Patents

Literature

52 results about "Ethylhexyl stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylhexyl stearate is an emollient derived from plant oil that prevents water loss. * Also known as Octyl Stearate. Contents. Uses. Benefits. Cautions. Interactions.

Precise investment casting technology

ActiveCN105057594AHigh strengthHigh dimensional accuracyFoundry mouldsFoundry coresElastomerMicrocrystalline wax

The invention provides a precise investment casting technology. In the wax laminating process, polyethylene wax and SEBS elastomers are inserted into paraffin, microcrystalline wax and ethylhexyl stearate in a penetrating manner, a grid-interpenetration structure is formed, and the strength of the structure is improved; polyamide wax swells under the effect of xylene to generate paste thixotropic agents; and a net-shaped structure is formed, the good strength and the good heat resistance are achieved, the storage stability is good, and the quite good anti-settling effect is achieved in the coating system. As for coatings adopted in the precise investment casting technology, polyvinyl alcohol and hydroxymethyl cellulose serve as auxiliary binding agents, silica sol serves as a main binding agent, and fused alumina, cubic boron nitride and titanium nitride serve as main fireproof materials, so that a manufactured shell is good in heat resistance and high in strength. In this way, an alloy steel investment cast product manufactured with the precise investment casting technology is high in size accuracy, fewer in casting crack and reliable in quality, and a casting obtained through casting with the technology is smooth in surface and high in quality.

Owner:NINGBO TIANYE PRECISION CASTING

Cleansing oil and preparation method thereof

ActiveCN108014031AGood emulsificationRemoves makeup wellCosmetic preparationsMake-upPlant SourcesRice Bran Extract

The invention discloses cleansing oil. The cleansing oil is prepared from the following components in percentage by weight: 11 to 31 percent of plant-sourced light oil, 30 to 60 percent of ethylhexylpalmitate / ethylhexyl stearate, 10 to 25 percent of isopropyl myristate, 3 to 10 percent of isohexadecane, 0.01 to 3 percent of water and 8 to 30 percent of polyglycerol emulsifier. By adopting the plant-sourced light oil, in particular to plant-extracted rice bran oil and sun-flower oil, the cleansing oil has a smooth touch feel and brings a fresh feel to a human after the cleansing oil is used; by adopting the polyglycerol emulsifier, optimizing the compound and reasonably adding an amount of the isohexadecane with polarity, the cleansing oil also has a more ideal cleansing effect when a handis wet and makeup is wet; moreover, an emulsification effect of the cleansing oil is excellent, and a makeup removal effect is good.

Owner:HUAANTANG BIOTECH GRP CO LTD

Antibacterial aerated brick

The invention discloses an antibacterial aerated brick, comprising the following materials in parts by weight: 20-25 parts of antibacterial kaolin, 4-6 parts of cement, 5-7 parts of river sand, 1-2 parts of glass fiber, 0.3-0.6 part of magnesium stearate, 0.1-0.2 part of aluminium stearate, 0.1-0.2 part of barium stearate, 1-2 parts of aluminum metasilicic acid, 1-2 parts of polypropylene fiber, 0.005-0.008 part of polyoxyethylene, 0.2-0.4 part of lauryl sodium sulfate, 0.05-0.08 part of epoxy butyl oleate, and 0.1-0.2 part of epoxy ethylhexyl stearate. According to the antibacterial aerated brick, antibacterial extracts are prepared by using the traditional Chinese medicine ingredients, are natural, healthy, free of pollution and good in effects, and is added to the materials of the aerated brick, so that the properties such as the strength of the aerated brick are kept when an antibacterial effect is achieved.

Owner:潘逸东

Compound enhanced wood-plastic composite plate and preparation method thereof

InactiveCN102732045AEasy to produceThe production is convenient, and the traditional wood-plastic composite material production process is convenientAntioxidantMechanical property

The invention discloses a compound enhanced wood-plastic composite plate and a preparation method thereof. The preparation method comprises the following steps of: diluting vinyltriethoxysilane with tap water; putting wood flour into the above water solution, evenly shaking, and ultrasonically processing with ultrasonic waves to obtain enhanced wood flour; stirring, extruding and pelleting the enhanced wood flour, plastic particles, plastic particles grafted by maleic anhydride, potassium titanate whisker, chopped glass fiber powder and oxidic polyethylene to obtain composite particles; and evenly stirring the composite particles, ethylhexyl stearate, terpene resin and an antioxidant again and then melting, blending and extruding via an extruder to obtain the wood-plastic composite plate. In the invention, the production process is convenient and the production cost is low. The compound enhanced wood-plastic composite plate has the advantages of small dosage of plastic, environmental protection, good ageing resistance and deformation resistance and good buckling deformation resistance; and compared with other wood-plastic composite plates, the mechanical properties such as the static bending intensity, the impact strength and the like are more excellent, the service life is longer, and the application range is wider. The compound enhanced wood-plastic composite plate cannot only be used for making floors, but also can be hung up.

Owner:江苏森诺塑胶科技有限公司

Low-temperature-resistant modified asphalt and preparation method thereof

InactiveCN105419356AGood low temperatureStrong penetrating powerBuilding insulationsNeedle penetrationChlorinated polyethylene

The invention discloses low-temperature-resistant modified asphalt. The low-temperature-resistant modified asphalt is prepared from, by mass, 100 parts of matrix asphalt, 15-30 parts of SBS, 11-16 parts of bentonite, 8-12 parts of epoxy ethylhexyl stearate, 4-6 parts of chlorinated polyethylene, 1-3 parts of ethylene-vinyl acetate copolymer, 1-5 parts of aromatic hydrocarbon oil and 2-5 parts of stabilizer. The low-temperature-resistant modified asphalt has good low temperature resistance, good needle penetration and ductility are still achieved under the low temperature condition, the critical cracking temperature is low, the low-temperature-resistant modified asphalt is applicable to the cold environment in Northern China, the preparation method is simple and easy to implement, and large-scale production can be conducted.

