Patents

Literature

134 results about "Aluminium stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porcine streptococcus disease and haemophilus parasuis disease combined inactivate vaccine and preparation method thereof

ActiveCN102329746AReduce stressEasy to useAntibacterial agentsBacterial antigen ingredientsHaemophilusAluminium stearate

The invention discloses a porcine streptococcus disease and haemophilus parasuis disease combined inactivate vaccine and a preparation method thereof. The preparation method comprises the following steps of: a, respectively carrying out enrichment culture on a porcine streptococcus strain, a haemophilus parasuis strain and a haemophilus parasuis strain to obtain a porcine streptococcus strain bacterial solution, a haemophilus parasuis strain bacterial solution and a haemophilus parasuis strain bacterial solution; b, respectively adding a formaldehyde solution into the porcine streptococcus strain bacterial solution, the haemophilus parasuis strain bacterial solution and the haemophilus parasuis strain bacterial solution, and inactivating; c, mixing the collected porcine streptococcus strain bacterial solution, the haemophilus parasuis strain bacterial solution and the haemophilus parasuis strain bacterial solution, adding Tween-80 for preparing a water phase, preparing white oil, Span-80 and aluminium stearate into an oil phase, mixing the water phase with the oil phase to prepare a uniform emulsion, i.e. an oil emulsion inactivating vaccine; and 4, sub-packaging the oil emulsion inactivating vaccine. The porcine streptococcus disease and haemophilus parasuis disease combined inactivate vaccine can effectively prevent the porcine streptococcus disease and haemophilus parasuis disease, does not have hidden danger of scattering viruses and is safe and reliable; and the immunization is realized by one vaccine, thus the cost is reduced.

Owner:WUHAN KEQIAN BIOLOGY CO LTD

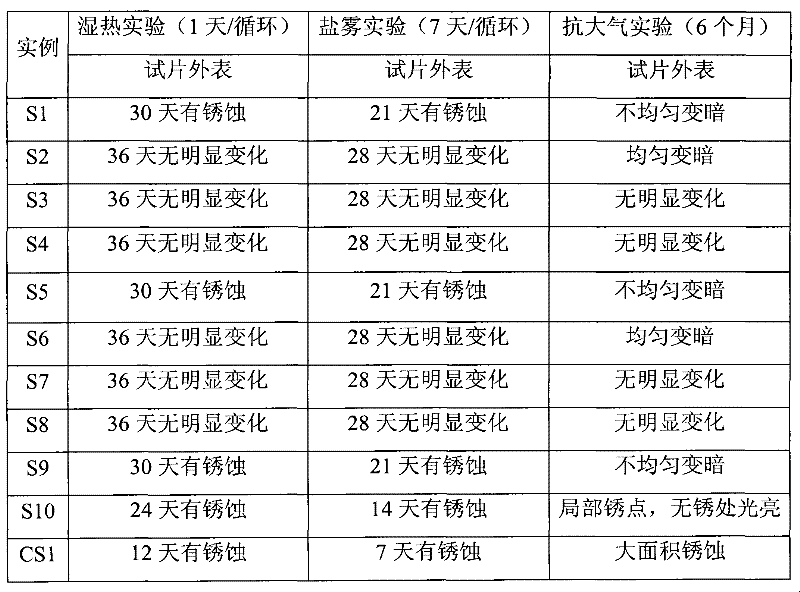

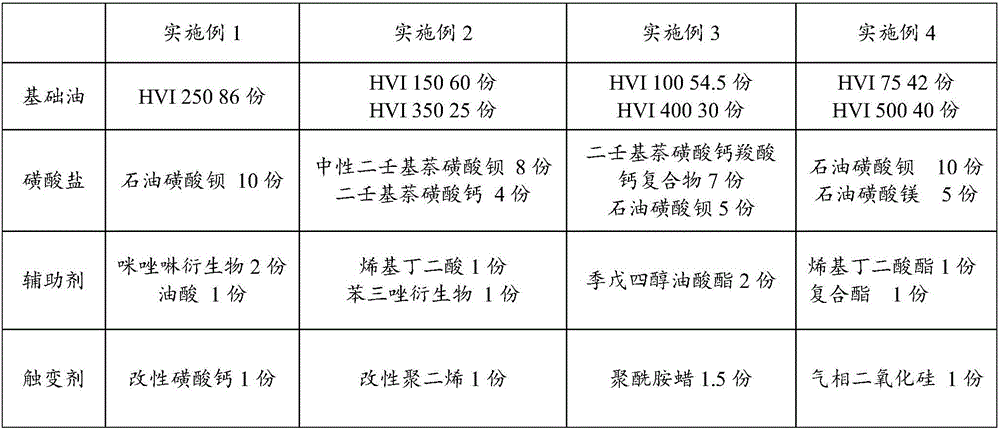

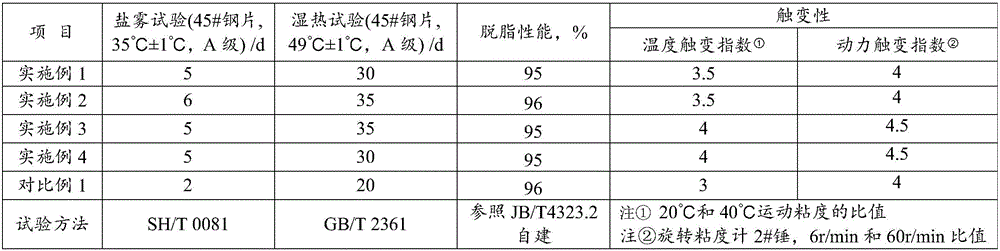

Rust preventive oil and preparation method thereof

The invention provides a rust preventive oil. The rust preventive oil comprises a composite antirust agent and base oil. The composite antirust agent is a mixture of a rare earth-beta-dione complex and at least one of barium petroleum sulfonate, sodium petroleum sulfonate, calcium petroleum sulfonate, barium dinonylnaphthalene sulfonate, barium heavy alkyl benzene sulfonate, non-barium heavy alkyl benzene sulfonates, a lanolin magnesium soap, a lanolin aluminum soap, aluminium stearate, a oxidized petroleum ester barium soap and zinc naphthenate. The invention also provides a preparation method of the rust preventive oil. The preparation method comprises putting the base oil into a reaction vessel, adding the composite antirust agent into the base oil, stirring the mixture with heating to dehydrating the mixture, and then filtering to obtain the rust preventive oil. The rust preventive oil prepared by the invention can keep a rust-preventing effect for a long time in three environments of a temperature and humidity experiment, a salt spray experiment and an atmospheric corrosion resistance experiment, and thus can satisfy needs.

Owner:BYD CO LTD

Antibacterial aerated brick

The invention discloses an antibacterial aerated brick, comprising the following materials in parts by weight: 20-25 parts of antibacterial kaolin, 4-6 parts of cement, 5-7 parts of river sand, 1-2 parts of glass fiber, 0.3-0.6 part of magnesium stearate, 0.1-0.2 part of aluminium stearate, 0.1-0.2 part of barium stearate, 1-2 parts of aluminum metasilicic acid, 1-2 parts of polypropylene fiber, 0.005-0.008 part of polyoxyethylene, 0.2-0.4 part of lauryl sodium sulfate, 0.05-0.08 part of epoxy butyl oleate, and 0.1-0.2 part of epoxy ethylhexyl stearate. According to the antibacterial aerated brick, antibacterial extracts are prepared by using the traditional Chinese medicine ingredients, are natural, healthy, free of pollution and good in effects, and is added to the materials of the aerated brick, so that the properties such as the strength of the aerated brick are kept when an antibacterial effect is achieved.

Owner:潘逸东

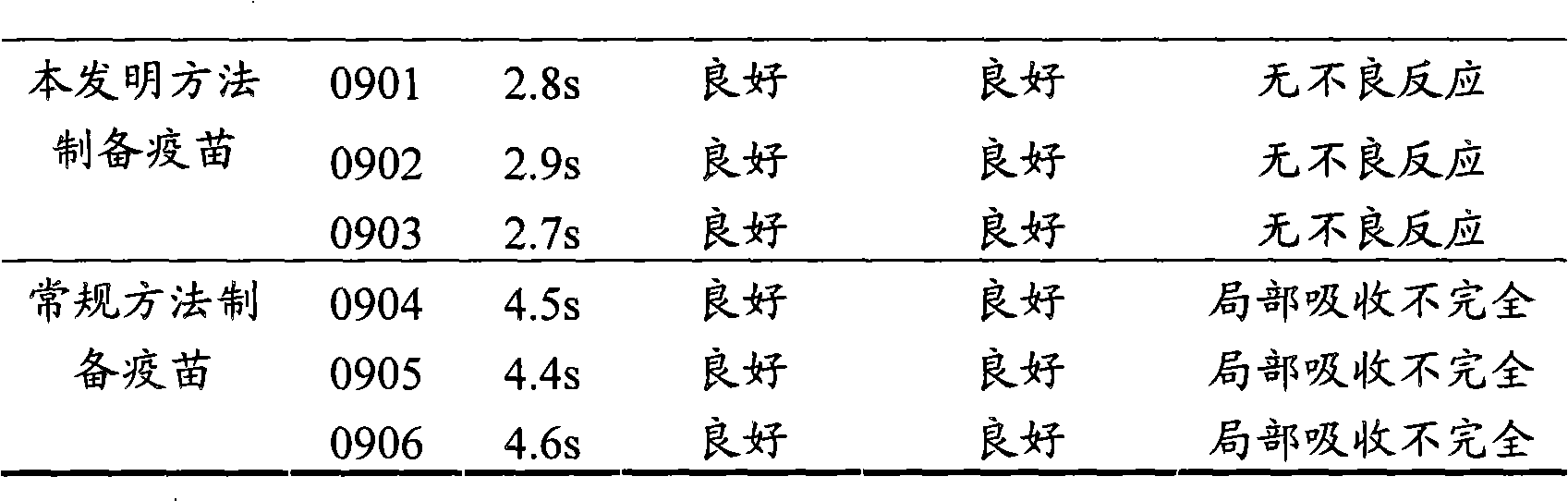

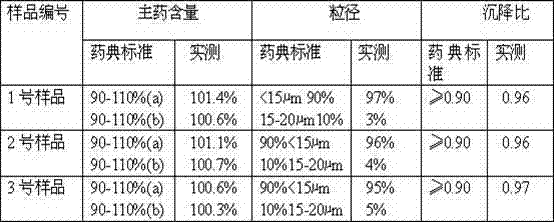

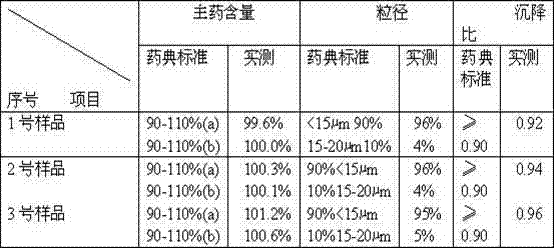

Preparation method of ceftiofur long-acting injector

InactiveCN101416968AReduce stress responseGood curative effectAntibacterial agentsOrganic active ingredientsHalf-lifeTherapeutic effect

A ceftiofur long acting injection consists of the following substances: 2.5g to 5.0g of ceftiofur crude drugs, 0.5g to 3.0g of span 80, 0.1g to 0.3g of Vitamin E, 0.2g to 0.5g of aluminium stearate, 0.25g to 0.5g of chlorobutanol and soybean oil. The preparation method of the ceftiofur long acting injection comprises the following steps: (1) smashing the ceftiofur crude drugs till the particle size of the ceftiofur crude drugs is 5 Mum; (2) adding the span 80 into a mortar for grinding till the span 80 becomes even; (3) then, adding the aluminium stearate, the Vitamin E and the chlorobutanol into the mortar together; and (4) moving the mixture into a measuring vessel and adding the soybean oil into the measuring vessel till the total volume of the substances in the measuring vessel reaches 100ml. The ceftiofur long acting injection has the advantages of obvious therapeutic effect, long half-life period, less adverse reaction, reducing medication times, saving manual labor and time and the like.

