Patents

Literature

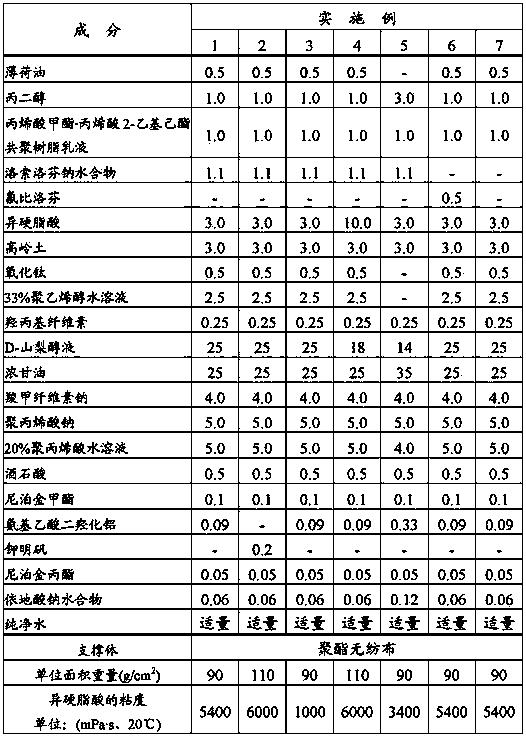

216 results about "Isostearic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

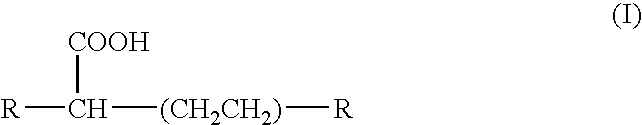

Isostearic acid is a fatty acid molecule with an 18-carbon atom chain backbone. It is an isomer of stearic acid, meaning that they both have a chemical formula of C18H36O2, but differ in the arrangement of their atoms.

Pharmaceutical composition and method for transdermal drug delivery

InactiveUS20050020552A1Increase concentrationImproves transdermal penetrationOrganic active ingredientsAerosol deliveryIsostearic acidHormones regulation

A pharmaceutical composition for transdermal administration of a hormone (e.g., testosterone), which includes isostearic acid as a penetration enhancer, and methods utilizing same for treating medical conditions in which elevating a hormone serum level is beneficial are disclosed.

Owner:AGIS INDUSTRIES (1983) LTD

Liquid ester compositions and cosmetic compositions containing the same

ActiveUS20070110702A1Sustain feelingImprove gloss feelingCosmetic preparationsHair cosmeticsIsostearic acidOctanoic Acids

The present invention provides a liquid ester composition which is obtained by esterifying a branched isostearic acid such as 2-(1,3,3-trimethyl)butyl-5,7,7-trimethyl octanoic acid with dipentaerythritol, and said liquid ester composition having a viscosity at 25° C. of 100,000 to 2,000,000 mPa·s; hydroxyl value of 10 to 160; and cloud point of less than 5° C. This liquid ester composition has pigment dispersibility and hydrating ability that polybutene, which is one of the raw materials of oil compositions for cosmetic compositions, does not have, together with their abilities to sustain feeling of cosmetic film and improve gloss and moisture feeling of cosmetic compositions and shape retaining ability of lipsticks and the like equal to those containing polybutene.

Owner:THE NISSHIN OILLIO GRP LTD

Thickener for hair care products

InactiveUS20040234471A1Easy to processEasy to incorporateCosmetic preparationsHair removalIsostearic acidEthoxylation

A cosmetic and / or pharmaceutical composition comprising a thickening concentrate, said concentrate containing: (a) an isostearic acid; (b) a fatty alcohol; and (c) an ethoxylated fatty alcohol.

Owner:COGNIS DEUT GMBH & CO KG

Titanium dioxide - containing polymers and films with reduced melt fracture

InactiveUS20050197428A1Improve efficiencyReducing melt fractureSpecial tyresPigment treatment with macromolecular organic compoundsIsostearic acidPolymeric surface

Pigmented polymer compositions and processes for preparing melt-processible polymer compositions contain a melt-processible polymer, surface treated organic pigment, typically titanium dioxide, and a polymer processing aid are described. The pigment is surface treated by contact with a silicon-containing compound, such as octyltriethoxysilane followed by contact with an organic compound such as isostearic acid or ethoxylated silicone. The pigmented polymer composition containing a polymer processing aid facilitates production of shaped articles with low melt fracture.

Owner:EI DU PONT DE NEMOURS & CO

Skin care oil containing peony oil and preparation method thereof

ActiveCN103271860AImprove circulationAnti agingCosmetic preparationsToilet preparationsBiotechnologyMeadowfoam seed oil

The invention belongs to the technical field of skin care oil medicine, in particular to skin care oil medicine containing peony oil and a preparation method thereof. The skin care oil medicine provided by the invention comprises the following components in parts by weight: main ingredients: peony seed oil, caprylic / capric triglyceride, cyclopentasiloxane and 1, 2 - butyl glycol 1-12, wherein the peony oil is peony seed oil or peony essence oil or the mixture of peony seed oil and peony essence oil; auxiliary ingredients: isostearic acid, butylated hydroxytoluene, avocado oil, simmondsia chinensis seed oil, meadowfoam seed oil and macadamia ternifolia seed oil; the skin care oil medicine containing peony oil prepared by the method provided by the invention can remarkably improve of the skin epidermis cell cycle function, promote the microcirculation of the blood capillary of the dermal skin effect, inhibit lipid peroxidation, improve metabolism, delay skin aging process, is provided with anti-wrinkle, moisturizing and whiting effect, people feels smooth and comfortable after the skin care oil medicine is used on the skin, and the skin care oil medicine containing peony oil is provided with better effect to chloasma, aging skin wrinkles, skin cutin hardening peeling and skin chap.

Owner:HEZE YAO & SHUN PEONY BIOTECH

Moisturizing and nourishing facial cream and preparation method thereof

InactiveCN105434285AImprove skin qualityImprove skin toneCosmetic preparationsToilet preparationsSodium hyaluronateTocopheryl acetate

The invention provides a composition for moisturizing and nourishing facial cream. The composition comprises effective components in parts by weight as follows: jojoba seed oil, avocado tree fruit grease, a purslane herb extract, phytosterol isostearate, mycose, decarboxy carnosine HCL, tocopheryl acetate, a Chinese angelica root extract, a baical skullcap root extract, sodium hyaluronate, aloe barbadensis leaf juice, a ginseng root extract and a centella leaf extract. The composition is applied to the facial cream, can provide lasting moisturizing and water supplement functions for the face, and can whiten the skin and resist wrinkles obviously after being used for a long time.

Owner:TIANJIN DARENTANG JINGWANHONG PHARMA

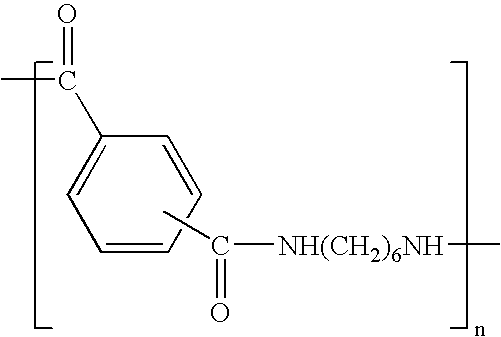

Moisture and gas permeable non-porous ionomeric films

Moisture and gas permeable ionomeric films are described. The films described herein are obtained from blends of ionomers with an organic acid salt in the amount of at least about 5 wt %, and have MVTR greater than films obtained from conventional ionomers. Particularly preferred are the potassium salts of stearic, oleic, isostearic, and isooleic acids. Films comprising a liquid-absorbent ionomer film layer and an impermeable layer are provided. The films are suitable for preparation of tubular casings and shrinkbags, in particular, casings for smoked foodstuffs.

Owner:PERFORMANCE MATERIALS NA INC

Moisture and gas permeable non-porous ionomeric films

Moisture and gas permeable ionomeric films are described. The films described herein are obtained from blends of ionomers with an organic acid salt in the amount of at least about 5 wt %, and have MVTR greater than films obtained from conventional ionomers. Particularly preferred are the potassium salts of stearic, oleic, isostearic, and isooleic acids. Films comprising a liquid-absorbent ionomer film layer and an impermeable layer are provided. The films are suitable for preparation of tubular casings and shrinkbags, in particular, casings for smoked foodstuffs.

Owner:PERFORMANCE MATERIALS NA INC

Preparation method of anti-cracking zinc acrylate antifouling paint

ActiveCN104629567AWith antifouling effectImprove crack resistanceAntifouling/underwater paintsPaints with biocidesCarboxylic acidPolymer solution