Owner:NINGBO BINHAI PETROCHEM CO LTD

Capacitor thin film containing modified nano clay and preparation method thereof

InactiveCN103102575AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethylenePolyester

The invention discloses a capacitor thin film containing modified nano clay and a preparation method thereof. The capacitor thin film comprises the following raw materials in parts by weight: 50-55 of metallocene linear low-density polyethylene resin, 25-30 of metallocene polypropylene resin, 10-15 of homo-polypropylene, 3-5 of epoxy linseed oil, 2-3 of polyvinyl alcohol, 1-2 of aluminum hydroxide, 1-2 of polyisobutylene, 8-12 of diatomite, 1-2 of ferrocene, 0.7-1.3 of poly-4-methyl-1-amylene, 8-12 of modified nano clay, 0.9-1.1 of antioxidant 1035, 0.6-0.8 of phthalic acid polyester, 1-2 of epoxidation ethylhexyl stearate, 4-6 of calcium stearate, and 1.7-2.0 of modified trees ash. The preparation method disclosed by the invention is simple; and simultaneously, the diatomite, the modified nano clay and the modified trees ash are added to the raw materials so that the barrier property and air tightness of the thin film are improved, and the thin film has good resistance to pressure and impact resistance and simultaneously has the characteristics of high heat-seal strength and good heat sealing property.

Owner:TONGLING YIHENGDA ELECTRONICS

White and bright face cream and preparation method thereof

ActiveCN107233236AFine and smooth textureBlock generationCosmetic preparationsToilet preparationsCetearyl glucosideDimethyl siloxane

The invention belongs to the technical field of the cosmetics, and particularly relates to white and bright face cream and a preparation method thereof. The provided white and bright face cream comprises ethylhexyl methoxycinnamate, carboxyl ethylhexyl stearate, PPG-15 stearyl ether, octyl methyl-silicone, isononyl isononanoate, C12-15 alcohol benzoate, hydroxyethylurea, propylene glycol, titanium dioxide, polydimethylsiloxane, glyceryl stearate / PEG-100 stearate, cetostearyl alcohol / cetearyl glucoside, butyl methoxy dibenzoylmethane, tocopheryl acetate, 4-butyl resorcinol, peony whitening essence, an apple seed extract, arbutin, an thyme extract, sodium hydrogen sulfite, polyhydroxystearic acid, triethyl citrate, xanthan gum, EDTA disodium and water and so on. The provided white and bright face cream is natural and safe, is easy to absorb, and has the good permeability and good effects of moisturizing, whitening and nourishing skin.

Owner:广州科玛生物科技股份有限公司

Modified nitrile rubber sheathing material for cable for oil well

InactiveCN104788758AGood dispersionGood compatibilityInsulated cablesInsulated conductorsPyrophosphateButadiene-styrene rubber

The invention discloses a modified nitrile rubber sheathing material for a cable for an oil well. The modified nitrile rubber sheathing material comprises raw materials in parts by weight as follows: 32-35 parts of nitrile rubber, 25-28 parts of a modified montmorillonite compound nylon / polypropylene composite material, 10-13 parts of butadiene styrene rubber, 7-10 parts of a polyurethane elastomer, 13-16 parts of inorganic filler, 1-1.3 parts of sulphur powder, 2-4 parts of an accelerator DM, 0.5-0.8 parts of an antioxidant 168, 0.3-0.6 parts of an antioxidant 1010, 1.1-1.4 parts of a DCHP (plasticizer dicyclohexyl phthalate), 1-3 parts of a mono-alkoxy pyrophosphate type titanate coupling agent and 4-7 parts of epoxy ethylhexyl stearate. The modified nitrile rubber sheathing material has excellent oil-resistant and flame-retardant performance, good mechanical performance such as tensile strength, stress at definite elongation, tearing resistance, extrusion and rolling and the like as well as good storage stability.

Owner:ANHUI WUZHOU SPECIAL CABLE GRP

Sound absorbing and noise lowering interior decoration PVC modified material and preparation method thereof

InactiveCN105255051AImprove mechanical propertiesGood weather resistanceNonylphenol ethoxylateCITRATE ESTER

The invention discloses a sound absorbing and noise lowering interior decoration PVC modified material. The sound absorbing and noise lowering interior decoration PVC modified material is prepared from, by weight, 80-100 parts of PVC resin, 6-8 parts of fly ash, 1-2 parts of hollow glass beads, 2-3 parts of calcium and zinc stabilizers, 5-10 parts of epoxidized soybean oil, 0.1-0.2 part of nonylphenol ethoxylates, 20-30 parts of acetyl tri-butyl citrate, 0.5-1 part of magnesium stearate, 2-4 parts of epoxy ethylhexyl stearate and 5-10 parts of modification aids. The interior decoration PVC modified material has good mechanical performance and moisture absorbing and adjusting performance, the comfort degree of the indoor environment can be effectively improved, the sound absorbing and noise lowering function are achieved, noise can be effectively relieved, the indoor environment is optimized, and high additional value and practical value are achieved.

Owner:WUHU EDISON AUTOMATION EQUIP

Heat-resistant rubber capacitor case packaging material

The invention discloses a heat-resistant rubber capacitor case packaging material. The heat-resistant rubber capacitor case packaging material consists of the raw materials including chloroprene rubber CR121, a SG-4 polyvinyl chloride (PVC) resin, poly-4-methyl-1-amylene, N, N'-m-phenylenedimaleimide, alumina powder, barium sulfate powder, an anti-aging agent RD, 2-mercaptobenzimidazole, zinc stearate, an accelerator CZ1-2, an accelerator DM, 3-aminopropyl trimethoxy silane, an aluminate coupling agent DL-411, an oxidant, highly-wear-resistant carbon black N330, carbon black N220, imarcaptoacetate dioctyltin, epoxy ethylhexyl stearate, glycerin triacetate, sodium bicarbonate, modified coal ash and dicyclopentadienyl iron. By virtue of a reasonable formula of the raw materials, the produced rubber material has good comprehensive performance and is high in metal adhesion, mechanical property, fatigue resistance, ageing resistance and the like, and can provide high-strength protection for capacitors.