Owner:PU LIKE BIO ENG

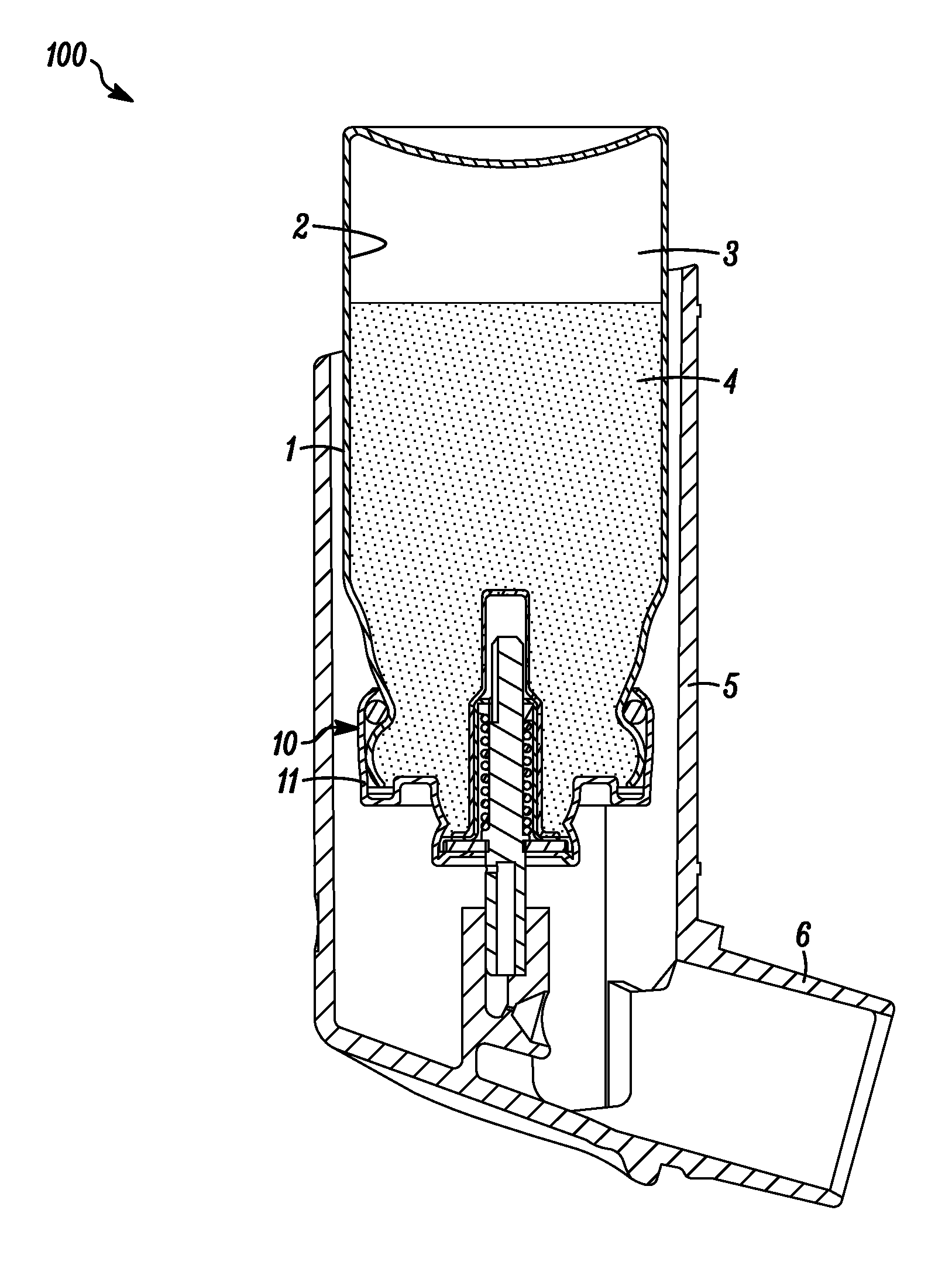

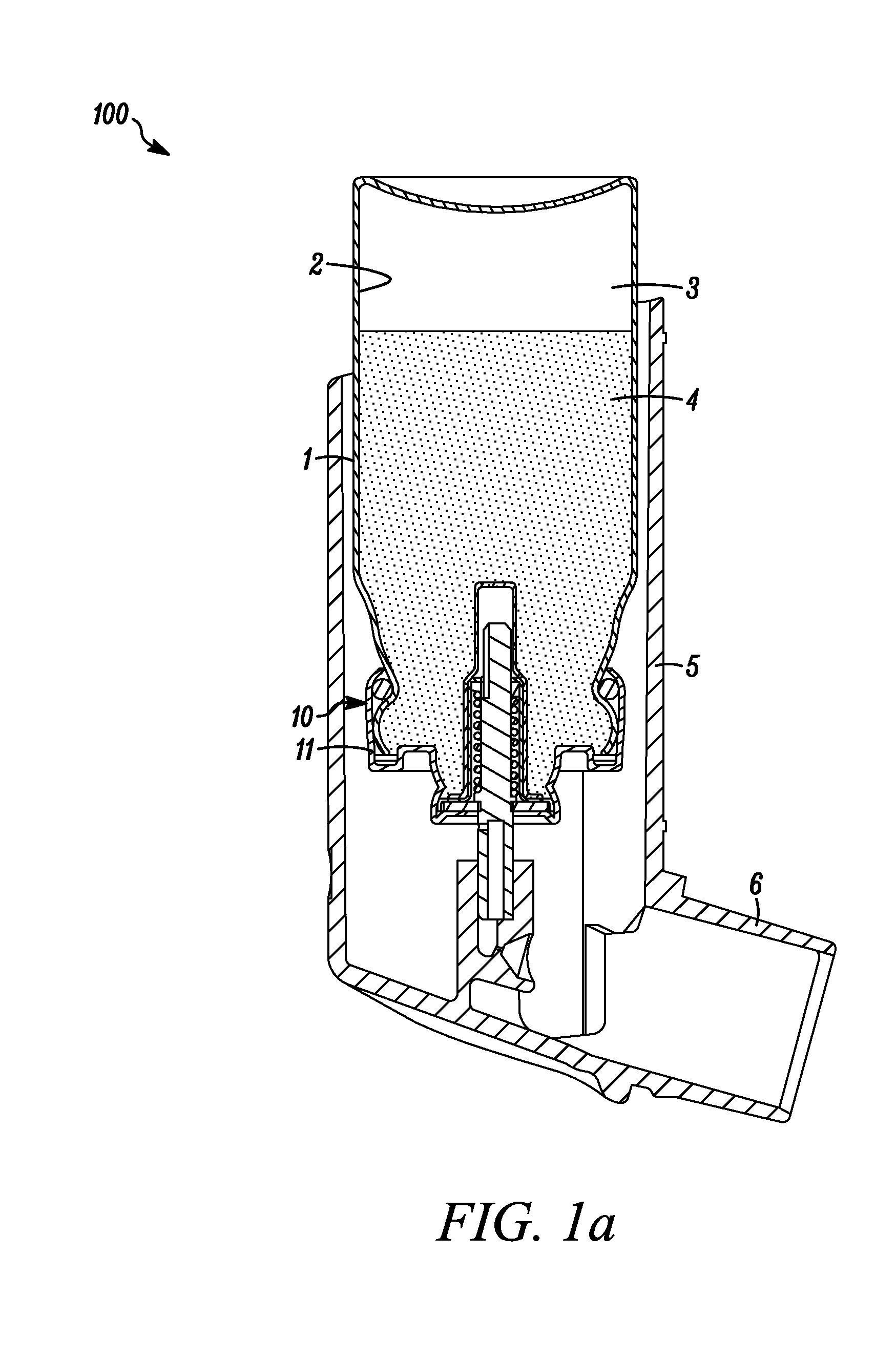

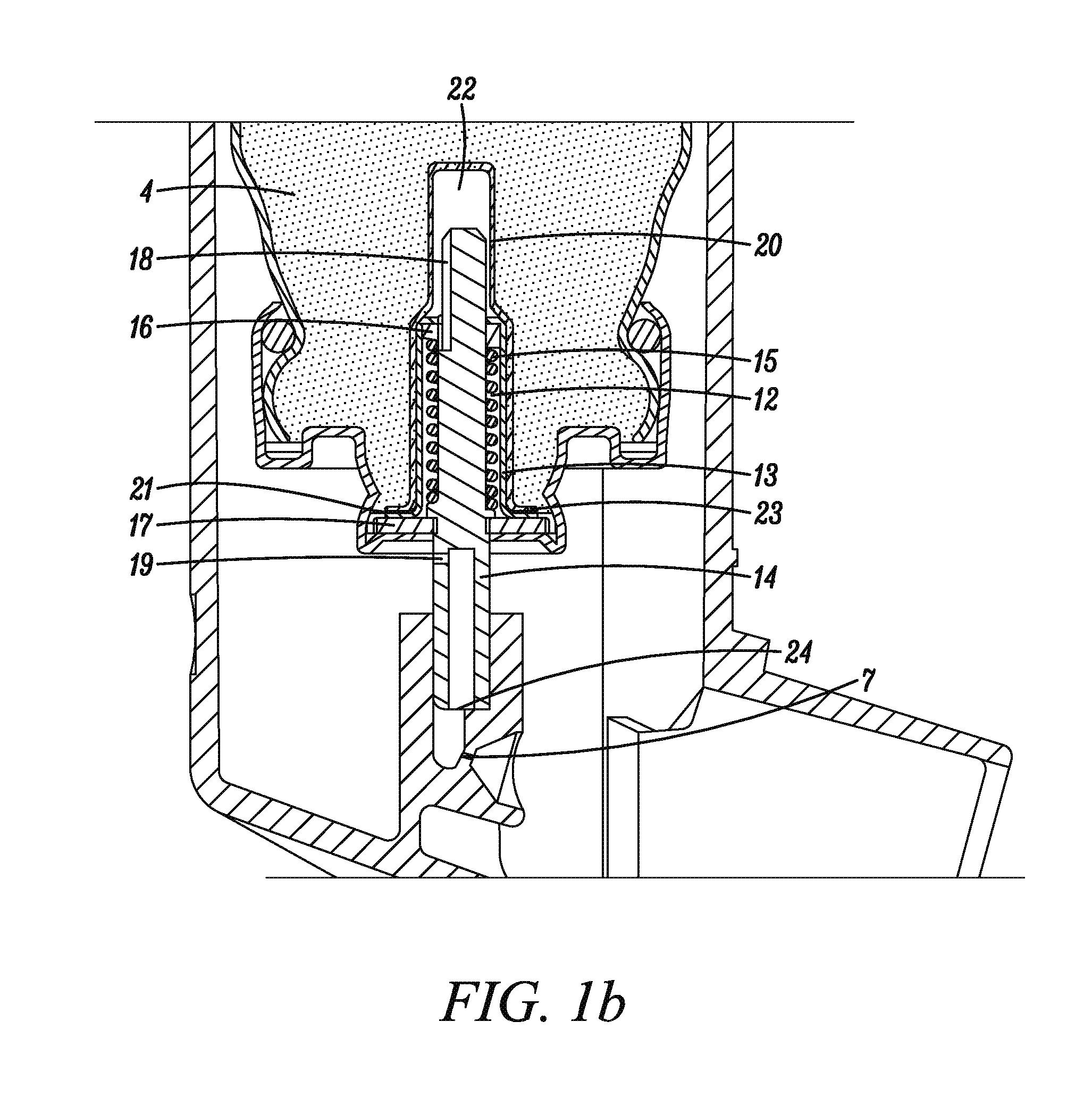

Medicinal inhalation devices, valves and components thereof

InactiveUS20140109900A1Favorable valve performanceSimple designRespiratorsValve arrangementsCalcium PalmitateStearic acid

A method of making a metered dose valve or a component including the step of forming a coating on at least a portion of a surface of the valve or the component, wherein said coating comprises a particulate material selected from the group consisting of Magnesium Stearate, Calcium Stearate, Zinc Stearate, Aluminium Stearate, Stearic acid, Magnesium Palmitate, Calcium Palmitate, Zinc Palmitate or Aluminium Palmitate, Palmitic acid, and mixtures thereof.

Owner:KINDEVA DRUG DELIVERY LP

Antirust agent containing modified vermiculite powder

The invention discloses an antirust agent containing modified vermiculite powder. The antirust agent containing modified vermiculite powder is prepared from the following raw materials by weight: 80-100 parts of castor oil, 5-8 parts of barium petroleum sulfonate, 1-3 parts of ferrocene, 0.8-1.0 part of polyisobutene, 0.5-1.0 part of bitertanol, 1-2 parts of ammonium benzoate, 5-8 parts of fatty acid amide, 8-10 parts of aluminium stearate, 0.8-1.2 parts of 2-aminoethyl heptadecenyl imidazoline, 1-2 parts of decylamine, 1-3 parts of zinc alkyl dithiophosphate, 5-8 parts of sodium citrate, 8-10 parts of phosphoric acid, 2-4 parts of sodium dodecyl benzene sulfonate, 2-3 parts of polyethylene glycol, 5-6 parts of a film-forming resin, 3-5 parts of lanolin, 3-5 parts of 1,3-glutaric acid morpholine and 5-8 parts of modified vermiculite powder. By adding the modified vermiculite powder and adjusting the formula, the antirust agent having a very good gas phase antirust effect is prepared. The antirust agent provided by the invention has excellent antirust performance and is convenient for use; and the production process is simple.

