Preparation method of anti-cracking zinc acrylate antifouling paint

A zinc acrylate, antifouling paint technology, applied in antifouling/underwater paints, coatings, paints containing biocides, etc. problem, to achieve the effect of excellent performance and excellent anti-cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

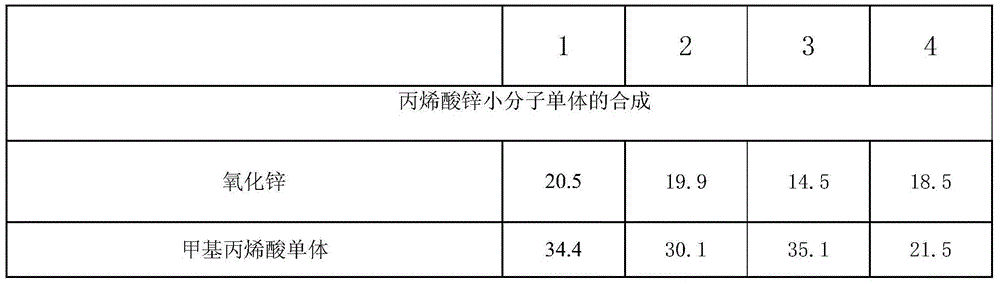

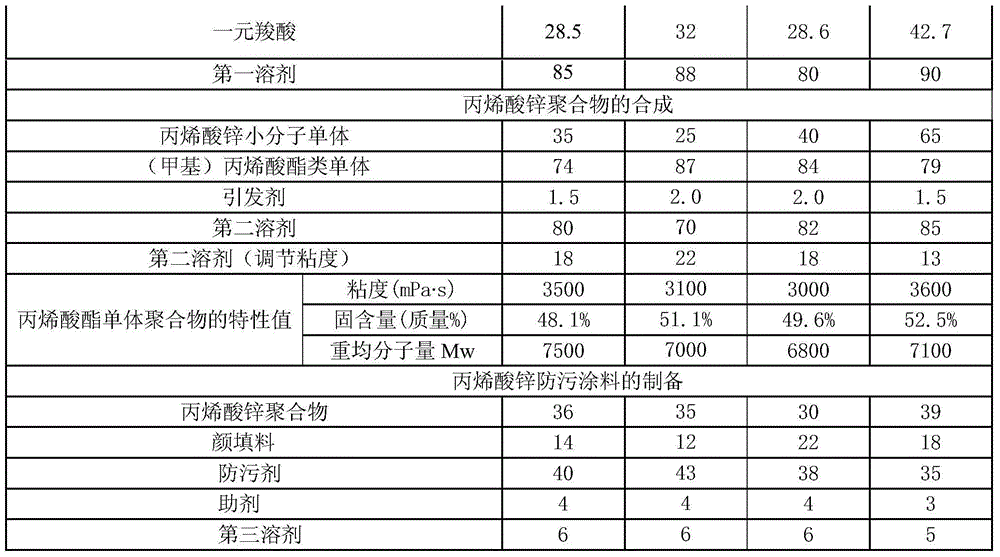

[0032] In the synthesis of zinc acrylate small molecular monomers, the monocarboxylic acid is isostearic acid or a mixture of isostearic acid and monobasic acid, and the monobasic acid is any one of formic acid, acetic acid, propionic acid, caprylic acid, and benzoic acid . The long chain branch of isostearic acid has a good internal plasticizing effect, which makes the subsequently synthesized zinc acrylate polymer have better flexibility, which is very beneficial to enhance the anti-cracking performance of antifouling coatings. When the monocarboxylic acid is a mixture of isostearic acid and monobasic acid, the preparation ratio of the mixture in parts by weight is for reference: isostearic acid:monobasic acid=1:{0.1~1}.

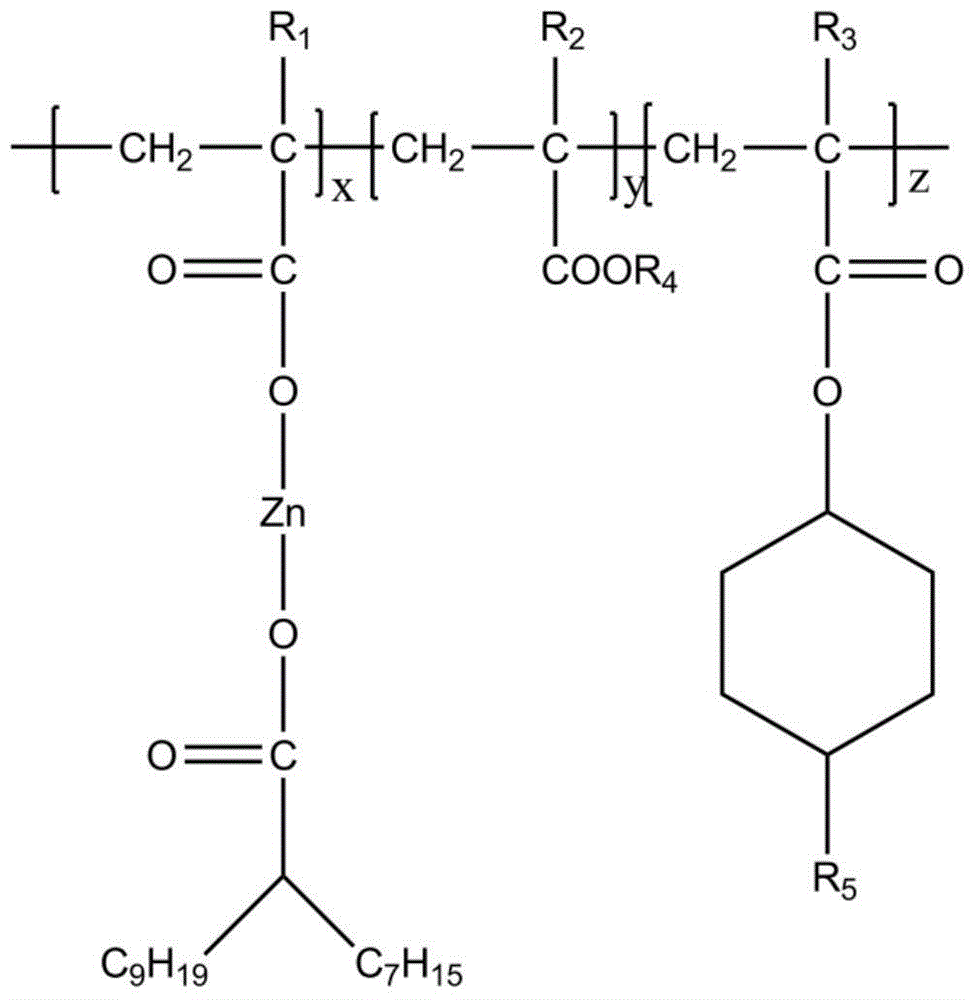

[0033] In the synthesis of zinc acrylate polymers, methacrylate monomers have a cyclohexyl structure, which is an aliphatic six-membered ring structure, and its six-membered ring can absorb stress when the molecule is subjected to external forces Deformat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com