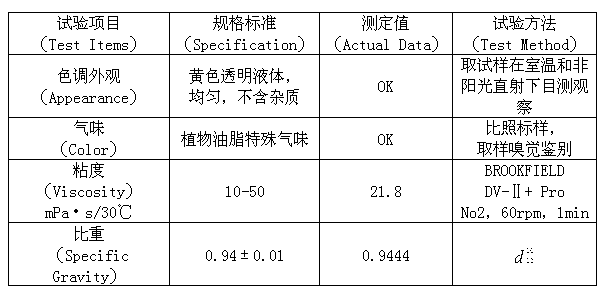

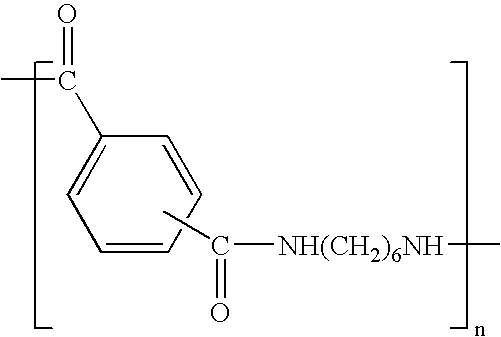

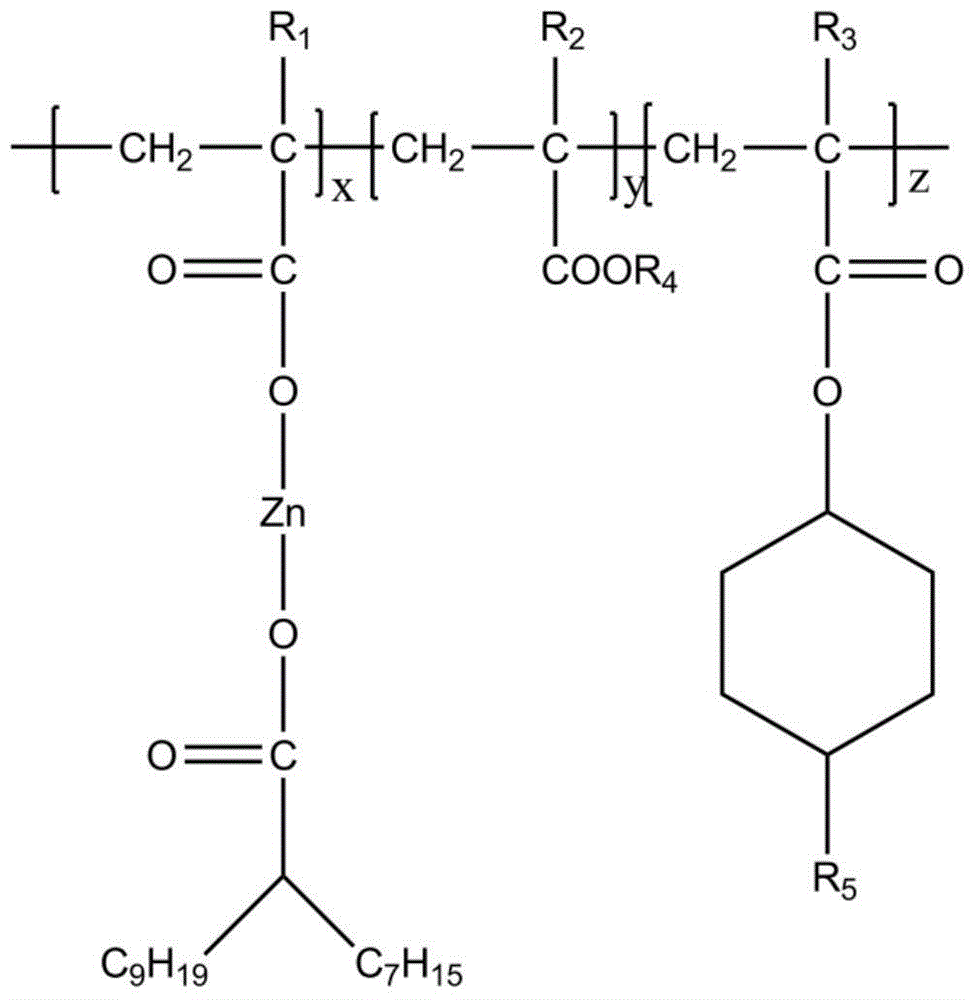

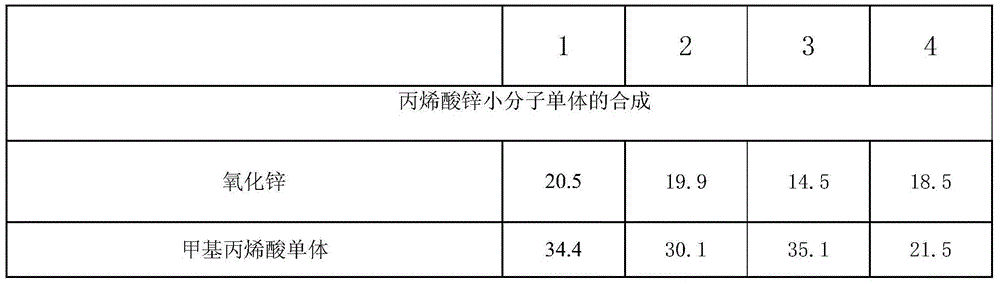

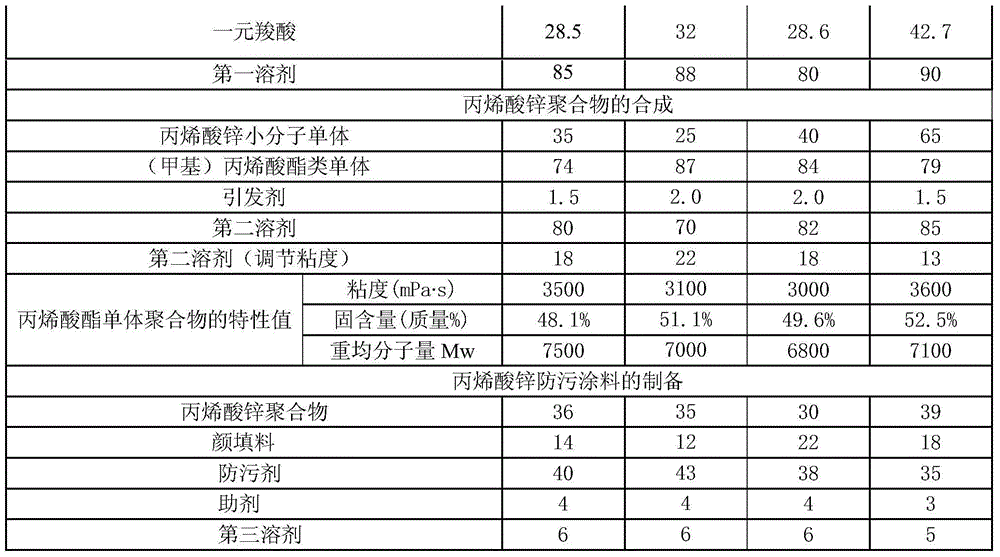

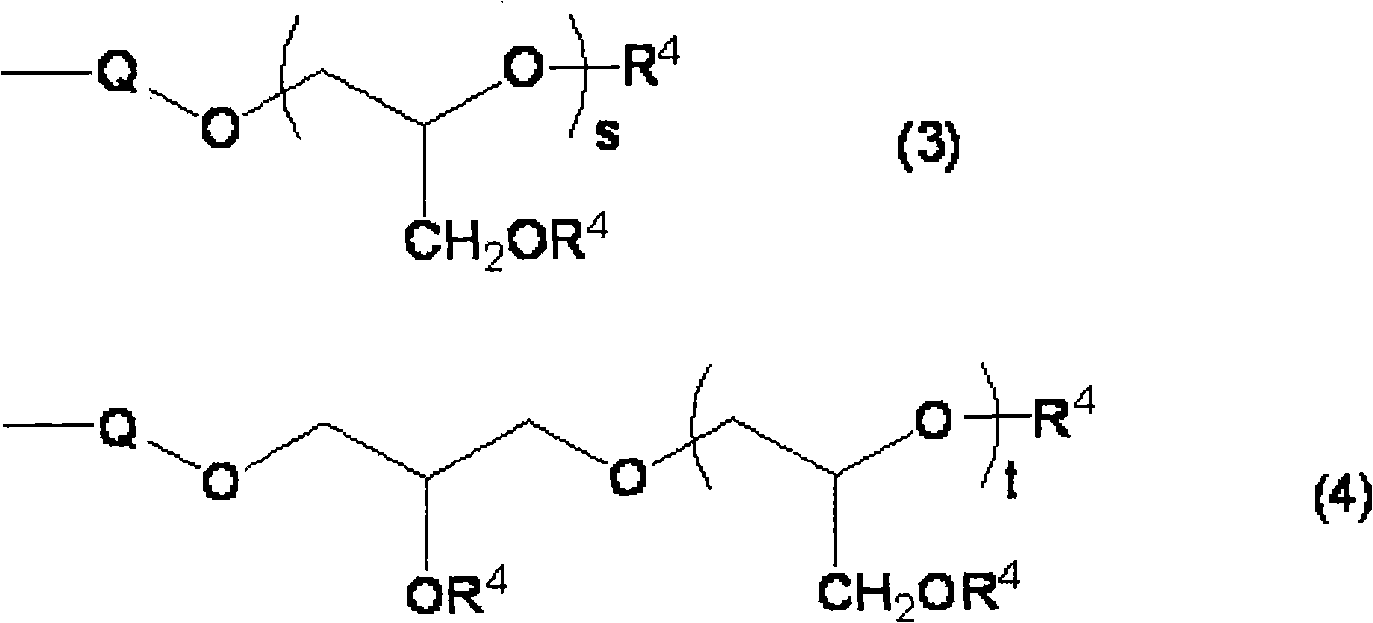

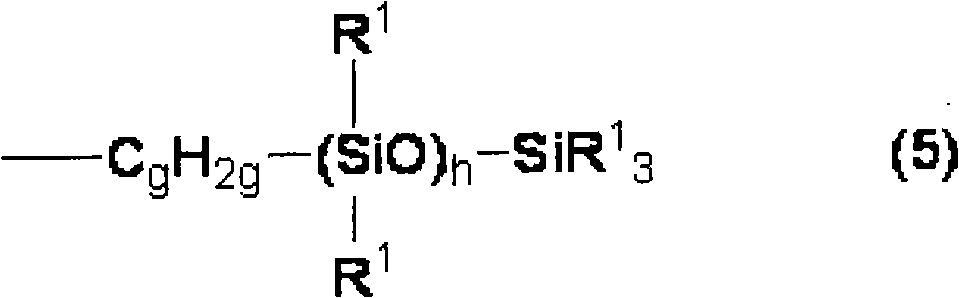

The invention discloses a preparation method of an anti-cracking zinc acrylate antifouling paint. The preparation method comprises synthesis of a zinc acrylate small-molecular monomer, synthesis of a zinc acrylate polymer and preparation of zinc acrylate antifouling paint, wherein the zinc acrylate small-molecular monomer contains a first solvent, zinc oxide, a methacrylic acid monomer and monocarboxylic acid; the zinc acrylate polymer contains a second solvent, a zinc acrylate small-molecular monomer, a methacrylate monomer and an initiator; the zinc acrylate antifouling paint contains a zinc acrylate polymer solution, pigment filler, a third solvent, an antifouling agent and an auxiliary; the structural formula of the synthesized zinc acrylate polymer is shown in the specification; the long branch of isostearic acid in monocarboxylic acid has relatively good internal plasticization function so that the synthesized zinc acrylate polymer has relatively good flexibility; and the methacrylate monomer is of a aliphatic six-membered ring structure with a cyclohexyl structure, the damage of the antifouling paint caused by excessive internal stress can be avoided, and the anti-cracking performance of the antifouling paint is enhanced.