Owner:辽宁宝瑞科技有限公司

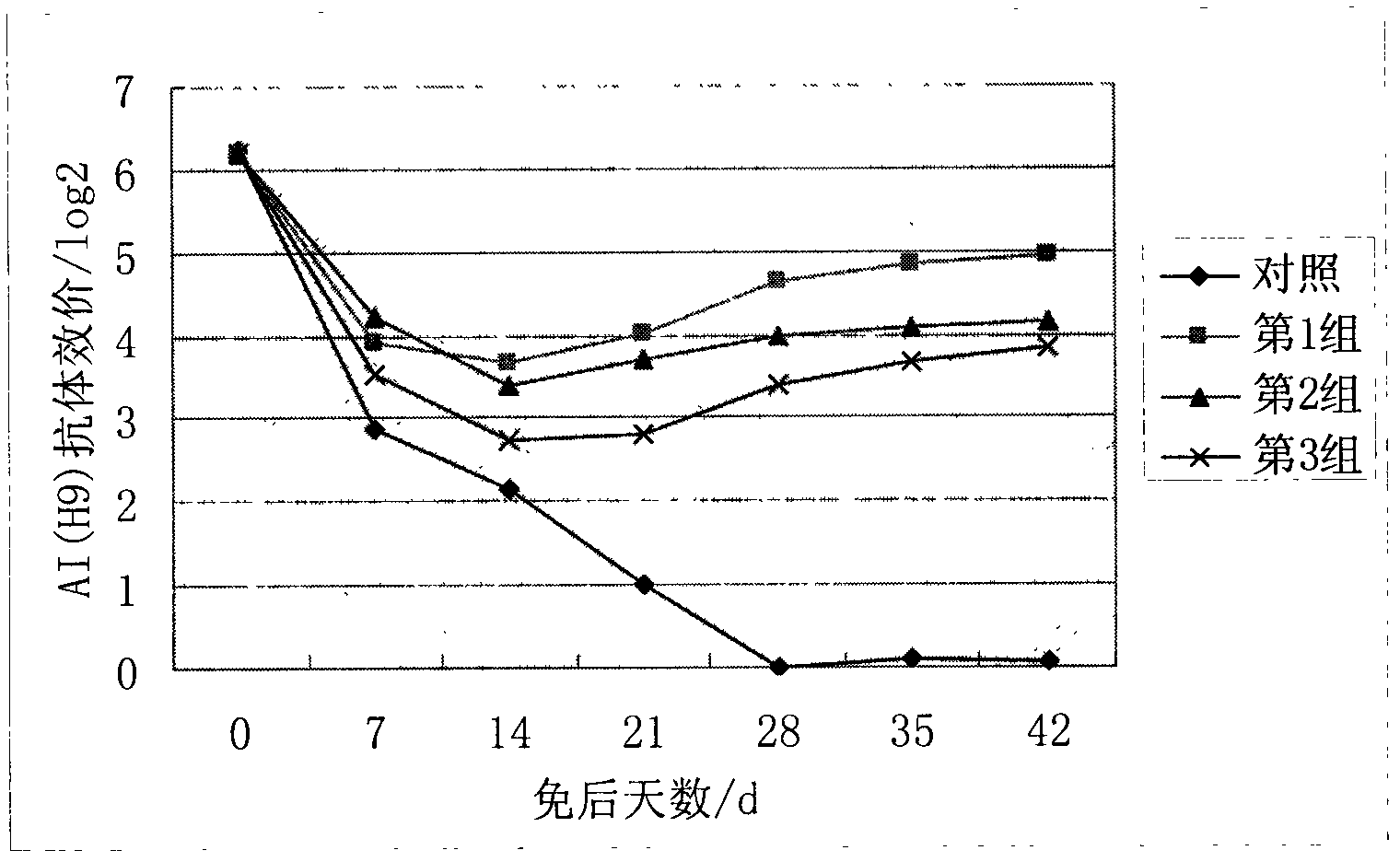

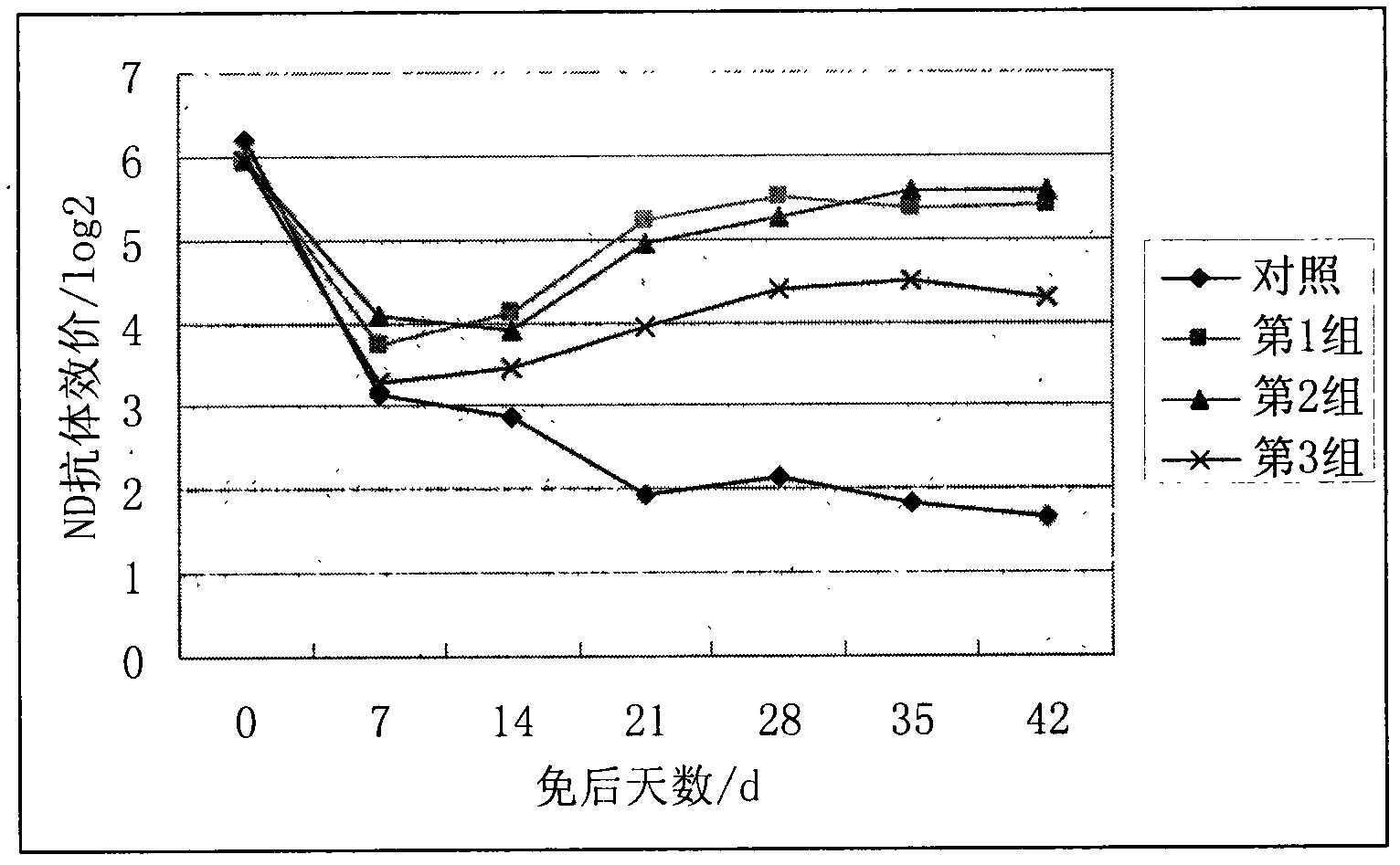

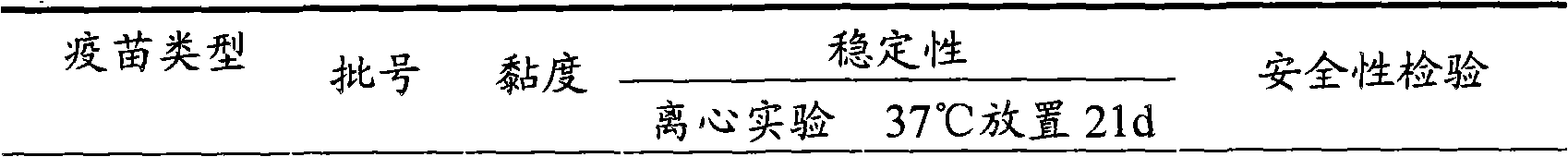

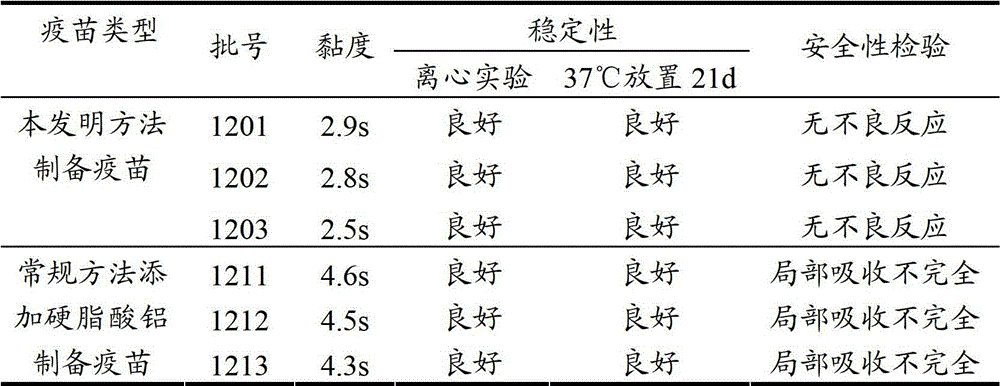

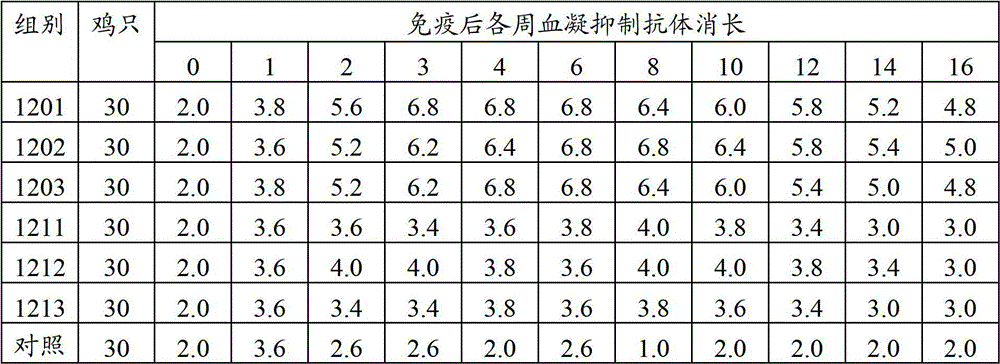

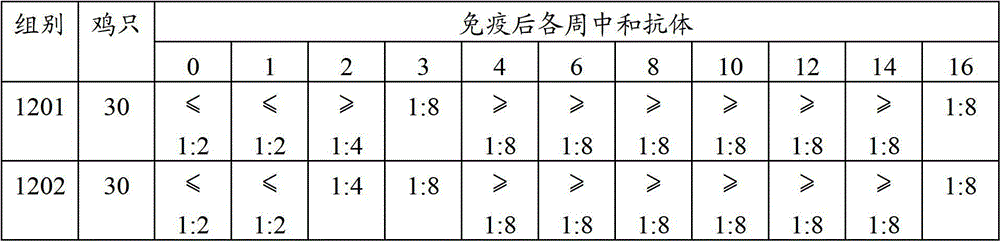

Oil emulsion vaccine for broilers and preparation method thereof

InactiveCN102579339APromote absorptionQuick resultsViral antigen ingredientsAntiviralsOil emulsionOil phase

The invention discloses an oil emulsion vaccine for broilers and a preparation method thereof. The oil emulsion vaccine comprises a water phase and an oil phase, wherein the water phase contains concentrated and inactivated ND (newcastle disease) and H9 AI (avian influenza) venom and Tween-80; the oil phase contains an oil adjuvant formed by white oil, Span-80 and aluminium stearate; the volume ratio of the water phase to the oil phase is (1:1.6) to (1:2); and the kinematic viscosity (40 DEG C) of the selected white oil is 4-8mm<2> / s. The oil emulsion vaccine has the characteristics of easiness in absorption, quick effect and high level of the generated antibodies, is suitable for growth of the broilers, can effectively increase the immune levels of the broilers, can effectively protect the broilers from being invaded by ND and H9 AI viruses and avoids ND and H9 AI in the immune phase.

