated by a twin-screw extruder. °C, 180 °C, 180 °C, 180 °C, 180 °C, 185 °C, the length-to-diameter ratio of the extrusion screw is 40, and the rotation speed of the extrusion screw is 350 rpm.

Embodiment 2

[0027] Add 72 parts of homopolypropylene, 8 parts of linear low-density polyethylene, 20 parts of inorganic filler fly ash, 0.05-0.1 part of vitamin E-type composite heat stabilizer and 0.05-0.1 part of titanium dioxide-based light stabilizer, and add them together to the temperature Mix in a high mixer at 50°C for 10 minutes;

[0028] The blend after the above raw materials are uniformly mixed is extruded and granulated by a twin-screw extruder. °C, 190 °C, 190 °C, 195 °C, 195 °C, 200 °C, the length-to-diameter ratio of the extrusion screw is 36, and the rotation speed of the extrusion screw is 350 rpm.

Embodiment 3

[0030] 67 parts of copolymerized polypropylene, 5 parts of low-density polyethylene, 2 parts of linear low-density polyethylene, 10 parts of inorganic filler talc, 15 parts of calcium carbonate, 0.05-0.1 parts of vitamin E-type composite heat stabilizer and titanium dioxide-based light Stabilizer 0.05-0.1 part, add together at 40°C, mix in high mixer for 15 minutes;

[0031] The blend after the above raw materials are uniformly mixed is extruded and granulated through a twin-screw extruder. °C, 185 °C, 185 °C, 200 °C, 200 °C, 195 °C, the length-to-diameter ratio of the extrusion screw is 40, and the rotation speed of the extrusion screw is 350 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com