Owner:XIAMEN SUNRUI SHIP COATING

Bicontinuous-phase eye-lip makeup remover and preparation method therefor

ActiveCN111096912ASimple ingredientsEasy to manufactureCosmetic preparationsMake-upNatural sourceGlycerol

The invention discloses a bicontinuous-phase eye-lip makeup remover and a preparation method therefor. The bicontinuous-phase eye-lip makeup remover comprises the following ingredients in percentage by mass: 15%-35% of PEG-20 glyceryl triisostearate, 5%-15% of sorbitol polyether-30 tetraisostearate, 10%-25% of emollient and 10%-35% of deionized water, wherein a mass ratio of the deionized water tothe emollient is 0.5 to 2. The makeup remover is simple in ingredient and convenient to prepare; and through adjusting an emulsifier ingredient, an HLB value is adjusted to about 9, thus, a stable bicontinuous-phase microemulsion can be formed, and the obtained makeup remover has the advantages that the makeup remover is stable and is good in spreadability (low in viscosity), transparent in appearance and high in makeup dissolving capability, and water-soluble and oil-soluble pigments can be simultaneously dissolved. In addition, through carrying out synergistic corrosion prevention by addingdisodium EDTA and a natural-source humectant, i.e., 1,3-propylene glycol, the consumption of a preservative is lowered, the irritability is lowered to the minimum, and sensitive eye and lip skin is protected.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

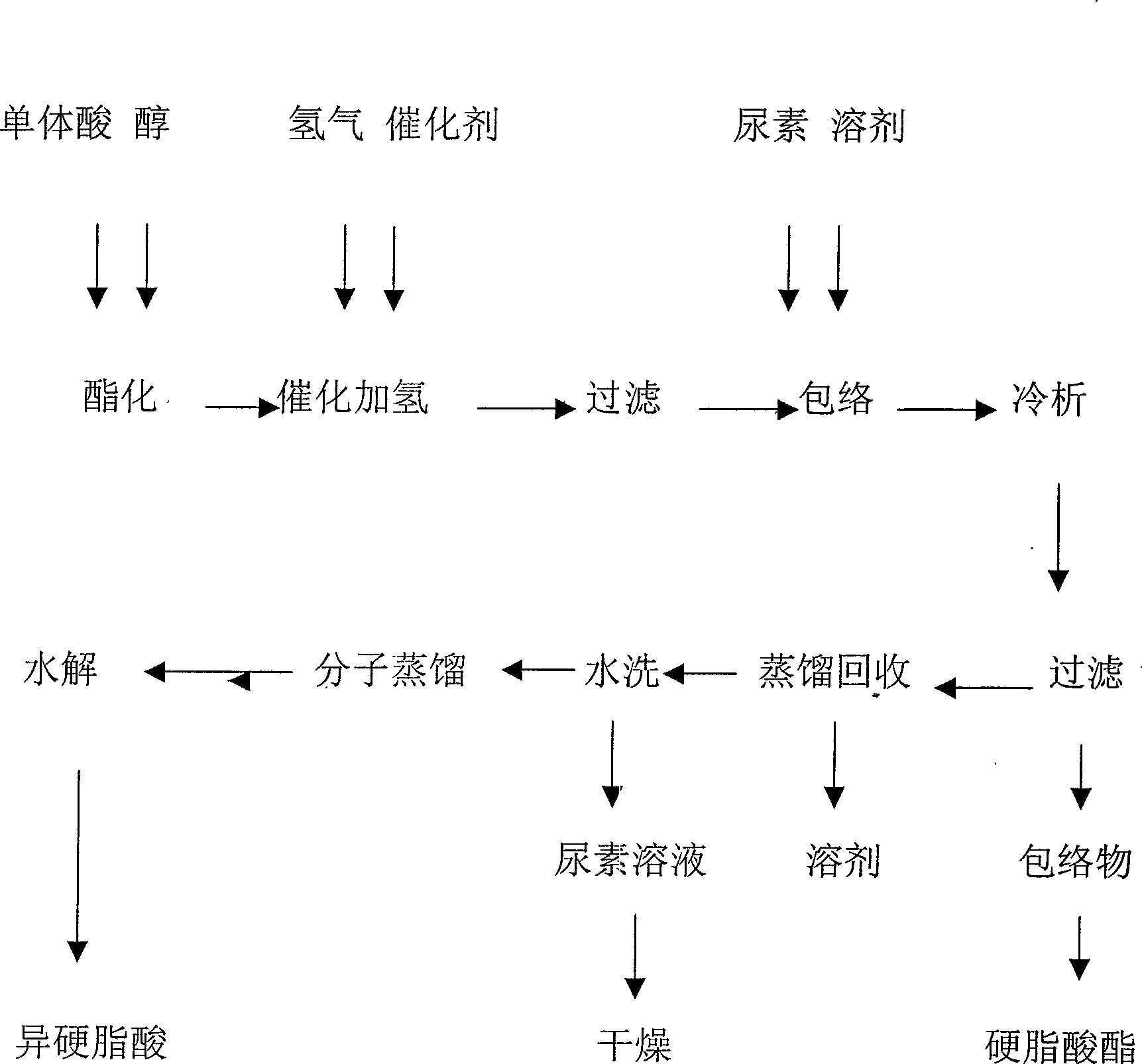

Method for separating and extracting isostearic acid from monomer acid

ActiveCN101544559ALow viscosityLow boiling pointCosmetic preparationsOrganic compound preparationDistillationDimer acid

The present invention discloses a method for separating and extracting isostearic acid from monomer acid. The present invention relates to a method for separating and extracting isostearic acid, in particular to a novel method for separating and extracting isostearic acid from monomer acid. The present invention provides a method for separating and extracting isostearic acid from monomer acid, which is suitable for use in commercial production. The method is characterized in: esterify the byproduct (monomer acid) obtain in production of dimer acid through bleaching earth catalytication process under medium pressure without catalyst to obtain monomer acid ester, treat by catalytic hydrogenation under medium pressure, and filter to obtain hydrogenised monomer acid ester; envelope with carbamide, filter, separate, and wash with water to obtain crude product of isostearic acid ester; perform molecular distillation to obtain refined isostearic acid ester, and then perform hydrolysis to obtain isostearic acid. Compared to the separation and extraction technique in the prior art, the present invention has the following advantages: the acidity and viscosity are low during hydrogenisation, and therefore the service life of catalyst is long, no nickel soap will be formed, and the corrosion to equipment is reduced; the product can be enveloped and separated by carbamide more easily; the distillation can be performed at a lower temperature; the iodine value of final product is low, the color is light, and the purity is high.

Owner:YIHAI TIANCHENG LIANYUNGANG CHEM INDSCO

Water-in-oil type sunscreen cosmetic

ActiveCN101773455AImprove emulsion stabilityNot easy to hang upCosmetic preparationsToilet preparationsIsostearic acidZinc

Owner:TOKIWA CORP

Lipstick and preparation method thereof

InactiveCN109172398AHigh glossBroaden applicationCosmetic preparationsMake-upIsostearyl alcoholBeeswax