Owner:TIANJIN RINGPU BIO TECH

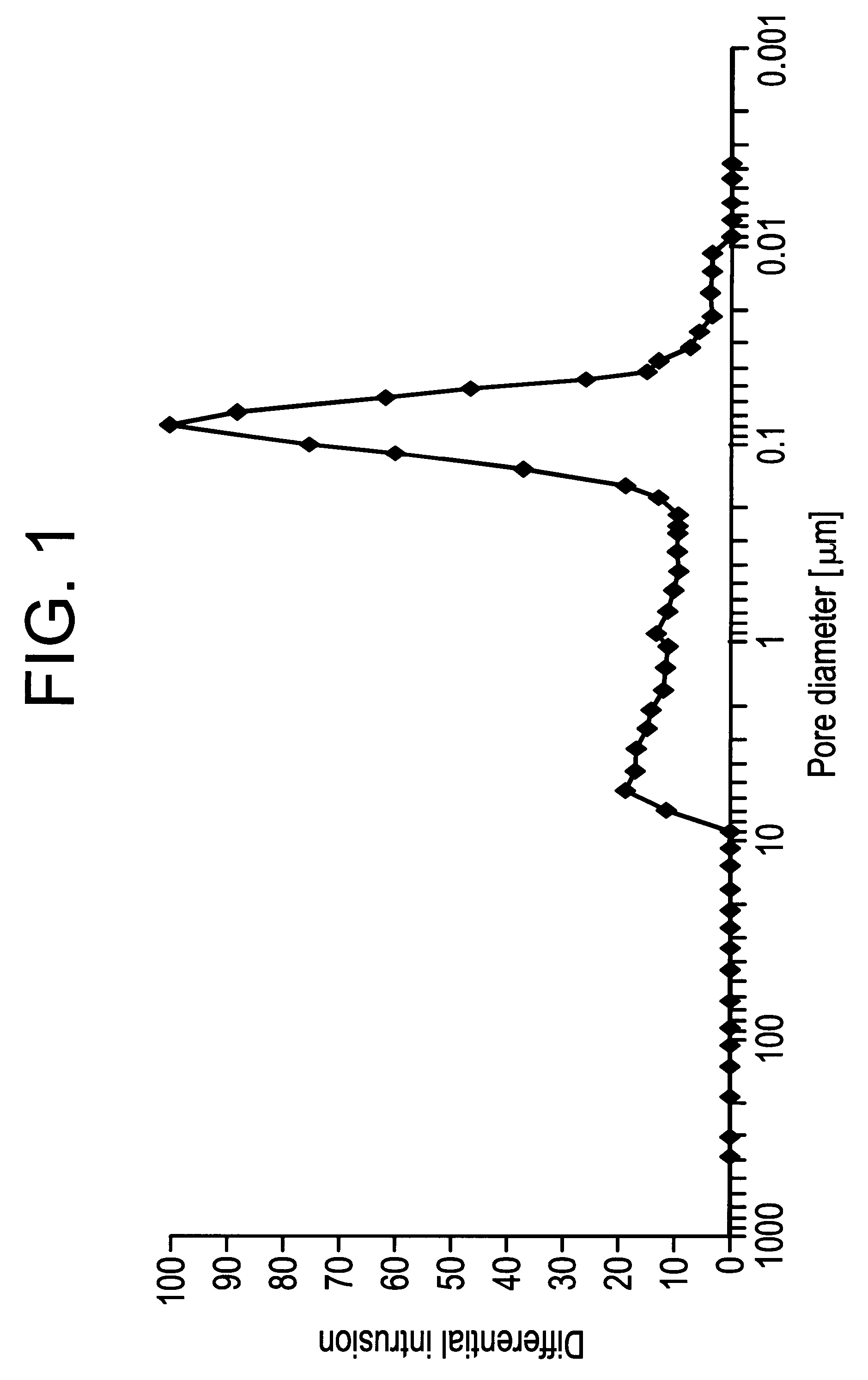

Moldings including pyrogenic mixed oxide and the use thereof

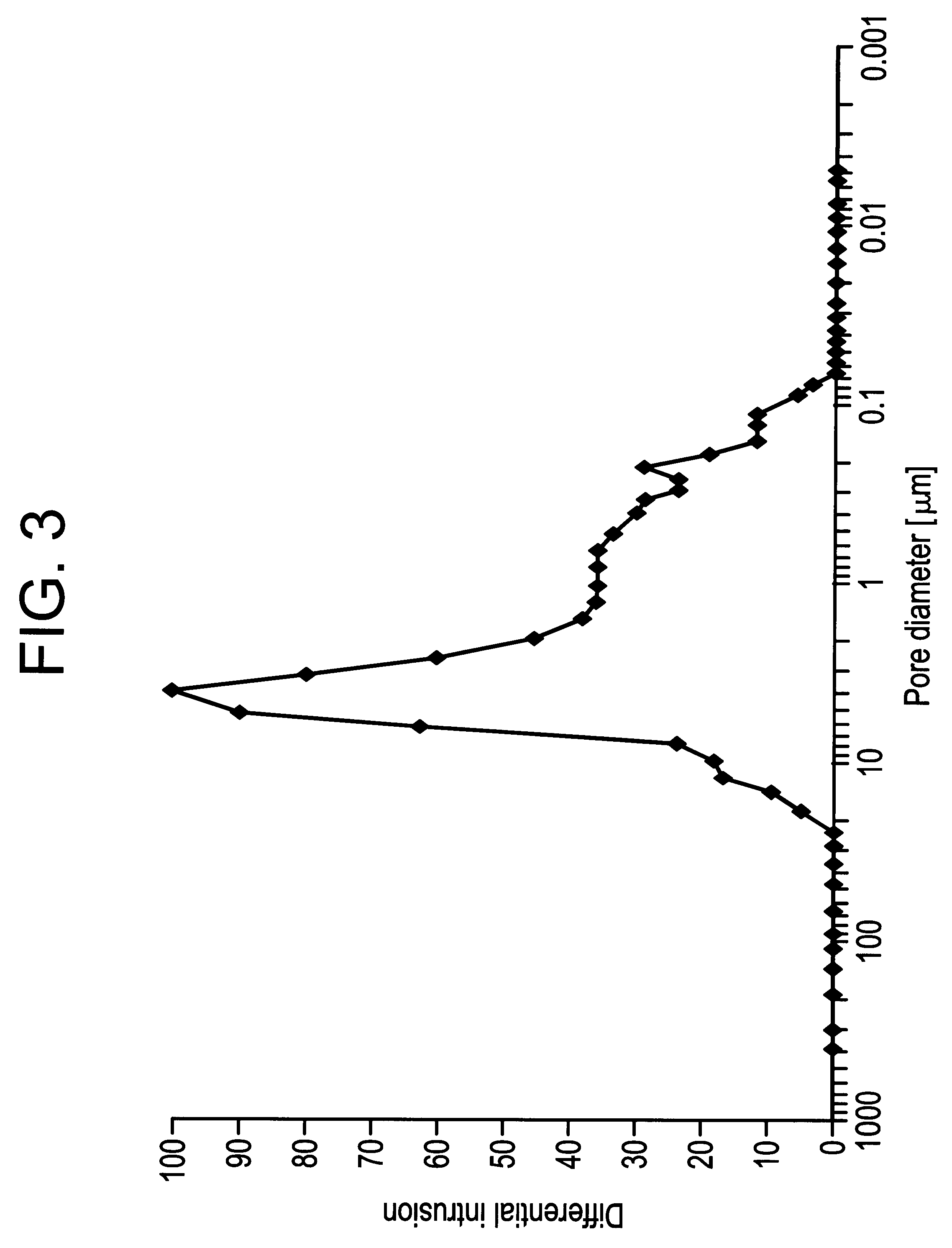

Moldings are disclosed for use as a catalyst or catalyst support for hydrating olefin, such as ethylene and propylene. The moldings are based on a pyrogenically produced mixed oxide having the following physicochemical parameters:The moldings are produced by homogenizing pyrogenically produced mixed oxide as desired with water and one or more compounds selected from the group of methylcellulose, methylhydroxyethylcellulose, wax, polyethylene glycol, magnesium stearate or aluminium stearate; drying the product at a temperature of 70-150° C.; optionally comminuting to yield a powder; optionally compression molding the powder to yield moldings; and performing heat treatment for a period of 0.5 to 10 hours at a temperature of 400 to 1200° C. Prior to drying, the mixture may also be subjected to kneading and / or shaping processes and extruded.

Owner:DEGUSSA AG

Skin-type waterproof coating and construction method

ActiveCN101792301ATightly boundOvercoming the "Two Skins" PhenomenonArtificial islandsUnderwater structuresLithium carbonateMethyl cellulose

The invention discloses a skin-type waterproof coating comprising the following components in percentage by weight of total weight of the coating: 85-90% of sulphoaluminate early strength cement, 5-10% of FEA cement expanding agent, 1-2% of hydroxypropyl methyl cellulose, 2-3% of aluminium stearate and 0.08-0.15% of lithium carbonate. The invention also provides a construction method of the skin-type waterproof coating in the waterproofing engineering. The skin-type waterproof coating is applied to the waterproofing construction of a building body, can eradicate the phenomenon of 'two skins' between a waterproof layer and the building body, can effectively improve the quality of waterproofing engineering, shortens construction period, quickens construction progress and lowers waterproofing engineering cost.