Owner:TONGXIANG GUANGSHENG PLASTIC IND CO LTD

Flame-retardant plastic packing and preparation method thereof

The invention discloses a flame-retardant plastic packing, which is prepared from the following raw materials in parts by weight: 3-5 parts of superfine porous silicon dioxide, 2-3 parts of nanoscale antimony trioxide, 1-2 parts of epoxy octyl stearate, 0.4-0.6 part of ethylene glycol monostearate, 0.2-0.3 part of avocado oil, 0.3-0.4 part of tragacanth gum, 2-3 parts of nano-iron slag, 200-220 parts of lightweight calcium carbonate, 5-9 parts of auxiliaries and 20-30 parts of water. Nanoscale antimony trioxide is added in the filler, so that the flame-retardant property of plastics can be improved; calcium carbonate is modified by using epoxy ethylhexyl stearate, ethylene glycol monostearate, avocado oil and tragacanth gum, so that the lipophilicity of calcium carbonate can be improved, and the reinforcement effect is good; through the auxiliaries, the dispersity and self-lubrication property of the packing can be improved.

Owner:青阳县吉祥塑胶有限公司

Adhesive for moisture-proof corrugated paper

InactiveCN107057622AImprove adhesionImprove wettabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSodium BentoniteAdhesive

The invention discloses an adhesive for moisture-roof corrugated paper. The adhesive is prepared from the following raw materials in parts by weight: 30-40 parts of bisphenol fluorene epoxy resin, 5-15 parts of p-aminophenol glycerin triglycidyl epoxy resin, 20-28 parts of cassava starch composite, 10-20 parts of calcined kaolin, 30-40 parts of nano bentonite, 2-6 parts of polyimide modified phenolic resin, 2-4 parts of m-xylylenediamine, 2-4 parts of carboxyl-terminated nitrile rubber, 1-3 parts of epoxy ethylhexyl stearate, 1-3 parts of triphenyl phosphate and 80-140 parts of epoxy propane glyceryl ether. The adhesive for moisture-roof corrugated paper is high in initial bonding force, is good in moisture-proof ability, is good in stability and is high in drying speed.

Owner:芜湖市广源包装科技有限公司

Permanent inflaming-retarding pbt material

ActiveCN104140648APermanent Flame RetardancyGood compatibilityAluminatePolytetramethylene terephthalate

The invention discloses a permanent inflaming-retarding pbt material. The permanent inflaming-retarding pbt material comprises, by weight, 73 parts to 80 parts of polybutylene terephthalate, 1 part to 2 parts of calcium aluminate, 1 part to 2 parts of epoxy chloropropane, 2 parts to 3 parts of ammoniummolybdat, 2 parts to 3 parts of hydroxystearic acid, 3 parts to 5 parts of polyethylene wax, 0.4 part to 1 part of ascorbic acid, 1 part to 2 parts of N-hydroxymethyl acrylamide, 0.7 part to 1 part of 2,6-di-tert-butyl-4-methylphenol, 2 parts to 3 parts of Poly(1,2-propylene glycol adipate), 2 parts to 3 parts of 2-ethyl hexanol, 1 part to 2 parts of sodium metaborate, 1 part to 2 parts of epoxy-2-ethylhexyl stearate and 1 part to 2 parts of processing agents. The permanent inflaming-retarding pbt material has the permanent flame retardance, and is reasonable in raw material compound, good in compatibility, high in finished product mechanical performance, high in resistance, simple in preparation technology and low in cost.

Owner:CHUZHOU YOUSHENG HIGH POLYMER MATERIAL

Polypropylene-nylon composite plastic thin film and preparation method thereof

InactiveCN105623092AImprove stabilityImprove mechanical propertiesDecabromobiphenyl etherPolyethylene glycol

The invention discloses a polypropylene-nylon composite plastic thin film. The plastic thin film is composed of, by weight, 1-2 parts of zinc hydroxystannate, 17-20 parts of nylon 66, 0.1-0.3 part of gluconolactone, 1-2 parts of coco fatty acid diethanol amide, 210-300 parts of polypropylene, 7-9 parts of montmorillonite powder, 1-2 parts of lanthanum chloride, 0.3-1 part of silane coupling agent KH560, 2-3 parts of sodium carbonate, 1-2 parts of epoxy ethylhexyl stearate, 0.7-1 part of cetyltrimethylammonium chloride, 0.1-0.2 part of 2, 6-butylated hydroxytoluene, 4-6 parts of polyethylene glycol, 0.3-0.5 part of eucalyptus oil, 4-6 parts of propenol, 0.8-1 part of deca-brominated diphenyl ether, 1-2 parts of aluminum tripolyphosphate and 0.8-1 part of dimethyl formamide. The preparation method includes: performing flame-retardant modification on nylon; mixing with lanthanum-based montmorillonite powder after being amidated; performing blending modification through a silane coupling agent to enable functional filler to be effectively dispersed in polypropylene. Surface strength of the plastic thin film is improved.