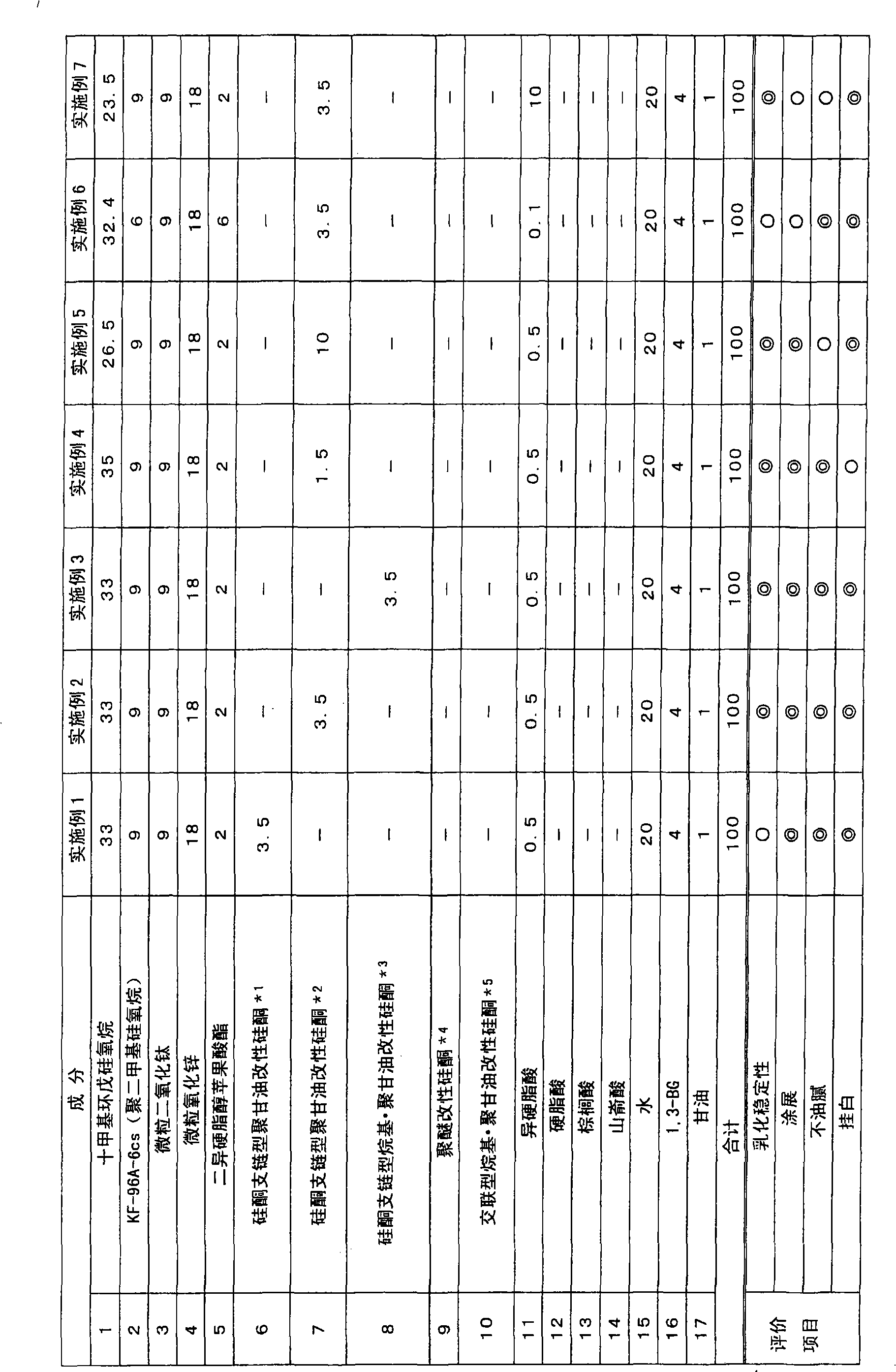

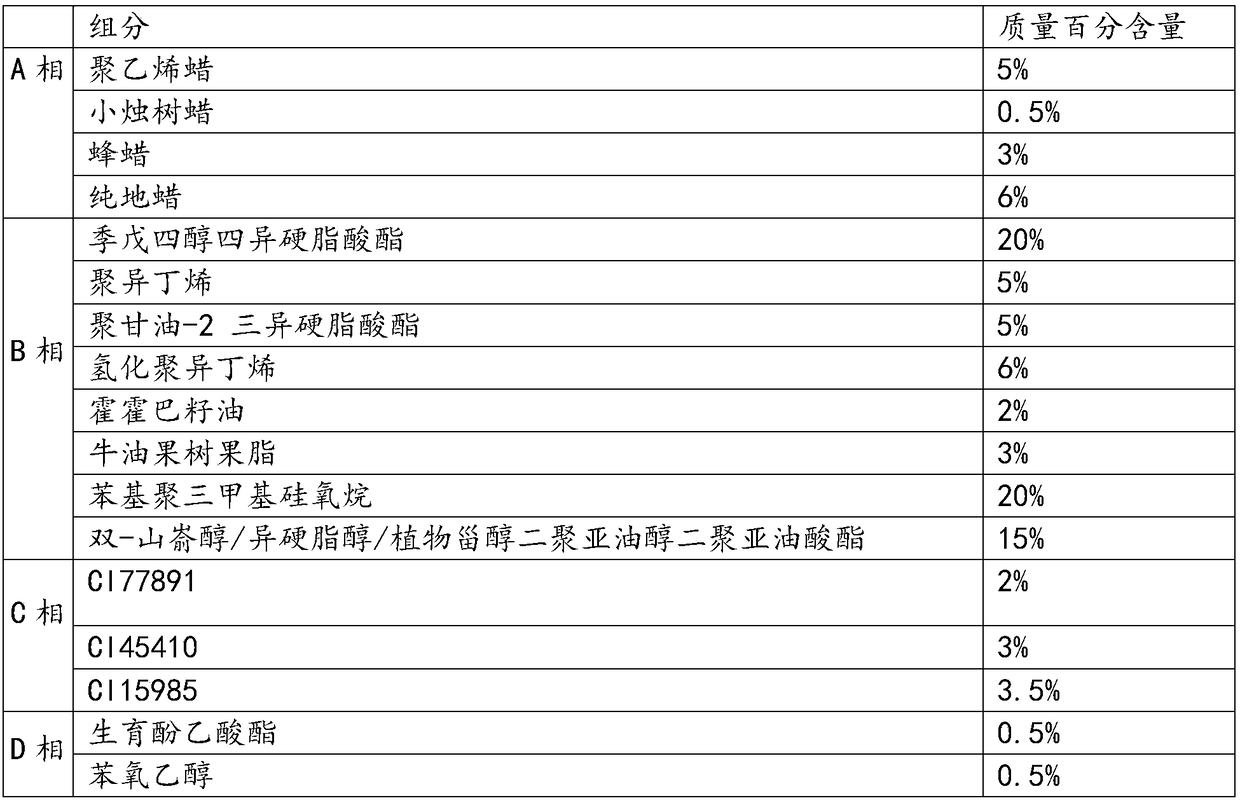

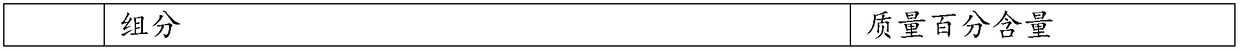

The invention belongs to the technical field of cosmetics. In order to improve the gloss of lipstick, the invention discloses a lipstick and a preparation method thereof, wherein, the lipstick comprises the following components in percentage by mass: polyethylene wax: 4-6%; Candlestick wax: 0.5-1%; Beeswax: 2-4%; Pure floor wax: 5-8%; Pentaerythritol tetraisostearate: 15-20%; Polyisobutylene: 4-6%; Polyglycerol-2 triisostearate: 4-7%; Hydrogenated polyisobutylene: 5-10%; Jojoba Seed Oil: 1-3%; Shea butter: 3-5%; Phenyl silicone oil raw material: 15-20%; Double-Behenyl alcohol or isostearyl alcohol or phytosterol dimeric linoleic alcohol dimeric linoleic acid ester alcohol: 10-15%; CI77891:1%-10%; CI45410:1%-10%; CI15985:1%-10%; Tocopheryl acetate: 0.5%-1%; and Phenoxyethanol: 0.1%-0.5%. The lipstick of the invention has the advantage of high gloss.

Owner:SHANGHAI ZHONGYI DAILY CHEM CO LTD

Cosmetic

ActiveUS20080188569A1Good moisturizing effectReduce the amount requiredBiocideCosmetic preparationsIsostearic acidAlcohol

The present invention relates to cosmetics comprising a hydroxyl compound obtained by the reaction of a di- or higher-valent alcohol with a monovalent carboxylic acid and dimer acid, characterized in that the hydroxyl compound is obtained by reacting diglycerin with isostearic acid, and then reacting the obtained ester compound with dimer acid, wherein a molar ratio among diglycerin, isostearic acid and dimer acid is in the range of 1.0:1.4 to 1.6:0.5 to 0.8. The present invention provides cosmetics comprising the hydroxyl compounds having a high hydroxyl value.

Owner:KOKYU ALCOHOL KOGYO

Preparation of pentaerythritol tetraoctyl stearate

ActiveCN101298417AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationIsostearic acidPentaerythritol

The invention relates to a preparation method of tetraisostearate: the mol ratio of pentaerythritol to isostearic acid is 1: 4.0 to 4.4; the temperature is raised to the range of 160 to 240 DEG C under normal pressure and reacted for 10 to 24 hours by distillation, wherein, the adding amount of a catalyst is 0.1 to 1 percent of the weight of the isostearic acid; after esterification is finished, the temperature is decreased to 50 to 90 DEG C; a nonpolar solvent and a polar solvent are added; the adding amounts of the nonpolar solvent and the polar solvent are respectively 5 to 80 percent and 5 to 80 percent of the weight of the isostearic acid; aqueous slkali is added for alkali washing neutralization; the adding amount is 0.5 to 3 percent of the weight of the isostearic acid; the concentration of the aqueous slkali is 5 to 30 percent; an organic phase is washed to neutral by water; the solvents and water are removed by reduced pressure distillation; then the product is obtained after filtration; each step is carried out under the protection of nitrogen; the preparation method of the invention has high yield; the obtained product has the advantages of light color, low acid value, high purity and being ideally applied to the cosmetic industry.

Owner:广州星业科技股份有限公司

Method for extracting isostearic acid from mono acid

InactiveCN1944375ANo pollution in the processSimple extraction methodOrganic compound preparationCarboxylic compound separation/purificationIsostearic acidWater baths

The present invention discloses process of extracting isostearic acid from mono acid, and the process is simple and has facile material, high product yield and low product cost. The process includes the following steps: 1. adding carbamide and solvent into reactor, stirring and reflux heating to 30-80 deg.c in a water bath to dissolve carbamide and obtain clear solution; 2. adding material mono acid before further reflux for 0.5-5 hr and stopping heating; 3. cooling the resultant to room temperature and cold separating at -10 deg.c to 20 deg.c for 1-20 hr; 4. suction filtering the cold separated resultant to obtain white fatty acid-urea inclusion compound and yellow filtrate; 5. vacuum distilling the filtrate to eliminate solvent; and 6 washing the product with hot water and stoving in a stove at 30-100 deg.c to obtain the isostearic acid product.

Owner:NANJING UNIV OF TECH

Bright and smooth matt lipstick and production technology thereof

ActiveCN109044889AImprove the sense of fogGood moisturizing effectCosmetic preparationsMake-upPolymer scienceSalicylic acid