Owner:石家庄天冕防水科技有限公司

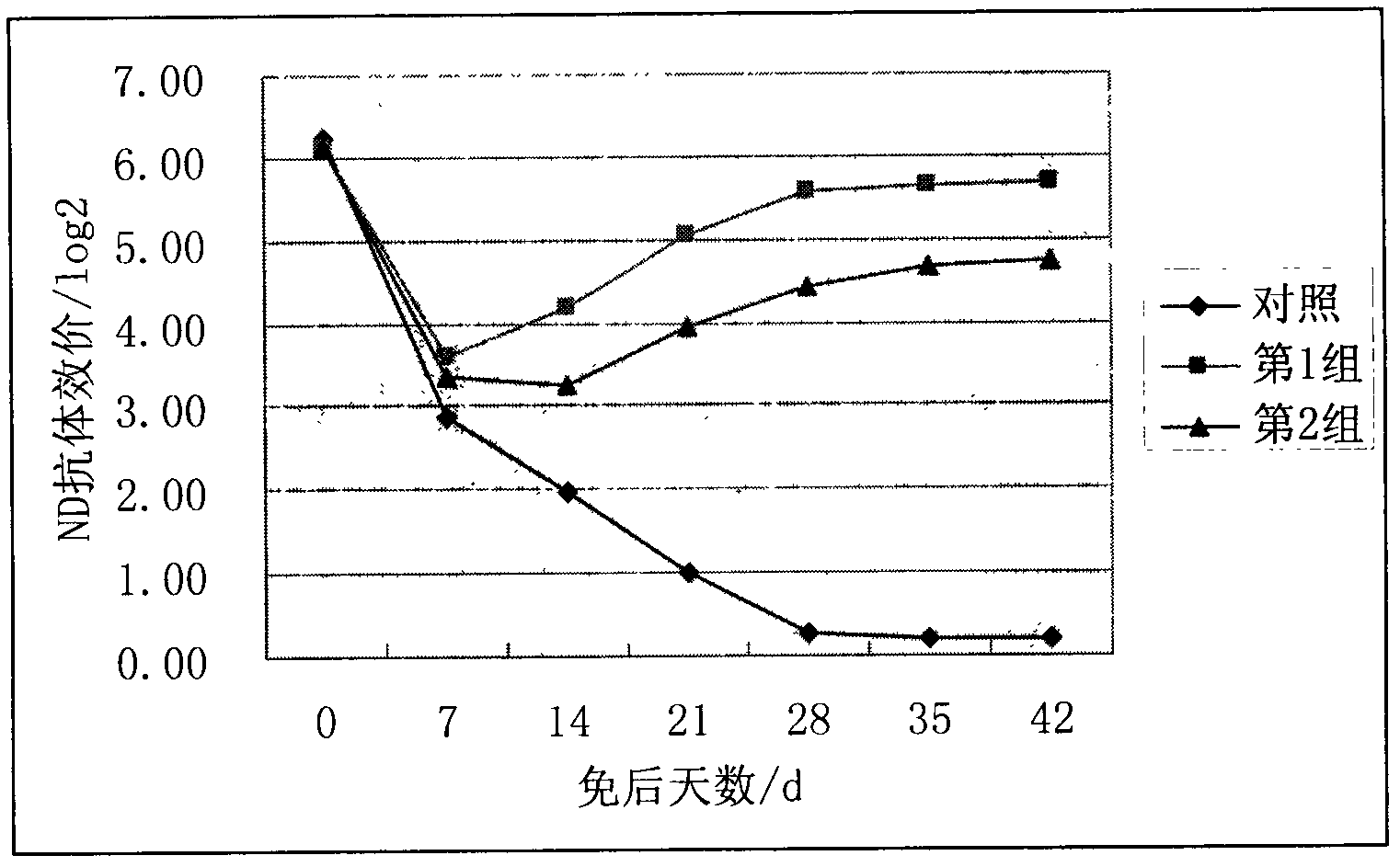

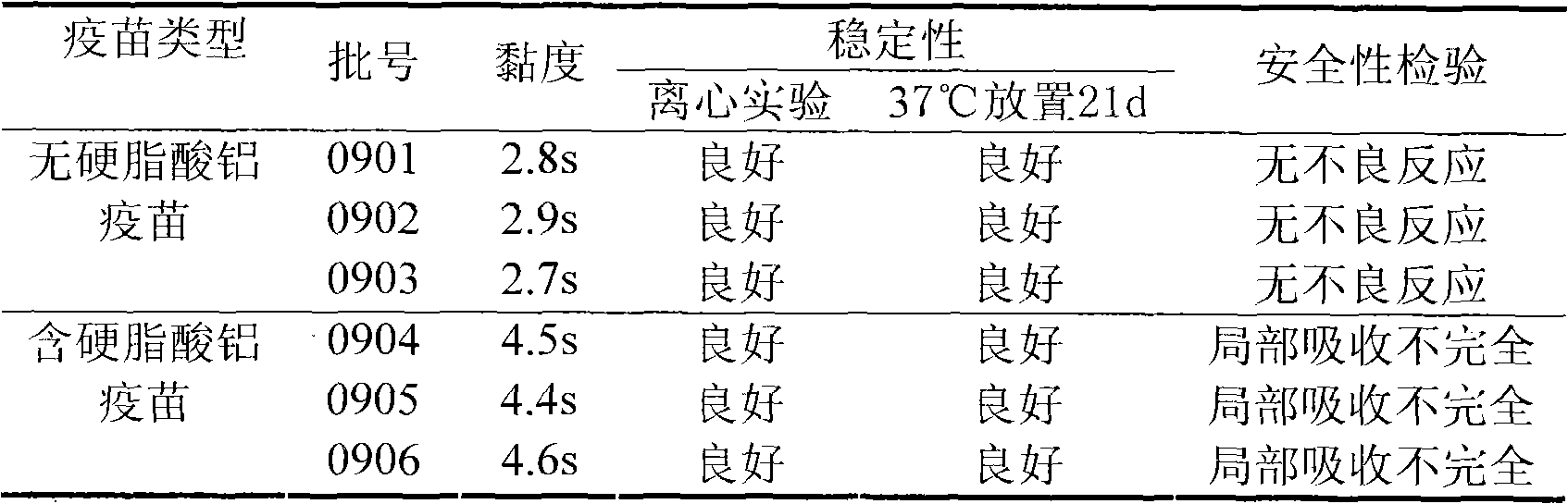

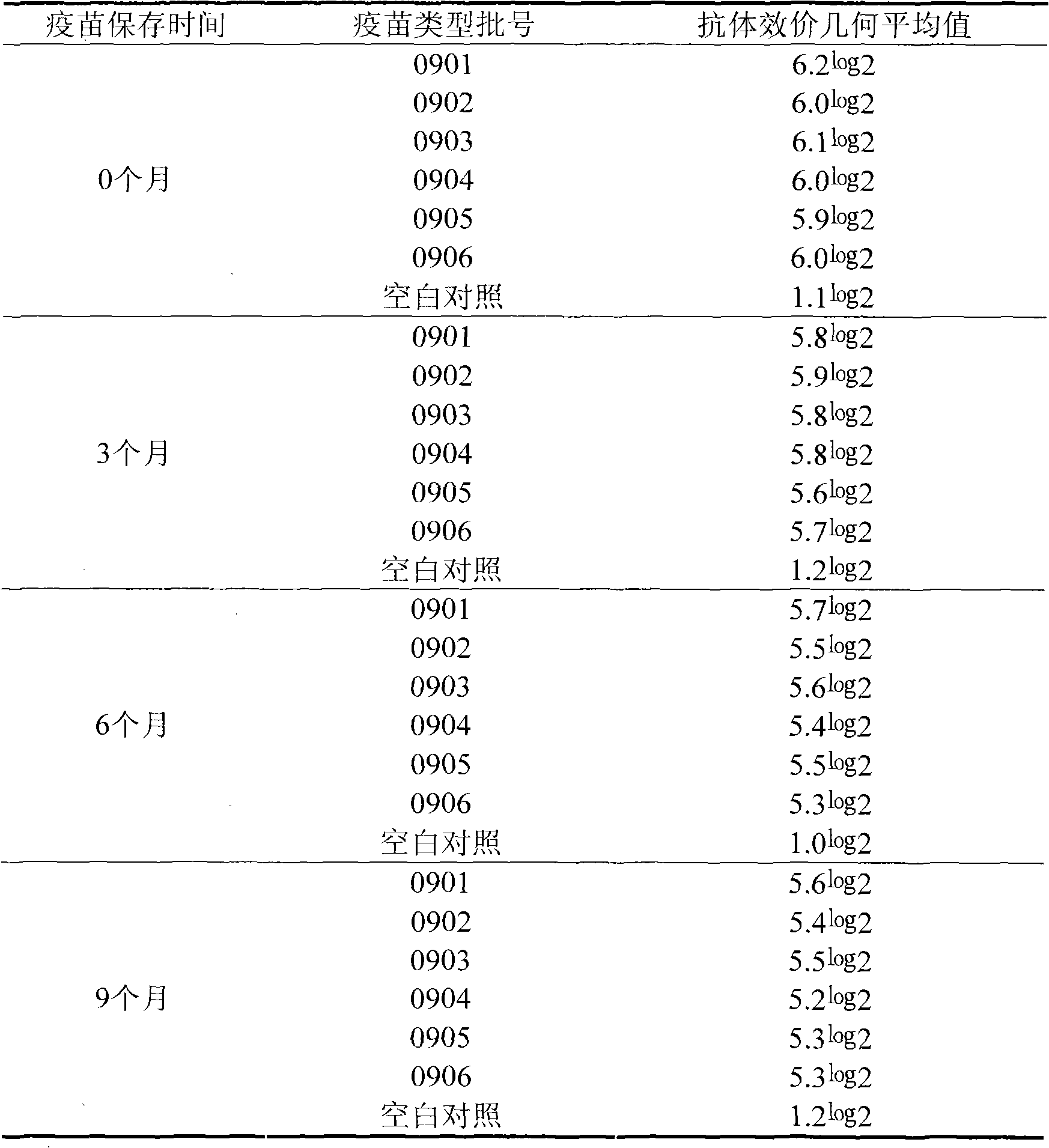

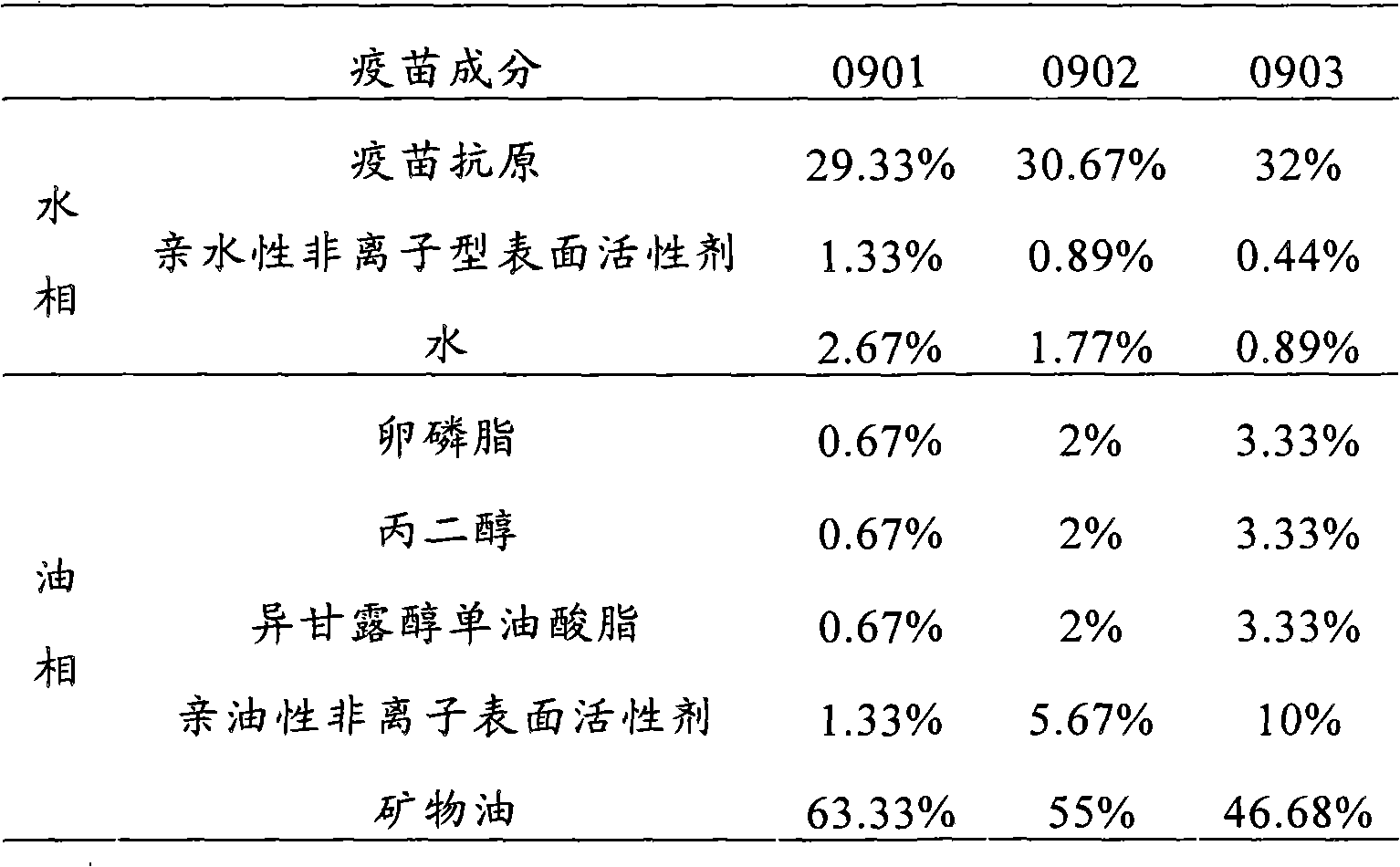

Poultry oil emulsion vaccine and preparation method thereof

Te invention discloses a poultry oil emulsion vaccine and a preparation method thereof, which is a water-in-oil adjuvant vaccine comprising 33.3 volume percent of water phase and 66.7 volume percent of oil phase, wherein the water phase contains an effective dose of antigen which is biologically acceptable and a hydrophilic nonionic surfactant; and the oil phase contains mineral oil, lecithin, propylene glycol, isomannino monooleate and a lipophilic nonionic surfactant. The vaccine does not contain aluminium stearate, can keep high antibody producing capacity for a long time and solve the problem of animal stress caused by vaccine injection and vaccine residue.

Owner:PU LIKE BIO ENG

Oil emulsion vaccine and preparation method thereof

ActiveCN101933903ALow viscosityReduce retentionViral antigen ingredientsAntiviralsOil emulsionMedicine

The invention discloses an oil emulsion vaccine and a preparation method thereof. The oil emulsion vaccine comprises 33.3 volume percent of water phase and 6.7 percent of oil phase, wherein the water phase contains vaccine antigen and hydrophilic nonionic surfactant; and the oil phase contains mineral oil, lecithin, propylene glycol, isomannitol monooleate and oleophylic nonionic surfactant. The vaccine does not contain aluminium stearate, can keep high antibody productivity in a long time and effectively solves the problems of animal stress reaction caused by vaccine injection and vaccine residue.

Owner:PU LIKE BIO ENG +1

Conductive printing ink

The invention relates to conductive printing ink which comprises the following components in parts by mass: 25-40 parts of acrylic resin M109, 60-70 parts of diol-type flexible relief block conductive printing ink connection material, 10-20 parts of glycol, 15-18 parts of chlorinated rubber liquid, 10-15 parts of carbamide, 5-10 parts of triethanolamine, 10-20 parts of diethylene glycol, 0.1-0.4 parts of aluminum stearate, 0.5-1 part of monoethanolamine, 1-4 parts of gas phase silicon dioxide and 25-30 parts of conductive carbon black. The conductive printing ink is excellent in conductivity, and good in adhesive force, printability and solvent resistance, and is applicable to criteria specified in QB / T 2023-1994; the viscosity is 30 000mPa.s / 25 DEG C; an acid value is 120mgKOH / g; the fineness is less than or equal to 20 micrometers; and the fluidity is 35mm / 25 DEG C.

Owner:苏州凹凸彩印厂

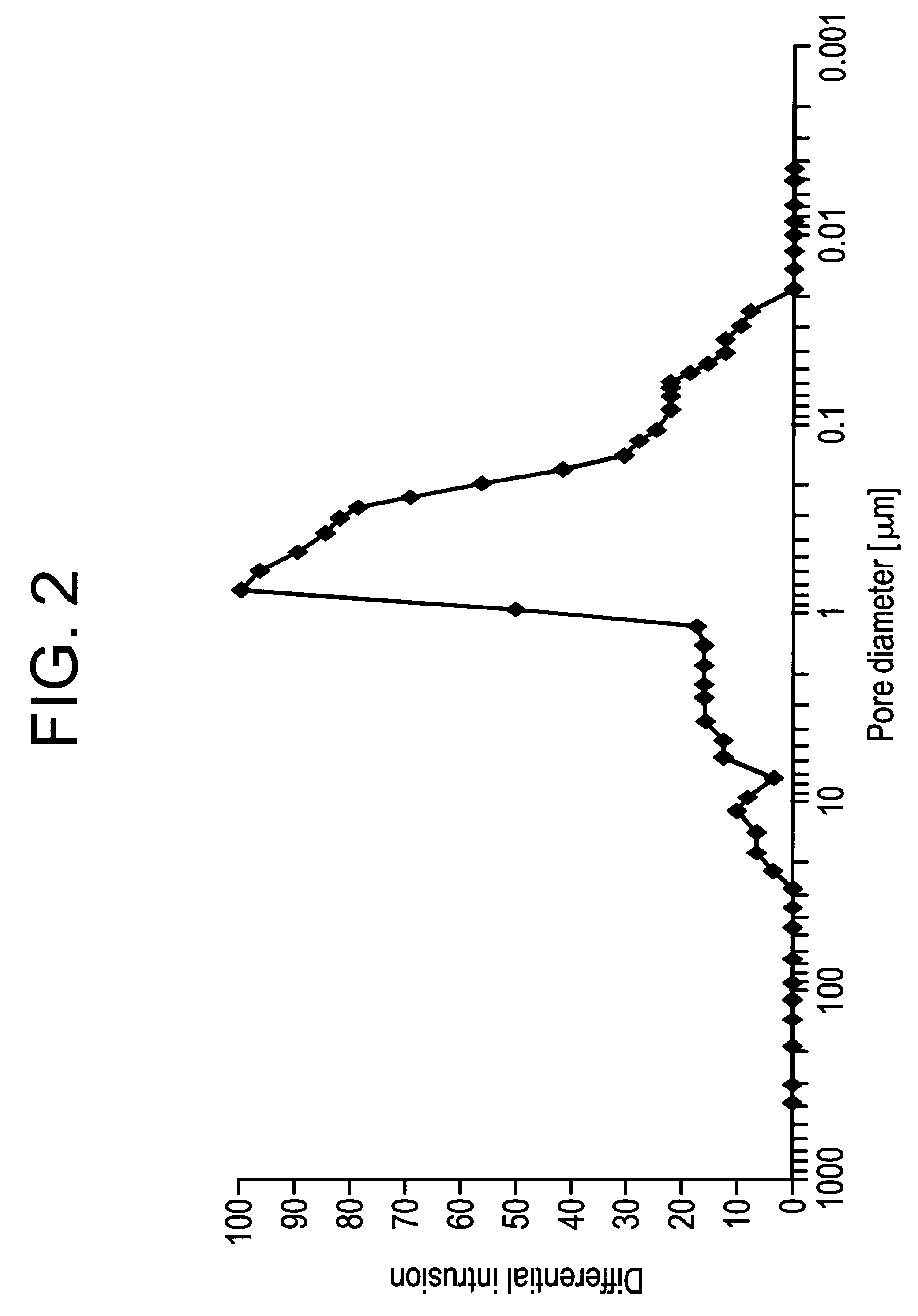

Load catalyst used for preparing vinyl acetate monomer

InactiveCN101722044AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRandom combinationGas phase

