Thixotropic antirust oil composition

A technology of antirust oil and composition, applied in the field of thixotropic antirust oil composition, can solve the problem of easy flow of thixotropic antirust oil film and the like

Inactive Publication Date: 2017-05-10

CHINA PETROLEUM & CHEM CORP

View PDF10 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, in the prior art, the thixotropic antirust oil film is easy to flow when painted on the facade of parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

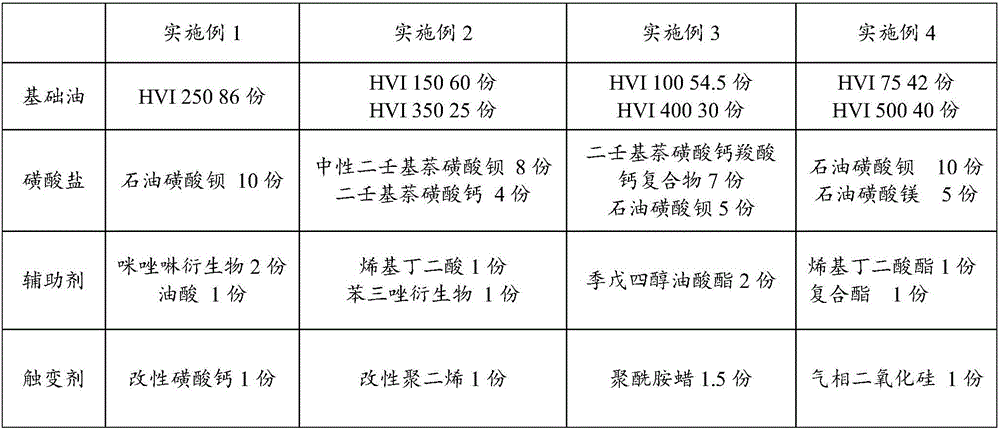

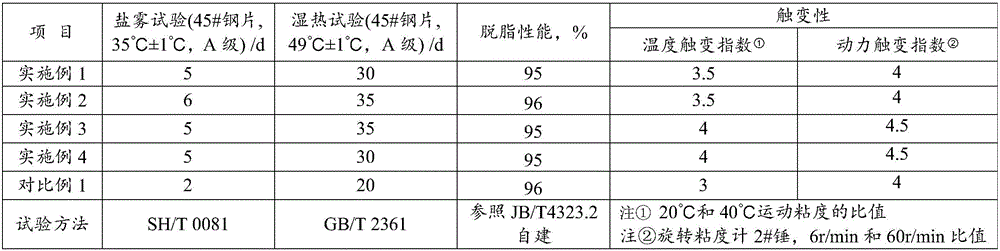

Embodiment 1~6

[0024] According to the parts by weight in Table 1, add the base oil into the blending kettle, heat and stir at 50-60°C, then add oil-soluble sulfonate antirust agent, auxiliary agent and thixotropic agent in sequence, and stir at 40-50°C for 3 After ~4 hours, filter through a 10um bag to obtain the thixotropic antirust oil composition.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to thixotropic antirust oil composition and mainly solves the problem that an antirust oil film flows easily after applied to a vertical face of a part in the prior art. The antirust oil composition is prepared from components in parts by weight as follows: a) 70-92 parts of base oil, b) 6-15 parts of an oil-soluble sulfonate antirust agent, c) 1-10 parts of a thixotropic agent and d) 1-5 parts of an auxiliary, wherein the base oil is selected from at least one of mineral oil or solvent oil; the oil-soluble sulfonate antirust agent is selected from at least one of petroleum sulfonate and synthetic sulfonate; the thixotropic agent is selected from at least one of modified calcium sulfonate, fumed silica, organobentonite, hydrogenated castor oil, modified polydiene, aluminium stearate and polyamide wax; the auxiliary is selected from at least one of pentaerythrityl oleate, Span 80, oleic acid, a triazole derivative, complex ester, alkenyl butanedioic acid, an imidazoline derivative and alkenyl succinate. The technical scheme better solves the problem and can be applied to industrial production of the thixotropic antirust oil composition.

Description

technical field [0001] The invention relates to a thixotropic antirust oil composition. Background technique [0002] Lubricating oil type anti-rust oil is a kind of anti-rust oil widely used in my country's iron and steel, machine tool and other related industries. Its advantages are easy to use, thick oil film with certain lubricity, non-volatile, and high flash point The safety performance is good, but the disadvantage is that when the workpiece facade is painted, it is easy to flow and drip to the ground, which not only causes waste of oil products, affects the anti-rust performance, but also causes pollution to the factory environment. When a certain amount of thixotropic agent is added to the lubricating oil type anti-rust oil to make it have a certain thixotropy, it can basically overcome the shortcoming that the lubricating oil type anti-rust oil is easy to flow, and a stable oil film can also be formed on the facade , reduce flow loss, can relatively improve anti-ru...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N30/12C10N30/04

CPCC10M169/04C10M169/044C10M2201/10C10M2205/06C10M2207/126C10M2207/127C10M2207/282C10M2207/283C10M2215/223C10M2215/224C10M2217/044C10M2219/044C10N2030/04C10N2030/12C10N2010/04

Inventor 邓象贤张志东黄劲松张明李谨王靖宇

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com