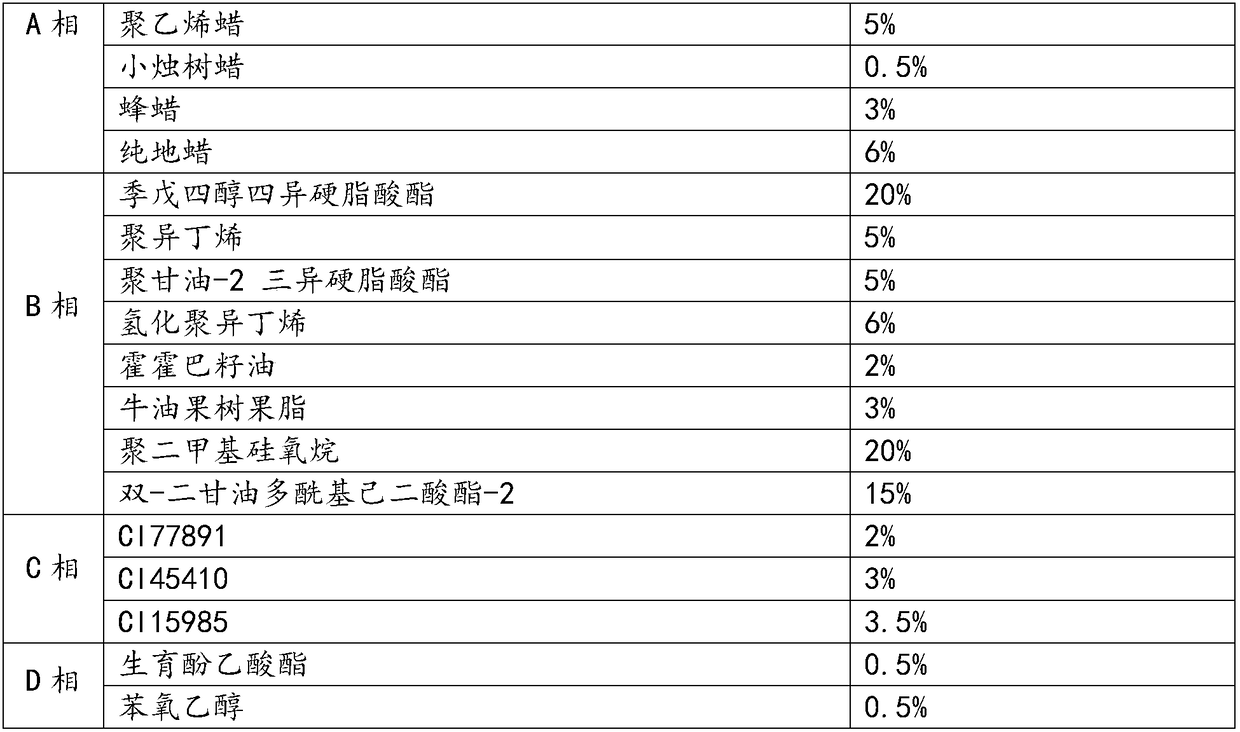

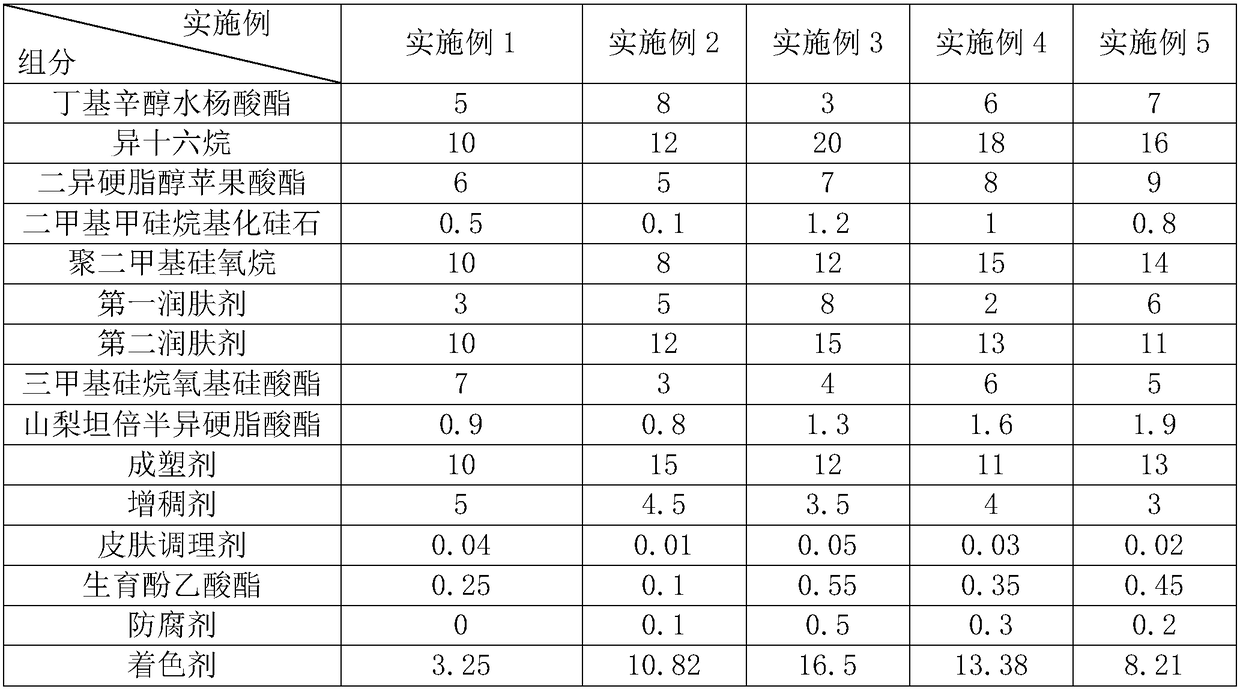

The invention discloses a bright and smooth matt lipstick and a production technology thereof. The bright and smooth matt lipstick comprises the following components in parts by weight: 3-8 parts of butyloctyl salicylate, 10-20 parts of isohexadecane, 5-9 parts of diisostearyl malate, 0.1-1.2 parts of silica dimethyl silylate, 8-15 parts of polydimethylsiloxane, 2-8 parts of a first emollient, 10-15 parts of a second emollient, 3-7 parts of trimethylsiloxysilicate, 0.8-1.9 parts of sorbitan sesquiisostearate, 10-15 parts of a plastizing agent, 3.5-5 parts of a thickening agent, 0.01-0.05 partof a skin conditioning agent, 0.1-0.55 part of tocopheryl acetate and 3.25-16.50 parts of a coloring agent. The bright and smooth matt lipstick has the advantages of being moisture, smooth, fresh andmatt.

Owner:虞琼斐 +1

Pentaerythritol isostearic acid ester synthesizing method

InactiveCN101293828AHigh selectivityWill not corrodeOrganic compound preparationCarboxylic acid esters preparationReaction temperatureNitrogen gas

The invention provides a synthetic method of pentaerythrityl isostearate, and belongs to the synthetic technology field of ester compounds in organic chemistry. The synthetic method comprises allowing pentaerythritol and isostearic acid to carry out ester reaction in nitrogen gas atmosphere in the presence of solid catalyst, and filtering. The solid catalyst can be stannous oxide or zinc oxide or ferric chloride in the amount of 0.03-0.10% of total weight of the pentaerythritol and the isostearic acid. The new solid catalyst has high selectivity, no by-product generation, equipment corrosion resistance, simple production process, and repeated use. Process parameters and conditions such as feed mixed ratio, catalyst amount, reaction temperature, reaction time, etc. can be reasonably determined by optimum design and repeated experimental study according to the operation requirement of the metal oxide catalyst. The reaction condition is mild and the adopted device is simple; therefore, cost and energy consumption of the device are reduced.

Owner:王伟松

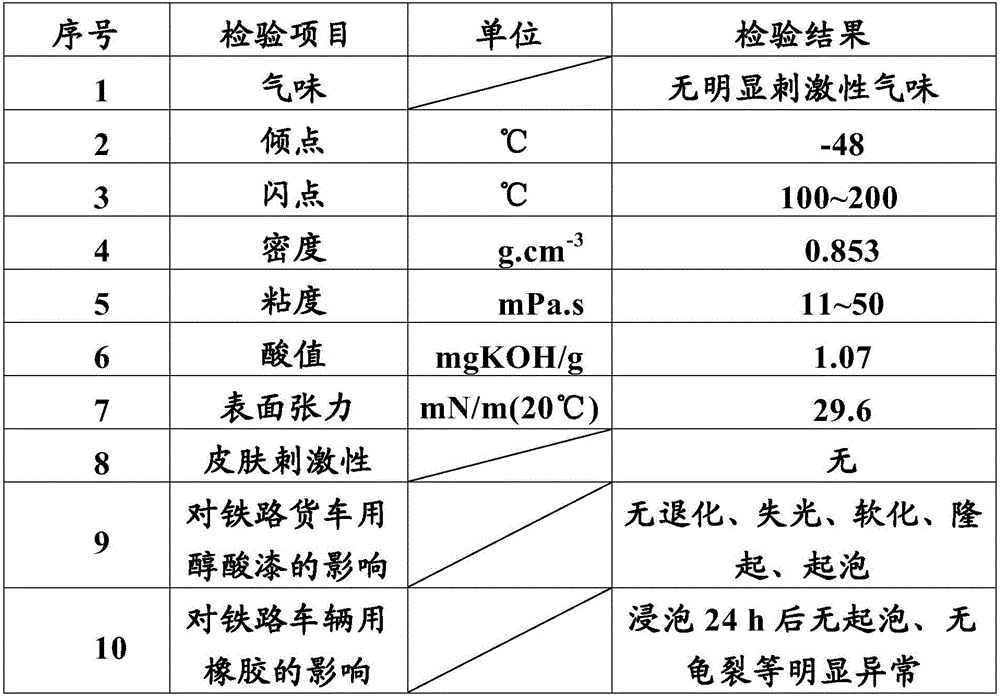

Application of biodegradable rolling emulsion composite in aluminum alloy plate strip hot rolling technology

The invention relates to the application of a biodegradable rolling emulsion composite in an aluminum alloy plate strip hot rolling technology. The biodegradable rolling emulsion composite is prepared from, by weight, 60-80 parts of vegetable oil and synthetic ester, 2-10 parts of at least one of oleic acid, triethanolamine and tall oil acid, 0-15 parts of at least one of petroleum sodium sulfonate, modified castor oil polyoxyethylene ether and alkylphenol polyoxyethylene ether, 0-5 parts of 12-14 alcohol, 0-10 parts of at least one of phosphite ester and phosphate ester, 1-5 parts of at least one of acid phosphate ester and isostearic acid, 0.5-2 parts of butylated hydroxytoluene, 0.05-1 part of octyl diphenylamine, 0.05-0.2 part of organosiloxane and 0.5-3 parts of at least one of methylene dimorpholine, iodo-n-butylproparglycarbamate and benzisothiazolones.

Owner:CHINA PETROLEUM & CHEM CORP

Sterilization type strippable high-molecular rust-preventing film with added chitosan

InactiveCN107033688AHave non-aggregateNoncondensationAntifouling/underwater paintsPaints with biocidesPolymer scienceMonoglyceride

The invention discloses a chitosan-added bactericidal peelable polymer antirust film, which is prepared from the following raw materials: aluminum isopropoxide, silane coupling agent KH560, tetraethyl orthosilicate, isostearic acid Monoglyceride, polyethylene glycol, methacryloxypropyltrimethoxysilane, polyvinyl alcohol, borax, chitosan, silver-loaded zirconium phosphate, silane coupling agent A151, glutaraldehyde, naphthenic acid Zinc, triethanolamine, benzotriazole, sodium lauryl sulfate, appropriate amount of lauryl dimethyl amine oxide, appropriate amount of nitric acid, appropriate amount of hydrochloric acid, appropriate amount of absolute ethanol, appropriate amount of acetic acid, appropriate amount of deionized water; the present invention The prepared antirust agent can form a thin film on the surface of the workpiece, which is antibacterial, hydrophobic, oleophobic, not easy to break, has good heat resistance and weather resistance, plays a good antirust and anticorrosion effect, and is easy to peel off later, which is worth promoting.