Owner:SUZHOU ZIJIN PLASTIC

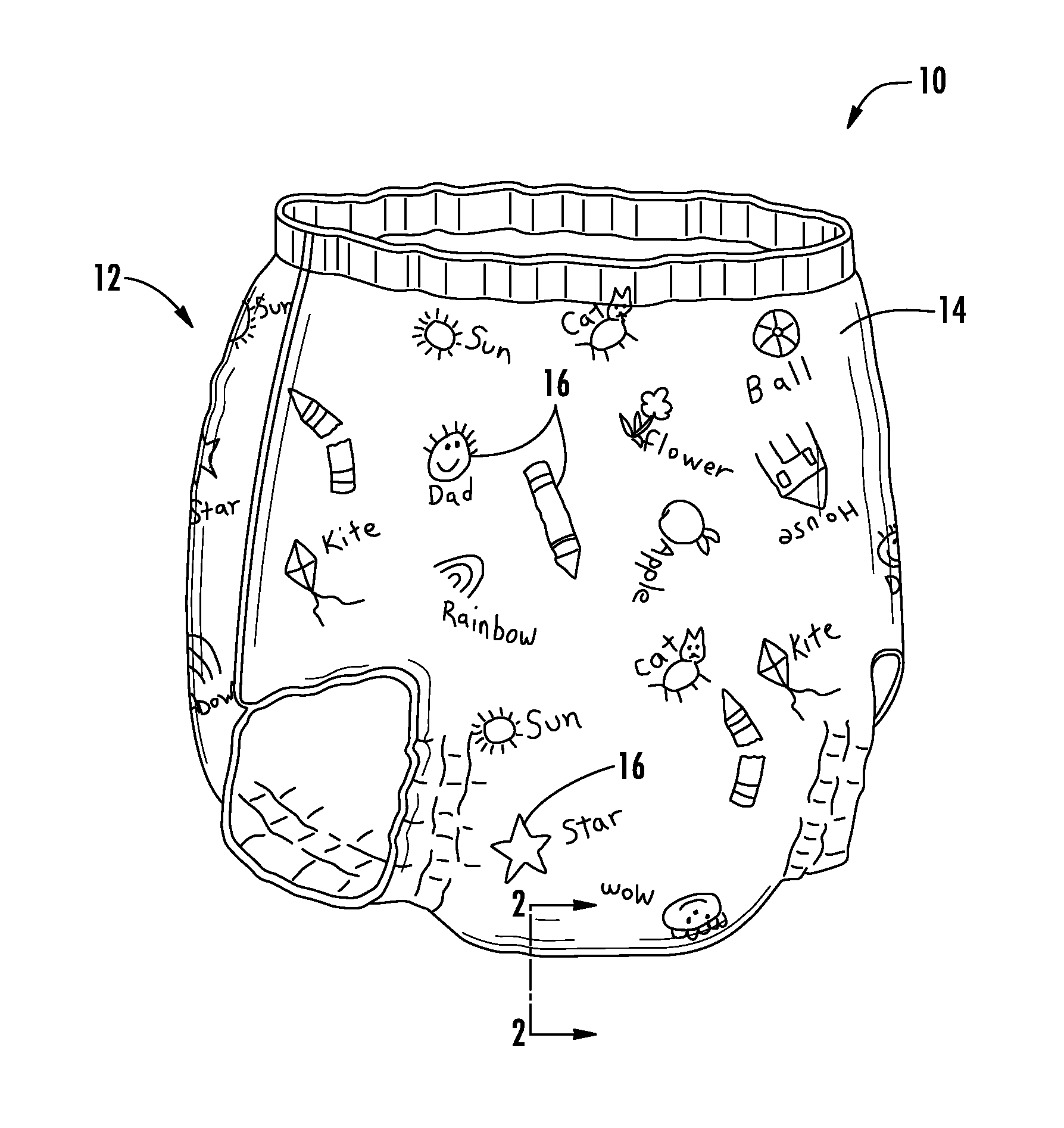

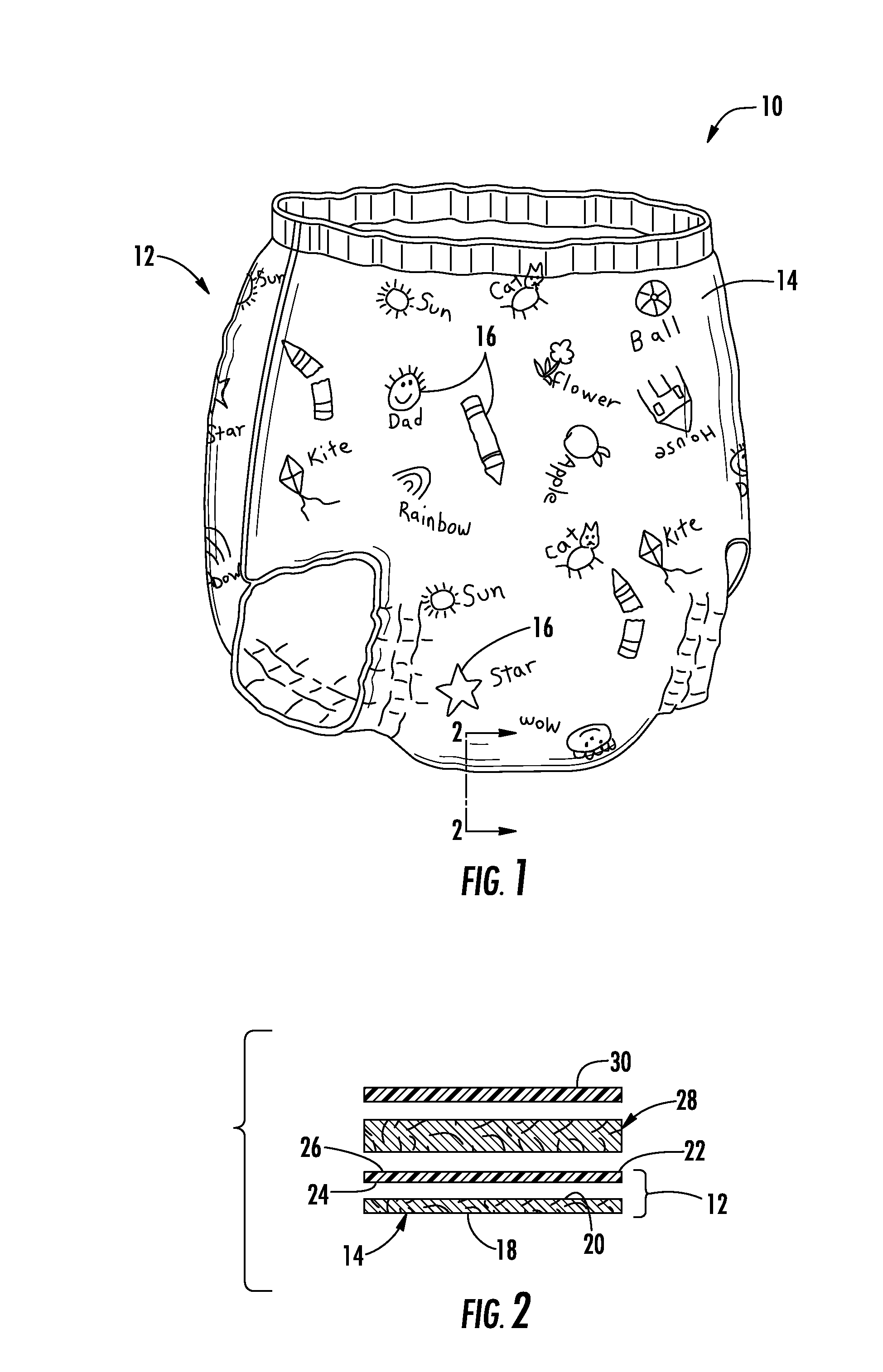

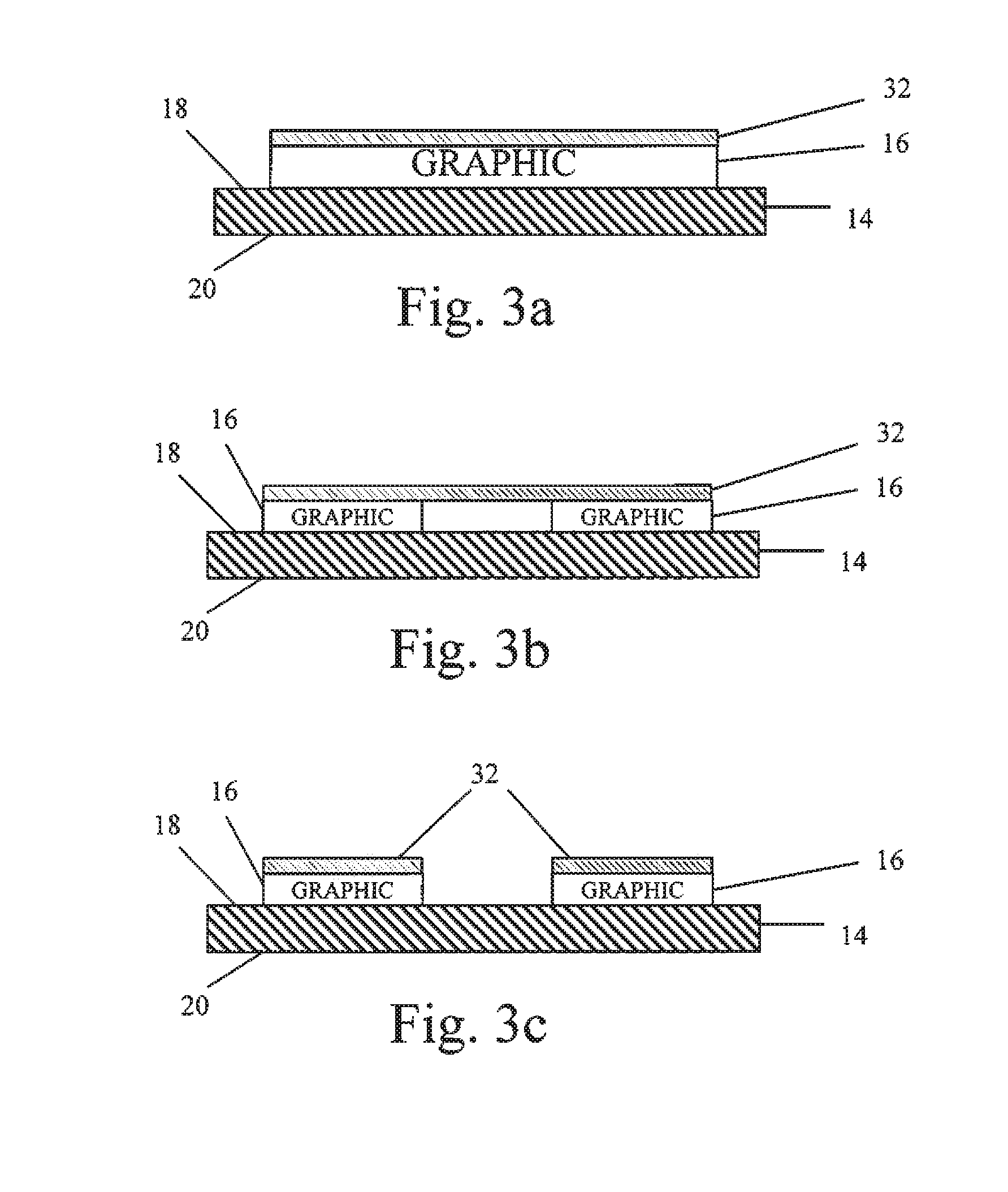

Sheet Materials Having Improved Softness

InactiveUS20120328850A1Layered productsDecorative surface effectsStatic friction coefficientEngineering