The invention provides a load catalyst used for preparing vinyl acetate monomer. Based on thermolysis-prepared mixed oxide with the following physic-chemical parameters, including that outer diameter is 0.8-25mm, BET surface area is 5-400m2 / g, pore volume is 0.2-1.8ml / g, fracture strength is 5-350N, composition is random combination of at least two of SiO2, Al2O3, TiO2 and ZrO2 and weight percent of other components is less than 1wt% besides SiO2 / Al2O3 mixed oxide with the weight percent of SiO2 more than 75wt% in the mixed oxide and bulk density is 250-1500g / L, molding bodies are prepared by the steps: the required thermolysis-prepared mixed oxide and one or multiple compounds selecting from methylcellulose, methyl hydroxyethyl cellulose, wax, polyvinyl alcohol, magnesium stearate and / or aluminium stearate are added with water, homogenized and then dried at the temperature of 70-150 DEG C, smashing at random is carried out to obtain powder, the powder is compacted at random to obtain molding bodies, and heat treatment is carried out at the temperature of 400-1200 DEG C for 0.5-10 hours. The moldings are doped with appropriate active components to prepare vinyl acetate monomer by utilizing gas phase process.

Owner:EVONIK DEGUSSA GMBH

A water-resistant eyelash grower having a lengthening effect

The invention belongs to the technical field of cosmetics, and relates to a water-resistant eyelash grower having a lengthening effect. The eyelash grower comprises following raw materials by weight: 3-5 parts of silk powder, 45-55 parts of petroleum ether, 3-9 parts of stearic acid, 20-30 parts of beeswax, 4-8 parts of palm wax, 2-6 parts of anhydrous lanolin, 0.5-3 parts of triethanolamine, 4-9 parts of natural melanin, 5-10 parts of glycerol, 0.2-2 parts of vitamin E, 0.1-0.3 part of an antiseptic substance and 2-4 parts of aluminium stearate. The eyelash grower is novel in formula, unique in composition, simple in preparation, low in cost and capable of lengthening eyelash by 1-1.5 mm after the eyelash grower is used, has effects of making eyelash fine, long, curved, intensified and natural, can improve an eye look instantaneously, has a good water-resistant effects, is free of smudge, and is a product with high market competitiveness.

Owner:刘幼芝

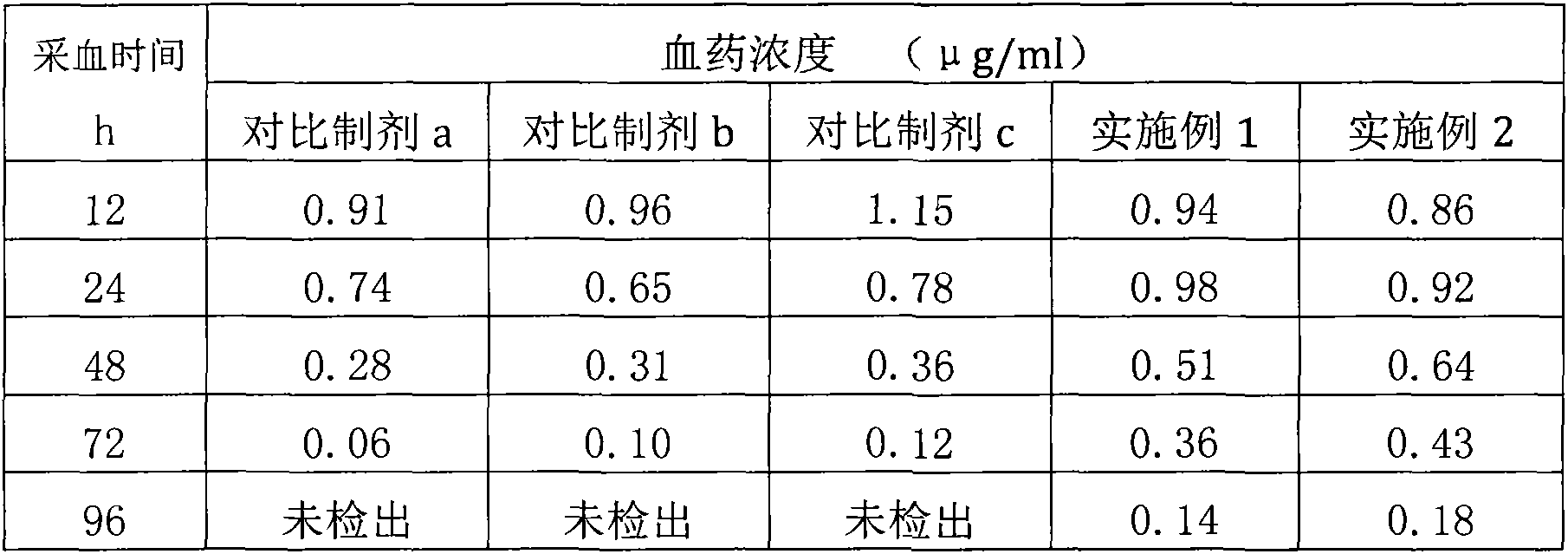

Doxycycline hydrochloride long-acting injection and preparation method

InactiveCN103536530AExpected treatment effectGood compatibilityAntibacterial agentsTetracycline active ingredientsGel preparationSucrose

The invention relates to an application of sustained-release material sucrose acetate iso-butyrate used in in-situ gel preparations to preparation of an oil suspension injection for livestock, and in particular relates to a method used for preparing a doxycycline hydrochloride long-acting injection by combining sucrose acetate iso-butyrate and hydrogenated castor oil or aluminium stearate. A dispersion medium of the preparation is isopropyl myristate, benzyl benzoate, ethyl oleate or a mixture of more than one of isopropyl myristate, benzyl benzoate and ethyl oleate. The preparation has good sustained release effects, stable characters and good tissue compatibility, and is easy to prepare.

Owner:中农华威制药股份有限公司

Preparation method for goose-origin reovirus inactivated vaccine

InactiveCN106540250AInfection Prevention and ControlViral antigen ingredientsAntiviralsReovirus RNAOil phase

The invention provides a preparation method for a goose-origin reovirus inactivated vaccine. The preparation method comprises the following steps that a goose embryo is inoculated against reoviruses through an allantoic cavity, dead embryo allantoic fluids or live embryo allantoic fluids are collected within 24-144 h after incubation, and reovirus fluids are obtained; the reovirus fluids are inactivated through formaldehyde, Tween-80 is added to be mixed to serve as a water phase, and white oil, Span-80 and aluminium stearate are mixed to serve as an oil phase; and the water phase is added into the oil phase to be mixed uniformly, and the inactivated vaccine is obtained. According to the preparation method, the prepared goose-origin reovirus inactivated vaccine has high protective effects on a gosling, and is suitable for virus immunity of the gosling.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Combined Newcastle disease and infectious bronchitis inactivated vaccine and method for preparing same

InactiveCN102716478AOvercome the adverse effects of interferenceSimple production processViral antigen ingredientsAntiviralsInfectious bronchitisAdjuvant

The invention discloses a method for producing a combined oil emulsion vaccine, and specifically relates a method for producing a combined Newcastle disease and infectious bronchitis inactivated vaccine, comprising the following steps of: carrying out homeomorphous inoculation, regulating the concentrations and proportions of Newcastle disease and infectious bronchitis viruses to achieve rational collocation, and regulating the components of an adjuvant in the vaccine so as to avoid aluminium stearate. The vaccine is capable of causing simultaneous production of Newcastle disease and infectious bronchitis antibodies, reducing disturbance, free of aluminium stearate, and capable of keeping high antibody production capability in a long time; and besides, the problems of stress reaction of animals and vaccine residue caused by vaccine injection can be solved.

Owner:PU LIKE BIO ENG

Thixotropic antirust oil composition

InactiveCN106635283AImprove rust resistanceGood anti-sag performanceLubricant compositionButanedioic acidPolyamide

The invention relates to thixotropic antirust oil composition and mainly solves the problem that an antirust oil film flows easily after applied to a vertical face of a part in the prior art. The antirust oil composition is prepared from components in parts by weight as follows: a) 70-92 parts of base oil, b) 6-15 parts of an oil-soluble sulfonate antirust agent, c) 1-10 parts of a thixotropic agent and d) 1-5 parts of an auxiliary, wherein the base oil is selected from at least one of mineral oil or solvent oil; the oil-soluble sulfonate antirust agent is selected from at least one of petroleum sulfonate and synthetic sulfonate; the thixotropic agent is selected from at least one of modified calcium sulfonate, fumed silica, organobentonite, hydrogenated castor oil, modified polydiene, aluminium stearate and polyamide wax; the auxiliary is selected from at least one of pentaerythrityl oleate, Span 80, oleic acid, a triazole derivative, complex ester, alkenyl butanedioic acid, an imidazoline derivative and alkenyl succinate. The technical scheme better solves the problem and can be applied to industrial production of the thixotropic antirust oil composition.