Owner:江海涛

Transparent lipstick and preparation method thereof

ActiveCN105326668AAppearance is clear and transparentIncrease moistureCosmetic preparationsMake-upPolymer scienceCosmetic appearance

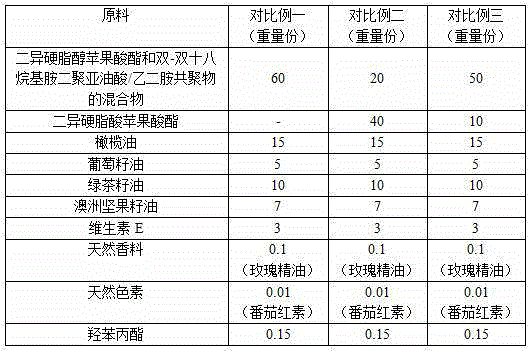

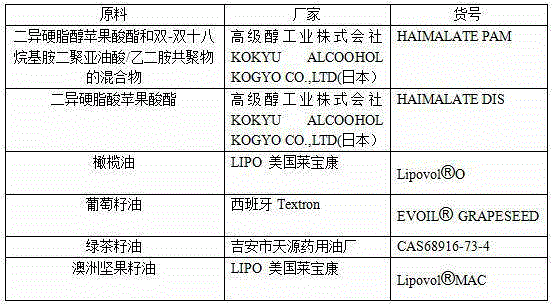

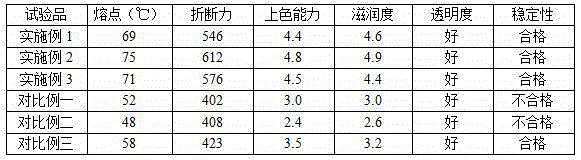

The invention belongs to the technical field of cosmetics, and particularly relates to a transparent lipstick and a preparation method thereof. The transparent lipstick is prepared from, by weight, 35-45 parts of a mixture of diisostearyl malate and double-double octadecylamine dilinoleic acid / quadrol copolymer, 15-25 parts of diisostearyl malate, 8-20 parts of olive oil, 1-8 parts of grape seed oil, 6-15 parts of green tea seed oil, 5-10 parts of macadamia nut seed oil, 2-5 parts of vitamin E, 0.1-0.5 parts of natural perfume, 0.005-0.05 part of natural pigment and 0.1-0.5 part of propyl hydroxybenzoate. The transparent lipstick is safe, free of stimulation, clear in appearance, high in transparency and good in moistening degree, and lips are bright in color after the transparent lipstick is adopted.

Owner:GUANGZHOU JINAN BIOMEDICINE RES & DEV CENT

Preparation method of low-solidifying point biodiesel

InactiveCN101935557AHigh yieldImprove pour point depressing effectOrganic compound preparationCarboxylic acid esters preparationIsostearic acidAlcohol

The invention discloses a preparation method of low-solidifying point biodiesel, wherein a method for synthesizing isostearic acid ester has the advantages of simplicity, high yield, mild condition, low cost, easy industrialization and obvious condensation-reducing effect on the biodiesel. In the method, the isostearic acid ester is prepared by mainly subjecting the isostearic acid and low-carbon alcohol to esterification and then adding the isostearic acid ester to the biodiesel to destroy the regularity of the biodiesel so that the biodiesel is not easy to crystallize and separate out at low temperature, thereby the low-temperature flowing performance of the biodiesel is improved. The preparation method of the low-solidifying point biodiesel comprises the following steps of: (A) adding the isostearic acid and alcohol to a reactor by a certain proportion, then adding a catalyst with the mass fraction of 5%-20%, and reacting for 6-20 hours at the temperature of 65-85 DEG C to obtain the isostearic acid ester; and (B) then adding the isostearic acid ester to the biodiesel, and uniformly stirring to obtain the low-solidifying point biodiesel.

Owner:NANJING UNIV OF TECH

Ultralow temperature nano antifreezing isolating emulsion, and preparation method thereof

The invention relates to an ultralow temperature nano antifreezing isolating emulsion, and a preparation method thereof. The ultralow temperature nano antifreezing isolating emulsion comprises, by weight, 100 parts of a mineral oil and / or a biological oil, 0.1 to 1 part of an accessory ingredient A, 1 to 2 parts of an accessory ingredient B, and 13 to 50 parts of water; the accessory ingredient A comprises ethylene / vinyl acetate copolymer, an acrylate polymer, a maleic anhydride copolymer, polyoxyethylene alkyl amine, or a mixture of three or more ingredients selected from the above; and the accessory ingredient B comprises a sorbitol fatty acid ester, a polyglycerol fatty acid ester, a polyoxyethylene fatty acid ester, an isostearic acid monoglyceride, a monoolefine succinimide, a polyene succinimide, or a mixture of three or more ingredients selected from the above. The ultralow temperature nano antifreezing isolating emulsion is an oil substance, is low in pour point and corrosivity, is hydrophobic, and is capable of avoiding freezing of coal conveyors effectively.

Owner:北京首创大气环境科技股份有限公司

Isostearic acid composite metal salt clearing agent and preparation method thereof

The invention belongs to the field of chemical engineering, particularly relates to an isostearic acid composite metal salt clearing agent, and further discloses a preparation method of the isostearic acid composite metal salt clearing agent. The isostearic acid composite metal salt clearing agent is prepared from, by weight, 0.5-2 parts of isostearic acid, 1.5-3 parts of pentaerythrityl tetraethylhexanoate base oil, 0.5-3 parts of calcium oxide, 0.5-3 parts of magnesium oxide, 10-30 parts of solvent, 0.2-1 part of methyl alcohol, 1-8 parts of water and 0.5-4 parts of carbon dioxide. The composite calcium / magnesium salt clearing agent is obtained by fine screening the raw material and ratio of the product with calcium oxide and magnesium oxide as the alkali raw materials; compared with a simplex magnesium salt clearing agent in the prior art, the clearing agent has the advantages of a calcium salt clearing agent and a magnesium salt clearing agent at the same time; the alkali value of the product is further increased, the acid neutralization capacity is higher, and meanwhile the product is better in oil solubility.