As disclosed herein, an article defining a visible surface includes a sheet material, an ink composition overlaying the sheet material, and a softening agent overlaying the ink composition, wherein the ink composition is positioned between the sheet material and the softening agent. For example, the softening agent may be selected from the group consisting of erucamide, cetyl 2-ethylhexanone, ethylhexyl stearate, ethylhexyl hydroxyetarate, perfluorinated dimethicone, and so forth. The articles have reduced static coefficient of friction and maintain oil Crockfastness.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Avocado oil moisturizing cream

InactiveCN105362101AGood moisturizing effectImprove anti-allergic effectCosmetic preparationsToilet preparationsIsostearic acidMOISTURIZING CREAM

The invention discloses avocado oil moisturizing cream. The avocado oil moisturizing cream comprises 2-6 parts of avocado oil, 1-3 parts of glycerol, 0.5-1 part of cetyl hydroxyethyl cellulose, 2-6 parts of isostearic acid, 2-4 parts of 2-ethylhexyl stearate, 2-4 parts of isopropyl myristate, 2-6 parts of propylene glycol stearate, 0.5-1.5 parts of 5% sodium hydroxide and 90-110 parts of deionized water. The avocado oil moisturizing cream is good in moisturizing capability, capable of making the skin soft and good in anti-allergy capability, thereby being capable of improving tolerance capability of the skin.

Owner:朱雪峰

Environment-friendly wet strength agent and preparation method thereof

InactiveCN103866638ANo releaseWill not polluteReinforcing agents additionCelluloseDiethylenetriamine

The invention discloses an environment-friendly wet strength agent and a preparation method thereof. The wet strength agent comprises the following raw materials in parts by weight: 10-20 parts of diethylenetriamine, 20-30 parts of sodium hydroxide, 30-50 parts of hydroxyethyl cetane cellulose, 20-30 parts of magnesium oxide, 36-40 parts of 1,6-hexanediol diacrylate, 45-50 parts of isostearic acid calcium, 45-50 parts of ethylhexyl stearate, 20-30 parts of propylene glycol stearate, 40-50 parts of simethicone, 60-70 parts of dodecyl trimethyl ammonium chloride, 40-50 parts of binary acid and 20-50 parts of polyhydric alcohols. The preparation method comprises the following steps: agitating for reacting the diethylenetriamine, the sodium hydroxide, the hydroxyethyl cetane cellulose, the magnesium oxide, the 1,6-hexanediol diacrylate and the isostearic acid calcium; adding residual components to carry out thermal reaction after warming up; dropwise adding a pH modifier. By the environment-friendly wet strength agent, the dry tensile strength of paper can be enhanced, and the water resistance of the paper surface can be greatly improved.

Owner:SUZHOU HENGKANG NEW MATERIALS

Low-temperature-resistant anti-freezing bronze sculpture super-hydrophobic anticorrosive coating and preparation method thereof

InactiveCN106010115AImprove stabilityImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsWater basedSucrose

The invention discloses a low-temperature-resistant anti-freezing bronze sculpture super-hydrophobic anticorrosive coating. The low-temperature-resistant anti-freezing bronze sculpture super-hydrophobic anticorrosive coating is prepared from, by weight, 40-60 parts of EP-44 water-based epoxy resin emulsion, 3-5 parts of carboxylic butadiene-styrene latex, 0.1-0.5 part of benzotriazole, 3-5 parts of mesoporous silica hollow spheres, 2-4 parts of methyl trimethoxy silane, 0.5-1 part of silane coupling agent KH-560, 6-8 parts of isopropanol, 0.1-0.2 part of sucrose fatty acid ester, 0.5-1 part of epoxy ethylhexyl stearate, 0.5-1 part of nano-magnesium hydroxide and 0.1-0.15 part of coconut oil ethanediol amide. A super-hydrophobic coating can be formed on the surface of a bronze base through the anticorrosive coating, has the advantages of being excellent in anticorrosive performance, good in coating stability and durable in hydrophobic effect, has good low-temperature-resistant anti-freezing performance, and is wide in application range.

Owner:TONGLING QINGTONGSHIDA SCULPTURE CO LTD

Nylon corrugated pipe

InactiveCN104072862AImprove high temperature resistanceImprove acid and alkali corrosion resistanceHexagonal boron nitrideEthylene urea

The invention discloses a nylon corrugated pipe, comprising the following raw materials in parts by weight: 1-2 parts of phosphite ester, 1-2 parts of hexabromocyclododecane, 10-14 parts of nylon 610, 0.4-1 part of di-methylol di-hydroxy ethylene urea, 1-2 parts of chromic carbonate, 1-2 parts of 2,2-dithienyl methyl glycolate, 2-4 parts of epoxy ethylhexyl stearate, 2-4 parts of hexagonal boron nitride, 6-8 parts of montmorillonite powder, 2-3 parts of polyvinylidene fluoride, 2-3 parts of dipropylene glycol, 1-2 parts of ammonium dihydrogen phosphate, 90-96 parts of polypropylene and 5-7 parts of compound additive. The corrugated pipe disclosed by the invention has good high temperature resistance, good acid and alkali corrosion resistance, strong shock resistance, excellent physical property, good tenacity, high surface hardness, and long service life, and is especially applicable to being used as a dry corrugated pipe material under a high-temperature condition.