Owner:CHINA PETROLEUM & CHEM CORP

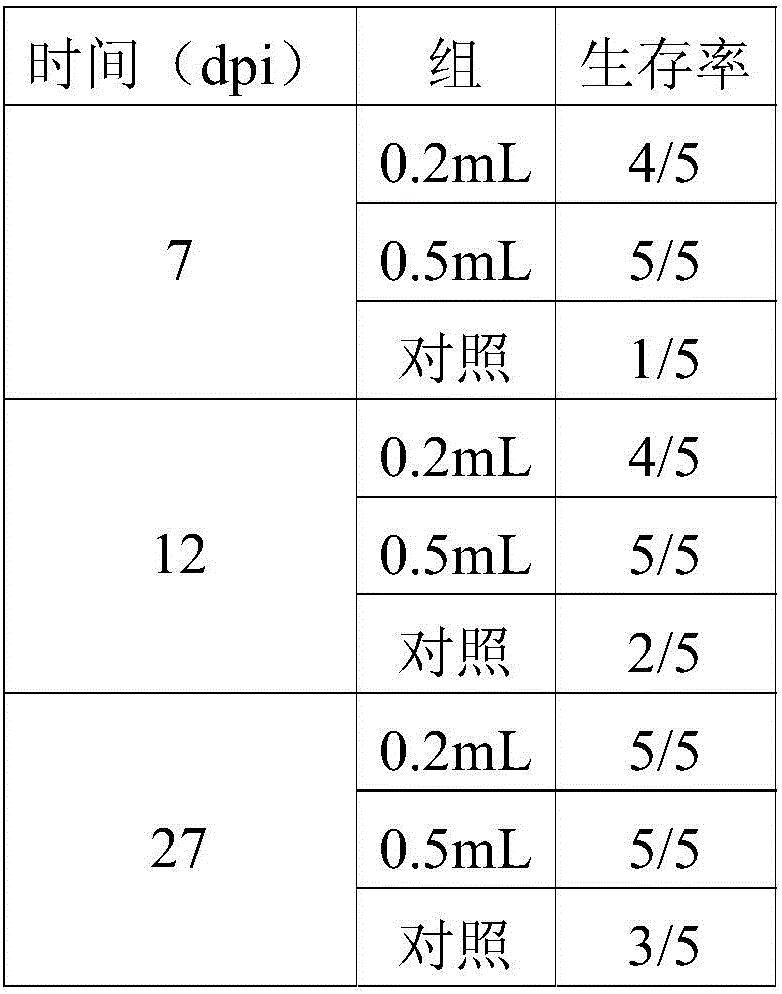

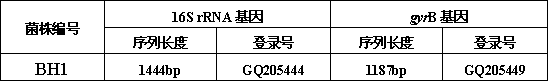

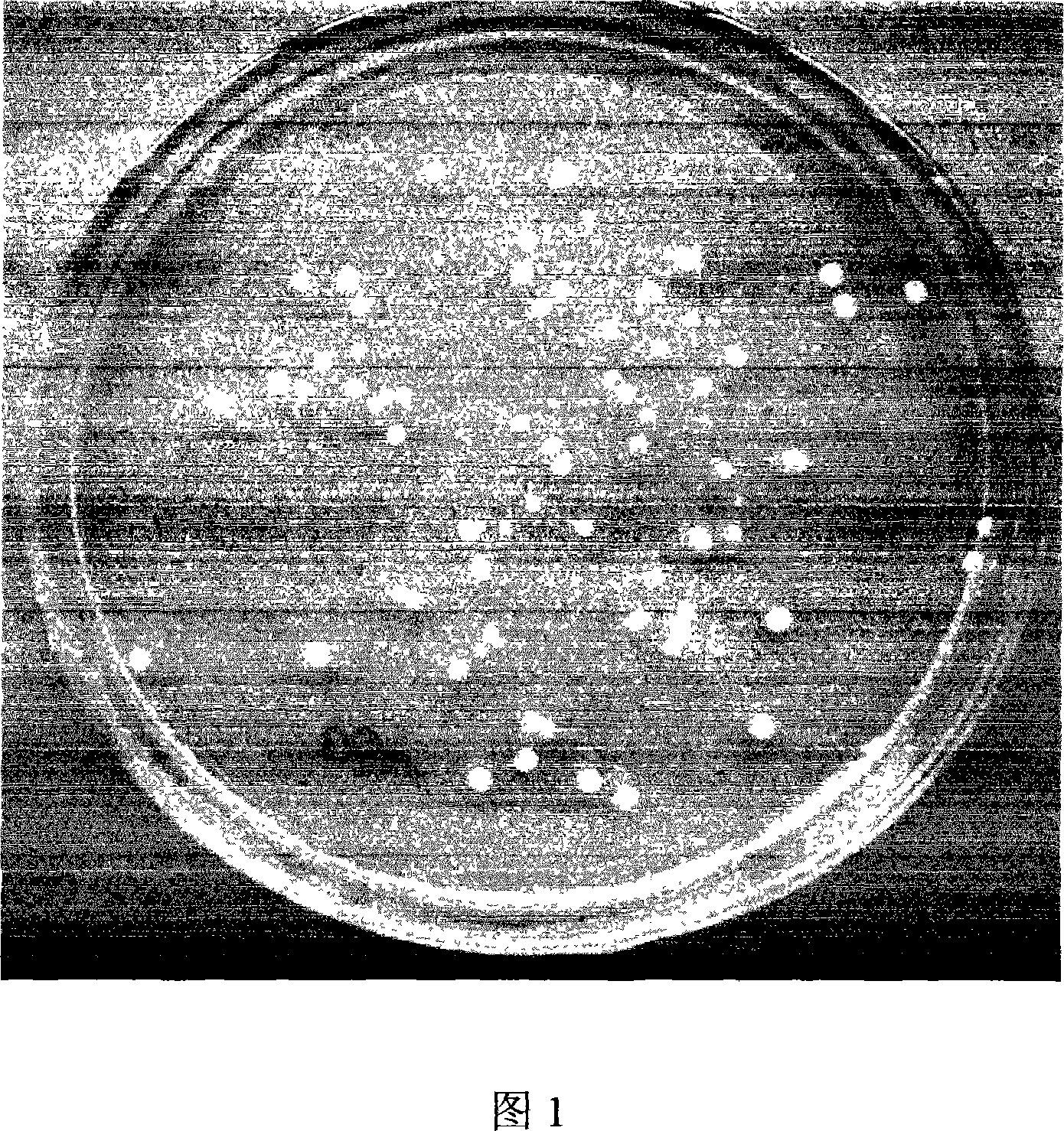

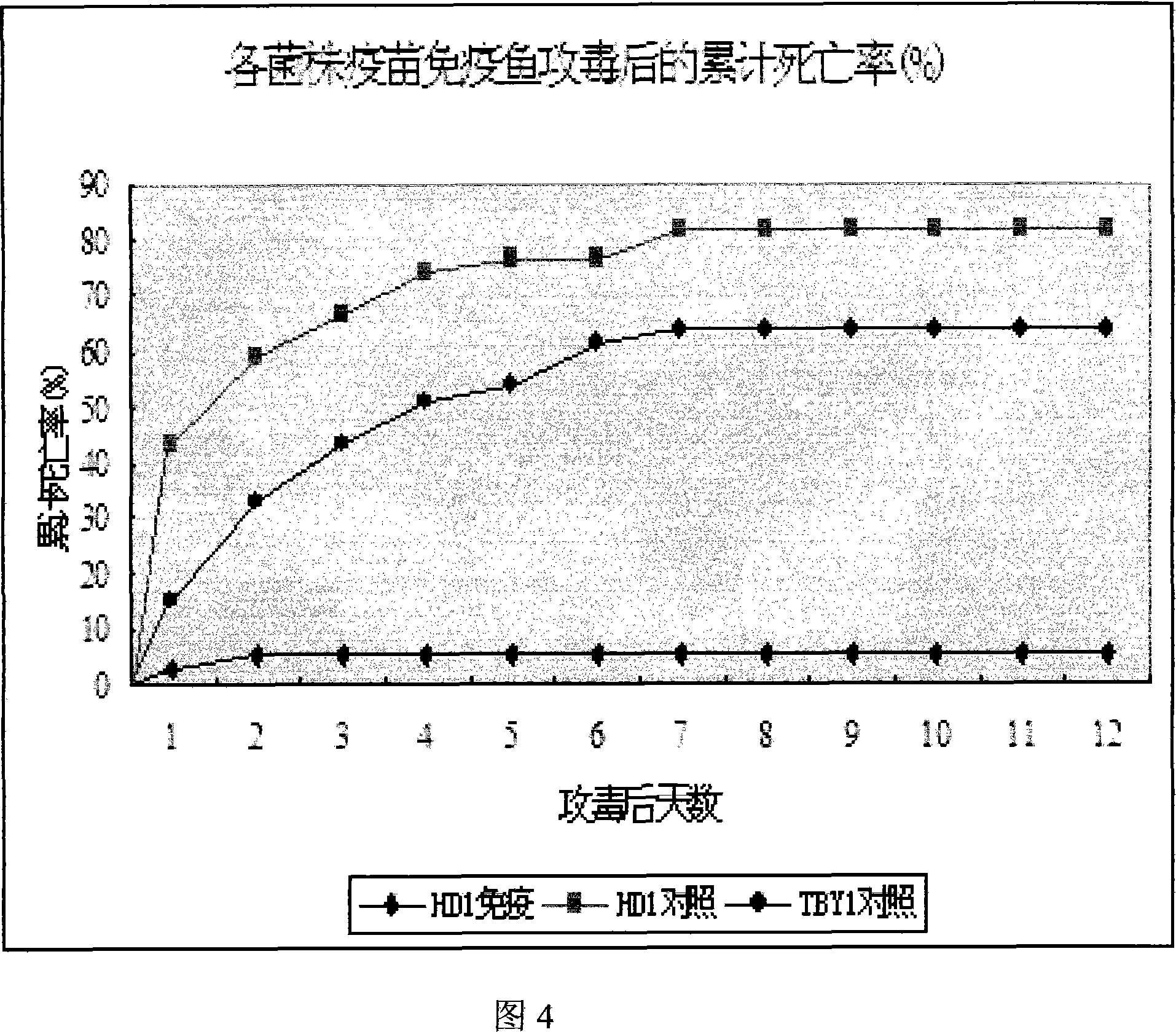

Method for preparing inactivated vaccine of anti-Listonella-anguillarum egg yolk antibody

InactiveCN102836431AImprove immunityImprove survival rateAntibacterial agentsAntibody ingredientsBiotechnologyDisease

The invention relates to a method for preparing inactivated vaccine of anti-Listonella-anguillarum egg yolk antibody. The method comprises the following steps: inactivating and centrifuging etiology Listonella-anguillarum BH1 so as to obtain inactivated thallus; preparing Astragalus mongholicus leachate; preparing oil phase by white oil, aluminium stearate and span-80; preparing vaccine water phase by the inactivated thallus and the Astragalus mongholicus leachat; finally, mixing the oil phase with the water phase according to the volume ratio of 2:1, emulsifying and milling for 5 minutes so as to obtain the Vibrio parahaemolyticus oil emulsion inactivated vaccine in which Astragalus mongholicus and oil white are used as united adjuvant. By adoption of the vaccine, the anti-Listonella-anguillarum egg yolk antibody can be obtained; by adoption of the anti-Listonella-anguillarum egg yolk antibody, the immunity of marine fishes such as cynoglossus semilaevis to etiology Listonella-anguillarum is improved, so that the survival rate is improved, the yield is improved, and the economic benefit of culture production of marine fishes such as cynoglossus semilaevis is improved. The problem that the Listonella-anguillarum caused diseases frequently occur in the culture production of marine fishes such as cynoglossus semilaevis, is solved.

Owner:HUAIHAI INST OF TECH

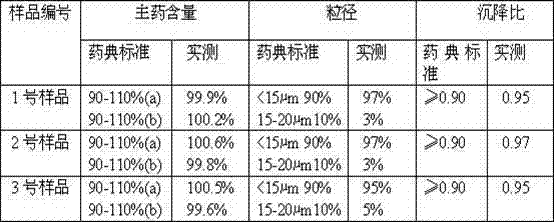

Method for preparing compound amoxicillin and potassium clavulanate injections

ActiveCN102846606AFast absorptionGood curative effectAntibacterial agentsSolution deliveryAmoxicillin-clavulanate potassiumPhysical chemistry

The invention discloses a novel method for preparing compound amoxicillin and potassium clavulanate injections. The novel method includes the steps of heating oil for injection to 130-150 DEG C, insulating, sterilizing and then cooling the oil for injection to the temperature of 60-90 DEG C; adding aluminium stearate into a part of the sterilized oil for injection, stirring, insulating, cooling to the room temperature after the mixture is uniform, filtering, slowly mixing the mixture with amoxicillin and potassium clavulanate mixture with a certain mass ratio while stirring, and stirring so as to disperse the mixture uniformly until the mixture is completely dispersed into suspension; and refining the mixture via a ball mill, replenishing the sterilized oil for injection to reach a full dose, and continuing stirring till uniform so as to obtain the compound amoxicillin and potassium clavulanate injections. Compared with the prior art, the novel method for preparing the compound amoxicillin and potassium clavulanate injections is simple in preparation process, raw materials and auxiliary materials are low in prices and easy to obtain, the prepared injections are stable in performance and obvious in treatment effect, and is high in cost performance as compared with a like product, the quality of the prepared injections is higher than the quality specified in relative standards of the current pharmacopoeia, and the prepared injections are suitable to be industrially produced in batches.

Owner:SHANGHAI TONGREN PHARM CO LTD

Dolphin streptococcal white-oil adjuvant inactivated vaccine and preparing method

InactiveCN101024080AGood control effectMeet the needs of actual productionAntibacterial agentsBacterial antigen ingredientsAlum adjuvantAdjuvant

The present invention relates to a dolphin streptococcus white oil adjuvant inactivated vaccine and its preparation method. Said preparation method includes the following steps: (1), separating out dolphin streptococcus from sea-water cultivated or fresh-water cultivated diseased dolphin; (2), making the above-mentioned obtained dolphin streptococcus undergo the processes of expansive cultivation, inactivation and concentration so as to obtain the concentrated inactivated streptomoccus liquor; (3), mixing 96% of the inactivated concentrated streptococcus liquor and 4% of steril Tween-80 and shaking to make Tween-80 be completely dissolved, and using their mixture as aqueous phase; mixing 94% of No.10 white oil and 6% of Span-80, adding 2% of aluminium stearate into the above-mentioned mixture solution and using said mixture solution as stabilizing agent, uniformly mixing and stirring them, heating to obtain a transparent material, making said transparent material undergo the process of high-pressure sterilization treatment and using it as oily phase; according to the ratio of aqueous phase: oily phase=3:7 high-speed stirring and emulsifying so as to obtain the invented product. Said vaccine can obtain good effect for preventing and curing dolphin streptococcicosis.

Owner:SUN YAT SEN UNIV

Quick-drying type oil paint formula and preparation method thereof

InactiveCN107523114AColor stableIngredients dry quicklyArtist's paintsEpoxy resin coatingsBenzoic acidEpoxy

The invention discloses a quick-drying type oil paint formula and a preparation method thereof. The quick-drying type oil paint formula comprises pigment, styrene-acrylate emulsion, quartz sand, polyamide, organic titanium, epoxide resin, marble powder, polystyrene glycol, benzoic acid, organic silicon, cellulose phthalate, polyurethane, tetrafluoroethylene oil, styrene, polyacrylate and aluminium stearate. Compared with the prior art, the quick-drying type oil paint formula is synthetized by various chemical materials through a specific synthesis process; in the drawing, the color is stable; the ingredient drying is quick; the drawing efficiency is improved; meanwhile, the fading cannot easily occur; popularization and application values are realized.