Owner:济南佳进新材料有限公司

Branched carboxylic acids as fuel lubricity additives

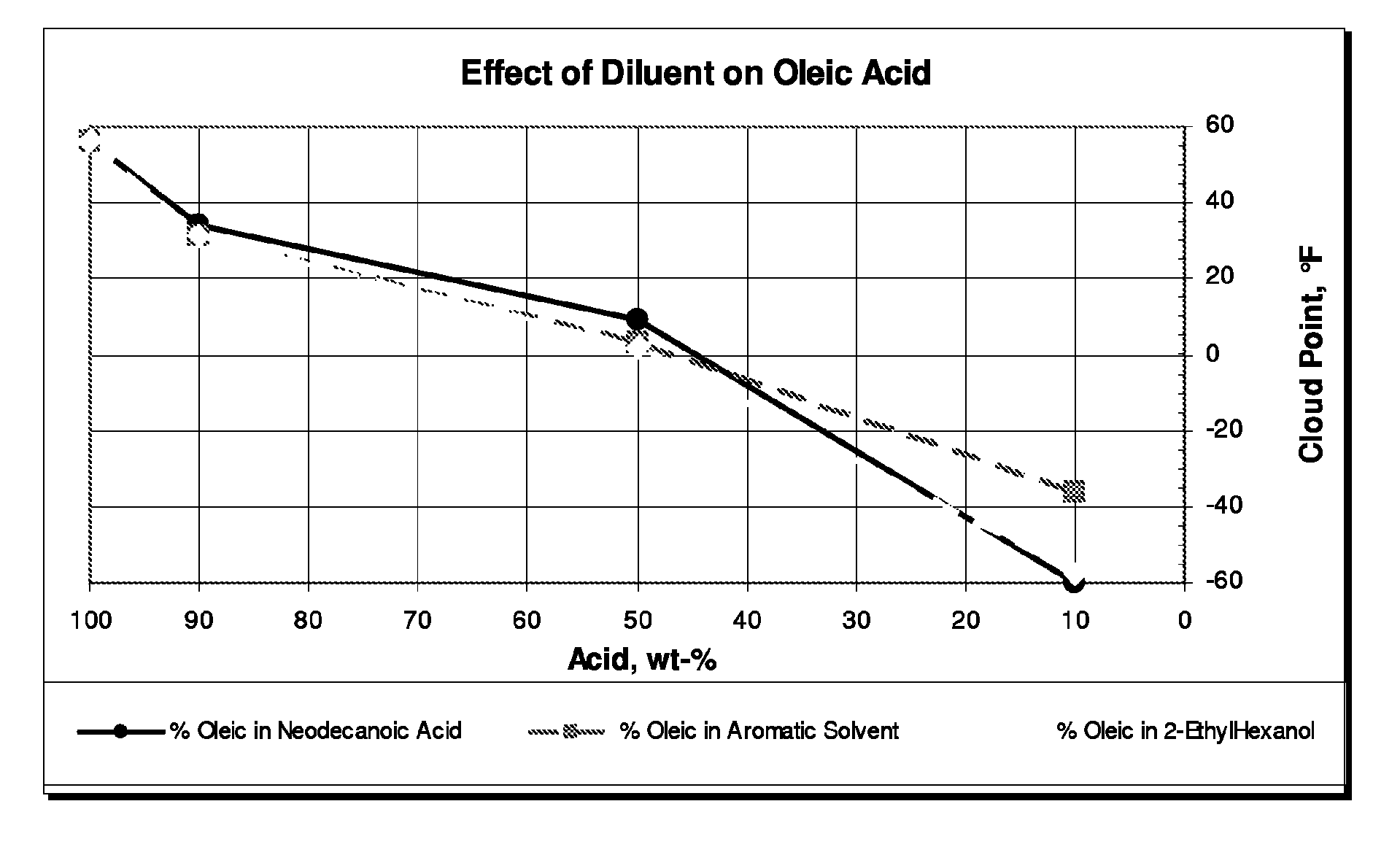

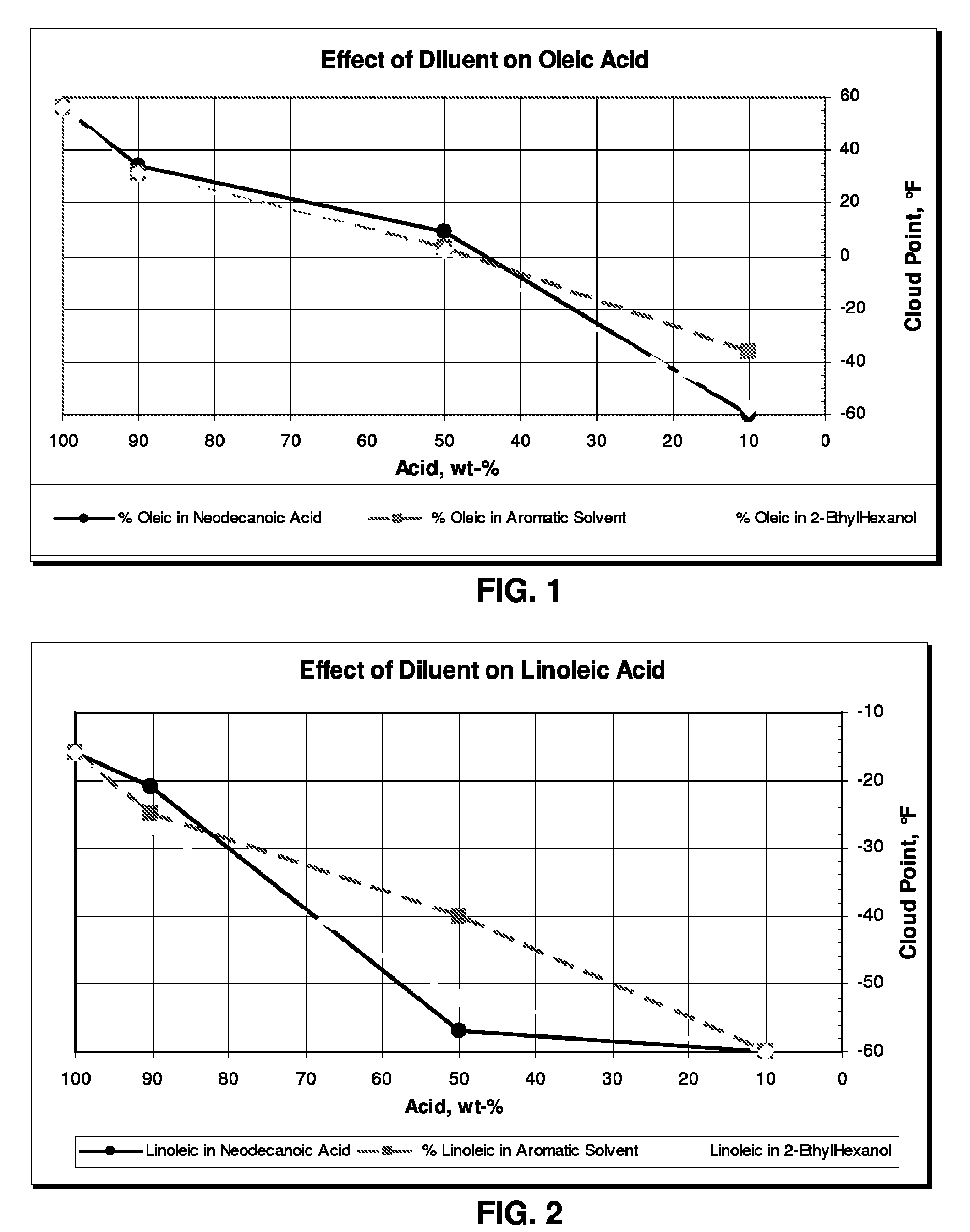

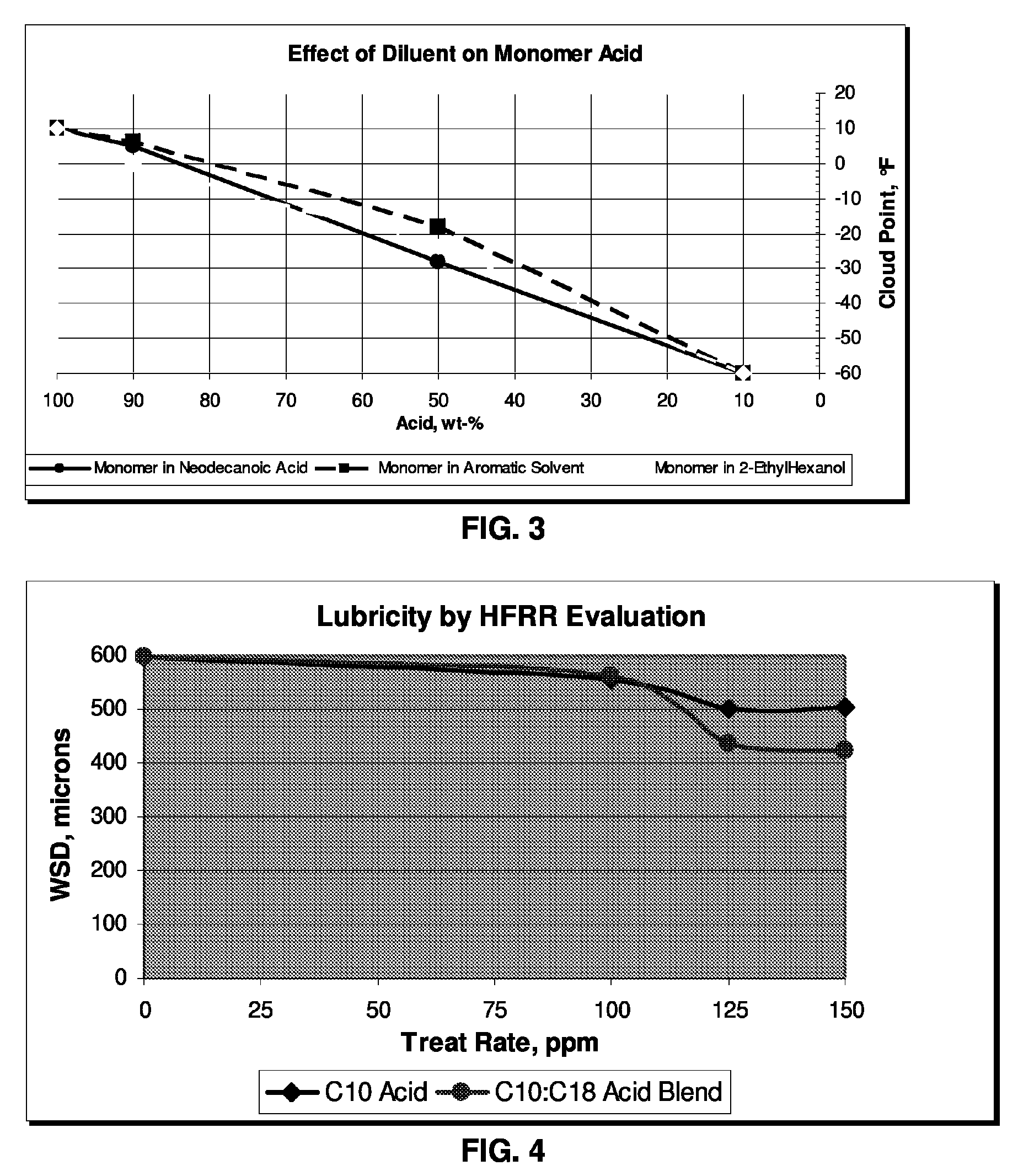

ActiveUS7867295B2Improve the lubrication effectLiquid carbonaceous fuelsFuel additivesPivalic acidIsostearic acid

Certain branched carboxylic acids may serve as improved lubricity additive compositions in distillate fuels, and in particular for cold weather applications. Suitable branched carboxylic acids may include, but are not necessarily limited to, isostearic acid, neodecanoic acid, isononanoic acid, neononanoic acid, neoundecanoic acid, isovaleric acid, pivalic acid, and the like and mixtures thereof. The branched carboxylic acids may be used alone or together with straight chain carboxylic acids, and optionally with an aromatic solvent.