Owner:ANHUI HAINA SICHUAN PLASTICS TECH

Aerosol deodorant antiperspirant compositions

InactiveUS20160296428A1Fast dryingLong-lasting effectCosmetic preparationsToilet preparationsDodecaneCeanothic acid

The present invention relates to a deodorant antiperspirant composition including: an anti-perspirant; a deodorant; an oil absorbent selected from the group consisting of aluminum starch octenylsuccinate, tapioca starch, and polymethylsilsesquioxane; a carrier comprising dodecane, an ester selected from the group consisting of isopropyl myristate, ethylhexyl stearate, isocetyl stearate, isopropyl isostearate, and myristyl myristate, and helianthus annuus seed oil; a suspending agent; and at least one propellant, wherein the composition is substantially free of silicone.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Nylon dry powder heat-radiating coating

InactiveCN103756553AImprove scratch resistanceImprove impact resistancePowdery paintsPolyamide coatingsFiberSolvent

The invention discloses a nylon dry powder heat-radiating coating which is prepared from the following raw materials in parts by weight: 80-86 parts of nylon TR90, 2-3 parts of 1, 4-cyclohexanedimethanol, 6-8 parts of gibbsite, 2-3 parts of acetate fiber, 1-2 parts of diisopropyl ethanol amine, 1-2 parts of ferrous sulfate, 4-7 parts of epoxy ethylhexyl stearate, 1-2 parts of konjac glucomannan, 4-6 parts of light calcium carbonate, 1-2 parts of propanediol butyl ether and 6-10 parts of modified filler. The powder coating disclosed by the invention has good scratching resistance, impact resistance and wear resistance, and is free from solvent, good in anti-aging performance, simple in preparation method and free from environmental pollution.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Oil-resistant and temperature-resistant PET cable sheath material with low cost

ActiveCN104086955AImprove performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsZinc compoundsSesquioxide

The invention relates to a cable material and particularly relates to an oil-resistant and temperature-resistant PET cable sheath material with low cost. The material is prepared from the following raw materials in parts by weight: 30-34 parts of waste PET bottle particles, 23-25 parts of polyvinylidene fluoride, 12-15 parts of EVA, 2-3 parts of a calcium and zinc compound stabilizer, 1-3 parts of ammonium molybdate, 4-5 parts of copper oxide, 3-4 parts of iron sesquioxide, 2-3 parts of sodium hexametaphosphate, 1-2 parts of 10-hydyroxyl-2-caproleic acid, 16-18 parts of acetyl tri-n-butyl citrate, 12-13 parts of epoxy ethylhexyl stearate, 3-6 parts of calcium sulfate, 30-40 parts of N330 carbon black, 5-6 parts of antimonous oxide and 14-16 parts of an assistant. The insulating material combines the advantages of raw materials such as PET, polyvinylidene fluoride and EVA. The prepared material is high in strength, good in mechanical performance, can resist oil and chemical corrosion, can resist high temperature and low temperature aging, can resist oxidization and ray radiation and has a long service life. PET in the formula is a recycled waste, so that the production cost is effectively lowered, and the material has an extremely huge market popularization and application value.

Owner:ZHEJIANG XINYUANHONG MACROMOLECULE MATERIAL

Eye cream and preparation method thereof

InactiveCN109106646AWith whitening and anti-freckleAntioxidantCosmetic preparationsToilet preparationsWater bathsGlycerol

The invention provides an eye cream and a preparation method thereof. The eye cream is prepared from the following raw materials: flavol acetate, retinol palmitate, ascorbyl palmitate, alchemilla japonica extract, sesame seed oil, glycerol, ethylhexyl stearate, squalane, xanthan gum, rhizoma atractylodis macrocephalae extract, carbomer, polyglycerol-3-oleate, sorbitol, maize oil, wheat germ oil, polyglycerol-3-polyricinoleate, glycine soja extract, beewax, phenoxyethanol, tea oil, magnesium sulfate, panthenol, carrot root extract, tocopheryl acetate and the like. The eye cream is prepared by stirring the raw materials in water bath and carrying out superfine treatment. The prepared eye cream has functions of whitening, removing freckles, resisting oxidization and resisting wrinkles; meanwhile, the eye cream has extremely excellent effect; compared with the existing eye cream, the prepared eye cream has various functions; each function has extremely excellent effect; the eye cream alsohas functions of resisting inflammation, resisting allergy and removing free radicals, is obvious in anti-aging effect, and also has functions of lifting and tightening.

Owner:袁浩卿

Dendrobium officinale essence cream and preparation method thereof

InactiveCN110585105AFully nourishedFeel comfortableCosmetic preparationsToilet preparationsBetaineAdenosine

The invention discloses dendrobium officinale essence cream and a preparation method thereof. The dendrobium officinale essence cream is prepared by combining the raw materials in parts by weight andcompounding ratio of water, glycerine, butanediol, betaine, panthenol, adenosine, ethylenediam inetetraacetic acid disodium, ethylhexyl stearate, hydrogenated polydecene, sunflower seed oil, shea butter, cyclopentasiloxane, Jojoba esters, cetostearyl alcohol, glyceryl stearate, cetearyl glucoside, stearic acid, PEG-4 Olivate, beeswax, polydimethylsiloxane, PEG-100 stearate, polyacrylate-13, a fucus extract, a common selfheal fruit-spike extract, a honey extract, pueraria thunbergiana, 1, 2-hexanediol, a dendrobium officinale extract, phenoxyethanol, ethylhexylglycerin, essence and the like. The essence cream can enable the skin to be soft and tender and have smooth touch sense, and can provide enough nutrients for skin, so that the skin can maintain moistening, soft and smooth, people havecomfortable feeling, and the skin and muscle are bright and smooth.