Owner:XINXIANG UNIV

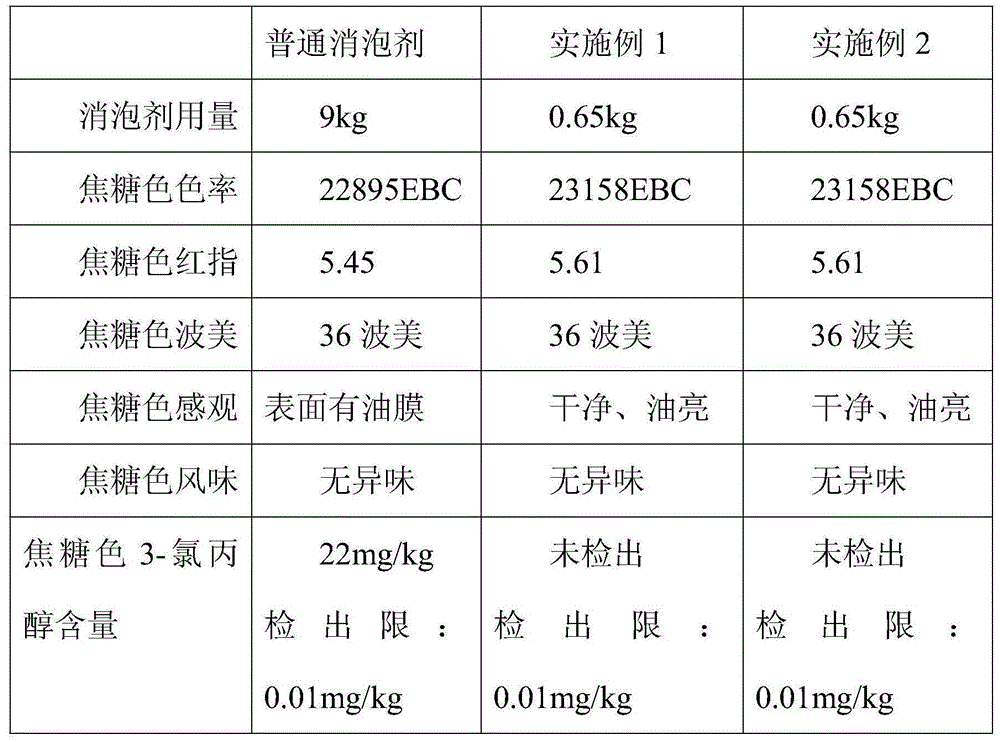

Defoaming agent for products having caramel color, and preparation method and application of defoaming agent for products having caramel color

ActiveCN105148572AReduce usageGood defoaming effectNatural dyesFoam dispersion/preventionAluminium stearateCaramel color

The invention relates to a defoaming agent for products having the caramel color, and a preparation method and application of the defoaming agent for the products having the caramel color. The defoaming agent comprises the following raw materials in percentage by weight: 9% of polyoxy oxosilane, 2% of aluminium stearate, 1% of sodium carboxymethylcellulose, 2% of sodium tripolyphosphate, 1.5% of disodium EDTA, 12% of Tween 60, and 72.5% of deionized water. The defoaming agent disclosed by the invention has the advantages of being good in defoaming effect, small in use amount, safe and capable of not influencing the appearance quality of the products having the caramel color.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Biodegradable agricultural plastic mulching film with insect damage preventing effect

InactiveCN106117625AAdd surface groupsImprove water retentionPlant protective coveringsEpoxySophocarpidine

The invention discloses a biodegradable agricultural plastic mulching film with the insect damage preventing effect. The biodegradable agricultural plastic mulching film is prepared from, by weight, 64-70 parts of dry-basis corn starch, 23-26 parts of ethyl alcohol, 11-15 parts of monochloro acetic acid, 14-16 parts of silicon dioxide, 0.08-0.1 part of epoxy chloropropane, 60-80 parts of dimethylformamide, 3-4 parts of aluminium stearate, 2-3 parts of carboxymethylcellulose, 2-3 parts of borax, 1-2 parts of tannic acid, 3-4 parts of mannitol, 3-4 parts of paraffinic oil, 6-8 parts of sophocarpidine, a proper amount of ethanol solution of 85% and a proper amount of deionized water. The biodegradable agricultural plastic mulching film is simple in material formula and low in raw material cost, and under the conditions that the cost is saved, and labor force is reduced, the crop growth promoting effect is achieved, insect damage is prevented, production increasing is promoted, full degradation is nontoxic and harmless for soil, and the biodegradable agricultural plastic mulching film is worthy of popularization.

Owner:ANHUI SHENGNONG AGRI GRP

Multicolor sodium carboxymethylcellulose paint

ActiveCN104073065AGood dispersionImprove the decorative effectRubber derivative coatingsMulticolor effect coatingsCyclohexanonePolyethylene glycol

The invention relates to a multicolor sodium carboxymethylcellulose paint which is prepared from the following raw materials in parts by weight: 100 parts of sodium carboxymethylcellulose, 10 to 20 parts of cyclohexanone, 20 to 30 parts of calcium carbonate, 40 to 50 parts of talcum powder, 10 to 30 parts of polyethylene glycol, 15 to 25 parts of aluminium stearate, 80 to 90 parts of deionized water, 25 to 35 parts of epoxidized soybean oil, 10 to 20 parts of pigment, 25 to 35 parts of castor oil, 5 to 25 parts of ammonium hydroxide, 10 to 30 parts of rosin water, 4 to 10 parts of plasticizer, 35 to 45 parts of paraffin, 30 to 40 parts of naphthalene sulfonic acid sodium salt and 45 to 55 parts of chlorinated rubber. The paint has the good dispersibility; a painting film is resistant to scrubbing, namely the painting film cannot be threadbare even after being scrubbed for 11500 to 12500 times; the solid content of the paint is between 30% and 40%; the painting film cannot be blistered and desquamated after being soaked in water at 20 DEG C for 8 to 10 weeks; the surface of the paint is dried within 20 to 30 minutes; the loss of the paint is within 0.004g / cm<2> to 0.006g / cm<2> after being tested by a reciprocating-type tester for 1000 times; and the painting film is bright in color and good in decorative effect. Thus, the paint can be widely produced and continuously used for replacing the existing material.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

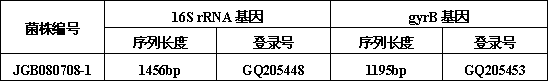

Inactivated vaccine preparation method for egg yolk antibody for resisting litopenaeus vannamei red body disease

InactiveCN102836428AImprove immunityImprove survival rateAntibacterial agentsAntibody ingredientsAdjuvantVibrio parahemolyticus

The invention provides an inactivated vaccine preparation method for an egg yolk antibody for resisting a litopenaeus vannamei red body disease. The inactivated vaccine preparation method comprises the steps of inactivating etiology vibrio parahaemolyticus JGB080708-1 bacterial strains and centrifuging to obtain inactivation thalli; preparing astragalus mongholicus lixiviums; preparing an oil phase by using white oil, aluminium stearate and span-80 and mixing the inactivation thalli and the astragalus mongholicus lixiviums to prepare a vaccine aqueous phase; and mixing the oil phase and the aqueous phase according to a volume ratio of 2:1 for emulsification and grinding for 5min to prepare vibrio parahaemolyticus oil emu inactivated vaccines with the astragalus mongholicus and the white oil serving as a unite adjuvant. The vibrio parahaemolyticus oil emulsion inactivated vaccines can be used for immunization of adult laying hens, the high egg yolk antibody for resisting the litopenaeus vannamei red body disease is further obtained, the immunity of litopenaeus vannamei etiology vibrio parahaemolyticus is strengthened, the rate of survival of litopenaeus vannamei culture is improved, the yield of the litopenaeus vannamei culture is increased, and economic benefits of litopenaeus vannamei culture and production are improved. A problem of incidental vibrio parahaemolyticus caused diseases in the litopenaeus vannamei culture and production process at present is fundamentally solved.

Owner:HUAIHAI INST OF TECH

Anti-ageing nano-modification outer wall emulsion paint and preparation method thereof

InactiveCN108641521AStrong UVStrong characteristicEmulsion paintsEpoxy resin coatingsEpoxyThermal ageing

The invention discloses anti-ageing nano-modification outer wall emulsion paint and a preparation method thereof. The outer wall emulsion paint is prepared from the following components in parts by weight, 30-50 parts of nanometer silica-modification acrylic resin, 7-9 parts of titanium dioxide, 6-8 parts of silica fume, 10-18 parts of titanium dioxide, 1-3 parts of aluminium stearate, 1-3 parts of polydimethylsiloxane, 4-8 parts of emulgator, 0.5-1 part of flatting agent, 14-18 parts of epoxy resin emulsion, 1-2 parts of anti-ultraviolet agent and 3-5 parts of hydroxypropyl methyl cellulose.According to the anti-ageing nano-modification outer wall emulsion paint and the preparation method thereof, nanometer silica is adopted for modifying acrylic resin, the nanometer silica can be used for forming a three-dimensional net-shape structure, and the net-shape structure can be formed when the paint is dried, so that the stability of the anti-ultraviolet agent and a pigment system is maintained, the ageing effect of ultraviolet light on dye is reduced, the color of the paint can remain unchanged over the long term, moreover, the nanometer silica has very high ultraviolet and infrared reflection property, a shielding effect of the paint is formed when the nanometer silica is added into the paint, and thus the purposes of ultraviolet ageing resistance and thermal ageing resistance are achieved.

Owner:CHONGQING UNIV OF ARTS & SCI +1

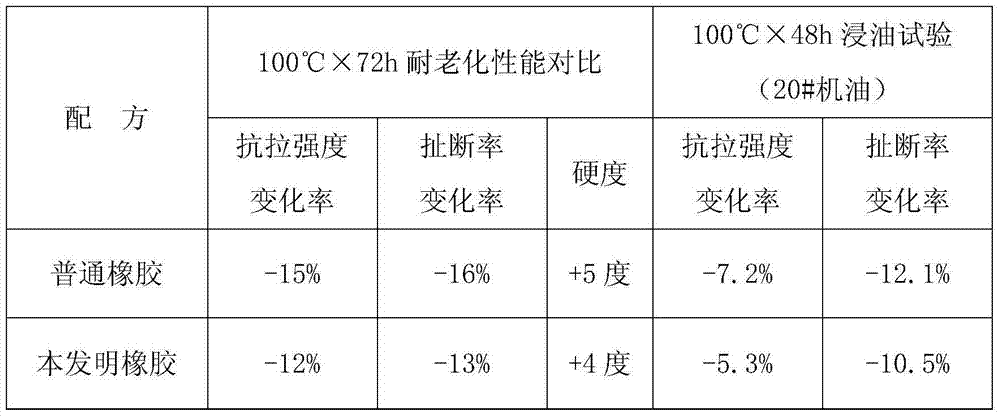

High-strength fluorine rubber gasket material and preparation method thereof

The invention discloses a high-strength fluorine rubber gasket material. The high-strength fluorine rubber gasket material is characterized by being prepared from the following raw materials in parts by weight: 75-80 parts of fluororubber, 20-24 parts of carbon black, 2-3 parts of 2.5-dimethyl-2.5 bi(tertiary butyl peroxyl) hexane, 4-5 parts of triallyl isocyanurate, 10-12 parts of diisobutyl phthalate, 2-3 parts of aluminium stearate, 1-2 parts of sulphur, 2-3 parts of zinc oxide, 3-4 parts of vaseline, 14-18 parts of butyl rubber (BBK232), 3-5 parts of glycerinum triacetate, 20-25 parts of bauxite powder, 10-15 parts of carbon black N339, 1-2 parts of a titanate coupling agent TMC-TTS, 0.8-1.2 parts of an accelerant Na-22, and 10-12 parts of modified attapulgite. The modified attapulgite is added in the high-strength fluorine rubber gasket material, so that the processing property of a sizing material is improved. The high-strength fluorine rubber gasket material has the advantages of high strength, good oil resistance, pressure resistance and sealing performance, simple process and low cost.

Owner:马鞍山市中澜橡塑制品有限公司

Methylcellulose multicolor coating

ActiveCN104073067AVariety of coating colorsLight and softPolyurea/polyurethane coatingsMulticolor effect coatingsCyclohexanoneLoss rate

The invention discloses a methylcellulose multicolor coating. The methylcellulose multicolor coating is prepared from the following raw materials in parts by weight: 100 parts of methylcellulose, 5-15 parts of zinc oxide, 10-20 parts of sodium pentachlorophenate, 30-40 parts of dimethylbenzene, 15-25 parts of montmorillonite, 25-35 parts of talcum powder, 70-90 parts of deionized water, 10-30 parts of cyclohexanone, 10-20 parts of pigment, 15-35 parts of trimethylolpropane, 20-30 parts of sodium orthophosphate, 5-25 parts of toluene diisocynate, 4-10 parts of plasticizer, 35-45 parts of aluminium stearate, 20-40 parts of polyving akohol and 25-45 parts of epoxidized soybean oil; the coating is multicolor and soft in gloss; the base of the coating is not exposed after the coating is scrubbed for 11,000-13,000 times; the content of solid accounts for 25-35%; when the coating is soaked in water at the temperature of 20 DEG C for 60-80 days, no bubble is formed and no powder is dropped; the surface is dried for 15-25 minutes and the solid is dried for 6-8 hours; and the loss rate of the coating in a coating reciprocating tester reaches 0.004-0.006g / cm<2> after running for 1000 times, so that the coating can be widely produced and used for continuously replacing the existing material.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Lubricant with good lubricating effect

InactiveCN108384628AImproved high coefficient of frictionEvenly dispersedLubricant compositionWater basedPolyethylene glycol

The invention discloses a lubricant with a good lubricating effect. The lubricant with the good lubricating effect is prepared from the following raw materials in percentages by weight: 35% of talcumpowder, 0.8% of sodium carboxymethylcellulose, 0.6% of kieselguhr, 8% of sodium pyrophosphate, 3% of aluminium stearate, 11% of borax, 10% of polyethylene glycol, 0.9% of glycerol monostearate and thebalance of water. The problem that the friction coefficient of a graphite-free lubricant is high is solved, and the environmentally friendly water-based clay lubricant which is dispersed uniformly, is sprayed easily, resists high temperature, and is good in lubricating effect, easy to clean and pollution-free is provided for hot-rolled seamless steel tubes.

Owner:黄继生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com