Owner:BAKER HUGHES HLDG LLC

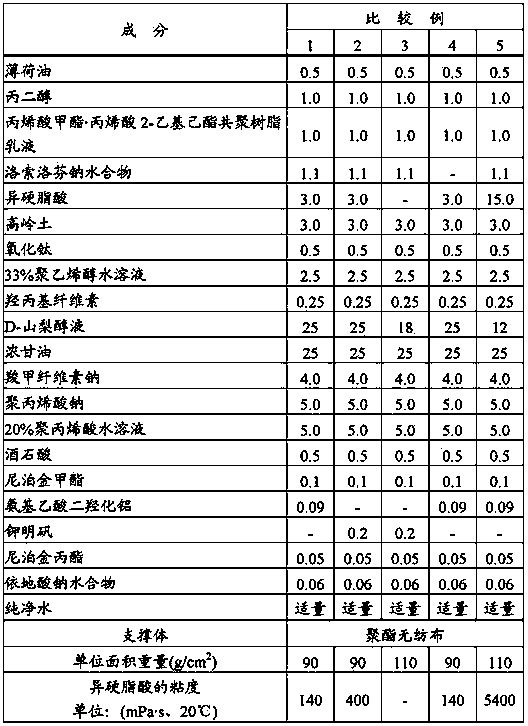

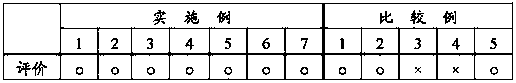

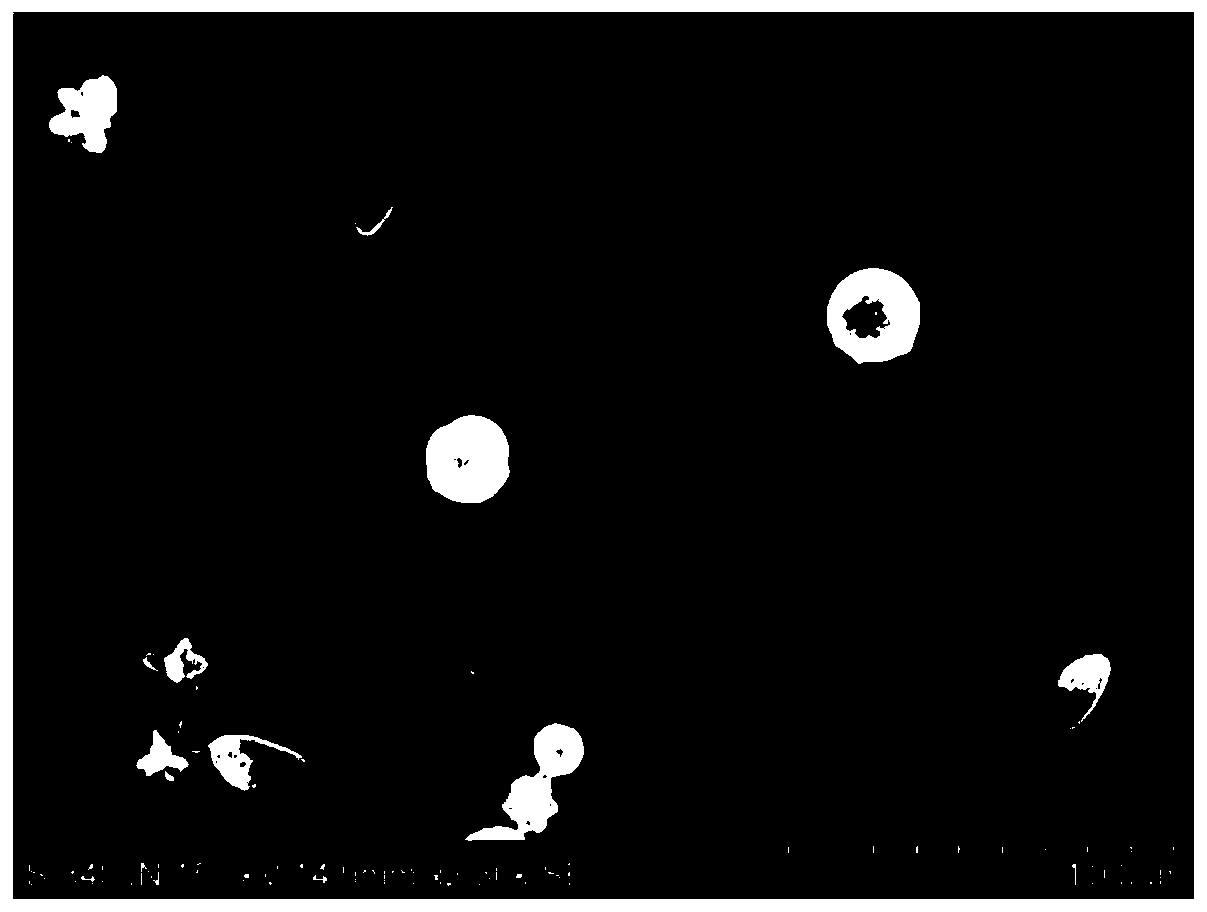

Water-based plaster

ActiveCN103796646AImprove adhesionUnequal spread does not occurInorganic non-active ingredientsAcid polymer adhesivesIsostearic acidPolymer science

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD

Cleansing oil

InactiveCN103479535ALeaving secondary pollutionOily littleCosmetic preparationsMake-upEtherMyristic acid

The embodiment of the invention discloses cleansing oil, comprising the following components in a mass ratio: castor oil, myristic acid-hexadecanol ester, isopropyl palmitate, white oil, polyoxyethylene lauryl alcohol ether isostearate, and the balance of essence. The cleansing oil is low in oiliness and easy to clean, and does not leave secondary pollution to a human body after cleansing.

Owner:广东柏亚化妆品有限公司

Silymarin nanometer anti-wrinkle eye cream and preparation method thereof

PendingCN110897908AAnti agingImprove existing fine linesCosmetic preparationsToilet preparationsGlycerolPhytic acid

The invention, which relates to the technical field of cosmetics, discloses silymarin nanometer anti-wrinkle eye cream comprising silymarin, superoxide dismutase, hydrolyzed collagen, egg yolk lecithin, glyceryl monostearate, sorbitan isostearate, wool fat, Polyglyceryl-10-stearate, stearic acid, tocopherol, squalane, polydimethylsiloxane, ethylparaben, tridecanoic acid triglyceride, glycerinum, phytic acid, honey, sodium hyaluronate and purified water. In addition, the invention further discloses a preparation method of the silymarin nano anti-wrinkle eye cream. With the nanometer form of thenatural anti-aging component silymarin, the disclosed eye cream is capable of delaying senescence of the skin around eyes and improving the e existing fine wrinkles around the eyes and has good moisturizing and anti-wrinkle effects; and the silymarin nanometer anti-wrinkle eye cream is used safely with good healthy and comfortable effects and has the great social and economic benefits.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

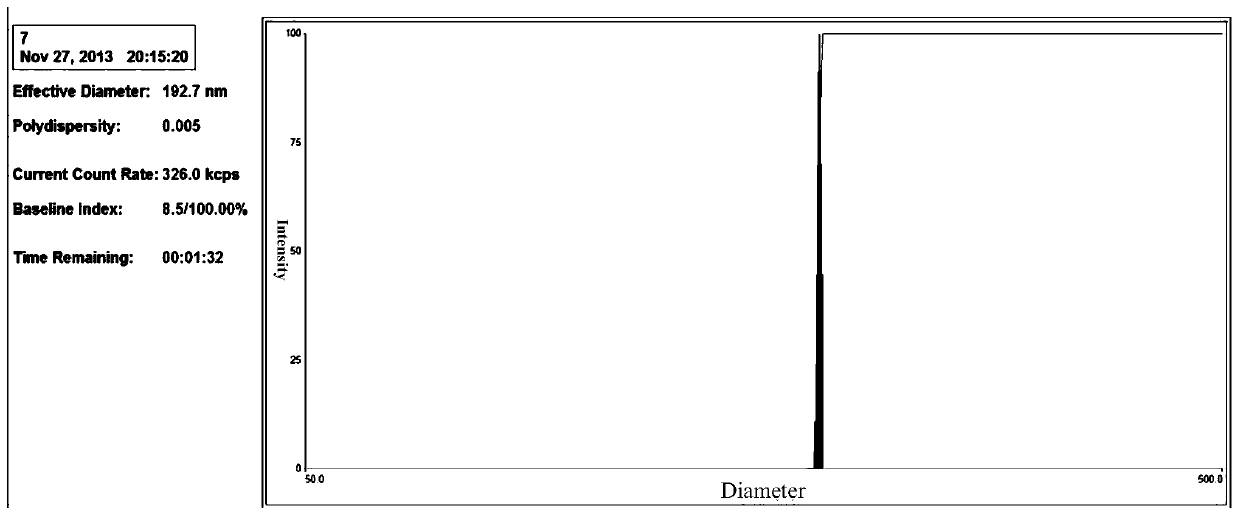

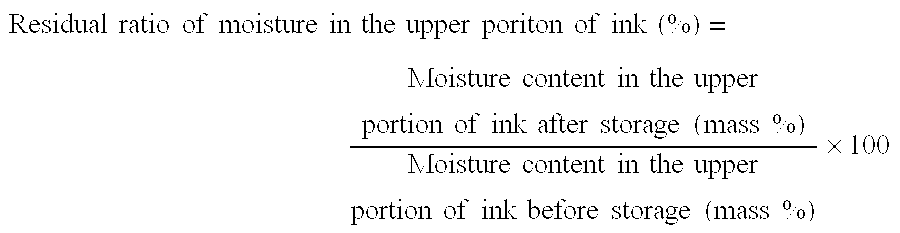

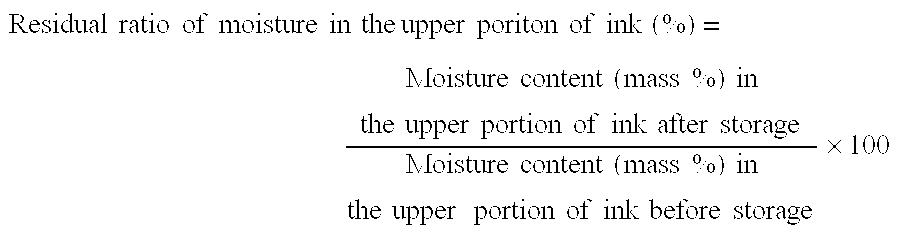

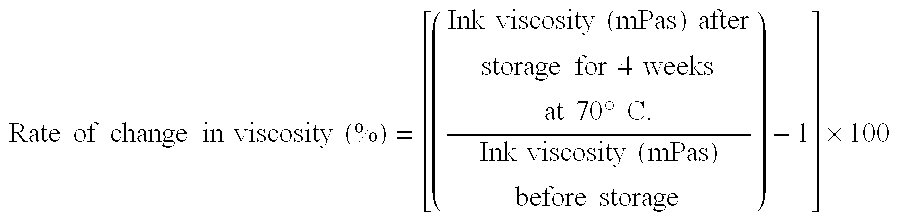

W/o emulsion ink for inkjet

A water-in-oil (W / O) emulsion ink having an ejection performance suitable for inkjet printing and superior storage stability at high temperature includes as emulsifiers, a polyglyceryl fatty acid ester (A) having a fatty acid moiety is isostearic acid or oleic acid with an HLB value of 7-14 and a glycerol polymerization degree of not less than 4, at least one nonionic surfactant (B) selected from (B-a) an esterification product of an organic compound with 3-5 hydroxyl groups and a fatty acid having 18 carbon atoms, (B-b) an alkyl glyceryl ether, (B-c) a diterpene alcohol and (B-d) a sucrose fatty acid ester having an HLB value of not more than 13.

Owner:RISO KAGAKU CORP

Lip care compositions

InactiveUS20080287540A1Improve moisturizingIncrease elasticityCosmetic preparationsBiocideIsostearic acidAlcohol

A lip care composition is provided which includes at least 40% petrolatum, at least 5% glycerin, and 1 to 20% of a C3 (alkyl or hydroxyalkyl) alcohol ester of isostearic acid, wherein the glycerin and the isostearic acid ester are present in a weight ratio ranging from 5:1 to 1:1. A method for moisturization of lips is also provided through application of the composition to the lips.

Owner:CONOPCO INC D B A UNILEVER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com