Owner:菲朗生物科技(湖北)有限公司

Preparation method of high-wear-resistance plastic piece

The invention relates to the technical field of plastic, in particular to a preparation method of a high-wear-resistance plastic piece. The preparation method comprises the following steps: preparingthe following components in parts by mass: 20 to 30 parts of ABS, 15 to 18 parts of polyamide, 13 to 16 parts of polycarbonate, 6 to 10 parts of silicon lime, 12 to 45 parts of polyvinyl chloride resin, 2 to 6 parts of rubber oil, 1 to 5 parts of 1,3-dihydroxy methyl-5,5-dimethyl glycolylurea and 2 to 4 parts of ethylhexyl stearate; forming: mixing the prepared components in a mixer completely anduniformly, conveying to an extruding machine, extruding particles by using the extruding machine, heating the particles to 180 DEG C to melt, injecting into a mode with the corresponding shape, maintaining the temperature to be 170 DEG C and the pressure to be 2 MPa for 0.3 minute, rapidly cooling to normal temperature and taking out of the mold. According to the preparation method of the high-wear-resistance plastic piece and through reasonable formula design and process design, the wear resistance of the plastic can be improved, so that the high-wear-resistance plastic piece is suitable forbeing used on a cover plate at the bottom of a dust remover, is not liable to scratch and wear in the repeated moving friction process, improves the use property and prolongs the service life.

Owner:桐乡市富鸿塑业股份有限公司

Anti-adherent Compositions and Methods of Inhibiting the Adherence of Microbes to a Surface

Methods of inhibiting microbes from attaching to a surface and anti-adherent compositions are disclosed. One method can include providing an anti-adherent composition that includes an anti-adherent agent configured to inhibit microbes from attaching to the surface. The anti-adherent agent can be: Acrylates Copolymer, Trimethylpentanediol / Adipic Acid / Glycerin crosspolymer, Trimethylpentanediol / Adipic Acid Copolymer, Ethylhexyl Stearate, Ethylhexyl Salicylate, Acrylates / C12-22 Alkylmethacrylate Copolymer, Octocrylene, Ethylene Oxide / Propylene Oxide Block Copolymer, Polyquaternium-101, or any combinations thereof. The method can include applying the composition to the surface and allowing at least some of the composition to remain on the surface such that the anti-adherent agent inhibits microbes from attaching to the surface. The anti-adherent composition can include a humectant and can be non-antimicrobial.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Special packing material for high-toughness water-resistant high-pressure rubber tube and preparation method thereof

The invention discloses a special packing material for a high-toughness water-resistant high-pressure rubber tube. The special packing material is prepared from the following raw materials in parts by weight: 2-3 parts of epoxy acrylate, 5-10 parts of ABS (Acrylonitrile Butadiene Styrene) resin, 3-4 parts of tridecafluoro trimethoxy silane, 0.3-0.4 part of tetraethoxysilane, 10-15 parts of chalk powder, 0.4-0.5 part of chlorinated paraffin, 0.4-0.5 part of epoxy ethylhexyl stearate, 50-55 parts of coal ash, a proper amount of 4-6% hydrochloric acid, a proper amount of water and 15-20 parts of additives. Due to the added tridecafluoro trimethoxy silane, the high-pressure rubber tube is good in hydrophobic, antifouling and uvioresistant property, and the service life is prolonged; due to the epoxy acrylate, the ABS resin and the tetraethoxysilane, the toughness and tearing strength of the high-pressure rubber tube are improved; due to the coal ash and the chalk powder, the cost is lowered, and the reinforcement property is good; due to the additives, the dispersity and reinforcement property of the packing material are improved, and the strength and impact resisting toughness of the high-pressure rubber tube are improved.

Owner:HEFEI HEAN MACHINERY MFG

Low-temperature setting zinc oxide conductive silver paste and preparing method thereof

InactiveCN104143378ALow curing temperatureImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteWeather resistance

The invention discloses a low-temperature setting zinc oxide conductive silver paste which is characterized by comprising, by weight, 35-45 parts of silver powder, 5-8 parts of nano-copper powder, 2-4 parts of zinc oxide, 1-3 parts of titanium dioxide, 1.2-3.4 parts of tungsten trioxide, 2.1-3.6 parts of etherified guar gum, 1.2-2.7 parts ofsodium alga acid, 3-6 parts of epoxy ethylhexyl stearate, 4-6 parts of glycerinum, 2-4 parts of dimethyl nylon acid, and 30-40 parts of auxiliaries. Compared with the prior art, the conductive silver paste has the advantages of being low in setting temperature, excellent in conductive performance, not prone to disengagement, good in weather resistance, low in production cost and the like.

Owner:滁州恒恩光电科技有限公司

Fibronectin extract component-containing efficient anti-aging, moisturizing, soothing, repairing and anti-wrinkle face cream

InactiveCN113730280APromote absorptionCreate a beautiful faceCosmetic preparationsToilet preparationsPolythylene glycolGlycerol

The invention discloses fibronectin extract component-containing efficient anti-aging, moisturizing, soothing, repairing and anti-wrinkle face cream. The face cream comprises the following components: water, hydrogenated coconut oil, butanediol, glycerol, cetostearyl alcohol, caprylic / capric triglyceride, isononyl isononanoate, polydimethylsiloxane, trehalose, a fibronectin extract, polyethylene glycol-8, biosaccharide gum-1, panthenol, glycosylglycerol, soybean milk fermentation product filtrate,1,2-pentanediol, phytosterols, glyceryl stearate, tocopheryl acetate, hydrogenated lecithin, bisabolol, licorice root extract, glycerol polyether-26, cyclopentasiloxane, polydimethylsiloxane crosspolymer, cetearyl glucoside, PEG-100 stearate, ammonium acryloyldimethyltaurate, sodium polyacrylate, ethylhexyl stearate, trideceth-6, 1,2-hexanediol , p-hydroxyacetophenone and phenoxyethanol. The face cream can supplement water and preserve moisture, deeply permeate through the skin, brighten and moisturize the skin, and creates a beautiful face.

Owner:广州健顺生物医药研究院有限公司

Stainless steel anticorrosion passivation paste and preparation method thereof

InactiveCN107419280ASecondary damageGood removal effectMetallic material coating processesCalcium hydroxidePhosphoric acid

Owner:SUZHOU JILI STAINLESS STEEL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com